Tek-Trol TEK-W AVE 4300C User manual

Technology Solutions

TAVE 4300C

EK-W

Instruction Manual

Free Space Radar Level Transmitter

Document Number: IM-4300C

www.tek-trol.com

© COPYRIGHT Tek-Trol LLC 2020

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum

product performance, make sure you thoroughly understand the contents before installing, using, or

maintaining this product.

For technical assistance, contact

Customer Support

796 Tek-Drive

Crystal Lake, IL 60014

USA

Tel: +1 847 857 6076

www.tek-trol.com

No part of this publication may be copied or distributed, transmitted, transcribed, stored in a

retrieval system, or translated into any human or computer language, in any form or by any means,

electronic, mechanical, manual, or otherwise, or disclosed to third parties without the express

written permission. The information contained in this manual is subject to change without notice.

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

1

Table of Contents

1Safety Instructions ...........................................................................................................................2

1.1 Intended Use ........................................................................................................................................2

1.2 Safety Instructions from the Manufacturer ............................................................................................2

1.2.1 Disclaimer..................................................................................................................................................... 2

1.2.2 Product Liability and Warranty .................................................................................................................... 2

1.2.3 Information Concerning the Documentation .............................................................................................. 2

1.3 Safety Precautions ................................................................................................................................ 2

1.4 Packaging, Transportation and Storage.................................................................................................. 3

1.4.1 Packaging ..................................................................................................................................................... 3

1.4.2 Transportation ............................................................................................................................................. 3

1.4.3 Storage ......................................................................................................................................................... 3

1.4.4 Nameplate.................................................................................................................................................... 3

2Product Description..........................................................................................................................4

2.1 Introduction ......................................................................................................................................... 4

2.2 Working Principle .................................................................................................................................4

2.3 Specifications........................................................................................................................................5

2.4 Dimensional Drawings ..........................................................................................................................6

2.5 Model Chart..........................................................................................................................................7

3Installations .....................................................................................................................................7

3.1 Mounting Position ................................................................................................................................8

3.2 Installation at Conical Tank ................................................................................................................... 8

3.3 Incorrect Installation.............................................................................................................................9

4Electrical Connection...................................................................................................................... 11

4.1 Wiring Connection .............................................................................................................................. 11

4.2 Protection Level.................................................................................................................................. 12

5Operation....................................................................................................................................... 13

5.1 Instrument Commissioning.................................................................................................................. 13

5.1.1 Different Debugging Method..................................................................................................................... 13

5.2 Display or Adjustments ....................................................................................................................... 14

5.3 Menu.................................................................................................................................................. 15

5.3.1 Program Operations................................................................................................................................... 15

5.3.2 Edit Parameter ........................................................................................................................................... 15

5.3.3 Menu Instruction ....................................................................................................................................... 16

6Menu Tree ..................................................................................................................................... 31

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

2

1Safety Instructions

1.1 Intended Use

Tek-Wave 4300C Free Space Radar Level Transmitter is widely used to measure level of tanks, lakes,

rivers or streams.

1.2 Safety Instructions from the Manufacturer

1.2.1 Disclaimer

The manufacturer will not be held accountable for any damage that happens by using its product,

including, but not limited to, direct, indirect, or incidental and consequential damages. Any product

purchased from the manufacturer is warranted by the relevant product documentation and our Terms

and Conditions of Sale. The manufacturer has the right to modify the content of this document of any

time with any reason without prior notice and will not be answerable for the possible consequence

of changes.

1.2.2 Product Liability and Warranty

The operator shall have authority for the suitability of the device for the specific application. The

manufacturer accepts no accountability for the consequences of misuse by the operator. A wrong

installation or operation of the devices (systems) will cause the warranty to be void. The respective

Terms and Conditions of Sale, which forms the basis for the sales contract, shall also apply.

1.2.3 Information Concerning the Documentation

To prevent any injury to the operator or damage to the device, it is essential to read the information

in this document and the applicable national standard safety instructions. This operating manual

consists of all the information that is required in various stages, such as product identification,

incoming acceptance and storage, mounting, connection, operation and commissioning,

troubleshooting, maintenance, and disposal.

1.3 Safety Precautions

You must read these instructions carefully before installing and commissioning the device. These

instructions are an essential part of the product and must be kept for future reference. Only by

observing these instructions, optimum protection of both personnel and the environment, as well as

safe and fault-free operation of the device can be ensured. For additional information that is not

discussed in this manual, contact the manufacturer.

The following safety symbol marks are used in this operation manual and on the instrument.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in

death or severe injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

3

NOTE

Indicates that operating the hardware or software in this manner may damage it

or lead to system failure.

1.4 Packaging, Transportation and Storage

1.4.1 Packaging

The original package consists of

1. Tek-Wave 4300C Free Space Radar Level Transmitter

2. Documentation

NOTE

Unpack and Check the contents for damages or sign of rough handling. Report

damage to the manufacturer immediately. Check the contents against the packing

list provided.

1.4.2 Transportation

•Avoid impact shocks to the device and prevent it from getting wet during transportation.

•Verify local safety regulations, directives, and company procedures with respect to hoisting,

rigging, and transportation of heavy equipment.

•Transport the product to the installation site using the original manufacturer’s packing

whenever possible.

1.4.3 Storage

If this product is to be stored for an extended period of time before installation, take the following

precautions:

•Store your product in the manufacturer’s original packing used for shipping.

•The storage location should comply with the following requirements:

oFree from rain and water

oFree from vibration and impact shock

oAt room temperature with minimal temperature and humidity variation

•Before storing a used flow meter, remove any fluid from the flow meter line completely.

Properties of the instrument can change when stored outdoors.

1.4.4 Nameplate

The nameplate lists the order number and other important information, such as design details and

technical data.

NOTE

Check the device nameplate to ensure that the device is delivered according to your

order. Check for the correct supply voltage printed on the nameplate.

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

4

2Product Description

2.1 Introduction

Tek-Wave 4300C Free Space Radar Level Transmitter is 26GHz high frequency radar type level

measuring instrument, which can measure up to 70 meters. The antenna is furthered optimized and

the new fast microprocessor can carry out signal analysis and processing at a higher rate, therefore the

Tek-Wave 4300C Free Space Radar Level Transmitter can be used for some complex measurement

conditions such as reactor, solid bin etc.

2.2 Working Principle

The Tek-Wave 4300C Radar Level antenna transmits a narrow microwave pulse, which is transmitted

downward through the antenna. When the microwave contacts the surface of the medium, it reflected

and received by antenna again. This received signal transmitted to electronic circuit and converted into

the material level signal.

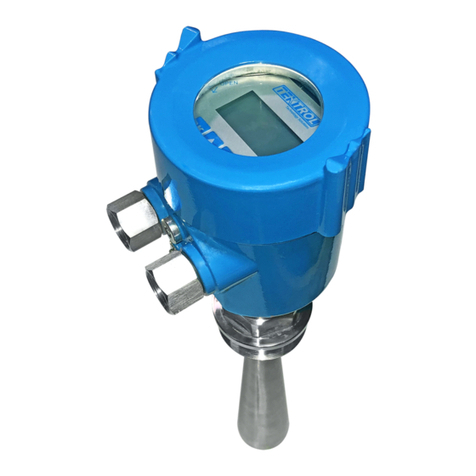

Fig 1: Tek-Wave 4300C Free Space Radar Level Transmitter

Where, A is Range Setting

B is Low Level Adjustment

C is High Level Adjustment

D is Blind Area Range

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

5

2.3 Specifications

Accuracy ±3mm

Measuring Range 90ft (30m)

Microwave Frequency 26GHz

Maximum Pressure Max. 580psi (4Mpa)

Process Pressure -14.50 to 580psi (0.1 to 4Mpa)

Operating Temperature -40 to 212°F (-40 to 100°C)

Process Temperature -40 to 482°F (-40 to 250°C)

Medium Temperature -40 to 300°F (-40 to 150°C)

Shock Resistance Mechanical vibration 32.80ft/s2(10m/s2), 10 to 150 Hz

Process Connection NPT or Flange

Electrical Connection ½” NPT (Two)

Terminal Block 18 to 22 AWG Wire

Protection Class IP67

Output Signal 4 to 20mA with HART® Optional Modbus RS485

Fault Signal

current output unchanged.

20.5mA; 22mA; 3.9mA

Integration time 0 to 50s adjustable

Power Supply 16 to 26VDC

Power Consumption Max 22.5mA/1w

Permissive Ripple

- <100Hz Uss<IV

- (100 to 100K) Hz Uss<I0mV

Blind Area Antenna end

Response Time About 1 second (depending on parameter setting)

Display LCD

Display Resolution 1mm

Approval CE

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

6

2.4 Dimensional Drawings

Fig 2: Front View Fig 3: Side View

Fig 4: Top View

Fig 5: Tek-Wave 4300C Free Space Radar Level Transmitter

Line Size

in (mm)

D

in (mm)

H

in(mm)

2” (50)

1 ¾” (φ46)

5 ½” (140)

2”NP T

H

D

Ø5”

(125mm)

M20x1.5

2 3⁄4”

(66mm)

½” NPT

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

7

2.5 Model Chart

Example Tek-Wave 4300C 1 A 1 A 1 A 1 Tag Tek-Wave 4300C-01-A-01—A-01-A-01-Tag

Series Tek-Wave 4300C

Free Space Radar Level Transmitter

Output 1

4-20mA, HART (2-wire)

2

Modbus RS-485 (4-wire)

Pressure Limits

A

-14.5 to 580psi (0.1 to 4Mpa)

X

Special

Temperature Limits

1

Standard: -40 to 300°F (-40 to 150°C)

2

High: -40 to 482°F (-40 to 250°C)

Process Connection

A

2” NPT

B

3" 150# Flange

C

4" 150# Flange

D

3" 300# Flange

X

Special

Electrical

Connection

1

½” NPT (Two)

X

Special

Power Supply

A

16 to 26VDC

X

Special

Range

1

90 feet (30 Meters)

Options

TAG SS Tag

FC Factory Configuration

3Installations

This section covers instruction on installations and commissioning. Installations of the device must be

carried out by trained, qualified specialists authorized to perform such works.

CAUTION

•When removing the instrument from hazardous processes, avoid direct contact

with the fluid and the meter.

•All installation must

comply with local installation requirements and local

electrical code

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

8

3.1 Mounting Position

Fig 6: Installation at 1/4 or 1/6 of Diameter

•Install at 1/4 or 1/6 of the diameter.

•Minimum distance of 8” (200mm) between instrument and vessel all during installation

3.2 Installation at Conical Tank

Fig 7: Installation at Conical Tank in Top Plane

•The conical tank's top plane can be installed in the middle of the tank top to ensure that the cone

bottom can be measured.

Fig 8: Installation at Conical Tank in inclined Plane

1

Reference Plane

2

Vessel Center or Symmetrical Axis

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

9

•When there is a material pile, the antenna must be vertically aligned with the material surface.

•If the material surface is uneven, the angle of the horn must be adjusted by the universal flange

to align the horn with the material surface as much as possible (because the inclined solid surface

may cause echo attenuation or even signal loss).

3.3 Incorrect Installation

•The conical tank cannot be installed above the feed port.

CAUTION

Sunshade and rainproof measures shall be taken during outdoor installation.

Fig 9: Installation at Conical Tank

•When there is an obstacle in the tank that affects the measurement, installing a reflection plate

for normal measurement is necessary.

Fig 10: Installation of Reflection Plate

•The instrument shall not be installed in the middle of the arch or round tank top.

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

10

•Indirect echo will be affected by multiple echoes.

•Multiple echoes may have a larger signal threshold than real echoes because multiple echoes can

be concentrated through the top. Therefore, it cannot be installed in the center position.

Fig 11: Installation at Round Tank

•Height requirement of connecting pipe: the antenna must extend at least 3/8” (10mm) into the

tank.

Fig 12: Installation with Height Requirement

3⁄”

(10mm)

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

11

4Electrical Connection

This section covers all electrical connection requirement. Electrical connection of the device must be

carried out by trained, qualified specialists authorized to perform such work by the installation site.

WARNING

•Connect all electrical cables when the power is switched off. If the device does

not have switch-off elements, then, overcurrent protection devices, lightning

protection and/or energy isolating devices must be provided by the customer.

•The device must be grounded to a spot in accordance with regulations in order

to protect personnel against electric shocks.

NOTE

When using the measuring device in hazardous areas, installation must comply with

the corresponding national standards and regulations and the Safety Instructions or

Installation or Control Drawings.

4.1 Wiring Connection

•4 to 20mA or Hart (two-wire system) power supply and output current signal share a two-core

shielded cable.

•Refer to technical data for specific power supply voltage range.

•A safety barrier should be placed between the power supply and instrument for an intrinsically

safe version.

•Standard 2- wire cable with an outside diameter of 5...9mm is used to assures the sealing

effect of cable entry. It can be used as a feeder cable.

•You are recommended to use screened cables in electromagnetic Connection cable with

special earth wire used as feeder cable.

Fig 13: Two-Wire System Wiring Diagram

•RS485/MODBUS power supply and MODBUS signal line respectively use a shielded cable.

•Refer to the technical data for the specific power supply voltage range.

+ -

+

-

(4 20)

~m A

1 2

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

12

Fig 14: 24V RS485/Modbus Wiring Diagram

NOTE

•Please observe the requirements of the local electrical installation regulations!

•

Please observe the local regulations on the health and safety of personnel. All

operations of electrical components of instruments must be completed by

professional personnel who have received formal training.

•Ple

ase check the nameplate of the instrument to ensure that the product

specifications meet your requirements. Please ensure that the supply voltage is

consistent with the requirements on the instrument nameplate.

4.2 Protection Level

•The Tek-Wave 4300A Free Space Radar Level Transmitter fully meets the requirements of

protection grade IP66/67.

•Please ensure the water resistance of cable sealing head as shown in figure 15:

Fig 15: Protection Level

•How to ensure that the installation meets the requirements of IP67:

oMake sure that the sealing head is not damaged.

oMake sure the cable is not damaged.

+ -

+

-

(6 24)

~v D C

1 2 34 5

RS 4 85

1

2

3

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

13

oMake sure that the cables are used to meet the requirements of the electrical connection

specifications.

oBefore entering the electrical interface, bend the cable downward to ensure that the water

will not flow into the shell, see 1

oPlease tighten the cable sealing head, see 2

oPlease block the unused electrical interface with a blind plug, see 3

5Operation

5.1 Instrument Commissioning

5.1.1 Different Debugging Method

•Display or Key

•Upper computer debugging

•Hart hand programmer

5.1.1.1 Display or Key

•The instrument is debugged by four buttons on the display screen.

•The language of the debug menu is optional.

•After debugging, it is generally used for display and the measured value can be read out very

clearly through the glass window.

Fig 16: Display or Key

1

Display

2

Key

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

14

5.1.1.2 Upper Computer Debugging

Connect to the upper computer through HART

Fig 17: Connection to the computer through HART

5.1.1.3 HART Handheld Programmer Programming

Fig 18: HART Handheld Programmer

5.2 Display or Adjustments

•Adjustments can be done with four buttons on the view point.

•Optional menu languages are available.

•View point is only used for display after adjustments.

•Measurement results would be displayed on the LCD.

24VDC

1

2

3

4

24VDC

1

2

3

1

RS232 interface / USB interface

2

Tek-Wave 4300C Free Space

Radar Level Transmitter

3

HART adapter

4

250Ω resistance

1

HART Hand Programmer

2

Tek-Wave 4300C Free Space

Radar Level Transmitter

3

250Ω resistance

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

15

Fig 19: Display of Tek-Wave 4300C

Table 1: Display Keys and its function

Display Key

Function

Enter programming mode;

Confirm programming options and modifications to parameters

Modify parameter values and select display mode

Select programming options and digit of parameters to edit;

Display the contents of parameters

Exit programming mode and return to higher menu level;

Display Echo Wave

5.3 Menu

5.3.1 Program Operations

•Enter program mode by press.

•Press after each parameter modify; Otherwise the modification will be abandoned.

•Press to quit program status.

5.3.2 Edit Parameter

•The first digit of the edit parameter is displayed in black background.

•Modify digit with .

•Edit next digit with .

•After editing, press to confirm and store the mod.

•Some settings can be done by selecting one of seeing optional menus and press to

confirm.

OK

BK

OK

OK

BK

OK

OK

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

16

5.3.3 Menu Instruction

5.3.3.1 Basic Settings

•These setting s are basic setup of the sensor such as minimum and maximum adjustment,

medium, damping etc.

•Press to bring the sensor to program mode from run mode. Then the menu is displayed as

shown below

*Note: The menu item number is displayed on the top right corner.

5.3.3.1.1 Minimum Adjustment

•Minimum adjustment setting regulates the linear scaled current output.

•At main menu, select basic settings with and press to confirm.

•Press for edit the percentage value.

•Press again to confirm the modification and furthermore you can edit the corresponding

distance value please refer edit parameter section to edit parameters.

5.3.3.1.2 Maximum Adjustments

•Maximum adjustment setting regulates the linear scaled current output.

•At main menu, select basic settings with and press to confirm.

•Press for edit the percentage value.

•Press again to confirm the modification and furthermore you can edit the corresponding

distance value please refer edit parameter section to edit parameters.

OK

OK

OK

OK

OK

OK

OK

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

17

5.3.3.1.3 Medium

•Each medium has different reflective properties.

•This menu is used to set the medium to be solid or liquid and another relative factor.

•Move arrow with .

•Solid or liquid medium can be selected.

•Press to confirm the selection and enter Fast level change submenu.

Fast Level Change

oPress to enter Fast Level Change Confirmation.

oMove arrow with to Select Yes or No for Fast level change.

oPress to confirm the selection

First Echo

OK

OK

OK

TechnologySolutions

Instruction Manual

Tek-Wave 4300C

www.tek-trol.com

18

oPress to enter First Echo menu.

oPress to select to way to set First Echo

oThere are five ways to set First Echo

Normal: No adjustments on first echo

Small: Decrease first echo by 10dB

Big: Increase first echo by 10dB

Bigger: Increase first echo by 20dB

Biggest: Increase first echo by 40dB

Agitated Surface or Large Angler Repose

oPress to enter Agitated surface or Large angler repose menu.

oPress to move the arrow, select whether the liquid surface is fluctuating or

whether the solid is a large number of angles.

oPress to confirm the selection.

Foaming or Powder Dust

oPress to enter the submenu of foaming or powder dust confirmation.

OK

Table of contents

Other Tek-Trol Transmitter manuals

Tek-Trol

Tek-Trol TEK-FLEX 4100A User manual

Tek-Trol

Tek-Trol TEK-BAR 3800XP User manual

Tek-Trol

Tek-Trol TEK-WAVE 4300C User manual

Tek-Trol

Tek-Trol TEK-WAVE 4300B User manual

Tek-Trol

Tek-Trol TEK-B AR 3120B User manual

Tek-Trol

Tek-Trol TEK-WAVE 4300B User manual

Tek-Trol

Tek-Trol TEK-BAR 3800E User manual

Tek-Trol

Tek-Trol TEK-BAR 3120B Series User manual

Tek-Trol

Tek-Trol Tek-Sound 4200B User manual

Tek-Trol

Tek-Trol Tek-Flex 4100A User manual