TEKNA TCK User manual

EM00136064 rev. 2.1 1

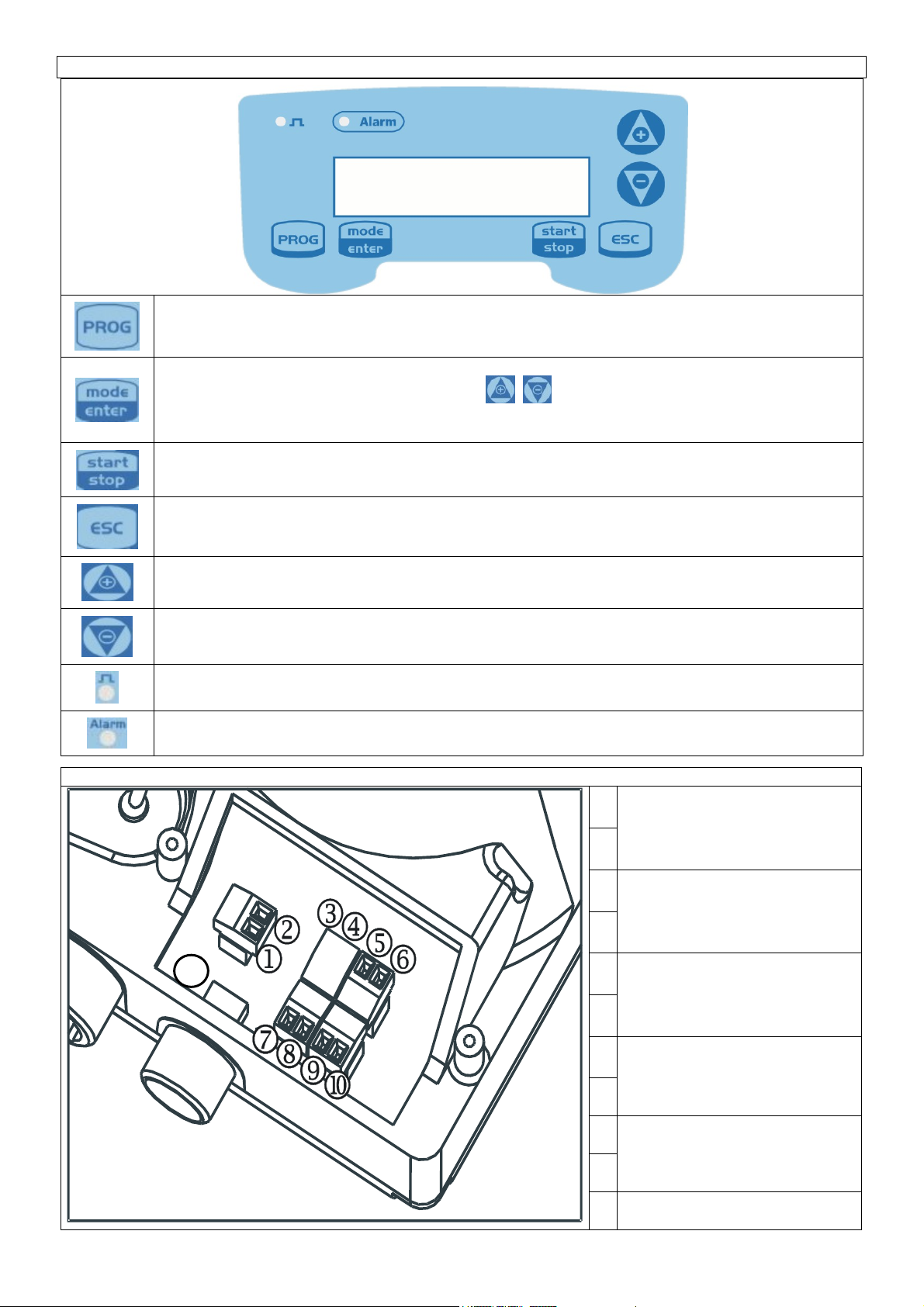

Control Panel – TEKNA TCK

Access to the programming menu

When pressed during the pump operation phase, it cyclically displays the programmed values on the

display; When pressed at the same time as the keys, it increases or lowers a value

dependent on the selected operating mode. During programming it carries out an “enter” function,

meaning that it confirms entry to the various menu levels and modifications within the same.

Starts and stops the pump. In the event of a level alarm (alarm function only), flow alarm and active

memory alarm, it deactivates the signal on the display.

Used to “exit” the various menu levels. Before definitively exiting the programming phase, you will be

asked if you wish to save any changes.

Used to run upwards through the menu or increase the numerical values to be changed. Can be used

to start dosage in Batch mode

Used to run downwards through the menu, or decrease the numerical values to be changed.

Flashing green LED during dosage

Red LED that lights up in various alarm situations

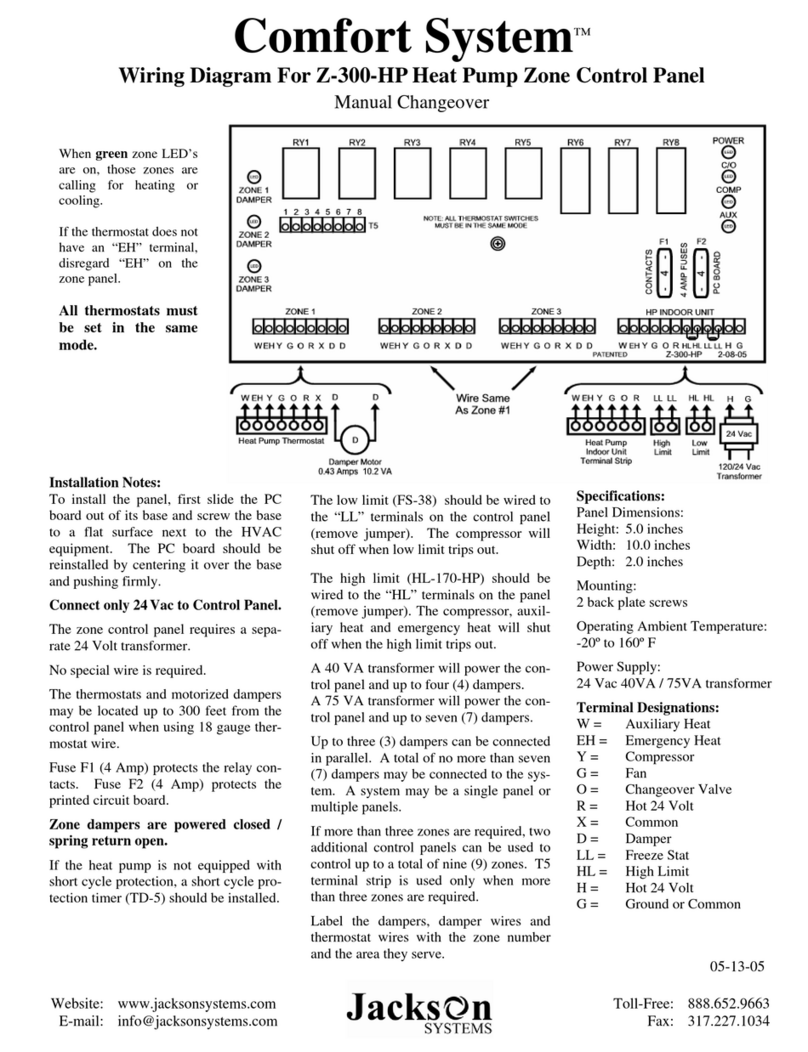

Electrical connections

1

2 Output relay

3

4 Not connected

5

6

-Remote control input (start-stop)

-Pause signal input

7

8 Trigger signal input

9

10 Flow sensor input

B Input level control

B

EM00136064 rev. 2.1 2

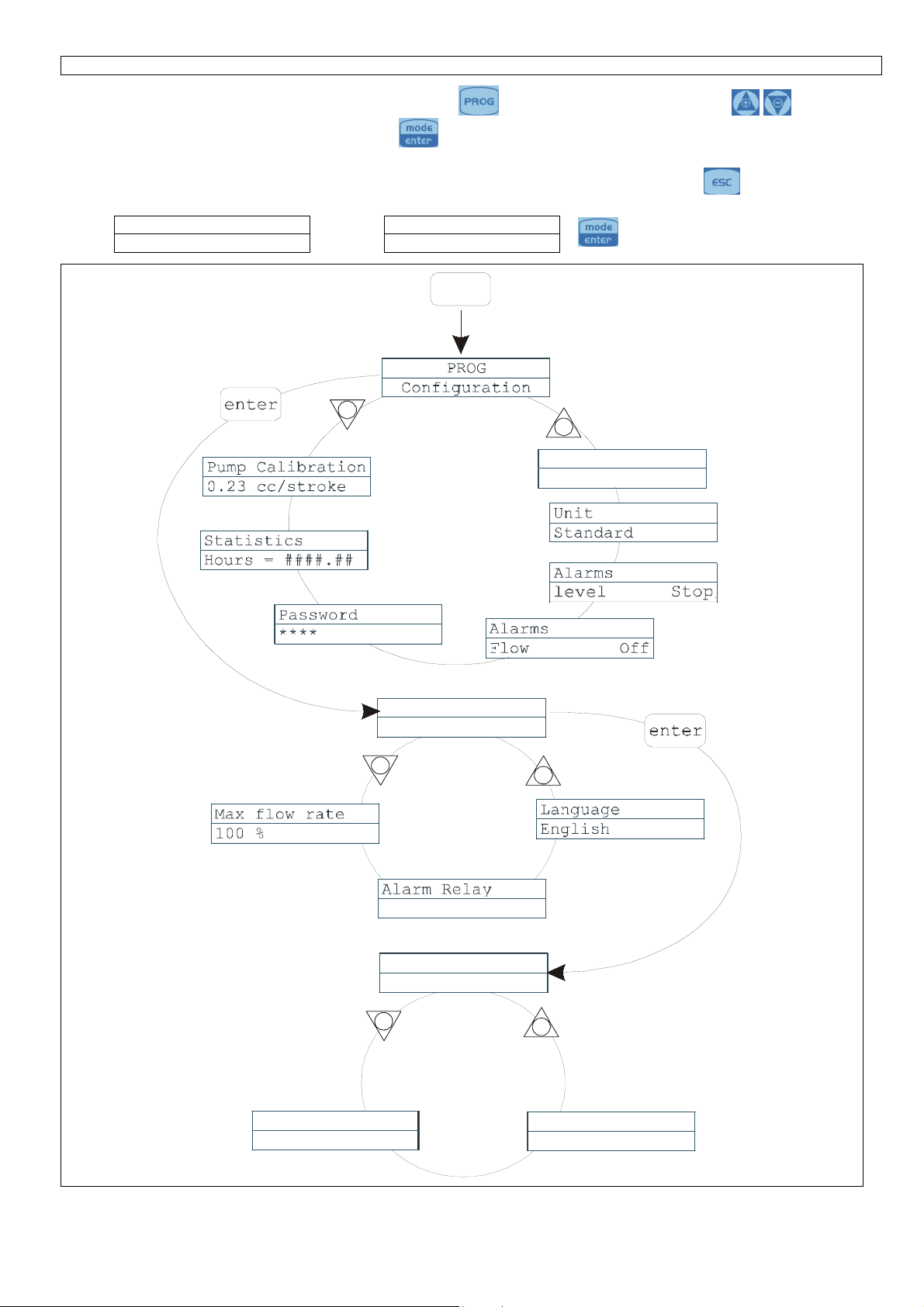

Programmiermenü Tekna TCK

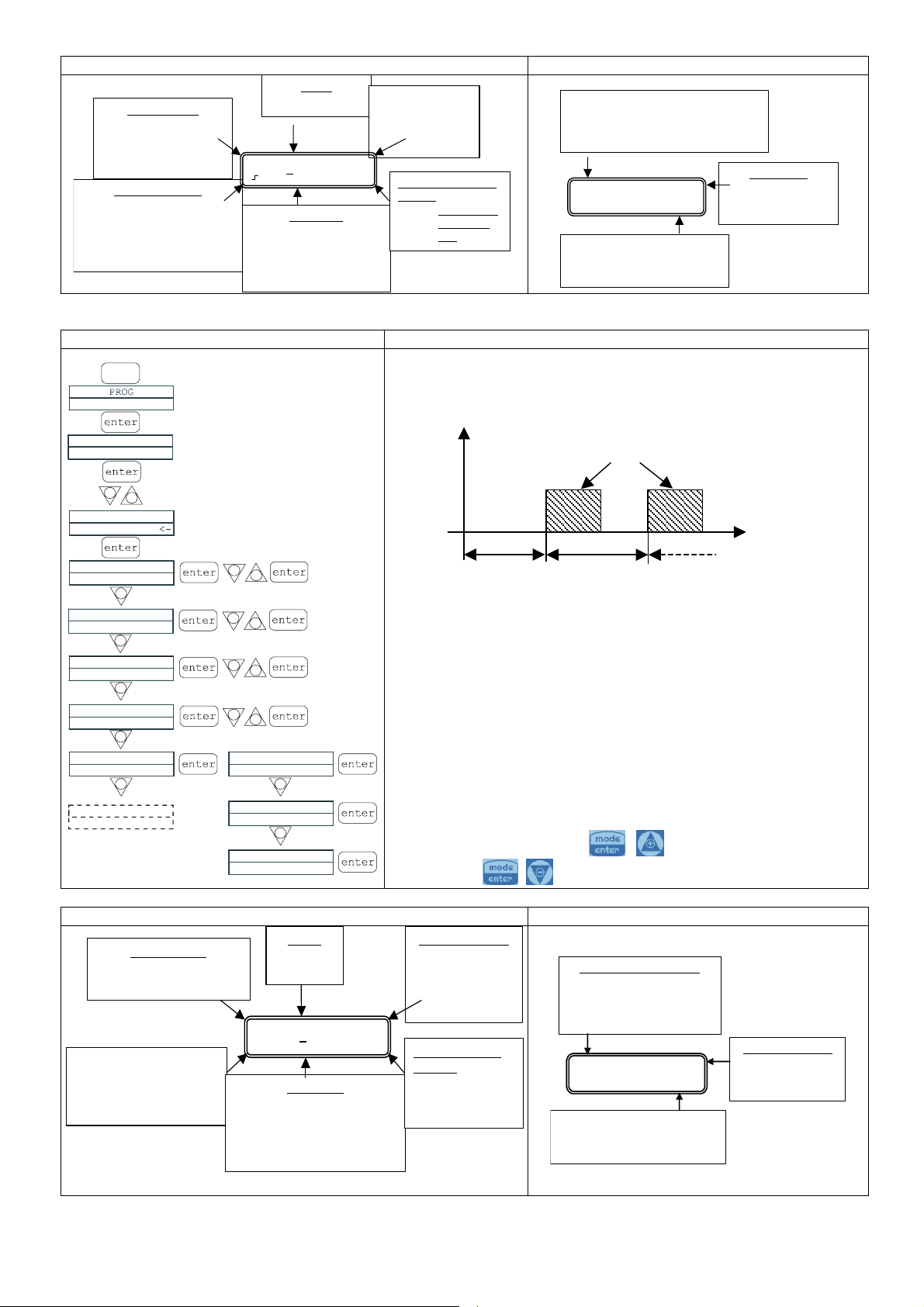

You can access the programming menu by pressing the key for over three seconds. The keys can

be used to run through the menu items, with the key being used to access changes.

The pump is programmed in constant mode in the factory. The pump automatically returns to the operating mode

after 1 minute of no activity. Any data entered in these circumstances will not be saved. The key can be used

to exit the various programming levels. Upon exiting programming, the display will show:

Exit Exit

No Save ∇∆Save to confirm the selection

+

-

+

-

Pump Funtions

Configuration

+

-

Pump

Functions

Pump

Functions

Timer

PROG

Pump

Functions

Weekly Timer

Manual <-

N.Open

Paragraph 1

Paragraph 4

Paragraph 5

Paragraph 6

Paragraph 7

Paragraph 8 Paragraph 9

Paragraph 10

Para

g

raph 11

Paragraph 2 Paragraph 3

Main

Menu

Setting

Menu

Functions

Menu

Paragraph 12

N.Open

Paus

EM00136064 rev. 2.1 3

Setting the Language

Programming Operation

-

-

-

--

Pump Functions

Max flow rate

Alarm Relay

Language

P100%

N.Open

English

PROG

+

-

Makes it possible to select the language. The pump is set in

English in the factory.

Changes can be made by pressing the key, then using

the keys to set the new value. Press to

confirm and return to the main menu

Paragraph 1 – Manual Dosage

Programming Operation

+

-

Pump Funtions

Configuration

Pump

Functions

PROG

The pump operates in constant mode and the flow can only be regulated

manually by pressing the keys at the same time in order to

increase the flow, or the keys to decrease it.

Display during Operation Display during Setting (MODE key)

MAN FFF

Lev Stop P100%

Operating mode

• Man = Manual

Alarms and statuses

• Lev = Level alarm

• Flw = Flow alarms

FLOW sensor

status

Pump status

• Empty = pump in start

• Stop = pump stationary

• Paus =

p

um

p

in

p

ause

Current dosage speed

(depends on selected unit of

measurement)

• Percentage, Frequency,

l/h, Gph, ml/m MAN

P100%

Operating mode

• Man (during manual modification of the

flow it displays the corresponding

frequency value)

Current dosage value

• Modify the maximum flow by pressing the

+ or – keys at the same time

EM00136064 rev. 2.1 4

Paragraph 2 – Timed Weekly Dosage

Clock

Wed 08:00

PROG01 MTWTFSS

00.00 _______

+

-

Pump Funtions

Configuration

Pump

Functions

Weekly Timer

Weekly Timer

PROG

-

+

-

PROG01 MTWTFSS

PROG01 hh.mm

PROG01

PROG01

PROG01 PROG01

Weekly _______

Time 00.00

Q.ty 0ml

Dos.Time 0 s

Rel.Off Rel.Off

-

-

-

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

ESC

-

1)

6)

2)

3)

4)

5)

It is possible to programme 10 dosages for the whole week. Press in the “weekly timer” mode in order to

programme the dosages.

1) The programme number can be modified using the keys and confirmed by pressing the key.

2) The dosage time can be modified using the keys and confirmed by pressing the key.

3) The dosage quantity can be set in “ml” using the keys and confirmed by pressing the key

4) The dosage time, that is to say the time (in seconds) during which you wish to dose the set quantity, can be set

in “cc” using the keys and confirmed by pressing the key

5) The values of the relay connected to dosage can be modified using the keys and confirmed by

pressing the key; in “Off” mode, the relay is not switched off (open), and in “after” mode the relay closes when

dosage is activated and remains closed once dosage is completed for the time (in seconds) set using the

keys and then confirmed by pressing the key. In “before” mode, the relay closes before the dosage activation

time, for the time (in seconds) set using the keys and then confirmed by pressing the key.

6) Day activation, or rather the days on which you want the set programme to be active (start time, quantity,

dosage duration and relay operating mode). Press the key to make changes, then press the key to

activate/deactivate dosage and the key to change the day of the week. Press to confirm and move

automatically to the next programme.

Repeat the whole procedure if you need to programme the new programme, or press to return to the main

menu.

The next step in the main menu is programming the clock. This can be done by pressing the to make

changes, using the to set the required values and then confirming by pressing the key. You can set

the day, hour and minutes in sequence. Obviously, the set time and day are those that the programming will refer

to.

EM00136064 rev. 2.1 5

Display during Operation Display during Setting (MODE key)

Weekly F

F

FMon

Lev Stop 12.01

Operating mode

•Weekly timer

Alarms and statuses

•Lev = Level alarm

•Flw = Flow alarm

•Mem = Memory alarm

FLOW

sensor

status •Day of the week

Displays the quantity during

dosages

Pump status

•Empty = pump in start

•Stop = pump stationary

•Paus = pump in pause

Time

•Displays hours

and minutes

P01:START Mon

14.40 12.01

Operating mode

• Displays in sequence:

programme number, activation

time, quantity, dosage time,

relay status.

• Day of the

wee

k

Time

• Displays hours and minutes

Paragraph 3 – Timed Dosage (Frequency signal input “TRIGGER” activated)

Programming Operation

+

-

-

-

-

+

-

+

-

+

-

Time

Quantity 100ml

Delay 0.01.50

interv. 0.01.50

PROG

Time

Time g.hh.mm

Time g.hh.mm

Configuration

Pump functions

Configuration

Pump functions

-

-

Trigger Mode

Pause Input Mode

-

Trigger Mode

-

Trigger Mode

Trigger Mode

N. Open N. Open

N. Closed

Disable

Trigger Mode

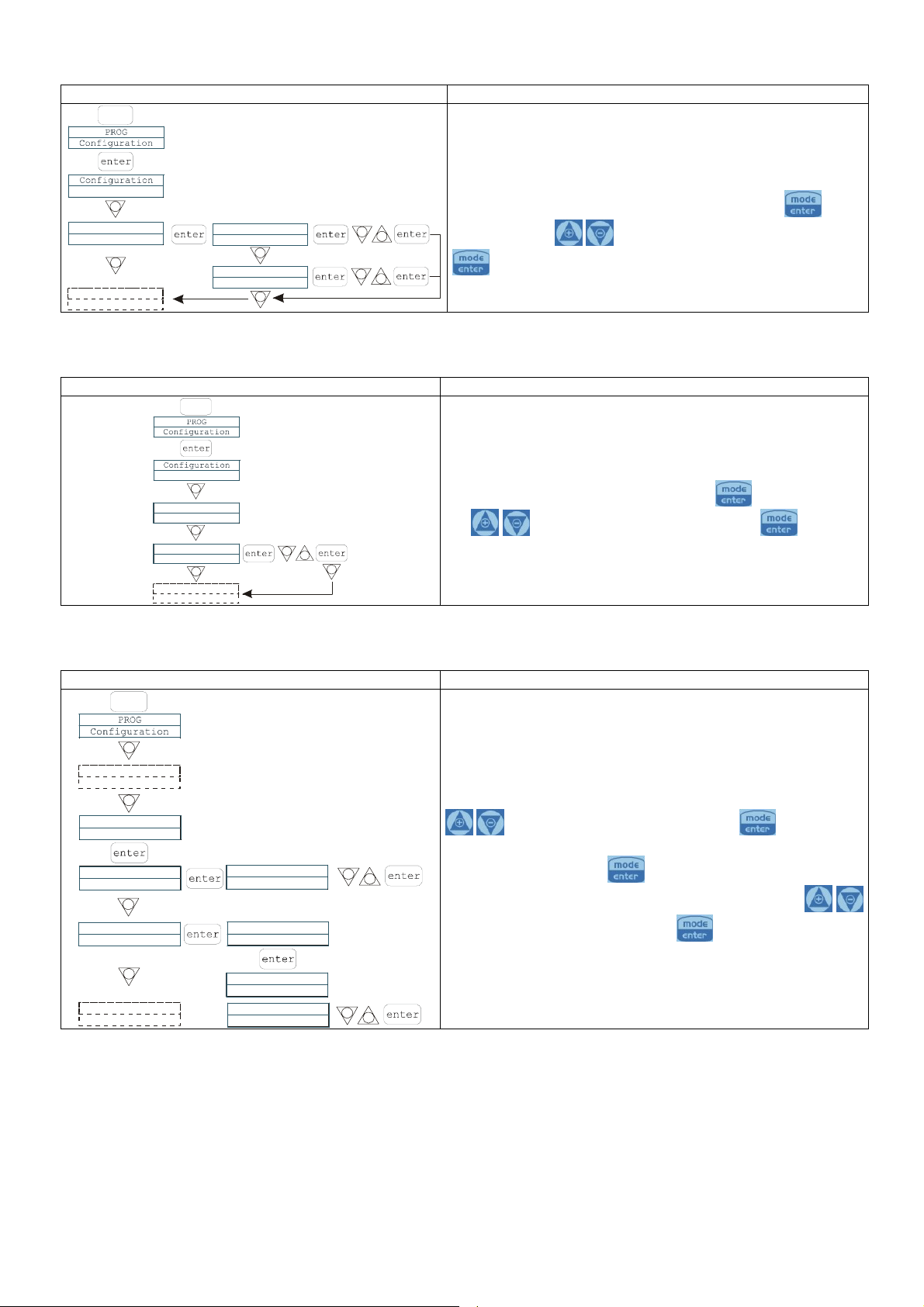

After receipt of the TRIGGER signal set, the pump doses a quantity

that can be programmed in ml. It is possible to set a delay time before

the dosing (Delay) and the interval between subsequent dosings

(Interv.) as illustrated in the diagram:

By setting for example an Interval.time = 0, a system is obtained in

which the programmed quantity is dosed after each TRIGGER signal

(with any delay that has been set):

It is possible to start the dosing by pressing the + key, which, in

practice, simulates the Trigger signal.

The Trigger signal can be set to N. Open (it is activated when the

input passes from the open to the closed mode) or to N. Closed (it is

activated when the input passes from the closed to the open mode).

The Trigger signal is locked during dosing (its receipt is neither stored

nor managed).

The Pause (Remote input) input cannot be programmed and its

activation stops the dosing, while its further deactivation makes the

system wait again for the Trigger signal for a new dosing.

The dosage frequency can be modified while the pump is operating,

by pressing the keys at the same time to increase the

frequency, or the keys to decrease it.

Delay Inter

v

.

Quantity

Trigger

Delay

Trigger

Ritardo

Release

EM00136064 rev. 2.1 6

Display during Operation Display during Setting (MODE key)

Timer FFF 7,0 ml

Stop P 0%

Operating mode

• Timer

Alarms and statuses

• Liv = level alarm

• Flow = flow alarm or

….Release wait

FLOW

sensor status Programmed value

• Quantity in ml

Pump status

• Dry = pump starting up

• Stop = pump stop

• Restart = pump restart

Value of the dosing in

p

rogress

• Percentage of

strokes/min

max

Q.tà 20,0ml

20,0ml P 100%

Operating mode

• The following are shown in sequence:

quantity to dose, delay in d.hh.mm.

and interval in d.hh.m

m

Dosing value

• Programmed

quantity in ml

Value of the dosing percentage,

which can be modified by

p

ressing the + or – keys

Paragraph 3 – Timed Dosage (Frequency signal input “TRIGGER” not activated)

Programming Operation

+

-

-

-

-

+

-

+

-

+

-

Tempo

Quantity 100ml

Delay 0.01.50

Interval 0.01.50

PROG

Time

Time g.hh.mm

Time g.hh.mm

Configuration

Pum functions

Configuration

Pum functions

-

-

Trigger Mode

Pause Input Mode

Disable

Restart Timer

+

-

-

Pause Input Mode

Restart Timer

-

Pause Input Mode

Freeze Time

Pause Input Mode

Pause Dosing

The pump doses a programmed quantity in ml. It is possible to set a

pump delay time (Delay) when the pump is started and an interval

between two successive dosings (Interval), as illustrated in the

diagram:

The Delay and Interval times are in dd.hh.mm (days, hours,

minutes)

The Pause input can be programmed in three different modes:

1. FreezeTime: when the pause is activated, the system cuts

out the current time count and restarts it when the pause is

deactivated.

2. Pause Dosing: with the pause activated, the system

continues to count time the and stops the dosing.

3. Restart Timer: when the pause is activated, the system

stops the dosing and when the pause is deactivated the

count starts again from the beginning.

Durante la fase di funzionamento della pompa, è possibile

modificare la frequenza di dosaggio premendo

contemporaneamente i tasti per aumentare la frequenza

oppure i tasti per diminuirla.

Display during Operation Display at start-up (MODE key)

Timer FFF 7.0 ml

Liv Stop P 0%

Operating mode

• Timer

• Alarms and Level

statuses = level alarm

• Flow= flowalarm

FLOW

sensor

status

Programmed value

• Quantity in ml

Pump status

• Dry = pump starting up

• Stop = pump stopping

• Restart = pump restarting

Value of dosing in

progress:

• Percentage of

strokes/min max

Q.tà 20,0ml

20,0ml P 100%

Modalità di funzionamento

•Vengono visualizzati in

sequenza:quantità da

dosare, ritardo in g.hh.mm e

intervallo in g.hh.mm

Valore del dosaggio

•Quantità

programmata in

ml

Valore della percentuale di

dosaggio, modificabile premendo

sui tasti + o -

Delay Interv.

Quantity

EM00136064 rev. 2.1 7

Paragraph 4 – Setting the Maximum Flow

Programming Operation

-

--

Pump Functions

Max flow rate Max flow rate

Max flow rate

P100% P100%

F320s/m

PROG

-

+

-

+

-

This makes it possible to set the maximum flow offered by

the pump, and the programmed mode (% or frequency) is

used as the standard unit of measurement when displaying

the flow. Changes can be made by pressing the key,

then using the keys to set the new value. Press

to confirm and return to the main menu

Paragraph 5 – Setting the Alarm Relay

Programming Operation

-

-

--

Pump Functions

Max flow rate

Alarm Relay

P100%

N.Open

PROG

+

-

This is used to set the alarm relay in the absence of an

alarm situation, if open (default) or closed.

Changes can be made by pressing the key, then using

the keys to set the new value. Press to

confirm and return to the main menu

Paragraph 6 – Flow rate Calibration

Programming Operation

-

-

-

-

Pump Calibration

Pump Calibration

Automatic Cal.

Automatic Cal.

Automatic Cal.

Pump Calibration

0,23 cc/stroke

cc/stroke 0,23

Start 100 strok.

Strokes 100

ml 20

Manual

PROG

+

-

+

-

Pump Calibration

Automatic

The memorised cc value per strike appears in the main

menu. It can be calibrated in two different ways:

MANUAL – manually enter the cc value per strike using the

keys and confirm by pressing the key

AUTOMATIC – the pump makes 100 strikes, which are

started by pressing the key. At the end of this process,

enter the quantity sucked up by the pump using the

keys and confirm by pressing the key.

The entered figure will be used in flow calculations.

EM00136064 rev. 2.1 8

Paragraph 7 - Statistics

Programming Operation

-

-

-

-

-

-

Statistic

Statistic

Statistic

Statistic Reset

Hours 10

Hours 10

Strokes 1000

NO

PROG

+

-

Statistic

Statistic

Statistic

Q.ty(L) 100

Power 10

Reset

ESC

The main menu displays the pump operation times. By

pressing the key you can access other statistics:

- Strokes = number of strokes made by the pump

- Q.ty (L) = quantity dosed by the pump in litres; this figure is

calculated on the basis of the memorised cc/stroke value

- Power = number of pump starts

- Reset = use the to reset the counters (YES) or

otherwise (NO), then confirm by pressing the key.

Pressing the key will take you back to the main menu.

Paragraph 8 – Password

Programming Operation

-

-

-

Password

Password

****

0000

PROG

+

-

By entering the password, you can enter the programming

menu and see all the set values. The password will be

requested whenever you seek to modify them.

The flashing line indicates the number than can be modified.

Use the key to select the number (from 1 to 9), and the

key to select the number to be modified. Confirm by

pressing the key. By setting “0000” (default), the

password is eliminated.

Paragraph 9 – Flow Alarm

Programming Operation

-

-

Alarms

Alarms

Alarm Flow

Alarm Flow

Alarm Flow - On

Flow Off

Flow Off

Off

On

Signals 6

PROG

+

+

-

-

-

-

-

ESC

This makes it possible to activate (deactivate) the flow

sensor.

When activated (On), press the key to access the

request for the number of signals that the pump waits for

before an alarm is triggered. The number flashes when you

press the key, and you can then use the keys

to set the value. Confirm by pressing the key. Press

to return to the main menu

EM00136064 rev. 2.1 9

Paragraph 10 – Level Alarm

Programming Operation

-

-

Alarm Level

Alarm Flow

Alarms

Level Stop

Alarms

Level Alarm

Stop

Alarm

PROG

-

-

-

ESC

This makes it possible to set the pump when the level

sensor alarm is activated. In other words you can decide

whether to stop dosage (Stop) or simply activate the alarm

signal without stopping dosage.

Changes can be made by pressing the key, then using

the keys to set the alarm type. Confirm by pressing

the key. Press to return to the main menu

Paragraph 11 – Flow Display Unit

Programming Operation

-

-

Unit Unit

Unit

Standard Standard <-

L/h

PROG

-

-

+

-

measurement on the display.

Changes can be made by pressing the key, then using

the keys to set the unit of measurement, choosing

between L/h (litres/hour), Gph (Gallons/hour), ml/m

(millilitres/minute) or standard (% or frequency, depending

on settings). Press to confirm and return to the main

menu

Paragraph 12 – Setting the Pause

Programming Operation

--

Paus

N.Aperto

PROG

+

-

Configurazione

+

The pump can be paused by remote input.

The factory setting is Normally Open.

Changes can be made by pressing the key, then

using the keys to set the new value ( N. OPEN or

N. CLOSED).

Press to confirm and return to the main menu.

Display contrast adjustment.

For adjusting the display contrast keep the key pressed and within 5 seconds press the keys or to

increase or decrease the contrast.

Alarms Display Cause Interruption

Fixed alarm LED

Flashing word “Lev”

I.e.

Man

Lev P100%

End of level alarm, without

interrupting pump operation Restore the liquid level.

Fixed alarm LED

Flashing words “Lev” and “stop”

I.e.

Man

Lev Stop P100%

End of level alarm, with interruption

to pump operation Restore the liquid level.

Fixed alarm LED

Flashing word “Flw”

I.e.

Man F

Flw P100%

Active flow alarm. The pump has

not received the programmed

number of signals from the flow

sensor.

Press the key

I.e.

Parameter Error

PROG to default

Internal CPU communication error. Press the key to restore the

default parameters.

Table of contents

Popular Control Panel manuals by other brands

jablotron

jablotron JA-82K OASiS installation manual

Gems

Gems CP16BXXX1 series Operation manual

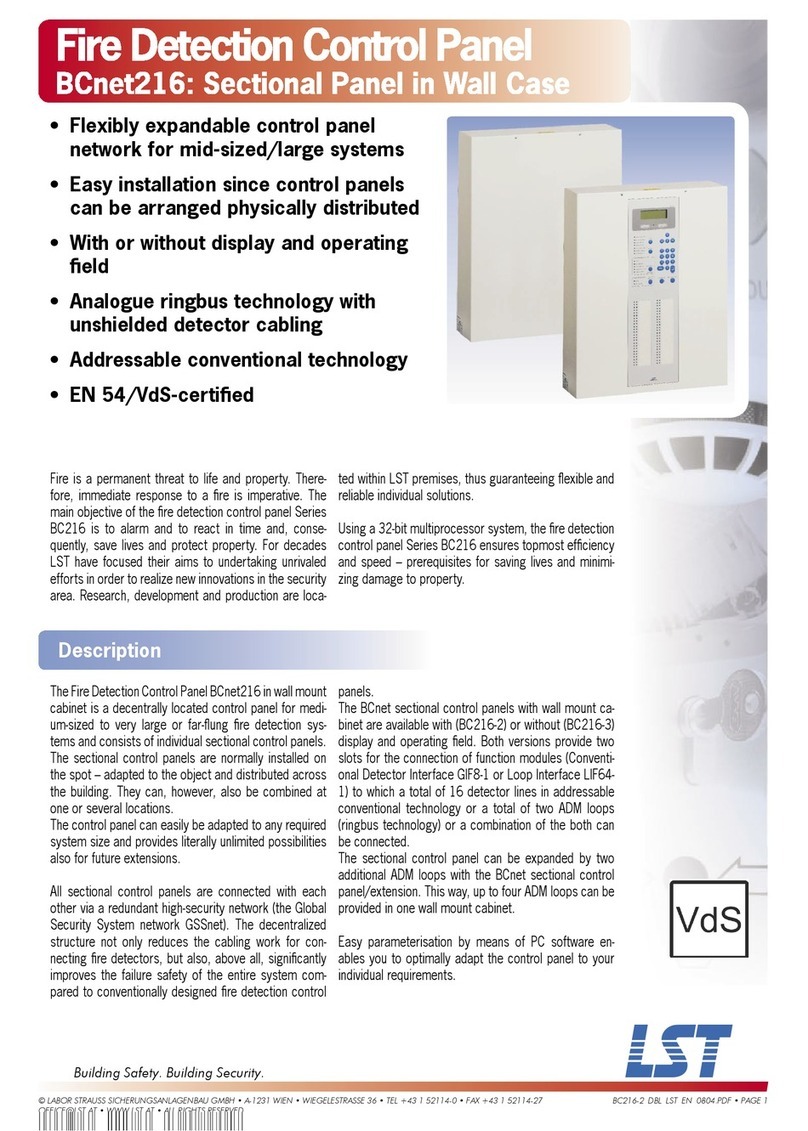

LST

LST Vds EN 12094-1 Brochure & specs

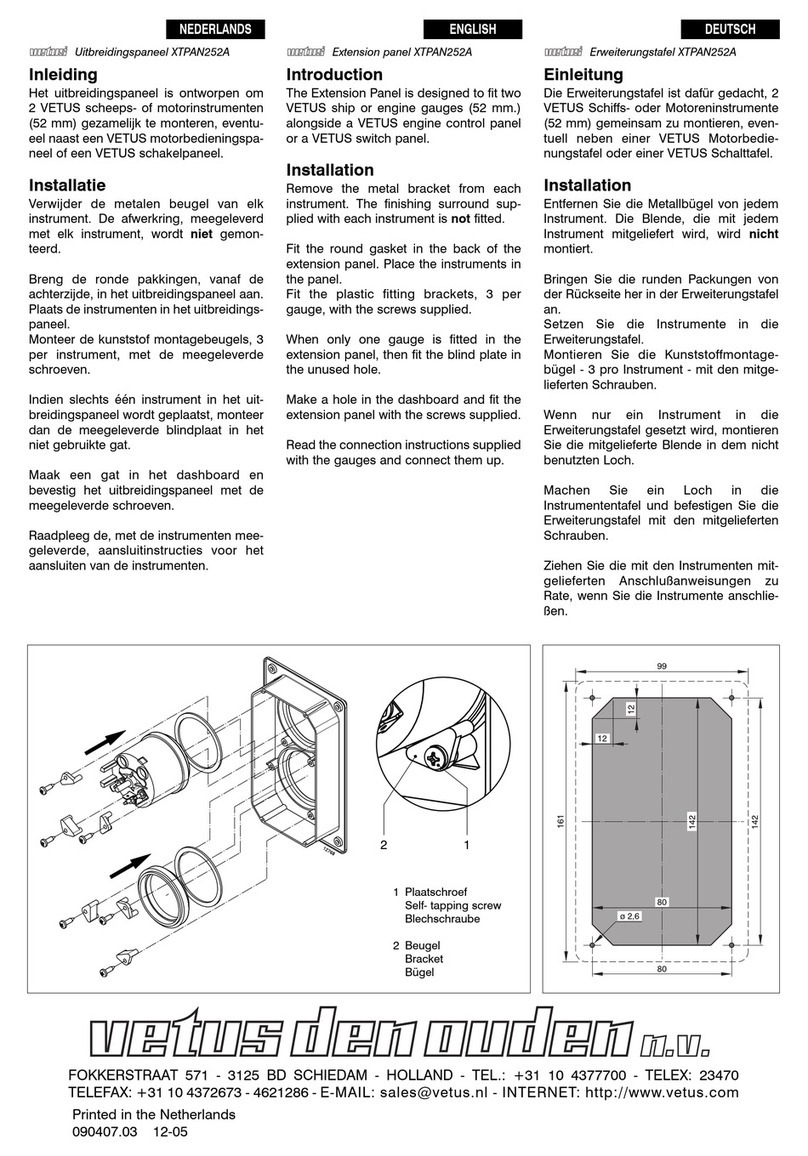

Vetus

Vetus XTPAN252A manual

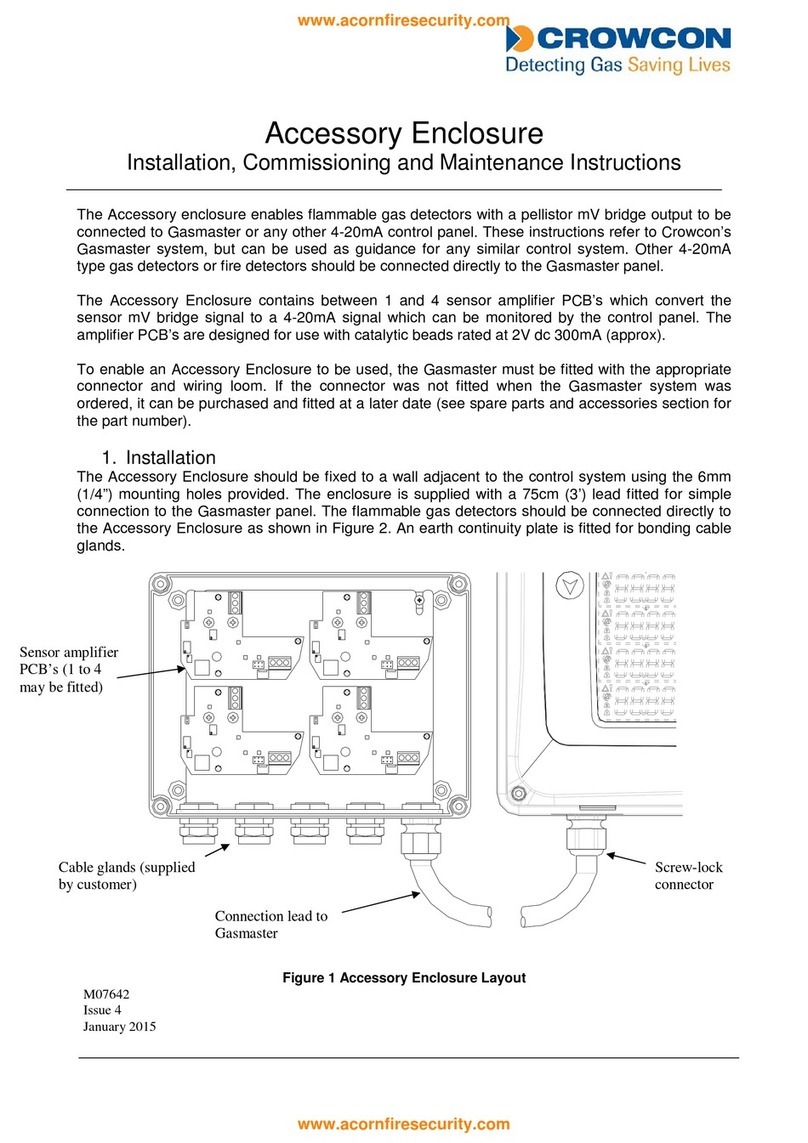

Crowcon

Crowcon Gasmaster 1 Installation, commissioning and maintenance instructions

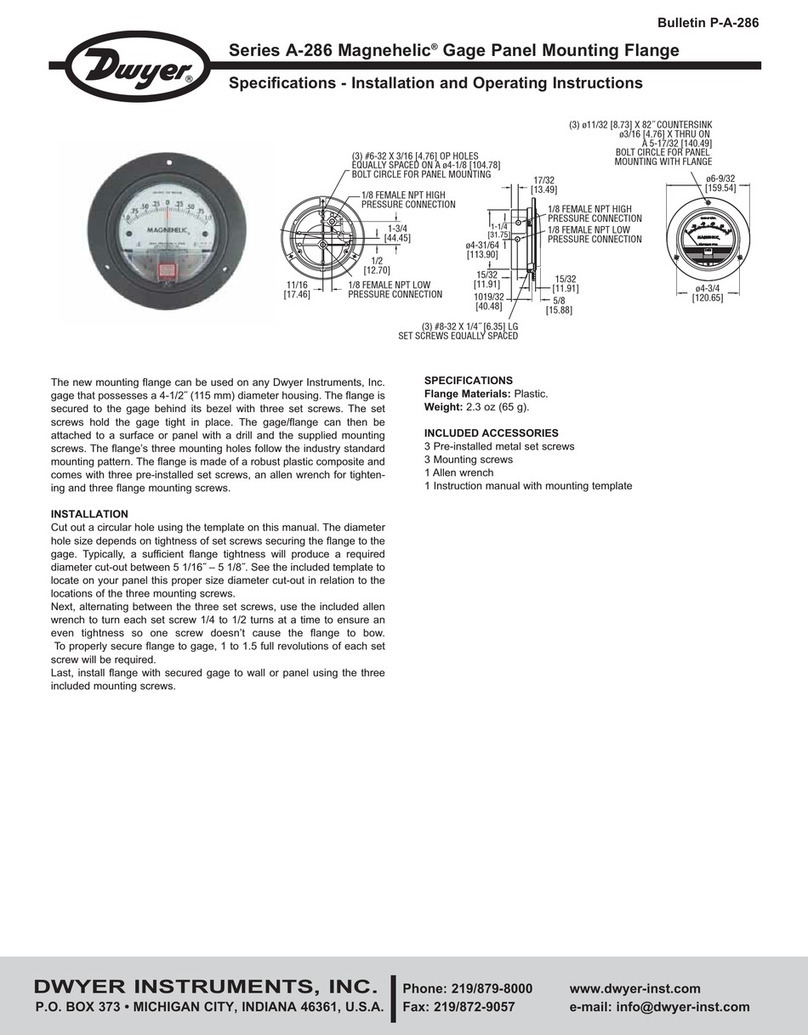

Dwyer Instruments

Dwyer Instruments Magnehelic A-286 Series Specifications-installation and operating instructions

Busch-Jaeger

Busch-Jaeger Busch-Welcome 83200-FM Series manual

Bosch

Bosch B6512 installation manual

IntelliSense

IntelliSense SECURIT 900C user manual

Whelen Engineering Company

Whelen Engineering Company PCC6W installation guide

ADB

ADB IMAGO installation guide

Truma

Truma Panel BC (616) Operating instructions & installation instructions