2

1. General

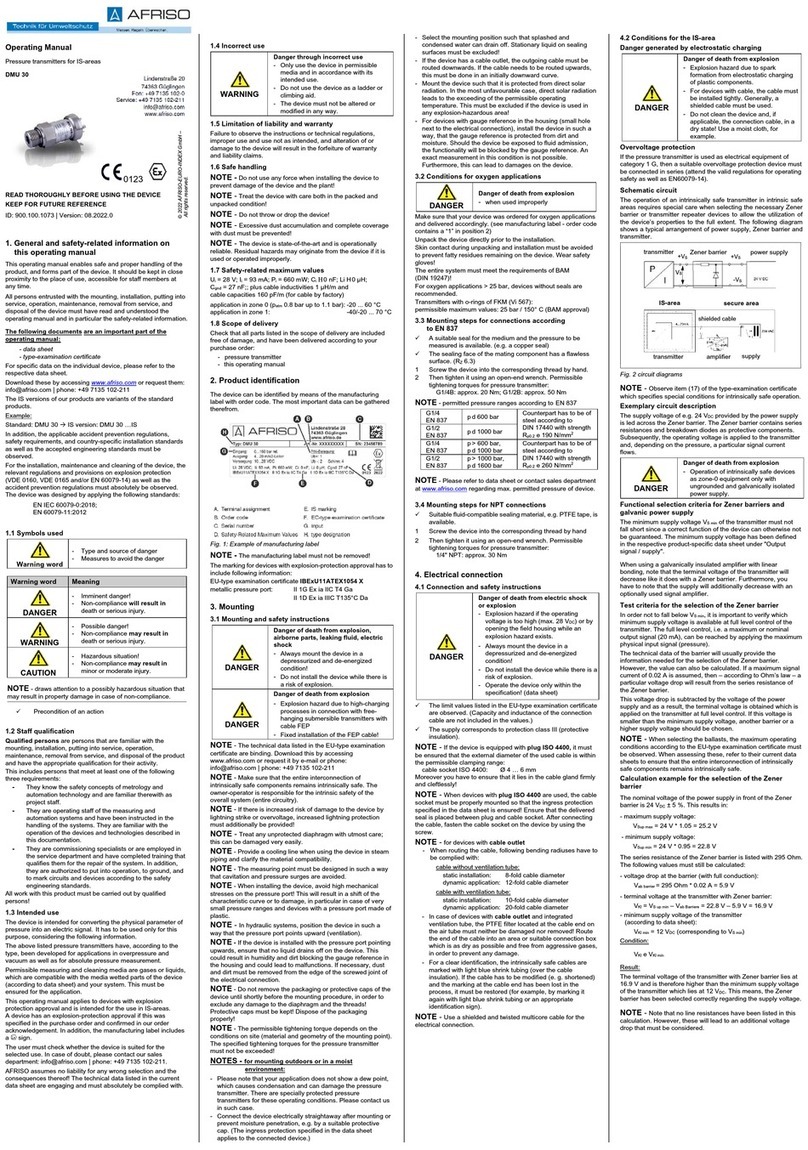

1.1 Information on the intended use

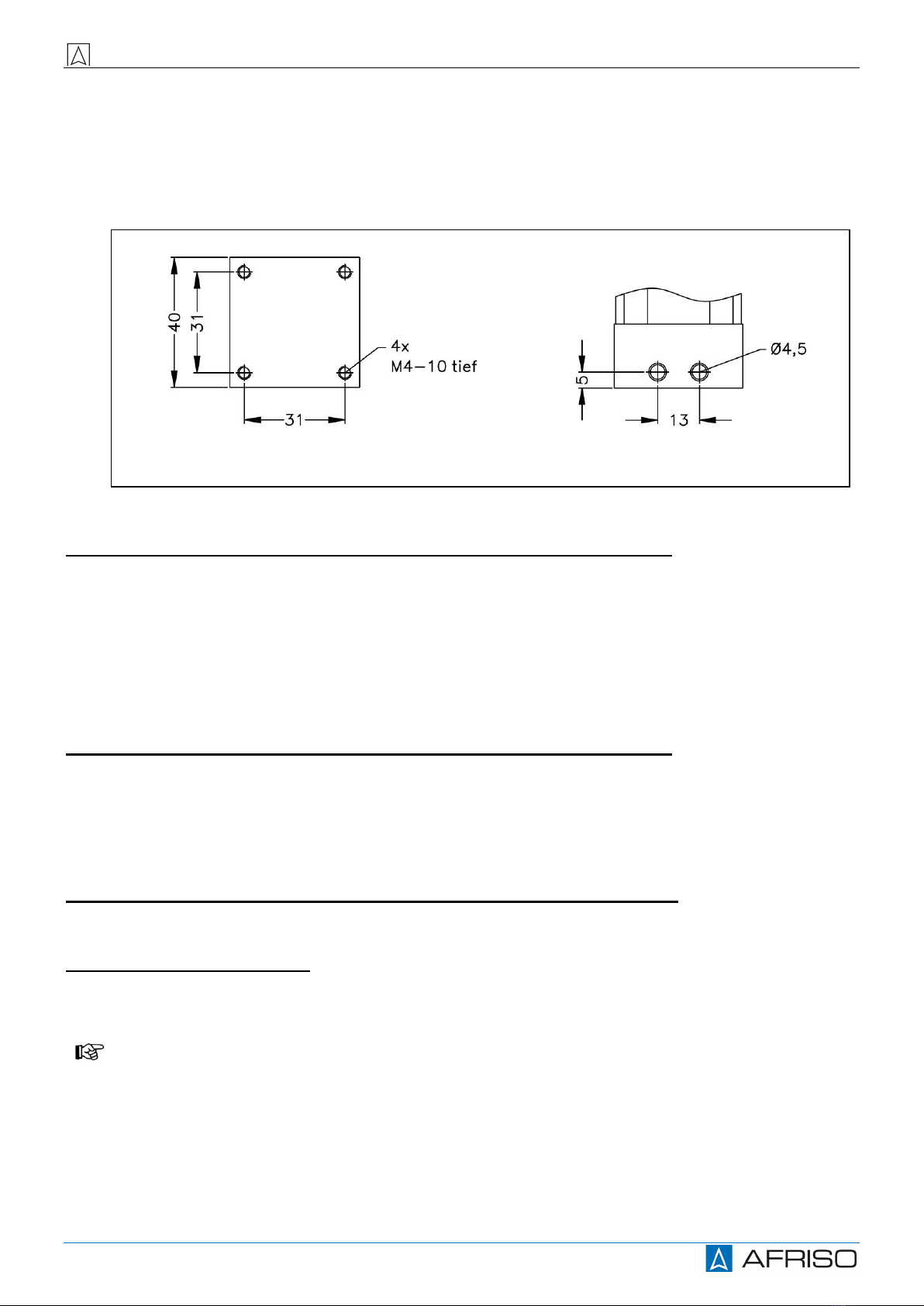

•The differential pressure transmitters DMU 10 D and DMU 11 D are intended for

industrial applications. The compact design allows a simple integration even in

constructions and machines with restricted space conditions.

•Base elements of DMU 10 D are 2 piezoresistive stainless steel sensors. DMU 11 D is

based on a piezoresistive silicon pressure sensor.

•For both sided pressure admission, the difference of the pressure between positive and

negative side is established and converted into a proportional electrical signal.

•DMU 10 D comes into operation e. g. in engineering and plant construction for filter

controlling and flow measurement as well as in hydraulic applications. As media, fluids

and gases are suitable, which are compatible with the sealing material as well as with

stainless steel 1.4571 and 1.4435.

•DMU 11 D is intended for the application in the filter controlling and air conditioning

technology. As media, non-aggressive gases and pressured air are suitable.

•The application of both differential pressure transmitters DMU 10 D and DMU 11 D is

summarized in this operating instruction, but the devices differ in the technical data

which can be taken out of the current data sheet.

•Use the device according to the area of application specified above! Furthermore,

compatibility with the medium to be measured has to be assumed.

•No liability is assumed and warranty claims are excluded in case of improper applica-

tion, modification of or damage to the device.

1.2 Target group

This operating instructions are intended for qualified technical personnel.

1.3 Symbols used

:: Caution! : Note

1.4 Safety notes

Observe the following notes:

The device may only be installed, used and serviced by persons who are familiar

with this operating manual!

Observe the applicable laws regarding occupational safety, accident prevention and

national installation standards!

The device must only be used within the specifications! (Compare the technical data

in the current data sheet)

Install the device in the depressurized and mechanical tension condition!