8

The installer must ensure that this control and its wiring are isolated and/or shielded from strong sources of electromagnetic noise.

Conversely, this Class B digital apparatus complies with Part 15 of the FCC Rules and meets all requirements of the Canadian

Interference-CausingEquipmentRegulations.However, if this control does cause harmful interference to radioortelevisionreception,

which can be determined by turning the control off and on, the user is encouraged to try to correct the interference by reorienting or

relocating the receiving antenna, relocating the receiver with respect to this control, and/or connecting the control to a different circuit

from that to which the receiver is connected.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

All specifications are subject to change without notice.

Printed in Canada on recycled paper.

Product design, software and literature are Copyright © 1997 by:

tekmar Control Systems Ltd. and tekmar Control Systems, Inc.

Control Systems

tekmar Control Systems Ltd., Canada

tekmar Control Systems, Inc., U.S.A.

Head Office: 4611 - 23rd Street

Vernon, B.C. Canada V1T 4K7

Tel. (250) 545-7749 Fax. (250) 545-0650

Limited Warranty

The liability of tekmar Control Systems Ltd. and tekmar

ControlSystems, Inc.("tekmar")underthiswarranty islimited.Pleasereadand

understand the conditions appearing herein.

tekmarwarrants each tekmar product againstdefects inworkmanship and materials,

when the product is installed and used in compliance with tekmar's instructions. The

warranty period is for a period of twenty-four (24) months from the production date if

the product is not installed during that period, or twelve (12) months from the

documented date of installation if installed within twenty-four (24) months from the

production date, but in any event the warranty period shall not extend beyond thirty-

six (36) months from the production date. During the warranty period, tekmar will, at

its discretion, either repair at no charge, exchange or give credit for the defective

product, provided the product is returned to tekmar.

Theliabilityoftekmarshallbelimitedtothecostofpartsand labourprovidedbytekmar

tocorrectdefectsinmaterialsand/orworkmanshiportotheexchangeofthedefective

productforareplacementproductortothegrantingofcreditlimitedtotheoriginalcost

of the product, at tekmar's discretion, and such repair, exchange or credit shall be

deemed to be the sole remedy available from tekmar. This warranty does not cover

the cost of the parts or labour to remove or to transport the defective product, or to

reinstalltherepairedorreplacementproduct.Returnedproductsthatarenotdefective

are not covered by this warranty.

This warranty does not apply if the product has been damaged by accident, abuse,

misuse, negligence, fire, Act of God, or has been damaged by modifications,

alterations or attachments made subsequent to purchase which have not been

authorized by tekmar, or if the product was not installed in compliance with the

local codes and ordinances, or if due to defective installation of the product.

The warranty applicable to a product is as set out in the statement of warranty

policy (the "Warranty") above, receipt of which is hereby acknowledged. The

liability of tekmar is limited to those obligations identified in the warranty as

obligations of tekmar. The warranty is understood to be in substitution for any

loss, costs or damages for which tekmar might otherwise be liable at law or in

equity and in particular, in lieu of any liability for fundamental breach of

contract.

tekmar disclaims any responsibility for losses, expenses, inconveniences, or

any special, indirect, secondary, incidental or consequential damages arising

from ownership or use of any items subject to any claim hereunder, regardless

of whether such claim is stated in contract, tort or strict product liability.

This warranty is in lieu of all other warranties, express or implied, including,

withoutlimitation,warrantiesofmerchantability,fitness foraparticularpurpose,

durability or description of the product, its non-infringement of any relevant

patentsortrademarks,anditscompliancewithornon-violationofanyapplicable

environmental, health or safety legislation. No implied warranties shall extend

beyond twenty-four (24) months from the production date.

Some states or provinces do not allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to you. This warranty gives you specific

legal rights, and you may also have other rights which vary from state to state or

province to province.

ProductReturnProceduresProductsthatarebelievedtohavedefectsinworkmanship

or materials must be returned, together with a written description of the defect, to the

tekmar representative for that territory. If the address of the representative is not

known, please request it from tekmar at the telephone number listed below.

Limited Warranty and Product Return Procedure

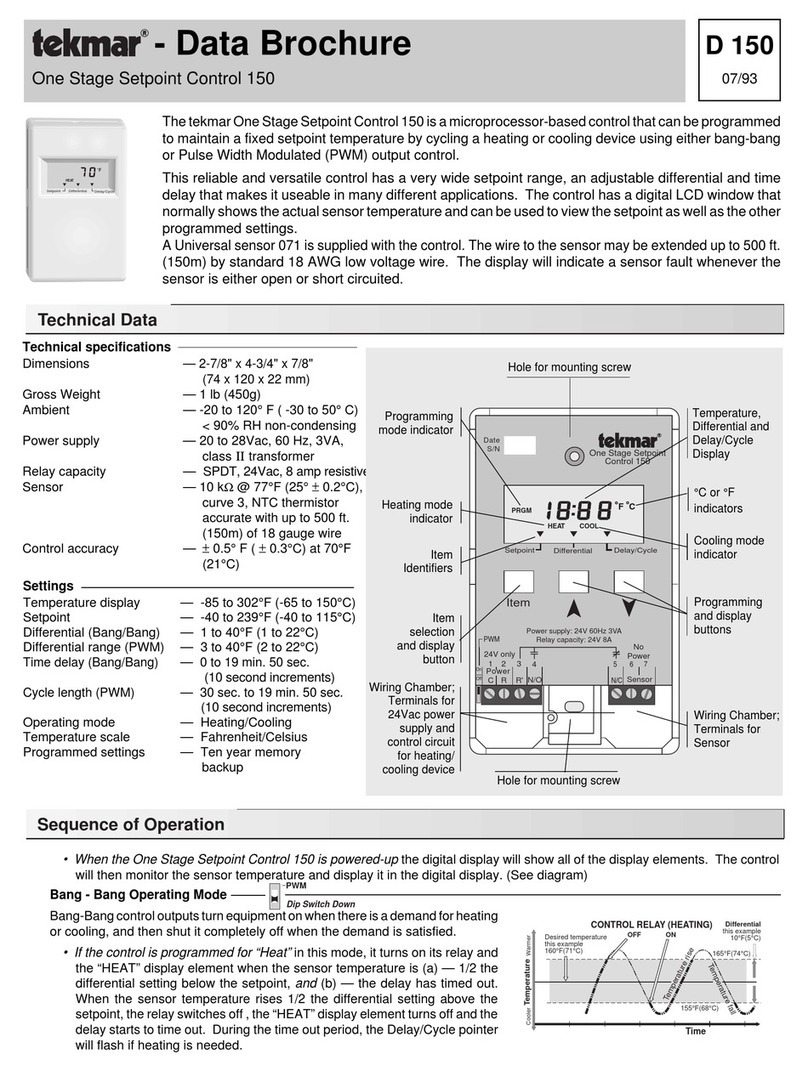

Technical Data

One Stage Boiler Control 253

Literature — A 000, A 253's, D 253, D 001, D 070

Control — Microprocessor PI control; This is not a safety (limit) control.

Packaged weight — 1.1 lb. (500 g), Enclosure C, PVC plastic

Dimensions — 4-3/4” H x 2-7/8” W x 7/8” D (120 x 74 x 22 mm)

Approvals — CSA NRTL /C; Meets ICES & FCC regulations for EMI/RFI.

Ambient conditions — Indoor use only, 15 to 120°F (-10 to 50°C), < 90% RH non-

condensing.

Power supply —

Class 2, 24 V ±10% 50/60 Hz 3 VA

Relays — 120 V (ac) 5 A 1/6 hp, pilot duty 240 VA 2 A

Sensors — NTC thermistor, 10 kW @ 77°F (25°C ±0.2°C) ß=3892

included: Outdoor Sensor 070 and Universal Sensor 071.

Starting Temp. —

35 to 150°F (2 to 66°C)

WWSD

— 35 to 85°F (2 to 29°C)

Curve

— 0.2 to 3.6

Differential

— Auto, 2 to 42°F (Auto, 1 to 24°C)

Minimum Boiler

— Off, 70 to 170°F (Off, 21 to 77°C)

Item

4

Boiler

56

T

1

H11461

PRGM

FC

WWSD

24 V 50/60 Hz 3 VA

120 V (ac) 5 A1/6 hp

pilot duty 240 VA

Power:

Boiler Relay:

Mar 97

31000265

- displays control settings

- displays hundreds of hours of use

- displays hours of use

Press & Hold:

Item

One Stage Boiler

Control 253

23

Com

Sen

Boil

Sen

Out

Sen

No power

78

Power

R+ C-

NRTL /C

LR 58223

R

USE

(hours)

Minimum Boiler

Differential

Curve

Boiler Supply

Target Boiler

Starting Temp.

H. Dem

Boiler

OUTDOOR

Signal wiring must be

rated at least 300V

Made in Canada