Teilch TCH Pro 202 User manual

Operation Manual TCH Pro 202 & 203

Handheld Particle Analyzer

Models TCH Pro 202

& TCH Pro 203

Page of1 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

Safety Information

This section gives instructions for promoting safe and proper handling of the Particle

Analyzer.

Laser Safety

The Model TCH Pro 20x handheld Particle Analyzer is a Class I laser-based instrument.

•During normal operation, you will not be exposed to laser radiation.

•WARNING: Class IV visible or invisible laser inside. Exposure to this light causes

blindness.

•DO NOT remove any cover or disassemble the device.

Important - Take these precautions

•DO NOT remove any parts from the particle analyzer unless you are specifically told to do

so in this manual.

•DO NOT remove the housing or covers. There are no user serviceable components inside

the housing. All repair and maintenance needs should be done by a qualified technician.

•Take precautions not to get any particles over 50 μm inside the unit. Failure due to

foreign objects found in the unit are not covered by the Warranty.

•Precautions for power use:

•AC Adaptor. The AC adapter accommodates voltage of AC 100~240V and frequency of

50/60 Hz.

•Batteries: 2 units of Li-ion, 3.7V, size 18650.

Page of2 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

Table of Contents

CHAPTER 1: PRODUCT OVERVIEW

Introducing TCH PRO MODELS"4

Specifications"6

CHAPTER 2: UNPACKING

Box Content"7

CHAPTER 3: THEORY OF OPERATION

II. Particle Detection"8

III. Calibration"11

CHAPTER 4: OPERATION

I. Getting Started"15

II. Screen Symbols"16

III. Menu Map"17

IV. Functionalities"18

V. Data Management"2 8

VI. Remote Operation"28

CHAPTER 4: TROUBLESHOOTING

CHAPTER 5: MAINTENANCE

I. Recommended Maintenance Schedule"30

II. TCH Pro Firmware Upgrade"30

III. Touchscreen Calibration"31

CHAPTER 6: WARRANTY

Warranty"32

Contact Information"33

Page of3 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

Chapter 1: Product Overview

INTRODUCING TCH PRO MODELS

The Handheld Particle Analyzer TCH Pro is a lightweight, handheld particle counter with a

3.5” Color LCD display, a touchscreen and a single button. It is simple to use and maintain.

It operates on battery or AC power. This model series has a 0.1 CFM with internal flow

meter (1% FS) and active flow control counts particle sizes of 0.2μm (50%) to 10μm full and

continuous particle size spectrum by turning the concept of channels obsolete. Over 1,000

data sets can be stored in removable SD card and downloaded for analysis and reporting

using the utility included with the device.

Page of4 33

TCH Pro v1.2.1

Key features:

•TCH PRO is the smallest 0.2μm particle

counter in the market. A truly portable device

•Not bound by channels. Full continuous

particle spectrum

•High power variable light source allows

unprecedented range of 0.2μm to 10μm

•State of the art analog and digital signal

processing

•Advanced particle analysis directly at device

•PM2.5 and PM10 display

•Differential pressure (1 Pa resolution) display

•Embedded flow meter (1% FS)

•Humidity and temperature sensors

Operation Manual TCH Pro 202 & 203

!

Page of5 33

TCH Pro v1.2.1

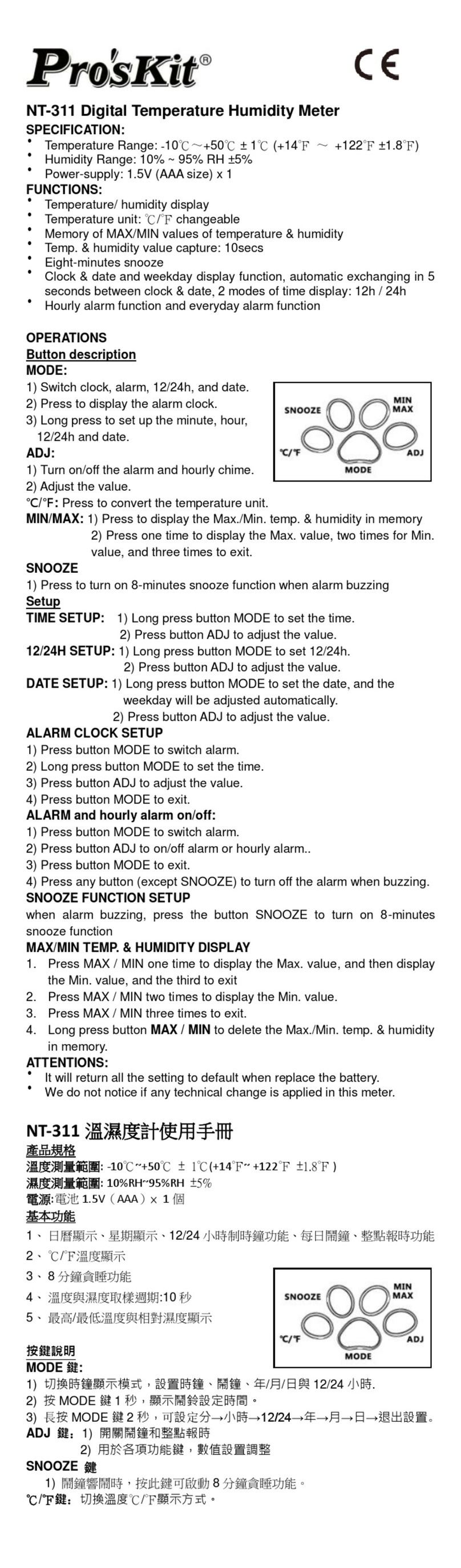

Back View Bottom-up View

Side Views

Note that the External Sensor Probe

only applies to Teilch Pro 203

Operation Manual TCH Pro 202 & 203

SPECIFICATIONS

!

Main Uses

Cleanroom certification. Air quality and filter

monitoring in household, office, industrial and

healthcare environments

Particle Size Range

0.2μm (50%) to 10μm, continuous

Channels

Unlimited number of channels. Capture size

information for each particle with 10nm resolution

Supported Standards

ISO 21501-4 (Instrument), US FED STD 209E and

ISO 14644-1 (Cleanroom Classification)

Sensor

High sensitivity, ultra-low noise and fully

compensated

Flow

0.1cfm with internal flow meter (1% FS) and active

flow control

Light Source

High power, >10,000hr laser diode with active

control. Full temperature compensation and

stabilization

Pressure

115kPa max, 1Pa noise-free resolution

Humidity

5% to 95%, +-2%

Temperature

0-50C, +-0.1C Internal and external (203) sensors

Display

3.5” Color LCD

Operating Method

Touchscreen and single button

Battery

User replaceable Li-Ion, 5 hr continuous counting,

10hr intermittent counting. Size 18650

Storage

External SD Card

Connection

USB, SD Card

Dimensions

82mm(W)x137mm(H)x42mm(D)

Weight

830gr (w/o accessories)

Page of6 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

Chapter 2: Unpacking

Carefully unpack Teilch Handheld Particle Analyzer from its case and verify that all the items

shown in the photos below and listed in the following tables are present. It is recommended

to unpack the particle counter within a cleanroom-type environment. Doing so will minimize

the counter’s exposure to dirt and moisture.

BOX CONTENT

Find below an inventory of the different components of the case . Contact us immediately if

any items are missing or broken.

•TCH Pro 202 Handheld Particle Analyzer

•Power Supply

•Isokinetic Probe

•Barbed Probe

•Inlet Filter

•Hand Strap (for 203 model only)

•External Sensor (for 203 model only)

•SD Memory Card (2GB) - Installed

•USB Cable

•USB Flash Drive (Software, documentation, and

Operation Manual)

•Inlet Caps (x2)

•Case Protector

•Carrying Case

•Inlet O-ring Seal Replacements (x4)

•Calibration Certificate and Quick Start Guide

Customer support in the US:"Customer support in Asia:

265 Cambridge Ave, #60250 "7B Mountain Drive, Light Industry & Science Park II

Palo Alto, CA 94306, USA" " Calamba City, Laguna 4027, Philippines

Ph. (+1) 650 319 3018" " Ph. (+63) 49 545 6957

Page of7 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

Chapter 3: Theory of Operation

A clean, contamination-free work environment is critical to maximize yields as certain

particles are likely to cause defects, irregularities, inaccuracies and even failures. Analyzing

particle contaminants is an important step in having control over operating environments

and reducing particle deposition in critical components.

Isolating, characterizing and understanding the types of particles found in products or

processes can usually yield a likely source for the particles. Once the source is known then

elimination of the particulate contamination becomes substantially easier.

II. PARTICLE DETECTION

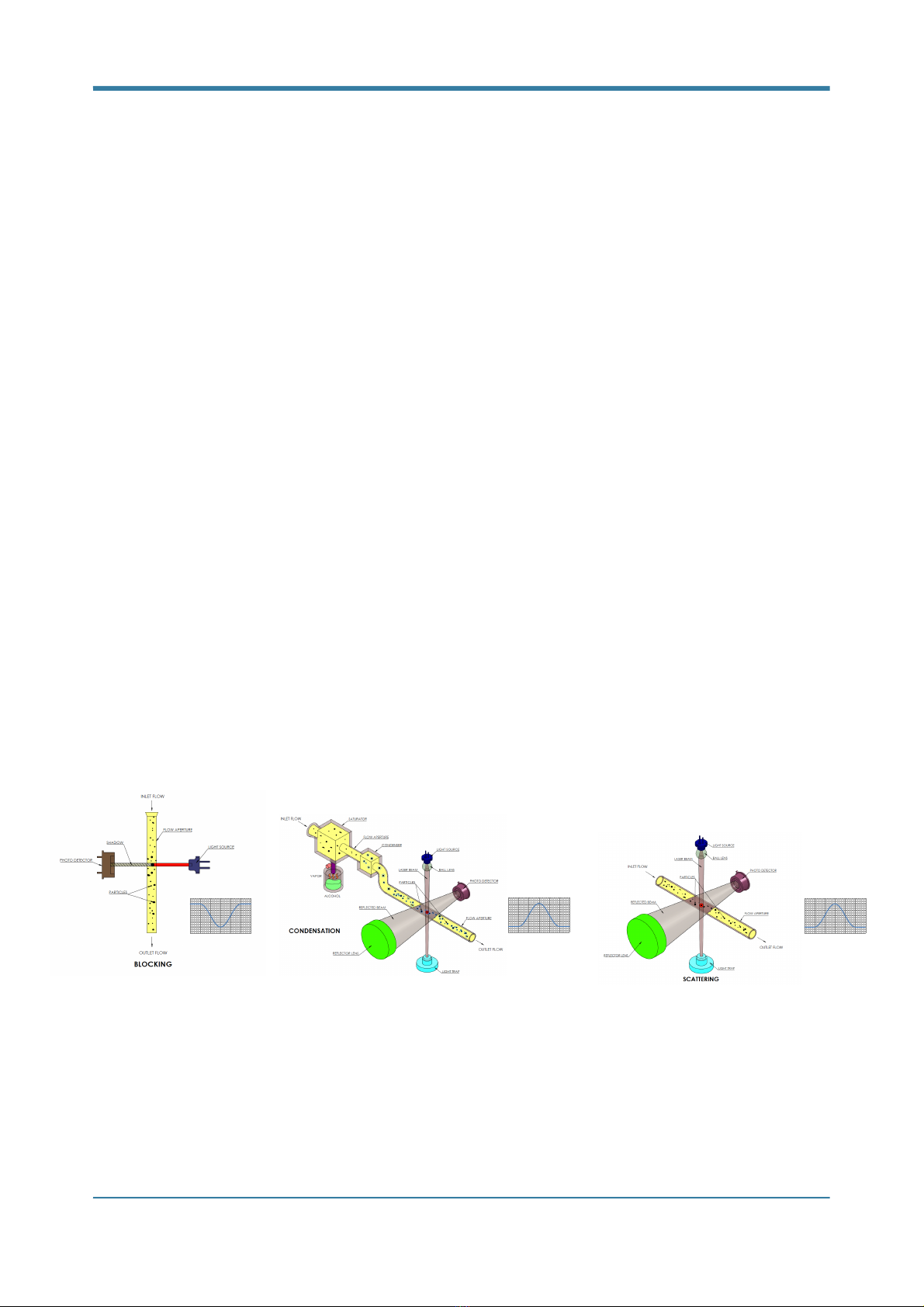

PARTICLE COUNTING PRINCIPLE

A particle counter is an instrument that detects and counts particles. A particle counter

works on the principle of either light scattering, light blocking, or condensation for detecting

and measuring particle size or size distribution.

When a particle is illuminated by a light beam, light is reemitted (if light scattering is used) or

absorbed (obstruction). The scattered or absorbed light (depending on method used) is

detected by a photo detector, measured, and the particle is counted and tabulated into

standardized counting bins. If direct imaging is used, light illuminates particles from the back

Page of8 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

within a cell while a high definition, high magnification camera records passing particles.

Recorded video is then analyzed by computer software to measure particle attributes.

Notes:

•The light blocking optical particle counter method is typically useful for detecting

and sizing particles greater than 1 micrometer in size. This type of technique allows high

resolution and reliable measurement.

•The light scattering method is capable of detecting smaller sizing particles. Typical

detection sensitivity of the light scattering method ranges between 0.1µm to 25µm.

Scattered light is significantly smaller for small particle sizes. A 0.2µm particle emits

1*10-10 of the intensity emitted by a 10µm particle.

•The condensation method is used to detect particles over 5nm, but it cannot

differentiate among different particle sizes.

Page of9 33

TCH Pro v1.2.1

1E-10%

1E-09%

1E-08%

0.0000001%

0.000001%

0.00001%

0.0001%

0.001%

0.01%

0.1%

1%

10%

0.1% 1% 10%

Light%Intensity%

Par6cle%Size%(um)%

Operation Manual TCH Pro 202 & 203

ANATOMY OF A PARTICLE COUNTER’S SENSOR

A particle counter is made up of the following components:

•Light Source (bright laser light)

•Reflector

•Light Sensor

•Electronic Signal Processing Circuit

•Pump

•Flow Sensor

•Filter"

Page of10 33

TCH Pro v1.2.1

Diagram: Anatomy of a particle counter

Operation Manual TCH Pro 202 & 203

III. CALIBRATION

PROCESS

Flow calibration is performed with a low back pressure - displaced volume - calibration-

grade flow meter. Particle size calibration is performed in four stages with NIST-traceable

mono-size polystyrene spheres.

•Stage 1, wet aerosol. Particles smaller than 2µm are diluted in UDI water and atomized.

The mist containing particles is dried, static charges are neutralized and the dry aerosol is

sampled by the Particle Analyzer.

•Stage 2, dry particles. Particles between 2µm and 10µm are stored dry and fed directly

into the Particle Analyzer.

•Stage 3, peak location determination and loading of calibration values.

•Stage 4, reference comparison. Calibrated device results are compared against a

reference unit to determine counting efficiency.

The APA Pro 202 and 203 are calibrated with 7 different traceable particle sizes:

•Liquid solution (atomized and dried): 0.2µm, 0.3µm, 0.5µm, 1.0µm and 2.0µm

•Dry: 3.0µm and 10.0µm

Page of11 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

CALIBRATION OUTPUTS

•Traditional Pulse Height Analyzer (PHA).

Noise level increases significantly for

smaller particle sizes.

•Picture is for 1µm mono-disperse aerosol

with device’s embedded PHA.

•0.3µm mono-disperse aerosol with

analog hardware particle detection noise

filtering.

•Graph caption: Median peak distribution

of mono-sized NIST-traceable PSL

spheres is utilized as threshold for each

calibrated particle size. Right of the mean

(red area) is included in the total count for

that specific particle size.

•0.5µm mono-disperse aerosol with

analog hardware noise filtering.

•Graph caption: Median peak distribution

of mono-sized NIST-traceable PSL

spheres is utilized as threshold for each

calibrated particle size. Right of the mean

(red area) is included in the total count for

that specific particle size.

Page of12 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

•As noise does not saturate the sensor

due to the particle detection filter, mono-

disperse aerosols may be combined to

execute a single-sample calibration.

•Graph caption: Median peak distribution

of 5 mono-sized NIST-traceable PSL

spheres is utilized as threshold for each

calibrated particle size. The image shows

peaks for 0.2µm, 0.3µm, 0.5µm, 1µm and

2.0µm. Right of the mean (shaded areas)

are included in the total count for each

specific particle size.

Page of13 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

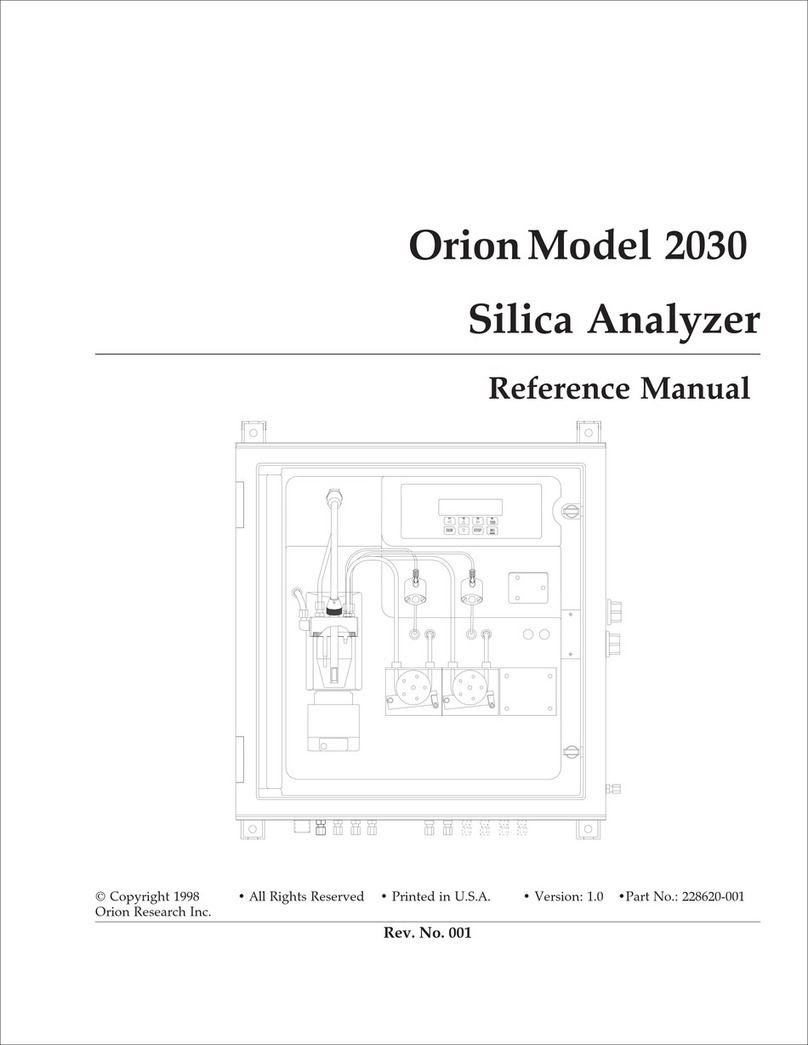

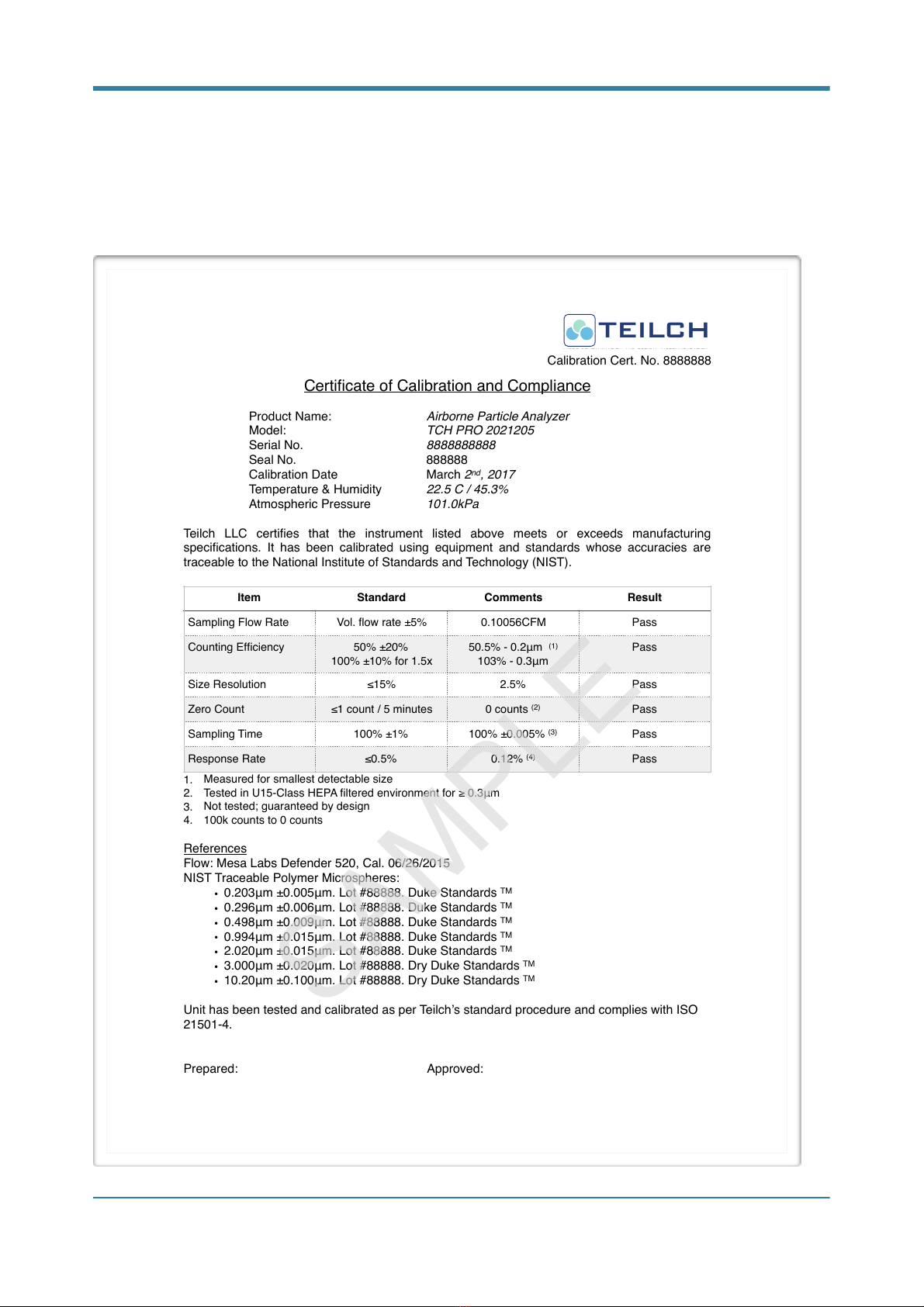

SAMPLE CALIBRATION CERTIFICATE!

Page of14 33

TCH Pro v1.2.1

Certificate of Calibration and Compliance

Product Name: Airborne Particle Analyzer

Model: TCH PRO 2021205

Serial No. 8888888888

Seal No. 888888

Calibration Date March 2nd, 2017

Temperature & Humidity 22.5 C / 45.3%

Atmospheric Pressure 101.0kPa

Teilch LLC certifies that the instrument listed above meets or exceeds manufacturing

specifications. It has been calibrated using equipment and standards whose accuracies are

traceable to the National Institute of Standards and Technology (NIST).

1. Measured for smallest detectable size

2. Tested in U15-Class HEPA filtered environment for ≥0.3μm

3. Not tested; guaranteed by design

4. 100k counts to 0 counts

References

Flow: Mesa Labs Defender 520, Cal. 06/26/2015

NIST Traceable Polymer Microspheres:

•0.203μm ±0.005μm. Lot #88888. Duke Standards TM

•0.296μm ±0.006μm. Lot #88888. Duke Standards TM

•0.498μm ±0.009μm. Lot #88888. Duke Standards TM

•0.994μm ±0.015μm. Lot #88888. Duke Standards TM

•2.020μm ±0.015μm. Lot #88888. Duke Standards TM

•3.000μm ±0.020μm. Lot #88888. Dry Duke Standards TM

•10.20μm ±0.100μm. Lot #88888. Dry Duke Standards TM

Unit has been tested and calibrated as per Teilch’s standard procedure and complies with ISO

21501-4.

Prepared: Approved:

Item

Standard

Comments

Result

Sampling Flow Rate

Vol. flow rate ±5%

0.10056CFM

Pass

Counting Efficiency

50% ±20%

100% ±10% for 1.5x

50.5% - 0.2μm (1)

103% - 0.3μm

Pass

Size Resolution

≤15%

2.5%

Pass

Zero Count

≤1 count / 5 minutes

0 counts (2)

Pass

Sampling Time

100% ±1%

100% ±0.005% (3)

Pass

Response Rate

≤0.5%

0.12% (4)

Pass

SAMPLE

teilch

micro-contamination and optical instrumentation

Calibration Cert. No. 8888888

SAMPLE

Operation Manual TCH Pro 202 & 203

Chapter 4: Operation

This chapter describes how to use TCH PRO.

I. GETTING STARTED

The device is ready to use out of the box. Battery may be charged to half capacity. To start

using the instrument, proceed as follows:

1. Make sure you are using the isokinetic inlet (installed by default) when sampling.

2. Position the instrument in the environment to be measured.

3. Remove the red protective cap from the inlet.

4. Turn the device ON by pressing the Power button and holding it for 3 seconds.

5. After pressing the power key, a SPLASH screen will appear for three seconds,

displaying model number, serial number, and firmware version number. The Start

screen then displays on the LCD.

6. When the MENU screen appears, the instrument is ready for use. Select mode and

follow on-screen instructions.

7. Press Count button to start sampling at any particle analysis screen

Page of15 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

II. SCREEN SYMBOLS

SYMBOLS

MEANING

SD inserted

SD busy. Do not remove

Data saved to SD

Data not saved (SD not present or full)

Save

Secure the device by locking the screen. To unlock, use the default

password 1234. To reset the password, press the reset button

Settings

Navigation

Red Dot: Coincidence Loss Error

Page of16 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

III. MENU MAP

Page of17 33

TCH Pro v1.2.1

•Count & Concentration

•Cumulative & Differential

•Set Location

UNITS

•Cleanroom Classification

•Count Limit

•Minimum Size

•Elapsed Time

•Total Counts

•Browse Saved Files

•Browse Folders

•Cleanroom Standard

•Temperature

•Pressure

•Set Backlight

•Auto Power Off

•Set Date & Time

•System Voltage

•Battery

•Temperature

•Laser

•Pump

•Sensor Contamination

•USB Mass Storage

•Set Admin Password

•Sound

•Model

•S/N

•Firmware

•Hardware

•USB Supply

SETTINGS

•PM 2.5 & PM 10

•Air Quality Settings

SIZE (UM)

SINGLE

CHANNEL

GRAPH

SINGLE RANGE

COUNT

•Sampling Settings

•Alarms

•Other Settings

DISPLAY &

POWER

DATE & TIME

SYSTEM INFO

SETTINGS

•Absolute Pressure

•Differential Pressure

OTHERS

STORAGE

CALIBRATION

INFO

SYSTEM CHECK

CONTINUOUS

PARTICLE LOG

CLEANROOM

PARTICLE

ANALYSIS

AIR QUALITY

ANALYSIS

PRESSURE

FILES

SYSTEM

CONFIGURATION

HOME

SCREEN!

Main Features

WELCOME

SCREEN

PULSE HEIGHT

ANALYZER

•Wall Supply

•Battery Voltage

•Current

•PCB Temperature

•Run Time

Operation Manual TCH Pro 202 & 203

IV. FUNCTIONALITIES

Different MENU options and functionalities of the instrument:

1. Cleanroom Particle Analysis

Purpose: To monitor particles in a cleanroom via handheld single measurement or fixed

multiple samples. Cleanroom particle monitoring can be performed in the following ways,

offering a wide range of insights:

MENU

SCREEN

COUNT

To count particles with 8 sized channels.

Upon completing a measurement sample with a particle

counter, the unit can display the count values as different

readings:

•Counts or Concentration

•Absolute (Σ) or Differential (Δ)

•Loc: Set 99 different locations

Time: Time elapsed since the start of sampling

Samp#: Sample x out of y total samples (x/y)

S/H: Sample time / Hold time between samples

T: Ambient Temperature

RH: Relative Humidity in %

P: Ambient Pressure

Page of18 33

TCH Pro v1.2.1

1. Cleanroom Particle Analysis: Cleanroom certification and monitoring

2. Continuous Particle Log: Save full particle log data into SD Card

3. Air Quality Analysis: Particulate Matter

4. Pressure: Differential Pressure Sampling

Operation Manual TCH Pro 202 & 203

SINGLE CHANNEL COUNT

To count a pre-defined particle size. In order to use it, enter

which particle size you would like to count and press the

count button below the screen.

“Sound On/Off” to activate or deactivate a beep sound for

each particle counted.

Note: single channel count is always cumulative total counts.

CLEANROOM ANALYSIS

Plot your count in real time and compare it to the ISO

14644-1 or FED STD 209E cleanroom standards. To begin

your sampling, choose your cleanroom classification and start

counting by pressing the count button below the screen.

•Straight red line: Cleanroom standard chosen;

•Pink line: Your actual count. If you are over the red line, the

environment is not compliant with the selected cleanroom

standard.

•Class: Cleanroom standards.

•Size: Six particle sizes displayed by default.

•Count/volume (ft3 or m3)

•Allowed/volume (ft3 or m3): Maximum particle

concentration as per cleanroom standard.

•%: Concentration of sample versus cleanroom standard.

Page of19 33

TCH Pro v1.2.1

Operation Manual TCH Pro 202 & 203

SIZE RANGE COUNT

Count particles that are only within the range of a particle size

with a 10 nanometer resolution.

Frame the particle size window you are interested in counting

by entering a minimum and maximum size. Press the count

button to begin the count.

CLEANROOM PARTICLE ANALYSIS > SETTINGS

Personalize the sampling process by choosing the individual

settings of Time, Volume, and Counts or Manual. Set number

of Samples and Hold Time.

•Hold Time: Time delay between samples

•Number of Samples: Desired number of samples or test

•Time: Sampling based on elapsed time

•Volume: Sampling based on accumulated sample volume

•Counts: Sampling based on number of counts of the

smallest channel

•Manual: Continuous sampling

Note: When setting hold time >30 secs, it is normal that

pump and laser turn itself off

Page of20 33

TCH Pro v1.2.1

This manual suits for next models

1

Table of contents

Other Teilch Measuring Instrument manuals