Tek-Trol TEK-BAR 3800XP User manual

Technology Solutions

TAR 3800XP

EK-B

Instruction Manual

Multivariable Transmitter / Flow Computer

Document Number: IM-3800XP

www.tek-trol.com

© COPYRIGHT Tek-Trol LLC 2021

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum

product performance, make sure you thoroughly understand the contents before installing, using, or

maintaining this product.

For technical assistance, contact

Customer Support

796 Tek-Drive

Crystal Lake, IL 60014

USA

Tel: +1 847 857 6076

www.tek-trol.com

No part of this publication may be copied or distributed, transmitted, transcribed, stored in a

retrieval system, or translated into any human or computer language, in any form or by any means,

electronic, mechanical, manual, or otherwise, or disclosed to third parties without the express

written permission. The information contained in this manual is subject to change without notice.

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solutions

1

Table of Contents

1Safety Instructions.....................................................................................................................3

1.1 Intended Use ...................................................................................................................................3

1.2 Certifications ...................................................................................................................................3

1.3 Manufacturer Safety Instructions.....................................................................................................3

1.3.1 Disclaimer............................................................................................................................................3

1.3.2 Product Liability and Warranty ...........................................................................................................3

1.3.3 Information Concerning the Documentation......................................................................................3

1.4 Safety Precautions ...........................................................................................................................3

1.5 Packaging, Transportation and Storage ............................................................................................4

1.5.1 Packaging.............................................................................................................................................4

1.5.2 Transportation.....................................................................................................................................4

1.5.3 Storage ................................................................................................................................................4

1.5.4 Nameplate...........................................................................................................................................5

2Product Description...................................................................................................................5

2.1 Introduction ....................................................................................................................................5

2.2 Components of Tek-Bar 3800XP Multivariable Transmitter / Flow Computer.....................................5

2.3 Specifications ..................................................................................................................................6

2.4 Dimensional Drawings .....................................................................................................................7

2.5 3800XP Models................................................................................................................................7

3Installation ................................................................................................................................8

3.1 General Instructions ........................................................................................................................8

3.2 Enclosure Cap Locking Screw............................................................................................................9

3.3 Pole Mounting.................................................................................................................................9

3.4 Installation for Wet or Dry Gas Flow...............................................................................................10

4Electrical Connection ...............................................................................................................10

4.1 Jumper Locations...........................................................................................................................11

4.2 Bootloader Protect and Bluetooth Disable Jumpers ........................................................................13

4.3 Battery Backup Memory Jumper (Disable Battery for Storage)........................................................13

4.4 Bluetooth (BT) OTA Update and BT Development Jumpers .............................................................14

4.5 Main Board Switch Location (SW1).................................................................................................14

4.6 Grounding .....................................................................................................................................15

4.7 Wire Gauges ..................................................................................................................................15

4.8 Wiring Instructions ........................................................................................................................16

4.9 Communication .............................................................................................................................18

4.9.1 Local Serial Communication Port ..................................................................................................... 18

4.9.2 Bluetooth LE ..................................................................................................................................... 18

4.9.3 RS232 Mode ..................................................................................................................................... 18

4.9.4 RS485 Mode ..................................................................................................................................... 18

4.9.5 Ethernet Port.................................................................................................................................... 18

4.9.6 Bluetooth Operation ........................................................................................................................ 19

4.9.7 HART Communication ...................................................................................................................... 19

5Operations ..............................................................................................................................20

5.1 Device Set Up Menu ......................................................................................................................20

5.2 Process Variable Menu ..................................................................................................................20

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

2

5.2.1 Configuration Process Variable Menu.............................................................................................. 21

5.3 Diagnostics or Service Menu ..........................................................................................................21

5.4 Status Info Menu ...........................................................................................................................21

5.5 Loop Test.......................................................................................................................................22

5.6 D/A Trim .......................................................................................................................................23

5.7 Input Calibration............................................................................................................................25

5.8 Basic Set Up Menu.........................................................................................................................28

5.9 Device Information Menu ..............................................................................................................28

5.10 Range Value Menu.........................................................................................................................29

5.11 Detailed Set UP Menu....................................................................................................................29

5.11.1 System Info Menu ............................................................................................................................ 29

5.11.2 System Configure Menu................................................................................................................... 29

5.11.3 Differential Press .............................................................................................................................. 31

5.11.4 Static Pressure Menu ....................................................................................................................... 31

5.11.5 RTD Temperature Menu................................................................................................................... 31

6Menu Tree...............................................................................................................................32

7Troubleshooting ......................................................................................................................32

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

3

1Safety Instructions

1.1 Intended Use

Tek-Bar 3800XP Multivariable Transmitter / Flow Computer is designed to use for gas and liquid

in harsh environments.

1.2 Certifications

Class 1 Div 1 and Div 2 Approval.

1.3 Manufacturer Safety Instructions

1.3.1 Disclaimer

The manufacturer will not be held accountable for any damage that happens by using its product,

including, but not limited to direct, indirect, or incidental and consequential damages.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer has the right to modify the content of this document, including the disclaimer,

at any time for any reason without prior notice, and will not be answerable in any way for the

possible consequence of such changes.

1.3.2 Product Liability and Warranty

The operator shall bear authority for the suitability of the device for the specific application. The

manufacturer accepts no liability for the consequences of misuse by the operator. Wrong

installation or operation of the devices (systems) will cause the warranty to be void. The

respective Terms and Conditions of Sale, which forms the basis for the sales contract shall also

apply.

1.3.3 Information Concerning the Documentation

To prevent any injury to the operator or damage to the device it is essential to read the

information in this document and the applicable national standard safety instructions. This

operating manual contain all the information that is required in various stages, such as product

identification, incoming acceptance and storage, mounting, connection, operation, and

commissioning, troubleshooting, maintenance, and disposal.

1.4 Safety Precautions

You must read these instructions carefully prior to installing and commissioning the device. These

instructions are an important part of the product and must be kept for future reference. Only by

observing these instructions, optimum protection of both personnel and the environment, as well

as safe and fault-free operation of the device can be ensured.

For additional information that are not discussed in this manual, contact the manufacturer.

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

4

Warnings and Symbols Used

The following safety symbol marks are used in this operation manual and on the instrument.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in

death or severe injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

NOTE

Indicates that operating the hardware or software in this manner may damage it

or lead to system failure.

1.5 Packaging, Transportation and Storage

1.5.1 Packaging

The original package consists of

1. Tek-Bar 3800XP Multivariable Transmitter

2. Documentation

NOTE

Unpack and Check the contents for damages or sign of rough handling. Report

damage to the manufacturer immediately. Check the contents against the packing

list provided.

1.5.2 Transportation

•Avoid impact shocks to the device and prevent it from getting wet during transportation.

•Verify local safety regulations, directives, and company procedures with respect to hoisting,

rigging, and transportation of heavy equipment.

•Transport the product to the installation site using the original manufacturer’s packing

whenever possible.

1.5.3 Storage

If this product is to be stored for a long period of time before installation, take the following

precautions:

•Store your product in the manufacturer’s original packing used for shipping.

•Storage location should conform to the following requirements:

1. Free from rain and water

2. Free from vibration and impact shock

3. At room temperature with minimal temperature and humidity variation

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

5

•Properties of the instrument can change when stored outdoors.

1.5.4 Nameplate

The nameplate lists the order number and other important information, such as design details

and technical data.

NOTE

Check the device nameplate to ensure that the device is delivered according to your

order. Check for the correct supply voltage printed on the nameplate.

2Product Description

2.1 Introduction

Tek-Trol’s Tek-Bar 3800XP (MVT) Multivariable Transmitter / Custody Transfer Flow Computer is

designed to provide the highest flexibility. It features a complete suite of measurement

calculations and control functions that enable customers to take control of their flow metering

requirements. The Tek-Bar 3800XP Multivariable Transmitter is configured for both gas and

liquid applications and designed for harsh environments seen in major oil and gas field

applications. The device meets both Class 1, Div 1 and Div 2 hazardous safety requirements and

meets CSA/ATEX/IECEX. The Tek-Bar 3800XP Multivariable Transmitter (MVT) is designed to

provide reliable and accurate Differential Pressure, Static Pressure, and in-Line Temperature

Measurements plus flow calculations compatible with the API MPMS 21.1 electronic flow

metering standard.

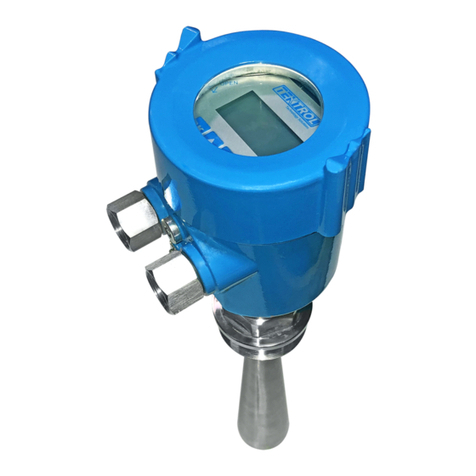

2.2 Components of Tek-Bar 3800XP Multivariable Transmitter / Flow Computer

Fig 1: Components of Tek-Bar 3800XP Multivariable Transmitter (MVT)

Mounting Hardware

1. Bracket, Pole Mounting

2. U-bolt 2 ½” ID, 5/16-18 THD with nuts

3. U-bolt 2” ID, 1/4-20 THD with nuts

4. Washer ¼ ID x 5/8 OD flat

5. Washer split lock

6. Washer 3/8 ID flat

7. Washer split lock 3/8

3800XP MVT Transmitter

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

6

2.3 Specifications

Alarm Log Storage User configurable, defaulting to 200 alarm events

Audit Trails User configurable, defaulting to 200 audit events

Certifications/Compliance

CSA/C-US Class I, Div 1, Groups B, C, D; ambient temperature range of -

40°C to +85°C (-40°F to +185°F), temperature code T6 (-40°C to 75°C) T5

(-40°C to 85°C) EN 61326-1: 2013 (Industrial Criteria); FCC 47 CFR Part

15, Subpart B; ICES 003: 2016; Measurement Canada pending

Data Memory 2 MB Static Random-Access Memory (SRAM)

Description 3800 XP - MVT / Flow Computer for Gas and Liquids

Diagnostic AGA 10 Speed of Sound (Comparison with GC SOS Prediction)

Differential Meters

(DP, Orifice) AGA 3/ANSI/API 2530-1992 Method 2; AGA 3/ANSI/API

2530-1985; ISO 5167 pt5; DP Cone meters; Averaging Pitot; GOST:

Venturi Meters - Steam Flow IF97

Display 128 x 65 backlit LCD display; User programmable scroll list and menus

Enclosure Rating NEMA 4X/IP67

Energy AGA 5; GPA 2172; ISO 6976

Ethylene Density Calculation API 2565 (Ch 11.3.2.1); Ethylene NBS 1045

Input Power 10VDC to 30VDC

Keypad 4 IR sensors through glass key input (hazardous area isolation method).

Linear Meters (Turbine) AGA 7; AGA 9; AGA 11

Live Density Input

Sarasota liquid density meter, Solartron, UGC, 4-20mA & density

meters.

Operating Humidity 0-95% RH, (non-condensing)

Operating Temperature Range -40° to +185°F (-40° to +85°C)

Processor 32 Bit

Program Memory 4 MB of flash memory

Propylene Density Calculation API Ch 11.3.3.2

Super Compressibility

(Fpv) AGA 8 Gross-1992; AGA 8 Detail-1992; AGA 8 Short-1988; NX-19;

NX-19 Analysis; GERG (ISSN 0178-9414 -2004/8 - European Gas Research

Group)

Turbine Meter Linearization 10 Point Frequency/K-factor Table

Volume Correction Factors

Consistent with API 2540/ASTM D1250-80/IP 200; 5/6 A/B; 23/24 A/B;

53/54 A/B; 6/24/54 C; CH 11.1 2004; Note: natural gas liquids (NGL) and

liquefied petroleum gases (LPG): OLD 23/24, OLD 53/54; (Note: Table E

is new standard to replace the Older version 23/24)

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

7

2.4 Dimensional Drawings

Fig 2: 3800XP MTV Front View Fig 3: 3800XP MTV Side View

2.5 3800XP Models

3800XP Basic CID1

3800XP-B-15CS-1 3800XP, Basic, 1500PSIA CS HW, CSA, CID1

3800XP-B-45CS-1 3800XP, Basic, 4500PSIG CS HW, CSA, CID1

3800XP Advanced CID1

3800XP-A-15CS-1 3800XP, Adv, 1500PSIA CS HW, CSA, CID1

3800XP-A-45CS-1 3800XP, Adv, 4500PSIG CS HW, CSA, CID1

3800XP Basic CID2

3800XP-B-15CS-4 3800XP, Basic, 1500PSIA CS HW, CSA, CID2

3800XP-B-15SS-4 3800XP, Basic, 1500PSIA SS HW, CSA, CID2

3800XP-B-45CS-4 3800XP, Basic, 4500PSIG CS HW, CSA, CID2

3800XP-B-45SS-4 3800XP, Basic, 4500PSIG SS HW, CSA, CID2

3800XP Advanced CID2

3800XP-A-15CS-4 3800XP, Adv, 1500PSIA CS HW, CSA, CID2

3800XP-A-15SS-4 3800XP, Adv, 1500PSIA SS HW, CSA, CID2

3800XP-A-45CS-4 3800XP, Adv, 4500PSIG CS HW, CSA, CID2

3800XP-A-45SS-4 3800XP, Adv, 4500PSIG CS HW, CSA, CID2

41⁄2”

(114.5mm)

81⁄8”

(202.75mm)

71⁄4”

(183.5mm)

11”

(275mm)

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

8

3Installation

This section covers instructions on installation and commissioning. Installation of the device must

be carried out by trained; qualified specialists authorized to perform such works.

CAUTION

•When removing the instrument from hazardous processes, avoid direct contact with

the fluid and the MVT wetted parts unless wearing PPE suitable for the environment.

•All installations must comply with local installation requirements and local electrical

code.

WARNING

•This section offers instructions for installation,

wiring, operation, and

troubleshooting. The user must read this manual carefully before installation and

operation because improper installation may cause incorrect measurement and even

damage the Transmitter.

NOTE

•Improper installation has the potential to cause injury and to damage instrument.

•

Periodically inspect the power cables, transducer cables, cable glands and the

enclosure for signs of damage. Inspect transducer installation and mounting hardware

for loose connections.

3.1 General Instructions

•Installation should be according to ANSI/ISA RP 12.6 and the NEC ANSI/NFPA 70, or Canadian

Electrical Code Part 1.

•All wiring requires a minimum of 85°C insulation rating.

•Approved conduit seals should be installed within 18 ¼” (457mm) of the housing.

•Equipment must be installed by qualified personnel.

•Do not disconnect equipment unless power has been turned off or the area is known to be

non-hazardous.

•Service connections can be used when the atmosphere is known to be safe and non-

hazardous.

•Open enclosure when the location is known to be non-hazardous and remove power from the

meter to perform servicing.

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

9

3.2 Enclosure Cap Locking Screw

Fig 4: Enclosure Cap Locking Screw

•List of required tools for Enclosure Cap Locking Screw:

oFlat Head Screwdriver

o¼” Wrench or Socket

o3/8” Wrench

o3/64” Allen Wrench

o1.5mm Allen Wrench

oStrap Wrench

3.3 Pole Mounting

WARNING

•Ensure the power is off and the area is non-hazardous before performing this

procedure.

•Installation must be carried out in accordance with local site requirements and

regulations.

The Tek-Bar 3800XP Multivariable Transmitter can be directly mounted to the orifice fitting or a 2”

support pole. Please refer to the following instructions for mounting the enclosure onto a 2” pole

and pole mounting (as shown in Figure 1).

•Please align the holes of the single tab mounting bracket with the groove on the enclosure

when the enclosure is vertical.

•Facing the enclosure's front, use item 3 (Figure 1) to hold the enclosure against the bracket.

Place flat and lock washers over the threads on item 3 (Figure 1) when facing the

enclosure's rear and join with nuts.

•Install the two pipe clamps on the pole using the provided hardware.

•Loosen set screw as shown in figure 1 to adjust meter orientation, maximum 180° rotation

from starting point.

Locking Screw

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

10

3.4 Installation for Wet or Dry Gas Flow

Fig 5: Installation for Wet or Dry Gas Flow

4Electrical Connection

This section covers all electrical connection requirement. Electrical connection of the device must

be carried out by trained; qualified specialists authorized to perform such work by the installation

site.

WARNING

•Connect all electrical cables when the power is switched off. If the device does not

have switch-off elements, then, overcurrent protection devices, lightning protection

and/or energy isolating devices must be provided by the customer.

•The device must be grounded to a spot in accordance with regulations in order to

protect personnel against electric shocks.

NOTE

•Improper installation has the potential to cause injury and to damage instrument.

•Periodically inspect the power cables, transducer cables, cable glands and the

enclosure for signs of damage. Inspect transducer installation and mounting

hardware for loose connections.

Upstream/ Downstream lengths

as per: AGA / ISO or API

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

11

4.1 Jumper Locations

Fig 6: Terminal Board Jumper Locations

Table 1: Terminal Board Jumper Locations

AI 2

AGND

PI 2

GND

DO 1

GND

DO 2

GND

DI 1

GND

DI 2

GND

PI 1

GND

TXD+

TXD-

RXD+

RXD-

GND

HW5PC

J11

J13

J7

J10

J4

ETHERNET

J14

REMOTE

J5

AI 1

AGND

AO+

AO-

TX

RX

CEN*

GND

RX/RX+

CTS/RX-

DCD

GND

TX/TX-

RTS/TX

Return

RTD-

RTD+

Exc

1

1

1

1

J9

J3 Advanced Only J6

J12

CHIT

HOST

J15

1

HOST ON OFF

J14 RS485 RS232

J7 TX AC

J10 TX DC

J11 RX AC

J13

J12 1-2

J12 2-3 2-WIRE 4-WIRE

RX DC

SW

DUAL/HALF

J16 FORCE DCD

J8 SEAL

J9 SLOT CONTACT

CLOSUR E

+

-

J1

PWR

J8

J16

Host

ON

OFF

J14

RS485

RS232

J7

TX AC

J10

TX DC

J11

RX AC

J13

RX DC

J12 1-2

SW Dual/ Half

4 Wire

J12 2-3

2-Wire

J16

Force DCD

J8

Seal

J9

SLOT

Contact Closure

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

12

Fig 7: Low Power Transmitter and Local Analog Inputs (4-20mA)

Figure 7 shows typical connections between the low-power transmitter and local analog inputs.

Tek-Trol offers an optional 250, high precision, axial lead resistor, P/N 5-1270-250, for

converting the 4-20mA current signal to the 1-5V voltage signal, connecting to instrument analog

inputs.

Table 2: Typical Switch Configurations

Board

Designator

Description

ON

OFF

Default

HMI

JP2

Bluetooth Development

Development

Auto-Run

OFF

HMI JP3

Over the Air Bluetooth

Update

OTA Mode Disable ON

CPU

JP1

Bootloader Protect

Protect

Write

ON

CPU

JP2

Bluetooth Disable

Disable

Enable

OFF

CPU SW1

Battery Disconnect

Switch

Battery Backup

Storage/Cold

Start

OFF

Terminal

J7

Host TX AC Termination

Terminated

Unterminated

OFF

Terminal

J8

Sealing Jumper

Sealed

Open

OFF

Terminal

J9

Pulse Mode

Slot

Contact

OFF

Terminal

J10

Host TX DC Termination

Terminated

Unterminated

OFF

Terminal

J11

Host RX AC Termination

Terminated

Unterminated

OFF

Terminal

J12 1-2

Host Duplex Setting

Software Control

4-Wire

OFF

Terminal

J12 2-3

2- Wire

ON

Terminal

J13

Host RX DC Termination

Terminated

Unterminated

OFF

Terminal

J14

Host Mode

RS485

RS232

OFF

Terminal

J16

Force DCD

Forced On

From User

OFF

I/O JP3

HART Processor

Configuration

Not Used

Normal

Operation

OFF

Signal

250 Ohm Resistor

V-

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

13

4.2 Bootloader Protect and Bluetooth Disable Jumpers

Fig 8: Bootloader Protect and Bluetooth Disable

4.3 Battery Backup Memory Jumper (Disable Battery for Storage)

Fig 9: Battery Backup Memory Jumper (ON position)

Fig 10: Battery Backup (ON and OFF position)

Bluetooth

Disable

Bootloader

Protect

Battery Backup

Memory

(On position shown)

OFF

(Cold Start and Shipping/Storage)

ON

(Battery Backup)

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

14

Fig 11: Backup Battery

4.4 Bluetooth (BT) OTA Update and BT Development Jumpers

Fig 12: BT OTA Update and BT Development Jumpers

Table 3: HMI Board Table 4: CPU Board Table 5: I/O Board

4.5 Main Board Switch Location (SW1)

Fig 13: Main Board Switch Location (SW1)

J7

OFF

J8

OFF

J9

OFF

J10

OFF

J11

OFF

J12

ON Position 2-3

J13

OFF

J14

OFF

J16

OFF

JP2

OFF

JP3

ON

JP1

ON

JP2

OFF

JP3

OFF

Table 6: Terminal Board

Lithium battery CR 2032W,

3V 210mAh

BT Development

(default off)

SW1

BT OTA Update

(default on)

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

15

Table 7: Main Board Switch SW1 Default Conditions

SW1

Description

Function

Default

1 Boot loader selection

CPU runs the boot loader upon

power-up when the switch is on

OFF

2 Debugger selection

CPU runs the debugger upon

power-up when the switch is on.

Function not available

OFF

3 Continuous power on

System stays in wake-up mode

when the switch is on

OFF

4 System reset

Momentarily switch on to reset the

system

OFF

4.6 Grounding

Fig 14: Grounding Connection

•Use copper stranded 12 AWG minimum wire for grounding, as shown in figure 14.

•Connect a grounding wire from enclosure ground lug to earth ground.

•The grounding wire length should be as short as possible.

•Ensure the earth and power ground are connected together, either internally or externally.

4.7 Wire Gauges

Table 8 provides the recommended wire gauges to be used for the Tek-Bar 3800XP

Multivariable Transmitter installation:

Table 8: Connection Data

Conductor cross section solid minimum

0.2mm2

Conductor cross section solid maximum

1.5mm2

Conductor cross section flexible minimum

0.2mm2

Conductor cross section flexible maximum

1.5mm2

Conductor cross section flexible with

ferrule, without plastic sleeve minimum

0.2mm2

Conductor cross section flexible with

ferrule, without plastic sleeve maximum

1.5mm2

External Earth

(Ground)

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

16

Conductor cross section flexible with

ferrule, with plastic sleeve minimum

0.2mm2

Conductor cross section flexible with

ferrule, with plastic sleeve maximum

0.75mm2

Conductor cross section AWG minimum

24/0.2mm2

Conductor cross section AWG maximum

16/1.3mm2

4.8 Wiring Instructions

Table 9 provides the wiring instructions used for the Tek-Bar 3800XP Multivariable Transmitter

installation:

Table 9: Wiring Instruction

Function

Pin Number

Details

Input Power J1-1 (+)

J1-2 (-)

10 to 30VDC @ 2Watt minimum; Customer supply must include 2A

slow blow fuse.

Serial Host

port J3

Configurable: J3-pin 7-12 (RS232); J3-pin 7-10, 11-12 (RS485 4-wire);

J3-pin 7-10, 11-12 (RS485 2-wire; Jumped TX+/RX+, TX-/RX-)

recommended 26 AWG; Twisted pair for RS485

Local serial

port or CHIT J3

J3-pin 3-6

Ethernet J4

CAT 5 shield cable

RTD J15

J15-pin 1-4; 4-wire J15-pin 1-3; 3-wire; with pin 3 and 4 jumped

AO (Analog

output) J3-1 and 2

4-20mA; loop power customer supply; minimum 10VDC, maximum

30VDC

+

J1

PWR

AO+

AO-

TX

RX

CEN*

GND

RX/RX+

CTS/RX-

DCD

GND

TX/TX-

RTS/TX

1

J3

CHIT

HOST

AO+

AO-

TX

RX

CEN*

GND

1

J3

J4

ETHERNET

Return

RTD-

RTD+

Exc

J15

1

AO+

AO-

1

J3

AO+

+-

AO-

J3

Analog Out put

420mA

Customer Device

Loop Power

RD

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

17

DO (Digital

Out) J6-4-6

DO1-pin 5-6; open drain; customer supply power

DO2-pin 7-8; open drain; customer supply power

AI (analog

input) J5; J6

AI1, J5-pin 1-4 (power/signal+; signal-/ground)

AI2, J6-pin 1-2 (signal+; ground)

PI (pulse

input) J5; J6

PI1, J5-pin 5-6 (slot sensor 5KHz; contact closure 300Hz)

PI2, J6-pin 3-4

J5

AI 1

AGND

1

AI 2

AGND

1

J6

AI

J5/J6

AGND

Analog Inp ut

Low Power

Transmitter

Customer

Power

+

-+

-

S

Trans mi tte r Si gn al

Trans mi tter G rou nd

Trans mi tte r Sh ie ld

PI 2

GND

DO

P11/

P12

GND

J5/J6

Pulse Input

Customer

Eq uip ment

Inp ut Signal

Inp ut Signal ± 15V Max

Signal Retur n

Signal Retur n

Cont ac t

Closur e

P11/

P12

GND

Cont ac t

Closur e

Customer

Device

Inp ut Signal

Disc r et e O utp ut

Custom er

Power

Custom er

Devic e

Custom er

Eq uip ment

Custom er

Power

Out p ut Signal

Out p ut Retur n

Pull up r esistor

(10K Typ ic al)

+

_

Out p ut Retur n

J6

D01/

D02*

GND

+

-

D01/

D02*

GND

DO 1

GND

DO 2

GND

Instruction Manual

Tek-Bar 3800XP

www.tek-trol.com

Technology Solution s

18

4.9 Communication

4.9.1 Local Serial Communication Port

The terminal board provides one RS232 compatible local communication port (CHIT) for

calibration and configuration of the unit using a laptop and configuration software.

Table 10: Cable assemblies for CHIT connector

Assembly P/N

Description

3-0446-090

DB9S connecter with 15-ft cable for use with the six-position connecter

3-0446-090B

DB9S connecter with 25-ft cable for use with the six-position connecter

4.9.2 Bluetooth LE

Bluetooth Low Energy connection is available. A Bluetooth Low Energy Dongle is required to

operate this function (Contact Tek-Trol for this device).

4.9.3 RS232 Mode

•If not used internally, the communication port can interface to any RS232 compatible

customer device, such as a radio.

•Do not exceed +15VDC on any of the communication lines.

•Host communication port RS232 connections are identified in the following Table 11.

Table 11: Host communication port RS232 connections

Signal

J3 on Terminal Board

RX (Receive)

J3-7

CTS (Clear to Send)

J3-8

TX (Transmit)

J3-11

RTS (Request to Send)

J3-12

DCD (Data Carrier Detect)

J3-9

GND (Ground)

J3-10

*Note:

For RS232 mode, do not install jumper J14.

For RS232 mode without DCD signal, install jumper J16.

4.9.4 RS485 Mode

•The host communication port supports RS485 communication.

•To use RS485 mode, jumpers J14 and J16 must be installed.

•Select RS485 2-wire mode by installing a jumper on J12 pins 2-3.

•Remove the jumper for 4-wire mode.

4.9.5 Ethernet Port

Jumper J4 on the main board is a 10M/100M Ethernet port supports standard TCP/IP protocol.

Table of contents

Other Tek-Trol Transmitter manuals

Tek-Trol

Tek-Trol TEK-WAVE 4300B User manual

Tek-Trol

Tek-Trol TEK-WAVE 4300B User manual

Tek-Trol

Tek-Trol Tek-Flex 4100A User manual

Tek-Trol

Tek-Trol TEK-BAR 3800E User manual

Tek-Trol

Tek-Trol TEK-BAR 3120B Series User manual

Tek-Trol

Tek-Trol TEK-WAVE 4300C User manual

Tek-Trol

Tek-Trol Tek-Sound 4200B User manual

Tek-Trol

Tek-Trol TEK-FLEX 4100A User manual

Tek-Trol

Tek-Trol TEK-B AR 3120B User manual

Tek-Trol

Tek-Trol TEK-BAR 3120C User manual