Tek-Trol TEK-B AR 3120B User manual

Technology Solutions

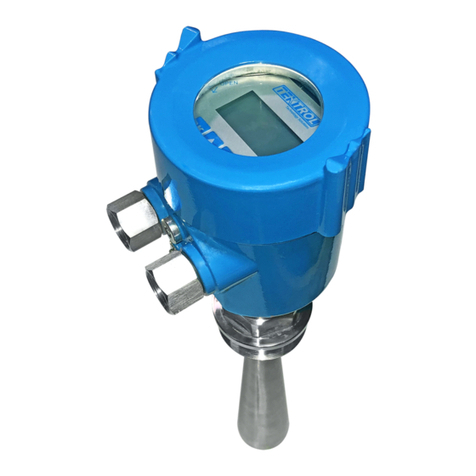

TAR 3120B

EK-B

Instruction Manual

Exp Absolute/Gauge Pressure Transmitter

Document Number: IM-3120B

www.tek-trol.com

www.tek-trol.com

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum

product performance, make sure you thoroughly understand the contents before installing, using, or

maintaining this product.

For technical assistance, contact

Customer Support

796 Tek-Drive

Crystal Lake, IL 60014

USA

Tel: +1 847 857 6076

© COPYRIGHT Tek-Trol LLC 2021

No part of this publication may be copied or distributed, transmitted, transcribed, stored in a

retrieval system, or translated into any human or computer language, in any form or by any means,

electronic, mechanical, manual, or otherwise, or disclosed to third parties without the express

written permission. The information contained in this manual is subject to change without notice.

www.tek-trol.com

1

Table of Contents

1Safety Instructions...........................................................................................................................3

1.1 Intended Use .......................................................................................................................................... 3

1.2 Certifications........................................................................................................................................... 3

1.3 Safety Instructions from the Manufacturer .............................................................................................. 3

1.3.1 Disclaimer ..................................................................................................................................................... 3

1.3.2 Product Liability and Warranty..................................................................................................................... 3

1.3.3 Information Concerning the Documentation ............................................................................................... 3

1.4 Safety Precautions .................................................................................................................................. 3

1.5 Packaging, Transportation and Storage .................................................................................................... 4

1.5.1 Packaging ...................................................................................................................................................... 4

1.5.2 Transportation .............................................................................................................................................. 5

1.5.3 Storage.......................................................................................................................................................... 5

1.5.4 Nameplate .................................................................................................................................................... 5

2Product Description.........................................................................................................................6

2.1 Introduction............................................................................................................................................ 6

2.2 Measuring Principle................................................................................................................................. 6

2.3 Specifications.......................................................................................................................................... 7

2.3.1 General Specification.................................................................................................................................... 7

2.3.2 Damping Time............................................................................................................................................... 7

2.3.3 Environmental Conditions ............................................................................................................................ 7

2.3.4 Power Supply ................................................................................................................................................ 7

2.3.5 Measuring Range Limit ................................................................................................................................. 8

2.4 Dimensional Drawings............................................................................................................................. 8

2.5 Model Chart............................................................................................................................................ 9

3Installation......................................................................................................................................9

3.1 Selecting the Installation Location ......................................................................................................... 10

3.2 Installation Procedure ........................................................................................................................... 10

3.2.1 Install Pressure Transmitter........................................................................................................................ 10

3.2.2 Process Connections ................................................................................................................................... 10

3.2.3 Housing Rotation ........................................................................................................................................ 11

3.2.4 Terminal Side of Transmitter ...................................................................................................................... 11

3.2.5 LCD Display ................................................................................................................................................. 11

3.2.6 Conduit Installation..................................................................................................................................... 12

3.3 Mounting Requirements........................................................................................................................ 12

3.3.1 Liquid Measurement................................................................................................................................... 12

3.3.2 Gas Measurement ...................................................................................................................................... 12

3.3.3 Steam Measurement .................................................................................................................................. 13

3.4 Field Adjustment................................................................................................................................... 13

3.4.1 Zero Point Adjustment................................................................................................................................ 13

3.4.2 Full Span Adjustment.................................................................................................................................. 14

3.5 Product Usage....................................................................................................................................... 14

3.5.1 Pipeline pressure measurement: Pressure Transmitter............................................................................. 14

3.5.2 Pipeline pressure measurement: Differential Pressure Transmitter.......................................................... 14

3.5.3 Steam Flow Measurement.......................................................................................................................... 14

3.5.4 Liquid Flow Measurement .......................................................................................................................... 14

3.5.5 Air Flow Measurement ......................................................................................................................14

www.tek-trol.com

2

3.5.6 Open Container Level Measurement: Single Flange Level Transmitter ..................................................... 14

3.5.7 Sealed Container Level Measurement: Single Flange Level Transmitter ................................................... 15

4Electrical Connections....................................................................................................................15

4.1 Grounding of Measuring Device............................................................................................................. 15

4.2 Power Supply Specifications and Connection.......................................................................................... 16

4.3 Cable Protection System........................................................................................................................ 17

4.3.1 Standard Protection System ....................................................................................................................... 17

4.3.2 Explosion-Proof Tube Protection System ................................................................................................... 17

4.3.3 Connection to the HART Handheld Communicator.................................................................................... 17

5Operation......................................................................................................................................18

5.1 Local Operation and Display .................................................................................................................. 18

5.2 Operation in safe and hazardous areas .................................................................................................. 18

5.3 Configuration ........................................................................................................................................ 19

5.3.1 Key Operation ............................................................................................................................................. 19

5.3.2 Factory Reset .............................................................................................................................................. 19

5.4 Analog button programming menu........................................................................................................ 19

5.4.1 Key Operation ............................................................................................................................................. 19

5.4.2 Detailed operating instructions. ................................................................................................................. 21

5.5 Modbus Programming Menu ................................................................................................................. 22

5.5.1 Key Operation ............................................................................................................................................. 22

5.5.2 Detailed operating instructions .................................................................................................................. 23

5.6 Flow Diagram........................................................................................................................................ 25

5.7 Handheld Communicator....................................................................................................................... 27

6Maintenance .................................................................................................................................28

6.1 Hardware Maintenance......................................................................................................................... 28

6.1.1 Test Terminal .............................................................................................................................................. 28

6.1.2 Disassembling the Electronics Housing ...................................................................................................... 28

6.1.3 External Cleaning ........................................................................................................................................ 28

6.1.4 Depot Repair ............................................................................................................................................... 29

6.1.5 Discard Disposal.......................................................................................................................................... 29

7Troubleshooting ............................................................................................................................29

7.1 Symptoms and Corrective Measures ...................................................................................................... 30

7.2 Tek-Bar 3120B Exp Absolute/Gauge Pressure Transmitter LCD Display error codes.................................. 31

www.tek-trol.com

3

1Safety Instructions

1.1 Intended Use

Tek-Bar 3120B is a Exp Absolute/Gauge Pressure Transmitter used for pressure and level measurement

of steam, liquids and Gasses.

The manufacturer is not liable for damage caused by improper or non-designated use.

1.2 Certifications

Tek-Bar 3120B has CE, CSA approval (Class I Div. I)

1.3 Safety Instructions from the Manufacturer

1.3.1 Disclaimer

The manufacturer will not be held accountable for any damage that happens by using its product,

including, but not limited to direct, indirect, or incidental and consequential damages.

Any product purchased from the manufacturer is warranted in accordance with the relevant product

documentation and our Terms and Conditions of Sale.

The manufacturer has the right to modify the content of this document, including the disclaimer, at

any time for any reason without prior notice, and will not be answerable in any way for the possible

consequence of such changes.

1.3.2 Product Liability and Warranty

The operator shall bear authority for the suitability of the device for the specific application. The

manufacturer accepts no liability for the consequences of misuse by the operator. Wrong installation

or operation of the devices (systems) will cause the warranty to be void. The respective Terms and

Conditions of Sale, which forms the basis for the sales contract shall also apply.

1.3.3 Information Concerning the Documentation

To prevent any injury to the operator or damage to the device it is essential to read the information

in this document and the applicable national standard safety instructions. This operating manual

contain all the information that is required in various stages, such as product identification, incoming

acceptance and storage, mounting, connection, operation and commissioning, troubleshooting,

maintenance, and disposal.

1.4 Safety Precautions

You must read these instructions carefully prior to installing and commissioning the device. These

instructions are an important part of the product and must be kept for future reference. Only by

observing these instructions, optimum protection of both personnel and the environment, as well as

safe and fault-free operation of the device can be ensured.

For additional information that are not discussed in this manual, contact the manufacturer.

www.tek-trol.com

4

Warnings and Symbols Used

The following safety symbol marks are used in this operation manual and on the instrument.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in

death or severe injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

NOTE

Indicates that operating the hardware or software in this manner may damage it

or lead to system failure.

1.5 Packaging, Transportation and Storage

1.5.1 Packaging

The original package consists of

1. Tek-Bar 3120B Exp Absolute/Gauge Pressure Transmitter

2. Accessories (optional)

3. Documentation

NOTE

Unpack and Check the contents for damages or sign of rough handling. Report

damage to the manufacturer immediately. Check the contents against the packing

list provided.

www.tek-trol.com

5

1.5.2 Transportation

•Avoid impact shocks to the device and prevent it from getting wet during transportation.

•Verify local safety regulations, directives, and company procedures with respect to hoisting,

rigging, and transportation of heavy equipment.

•Transport the product to the installation site using the original manufacturer’s packing

whenever possible.

1.5.3 Storage

If this product is to be stored for a long period of time before installation, take the following

precautions:

•Store your product in the manufacturer’s original packing used for shipping.

•Storage location should conform to the following requirements:

1. Free from rain and water

2. Free from vibration and impact shock

3. At room temperature with minimal temperature and humidity variation

•Properties of the instrument can change when stored outdoors.

1.5.4 Nameplate

The nameplate lists the order number and other important information, such as design details and

technical data.

NOTE

Check the device nameplate to ensure that the device is delivered according to

your order. Check for the correct supply voltage printed on the nameplate.

Tek-Bar 3120B

Smart Pressure Transmitter

Model: Te k -Bar 3120B-G-5-CSA-1-HC-1

Output: 4 to 20mA+HART Range: 0 to 1450 psig

Accuracy: ±0.075% F.S. Power: 16.5 to 55 VDC

SN.: F1911-130-008-6-S3217 Max W .P.:2900 psi

Cl a ss I , Division 1, Group A, B, C and D T6

Cl a ss I I , Division 1, Group E, F, and G T80ºC

Cl a ss I I I

MC

601726

IP66

www.tek-trol.com

6

2Product Description

This specification covers the reference and specification data, as well as ordering information.

2.1 Introduction

Tek-Bar 3120B Exp Absolute/Gauge Pressure Transmitter utilizes world’s leading mono crystal silicon

pressure sensor technology. It can handle rigorous industrial applications and it can withstand extreme

chemical, mechanical and electrical working conditions. Highly accurate and reliable measurement of

level and pressure of liquid, gases or steam. The performance accuracy is up to 0.04% of URL. This

high-performance pressure transmitter meticulously designed by Tek-Trol supports HART

communication protocol or Modbus RS485 and IP67 waterproof protection. It is well equipped with

several features that facilitate easy installation, start-up and minimum maintenance.

2.2 Measuring Principle

The Tek-Bar 3120B works on the principle of Piezo technology. The pressure sensor is located on the

top of the body, away from the service fluid. This enables mechanical and thermal isolation of the

sensor from the fluid in service.

When pressure is applied on the diaphragm and the Piezo sensor, they become stressed and undergo

a change in voltage resistance. This change in resistance is directly proportional to the applied

pressure, which is transferred to the transmitter body using lead wires.

Built on semiconductor technology, the resistance change (piezoelectric effect) is notably higher than

exhibited in standard strain gauges. Therefore, the sensitivity of monocrystalline sensors is higher than

the sensitivity of most other types.

Fig 1: Tek-Bar 3120B Exp Absolute/Gauge Pressure Transmitter

P

e

P

e

1

2

2

6

5

5

4

4

4

3

3

1 Reference pressure

2 Measuring cell

3 Process connection

4 Seal diaphragm

4 Filling liquid

6 Relative pressure sensor

P

e

Pressure as input variable

1 Measuring cell

2 Process connection

3 Seal diaphragm

4 Filling liquid

5 Absolute pressure sensor

P

e

Pressure as input variable

www.tek-trol.com

7

2.3 Specifications

2.3.1 General Specification

Pressure Type

Gauge or Absolute

Accuracy

±0.075% F.S. (Optional ± 0.04%F.S.)

Diaphragm Materials

Hastelloy C

Measuring Range

5 to 10000psig (5 to 1500psig)

Stability

±0.2 % URL/5 year

Process Connections

½” MNPT (other options available)

Wetted material

316L SS and Hastelloy C

Working Humidity

5 to 100%

Output Signal

4mA to 20mA with HART® Communication

(Optional Modbus RS485 and 1-5VDC)

Mounting Position Effect

Apply to any position. Max value lower than 1.6

w.c. (400 Pa) can be corrected by zero clearing

function

Insulation Resistance

≥20MΩ at 100VDC

Enclosure Rating

NEMA 4X (IP67); Optional IP68

Weight (excluding Optional Items)

3.43 lb (1.55kg)

Testing Standard

IEC60770

Agency Approvals

CE, CSA Class I Div I

2.3.2 Damping Time

Damping time of amplifier

0-100s adjustable

Diaphragm capsule (isolated diaphragm

and silicon oil filling) damping time

≤0.2s

Start-up after power off

≤6s

2.3.3 Environmental Conditions

Working Temperature

-40 °F to 180 °F (-40 °C to 82 °C)

Storage Temperature

-40 °F to 230 °F (-40 °C to 110 °C)

Media Temperature

-40 °F to 248 °F (-40 °C to 120 °C)

Working Humidity

5-100% RH at 104 °F

2.3.4 Power Supply

Standard/flame proof

10.5-55 VDC (Hart 16.5-55 VDC, 250 Ω)

Load Resistance

0-2119 Ω for working condition, 250- 600 Ω for HART protocol

Transmission Distance

<1000 m

Power Consumption

≤500 mW at 24 VDC, 20.8 mA

www.tek-trol.com

8

2.3.5 Measuring Range Limit

Nominal Value

Smallest Calibrated

Span

Lower Range

Limit (LRL)

Upper Range

Limit (URL)

Overload Limit

5psi 8 in.WC -14.5psi 5psi 145psig

36psi 2psi -14.5psi 36psi 580psig

145psi 7.25psi -14.5psi 145psi 870psig

435psi 22.25psi -14.5psi 435psi 2175psig

1500psi 72.5psi -14.5psi 1500psi 2900psig

3000psi 725psi 0psi 3000psi 11600psig

6000psi 725psi 0psi 6000psi 11600psig

10000psi 5000psi 0psi 10000psi 16000psig

Nominal Value

Smallest Calibrated

Span

Lower Range

Limit (LRL)

Upper Range

Limit (URL)

Overload Limit

0.344bar 20mbar -1bar 0.344bar 10bar

2.5bar 0.14bar -1bar 2.5bar 40bar

10bar 0.5bar -1bar 10bar 60bar

30bar 1.5bar -1bar 30bar 150bar

103bar 5bar -1bar 103bar 200bar

207bar 50bar 0bar 207bar 800bar

414bar 50bar 0bar 414bar 800bar

690bar 344bar 0bar 690bar 1103bar

2.4 Dimensional Drawings

4 1/4"

(107.5mm)

4 1/4"

(107.5mm)

5 1/8"

(127.5 mm)

3 1/2"

(85.5mm)

www.tek-trol.com

9

2.5 Model Chart

Example Tek-Bar 3120B G-A 3 WP 1 HC 1 BA Tek-Bar 3120B-G-A-3-WP-1-HC-1-BA

Series Tek-Bar 3120B Exp Absolute/Gauge Pressure Transmitter

Types G Gauge Pressure

A Absolute Pressure

Range Options

1

0 to 5psi (G or A) (40:1 Turndown, Adj. Range: -5 to 5psi)

2 0 to 36psi (G or A) (40:1 Turndown, Adj. Range: -14.5 to 36psi)

3 0 to 145psi (G or A) (40:1 Turndown, Adj. Range: -14.5 to 145psi)

4 0 to 435psi (G or A) (40:1 Turndown, Adj. Range: -14.5 to 435psi)

5 0 to 1500psi (G or A) (40:1 Turndown, Adj. Range: -14.5 to 1500psi)

8 0 to 3000psi (G) (4:1 Turndown, Adj. Range: 0 to 3000psi)

6 0 to 6000psi (G) (8:1 Turndown, Adj. Range: 0 to 6000psi)

7 0 to 10000psi (G) (2:1 Turndown, Adj. Range: 0 to 10000psi)

Approval Rating

WP

CSA

General Purpose NEMA 4X/IP67

CSA Class I Div I Explosion Proof

Process Connections

1

X

½" NPT Male

Diaphragm Seal

Diaphragm Material

HC Hastelloy C

Electrical

Connections

1 ½" NPT Female

Options

CC Custom Calibration with 5-point Calibration Certificate

FC Factory Configuration, No Certificate

BA Stainless Steel Bracket (Angle type) with SST Bolts

TAG Custom Etching of the Name Plate (Must specify on P.O.)

MOD Modbus RS485 Communication

IP68 Submersible Rated

2WB 2-Valve Manifold

EA Extended Accuracy ±0.04%

VDC 1-5VDC Output

3Installation

This section covers instructions on installation and commissioning. Installation of the device

must be carried out by trained, qualified specialists authorized to perform such works.

•When removing the instrument from hazardous processes, avoid direct contact

with the fluid and the meter.

•All installation must comply with local installation requirements

and local electrical code.

CAUTION

www.tek-trol.com

10

3.1 Selecting the Installation Location

Prior to product installation, check the model, specifications and installation location for the

transmitter. The transmitter is designed to withstand severe environmental conditions. However,

follow the enlisted precautions while selecting the installation site to ensure stable and accurate

operation for years.

•Ambient Temperature

Avoid locations subjected to significant temperature gradient or wide temperature variations.

If transmitter is exposed to radiant heat from plant’s equipment, then providing adequate

thermal isolation and/or ventilation is desirable.

•Ambient Atmosphere

Avoid corrosive atmosphere while installing the transmitter. If it must be installed in a corrosive

atmosphere, then provide adequate ventilation and take the necessary measures to prevent

intrusion or stagnation of rainwater in conduits.

•Shock and Vibration

Although the transmitter is designed to withstand shock and vibrations, it is recommended to

select an installation site with minimum shock and vibration to avoid device damage and

improve measurement accuracy.

3.2 Installation Procedure

This section includes the information regarding installation of the transmitter for safe and precise

functioning. It provides the procedure and instruction for mounting, transmitter functions, and

installation for specific applications.

3.2.1 Install Pressure Transmitter

Direct installation or mounting bracket installation may be used depending on the application and

installation site requirement. Various mounting scenarios are illustrated in sections below.

3.2.2 Process Connections

3.2.2.1 Taper Thread Connection

Use tapered thread connections to make better seals. Sealing with Teflon tape or sealant glue

results in strong and leak resistant connections.

3.2.2.2 Flange Connection

www.tek-trol.com

11

Choose gasket according to the properties of the process medium and the temperature range.

Pay attention to the bolt balance lock.

3.2.2.3 Clamp Connection

Choose gaskets that meet specified standards to avoid excessive clamp locking and

squeezing gasket. Excessive locking of clamp may damage the sensing diaphragm and

cause measuring error.

NOTE

Engage process connection with a minimum of 7 thread connections and tighten

the housing rotation set screw to prevent it from rotating.

3.2.3 Housing Rotation

To ensure the visibility of LCD display

•Loosen the housing screw.

•Rotate housing to the desired angle up to 360o.

•Re-tighten the housing screw.

3.2.4 Terminal Side of Transmitter

Mount the transmitter in such a way that the terminal side is easily accessible to the operator.

3.2.5 LCD Display

Display module is used in field adjustment for parameter settings and site configuration before

starting the measurement process. The local 5-digit LCD displays important parameters, which can

be directly monitored at the measuring point. It enables the operator to configure the device using

the function matrix. Display can be rotated 355°.

www.tek-trol.com

12

3.2.6 Conduit Installation

Improper sealing of connections may damage the transmitter due to excess moisture

accumulation. Mount the transmitter with electrical housing positioned downward so that

the excess of moisture is condensed and drained out from the casing. Secondly, install

wiring with a drip loop and ensure the bottom of the drip loop is mounted lower than the

conduit connections or the transmitter housing to avoid moisture accumulation in the

housing.

NOTE

Conduit thread must be engaged with a minimum of 5 thread connections.

3.3 Mounting Requirements

Impulse piping configuration and transmitter position depends on specific measurement

conditions. Follow the procedure below while installing transmitter for liquid, gases or steam

processes.

3.3.1 Liquid Measurement

•Place the taps to the side of the line/pipe to prevent residue deposits on the

transmitter process isolators.

•Mount the transmitter beside or below the taps so gases can vent into the process line.

•Mount drain/vent the valve upward to allow gases to vent.

3.3.2 Gas Measurement

•Place the taps in the top or side of the line.

•Mount the transmitter beside or above the taps so liquid will drain into the process

line.

Flow

Flow

www.tek-trol.com

13

3.3.3 Steam Measurement

•Place taps to the side of the line.

•Mount the transmitter below the taps to ensure that the impulse piping stays filled with

condensate.

•In steam service above 250°F (121°C), fill impulse lines with water to prevent the direct steam

contact with the transmitter and to ensure accurate measurement at start-up.

NOTE

For steam or other higher temperature processes, ensure that the temperature at the

process connection does not exceed the transmitter’s process temperature limits.

3.4 Field Adjustment

Perform field adjustments only after installing the transmitter at its final work location otherwise the

set parameters may drift due to jerks while transporting or handling.

3.4.1 Zero Point Adjustment

•For sensor zero trim, ensure that the vessel is empty and there is no input medium

pressure on the diaphragm. The vessel should be applied a normal atmospheric

pressure. If applying external pressure to the transmitter make sure that the display is

sufficiently stabilized (after approximately 10 to 15 seconds), before initiating any trim

function.

•There are 3 ways of making input pressure “Zero”.

Apply a “Zero” pressure source (mandatory for absolute pressure models).

Apply equal pressure on both HP and LP ports (DP models only).

Open equalizing valve of manifolds installed and venting to atmospheric pressure

(applicable for Gauge & DP type models only).

•Sensor zero trim can be performed using an external HHC (Handheld calibrator), PC or

PDA configurator, and/or using Zero/Span local push buttons provided on the

transmitter.

•Using local push buttons set PV=0, refer to section 5.2.1 of this manual for detailed

instructions. If using an external HHT or HART® PC configurator, refer to the user

manual supplied by the third-party supplier.

Flow

www.tek-trol.com

14

3.4.2 Full Span Adjustment

•For full span adjustment, ensure that the vessel is filled with process medium to the

maximum level.

•Maintain static pressure value within the minimum and maximum pressure range.

•Using local push buttons set output for lower and upper limit of the full scale i.e.,

4mA and 20mA, refer to section 5.2 of this manual for detailed key operations.

•The device is now ready for the real-time process measurement.

•The URV and LRV can be set with Hart or Push buttons.

3.5 Product Usage

3.5.1 Pipeline pressure measurement: Pressure Transmitter

For high temperature steam measurements, pre-inject more than half-tube cooling

water in the condenser. Once the steam pipes are stable, gradually open the shut-off

valve to start measurement.

3.5.2 Pipeline pressure measurement: Differential Pressure Transmitter

For high temperature steam measurement in a pipeline by differential pressure transmitter,

pre-inject cooling water into the guided pipe. Once the steam pipes are stable, slowly open

the shut-off valve and start measuring.

Differential pressure transmitters are commonly used for micro pressure measurement of

hydrostatic pressures such as filter and equipment leakage tests for improving accuracy.

3.5.3 Steam Flow Measurement

For steam flow measurement, up-tilt the guiding pressure tube by 45°. Ensure that

transmitter installation location is at lower level than that of the process pipeline. Pre-

inject cooling liquid into the guiding pressure tube. Slowly open the shut-off valve to start

measurement. Periodically open the drain vent to clear the residual steam from guided

pipeline to improve the measurement accuracy.

3.5.4 Liquid Flow Measurement

For liquid flow measurement, tilt down the guiding pressure tube by 45°. Ensure that

transmitter installation location is at lower level than that of the process pipeline. Pre-

inject cooling liquid into the guiding pressure tube. Slowly open the shut-off valve to

start measurement. Periodically open the drain vent to clear the residual liquid, which

will improve the measurement accuracy.

3.5.5 Air Flow Measurement

For liquid flow measurement, up-tilt the guiding pressure tube by 45°. Ensure that

transmitter installation location is at lower level than that of the process pipeline. Pre-

inject cooling liquid into the guiding pressure tube. Slowly open the shut-off valve to start

measurement. Periodically open the drain vent to clear the residual gas from the guiding

pressure tube, which will improve the measurement accuracy.

3.5.6 Open Container Level Measurement: Single Flange Level Transmitter

Verify the process medium compatibility in case of open container level measurement.

www.tek-trol.com

15

For accurate measurement, install the transmitter at a location where liquid level and

temperature fluctuations are minimal.

3.5.7 Sealed Container Level Measurement: Single Flange Level Transmitter

Use a single flange diaphragm system for sealed container level measurement. Increase

the isolation tank and multiple shut-off valves. Periodically open the drain/vent valve to

clear off the residual gas and liquid in the guiding pressure tube for higher accuracy.

4Electrical Connections

This section covers all electrical connection requirement. Electrical connection of the device

must be carried out by trained, qualified specialists authorized to perform such work by the

installation site.

WARNING

•Connect all electrical cables when the power is switched off. If the device does not

have switch-

off elements, then, overcurrent protection devices, lightning

protection and/or energy isolating devices must be provided by the customer.

•The device must be grounded to a spot in accordance with regulations to protect

personnel against electric shocks.

NOTE

•When using the measuring device in hazardous areas, installation must comply

with the corresponding national standards and regulations and the Safety

Instructions or Installation or Control Drawings.

4.1 Grounding of Measuring Device

•Ensure proper grounding at control cabinet and pressure transmitter.

•Ground terminals are provided on the either sides (inside and outside) of the terminal

box. Either one of these terminals may be used for grounding the transmitter.

•Use shielded twisted pair cable to avoid ground loops.

•Use internal ground terminals for direct grounding.

www.tek-trol.com

16

4.2 Power Supply Specifications and Connection

•Use independent linear direct current power supply for pressure transmitter. Large

resistive load results in high pressure drop.

•Therefore, it is recommended to consider the resistance across the signal cable, display

meter and other equipment to ensure sufficient voltage is provided to the pressure

transmitter for its normal operation.

Standard current signal output: 12-30VDC, Current signal output with HART: 16.5-55VDC,

Current signal output with intrinsic safety: 12-30VDC

Modbus-RTU/RS485 signal output: 5VDC/9-30VDC

•Remove the housing cover on terminal compartment side. Do not remove the cover in

explosive atmospheres when the circuit is live.

Label

Two Wires

Three Wires

Four Wires

+

Power +

Power +

Power +

-

Signal -

Power -

Power -

A

Signal +

Signal +

B

Signal -

NOTE

•4-20mA can be 2 or 3-wire; 1-5vdc is 3-wire; Modbus is 4-wire.

•Power supply connections:

Connect power supply ‘+’ terminal to transmitter ‘+’ terminal.

Connect signal ‘+’ terminal to transmitter ‘-’ terminal.

Connect signal ‘-’ terminal to power supply ‘-’ terminal.

Do not connect power signal wiring to the test terminals as it could damage

the test diode.

Fig 2: Power Supply Connection

3

1

2

+

-

P+ P-

Power

S- S+

Signal

Transmitter

term i nals

www.tek-trol.com

17

4.3 Cable Protection System

Apply following cable protection measures to protect the connecting cables from various

factors that affect negatively on the cable lifetime.

4.3.1 Standard Protection System

•To avoid liquid flowing along with the cable into the terminal box, configure a U-shaped

ring between pull box and pressure transmitter as shown in the figure below.

•Ensure that the level of U-shaped bottom is maintained below the pressure

transmitter.

•Use sufficiently long cable considering the maintenance and repair factors.

4.3.2 Explosion-Proof Tube Protection System

•If the transmitter is situated in dangerous area, use a high-quality metallic explosion-

proof tube as a casing for the cable connecting the transmitter to the terminal box.

4.3.3 Connection to the HART Handheld Communicator

A loop resistance for HART Communicator is between 250Ω and 550Ω. Transmitter operates on 1.9

to 45 VDC. Figure below illustrates the connection details for HHT communicator.

www.tek-trol.com

18

5Operation

This section covers operation techniques and guidelines along with the configuration and calibration.

NOTE

Calibrate the instrument according to the instructions given in this section,

otherwise it could lead to measurement error.

5.1 Local Operation and Display

Tek-Bar 3120B is available with the optional LCD display. The local display enables user to read

important parameters directly at the measuring point and configure the device using the function

matrix. The display indicates output and diagnostic messages. It features a two-line display with 5-

digit. The first line displays measured value and the second line displays the engineering units. If LCD

display is not available, then use HART for communication (Refer section 5.5).

5.2 Operation in safe and hazardous areas

The internal and external buttons are provided for operation in safe and hazardous areas,

respectively.

•While operating in safe area, open the front cover and use internal buttons.

•While operating in hazardous area, slide the nameplate located at the upper side of the

transmitter and use the external buttons.

Fig 3: External buttons for operation in hazardous area

Table of contents

Other Tek-Trol Transmitter manuals

Tek-Trol

Tek-Trol TEK-WAVE 4300C User manual

Tek-Trol

Tek-Trol TEK-WAVE 4300B User manual

Tek-Trol

Tek-Trol TEK-BAR 3800E User manual

Tek-Trol

Tek-Trol TEK-BAR 3120C User manual

Tek-Trol

Tek-Trol TEK-WAVE 4300B User manual

Tek-Trol

Tek-Trol Tek-Flex 4100A User manual

Tek-Trol

Tek-Trol TEK-BAR 3120B Series User manual

Tek-Trol

Tek-Trol TEK-W AVE 4300C User manual

Tek-Trol

Tek-Trol TEK-BAR 3800XP User manual

Tek-Trol

Tek-Trol TEK-FLEX 4100A User manual