Telco Sensors Space Scan SS02 Series User manual

SS02 - USER MANUAL

Space Scan Series

Photoelectric measurement light curtains

Website: www.telcosensors.com

Warning

V 1.6 Part Number: L40-0666220746

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

April 2019 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

Page 1 of 7

tel

!

EN

Product Data

Electrical Data

SST (Transmitter)

SSR (Receiver)

Supply voltage

18 – 30 V dc

Max. Voltage ripple

15 % (within supply range)

Current consumption

100 mA (RMS)

75 mA

Max. outputs load

Digital

-

100 mA

Analogue -

Voltage: Z

load

≥1kΩ

Current: Zload ≤600Ω

Reverse polarity protected

Yes

Short circuit protected

Yes

Inductive load protection

-

Yes

Environmental Data

Light immunity @5º incidence

> 100.000 lux

Temperature, operation

-30 to + 60 ºC

Sealing class

IP 67

Marking

Available Models

Model

Beam spacing

Sensing Range

Transmitter

SST 02-10-xxx-xxx-05-H-1D1-0.5-J5

5 mm

10 m

SST 02-10-xxx-xxx-10-H-1D1-0.5-J5

10 mm

SST 02-10-xxx-xxx-20-H-1D1-0.5-J5

20 mm

SST 02-10-xxx-xxx-40-H-1D1-0.5-J5

40 mm

Receiver

SSR 02-10-xxx-xxx-05-H-UUK-ZZW--0.5-J12

5 mm

0.5 m – 10 m

SSR 02-10-xxx-xxx-10-H-UUK-ZZW--0.5-J12

10 mm

SSR 02-10-xxx-xxx-20-H-UUK-ZZW--0.5-J12

20 mm

SSR 02-10-xxx-xxx-40-H-UUK-ZZW--0.5-J12

40 mm

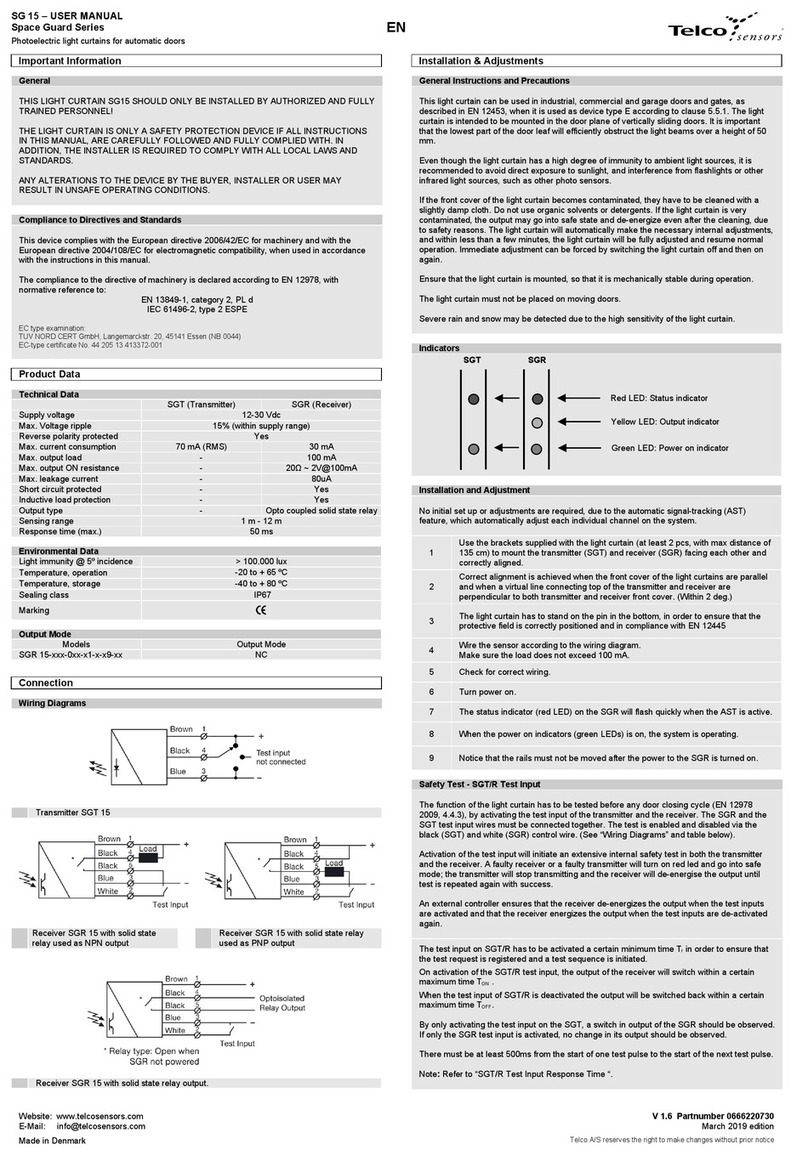

Connection

Wiring Diagrams

5 pin, M1212 pin, M12

SST 5 pole M12 male connector

SSR 12 pole M12 male connector

Transmitter Model

Black wire

connected to ( - )

Black wire

not connected

Black wire

connected to ( + )

SST 02-10-xxx-xxx-xx-H-1D1-0.5-J5

not transmitting

transmitting

transmitting

Wiring diagram

UUK-ZZW

Pin 5

Pink

Pin 6

Yellow

Pin 7

Black

Pin 8

Green

Pin 9

Red

Pin 10

Violet

AC2 - DN2

Dig. NPN Out 2

Dig. Input 1

Analog Out +

Analog Out -

-

Dig. NPN Out 1

AC2 - DP2

Dig. PNP Out 2

Dig. Input 1

Analog Out +

Analog Out -

-

Dig. PNP Out 1

ANN - DN4

Dig. NPN Out 2

-

-

Dig. NPN Out 3

Dig. NPN Out 4

Dig. NPN Out 1

ANN - DP4

Dig. PNP Out 2

-

-

Dig. PNP Out 3

Dig. PPN Out 4

Dig. PNP Out 1

“ - “ = Not used

Type name: SSR 02-10-xxx-xxx-xx-H-UUK-ZZW--0.5-J8.

The letters UUK-ZZW determine the output configuration of the SSR 02.

Output configurations

Installation & Adjustments

Installation

The light curtain is configured by the PC program ‘Telco Space Scan Terminal’, described in

the following pages. Before using it, check the power supply complies with electrical data.

1 Mount the transmitter (SST) and receiver (SSR) facing each other and correctly aligned.

2

Wire the sensor according to the wiring diagram.

Notice that the pin 2 on the SSR and the pin 3 on SST (blue wires) must be connected

together to a common GND ( – ).

Make sure the SSR output load does not exceed 100 mA.

3 Check for correct wiring before turning power on.

4 When the power on indicator (green LED) on SSR and SST is on, the system is

operating.

5 The position of the receiver and transmitter must not be changed after power-up. The

light curtain is only intended for static applications.

SST Test Input

The transmitter SST can be externally disabled and enabled via the black control wire for test

purposes. When the transmitter is disabled the action of the receiver corresponds to breaking

all beams.

SSR Digital Input 1

The digital input can be used to switch between two different output readings on the analogue

output.

The time from a transition on the digital input to a transition on the analogue output is

dependent on the number of beams.

The maximum transition time can be calculated as 500us + the number of beams multiplied by

15us.

Using cross beam scan mode will double the number of beams.

While communication on the RS485 in ongoing, the transition time will be considerably longer.

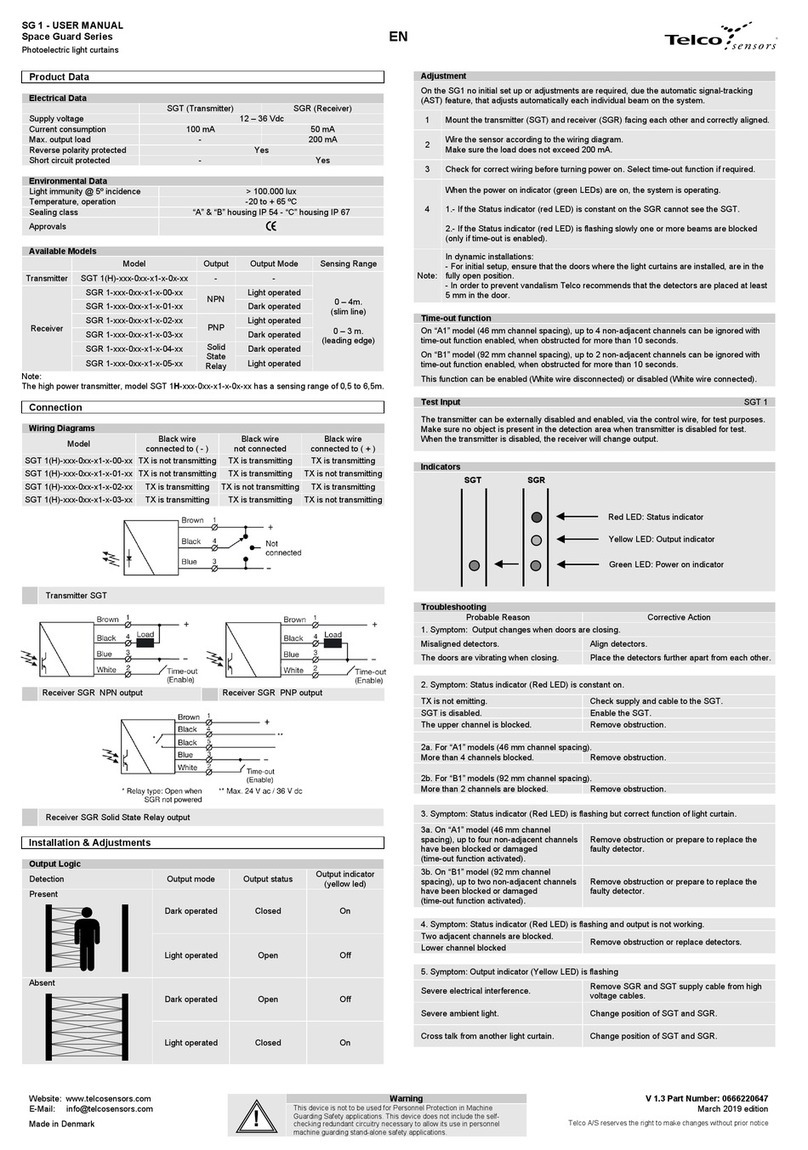

Indicators

SSR

Red LED

Status indicator

SSR

Yellow LED

Follows state of Digital Output 1

SSR & SST

Green LED

Power on indicator

Troubleshooting

Probable Reason

Corrective Action

1. Symptom: Status indicator (Red LED) on SSR is constant on.

SST has no power. Check supply and supply cable to the SST

SST & SSR white, grey and blue wires are

not connected correctly. Connect the wires.

2. Symptom: Output indicator (Yellow LED) on SSR is flashing.

Severe electrical interference. Separate SSR and SST supply cable from high

voltage cables.

Severe ambient light. Swap position of SSR and SST.

Cross talk from another light curtain or

photo sensor Swap position of SSR and SST.

Cross talk from a nearby HF strip light Swap position of SSR and SST or remove the

strip light.

3. Symptom: Digital outputs do not response when IR beams are obstructed.

One or more beams are blocked or the

rails are out of sensing range.

Remove obstruction or reduce the distance

between the rails.

The test input on SST is activated Remove SST pin 4 (black wire) from ground.

Outputs are not configured for simple

detection of obstructions

If needed factory reset the SSR using the

System Information page in the PC program

‘Telco Space Scan Terminal’

SS02 - USER MANUAL

Space Scan Series

Photoelectric measurement light curtains

Website: www.telcosensors.com

Warning

V 1.6 Part Number: L40-0666220746

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

April 2019 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

Page 2 of 7

tel

!

EN

SSR02 and PC connection

To setup or adjust a SS02 it is required to use the Telco Space Scan Terminal software together with an RS485 data link.

1. Start by selecting the RS485 Serial Port and Modbus Set Up and select the correct port to communicate with the SS02. If the port number is not known it is possible to press the Get

Com Port Information. This will list all COM Ports used by the PC. (Full Com port details in Win7, WinXP only basic details are shown ). The RS485 BUS ADDRESS is default 127, but

address can be changed in the menu Function -> System Information.

2. Next press Connect and wait a few seconds before the connection is active.

SS02 - USER MANUAL

Space Scan Series

Photoelectric measurement light curtains

Website: www.telcosensors.com

Warning

V 1.6 Part Number: L40-0666220746

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

April 2019 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

Page 3 of 7

tel

!

EN

File menu

RS485 Serial Port and Modbus Setup:

See SSR02 and PC connection.

Search for Telco light curtains on a Modbus.

Used for finding and identifying the Modbus address(es) of one or more light curtains on the

Modbus. For more info see below.

Connect

See SSR02 and PC connection.

Load configuration

Used to load a file that will configure all functions of the light curtain in one go. The information

is stored in a previously saved configuration file in ASCII format.

Save configuration

Saves information about the current configuration of the light curtain.

Colour Preference

It is possible to set up to 7 different colours for the beams on the screen.

Exit

Exit and close the program.

Language

Language selection.

File -> Search for Telco Light curtain on a Modbus

Use this function to find the Modbus Address(es) of Telco Light curtains on a Modbus, if the address(es) are unknown.

Functions menu

Overview:

For configuration of outputs and measurement functions and for reading output states.

System Information:

For basic system information and configuration of Modbus address.

Status Messages:

Status messages are logged and displayed by choosing this menu item.

Each functions associated with each of these menu items will be described in detail the

following.

Functions -> Overview -> General Setup tab

General Setup:

Right side shows the light curtain and the beam pattern. Unbroken or made beams are indicated by green and broken beams by red. The light curtain is in the setup oriented with the cable entry in the

bottom.

SS02 - USER MANUAL

Space Scan Series

Photoelectric measurement light curtains

Website: www.telcosensors.com

Warning

V 1.6 Part Number: L40-0666220746

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

April 2019 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

Page 4 of 7

tel

!

EN

Scan Mode. Parallel or Cross beam selection.

On cross beam mode, the number of actual beams are increased from N straight beams to (3*N)-2 beams giving a more dense beam pattern, with larger detection certainty.

If objects are positioned in the centre, or close to the centre, between transmitter and receiver the measurement resolution is increased to the double, i.e. the crossed beam mode adds an additional

virtual beam between each of the straight beams, in total N-1 extra virtual beams. When crossed beam mode is selected the number of beams is increased to (2*N)-1 in total, which therefore also will

be the new maximum of the analogue output. Be aware that objects has to be taken out of the light curtain when switching from parallel beam mode into crossed beam mode when it is in automatic gain

mode. The reason is that the gain of the crossed beams has to be initialised.

Gain Control:

In the Manual Gain it is possible to set the Manual Gain Level (a fixed gain level). In Automatic Gain mode it is possible to set the excess gain level. In both manual and automatic gain is it possible

to set the Hysteresis level. Keep objects out of the light curtain when switching to automatic gain mode or when adjusting the excess gain level, because the initial setting of each beam requires

information about signal strength for an unbroken beam.

Operation Mode:

It is set by choosing between Digital Output INV (digital output inverted) and Digital Output NOT INV (digital output not inverted) and possibly by check-selecting the Hole Detection.

When the digital output is not inverted the logical value of all the digital outputs will correspond to the logical value of the Boolean expressions set up in the definition of the digital outputs. This means

that when the Boolean expression is TRUE, the output will be HIGH/energized/activated and the corresponding LED indicator on this page (Digital Output 1, 2, 3, 4) will be yellow, as shown below.

If Hole Detection is activated, the status of all beams will be individually inverted, that means that ‘made beams’ are converted to ‘broken beams’ (and inversely), whereby holes (unbroken beams ) will

be perceived as objects obstructing beams for the following analysis.

Blanking:

It means to deactivate beams resulting one or more areas in the light curtain where the status of the beams are ignored. Blanking can either be setup by writing directly which beams to be blanked in

the text box. Writing ’12-16, 20’ means that all beams starting from beam no 12 and ending with beam no.16, and beam no. 20 are blanked. When the blanking is written, it shall be transferred to the

light curtain pressing the button Write to Light Curtain, whereby it becomes active. Blanked beams are marked blue as seen below.

Beams can also be blanked by simply reading obstructed beams from the light curtain by pressing the button Measure From Light Curtain, whereby the obstructed and now blanked beams will be

written in the text box. It is not necessary to press Write to Light Curtain for activating the blanking.

Smoothing Function (Minimum Size of Coherent Area):

The Smoothing Function tells the SSR to ignore objects which are smaller than a specific size. If the Smoothing Function is set to 3, any object that interrupts 3 or less adjacent beams will be ignored.

Smoothing can be used, e.g., to ignore interference caused by wood chips while sawing a log.

The effect is obtained by a pre-processing of the beams status where all groups of adjacent broken beams with less than or equal to 3 beams are substituted by made beams.

This smoothing function is carried out after the ‘hole detection’ pre-processing.

Input and Output Status

Activated/energised/logical high digital output is indicated by yellow; else the indicator will be grey.

Digital Input 1 indicator: green for high input and grey for low input.

Signal OK indicator: when the signal level is sufficient for stable operation of the light curtain the Signal OK indicator will be green. If the Signal OK indicator is off, the gain should be increased or

distance between transmitter and receiver should be decreased. The Signal OK indicator will also go out if there is a loss of synchronisation between the SST02 and the SSR02.

Analogue Output value shows the value of the Analogue output function that is chosen in the tab Analogue Output. The measurement unit is the beam number. This value will be scaled

correspondingly in the analogue current output or in the analogue voltage output. If Crossed Beam Mode is selected the span of the output values will be doubled, reflecting the double resolution

achieved (objects has to be positioned in the centre of the light curtain, see Scan Mode)

Save settings permanently: When checked the settings will be saved to the permanent memory in the SSR02 light curtain, so that they will not be deleted when taking off the power. When using a

PLC to continually writing settings to the SSR02, this setting should be unchecked because repeated writing to the permanent memory is only guaranteed for a minimum of 10000 times. This setting is

checked as factory default. When the checkbox is unchecked the latest setting will be remembered. The checkbox will only work with light curtain software version 1R18 or newer.

Change light curtain orientation:When this is checked the illustration of the light curtain will be reverted.

SS02 - USER MANUAL

Space Scan Series

Photoelectric measurement light curtains

Website: www.telcosensors.com

Warning

V 1.6 Part Number: L40-0666220746

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

April 2019 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

Page 5 of 7

tel

!

EN

Functions -> Overview –> Analogue output tab

The figure below shows the window that appears when the Analogue Output tab is selected under Function->Overview.On this tab it is possible to define the operation of the analogue output i.e. the

measurement on the beam pattern that is going to be performed. The tab contains a number of marked areas; Analogue Output, Analogue Output Function and Set Analogue output.

Analogue Output: In this box it is possible to Enable Output and Disable Output. When the output is enabled it is possible to select between Current output (4-20mA)* and Voltage output (0-10V)*

using the pull down box.

*Referred to 0 Vdc, pin 8 green wire (Analogue Out - )

Analogue Output Function: The function of the analogue output depends on the setting of the control input on the receiver. If the Digital Input 1 is connected to + (high), the function selected in the

pull down box next to Control input high is active. If the Digital Input 1 is connected to – (i.e. low) or not connected (N.C.), the function selected in the pull down box next to Control input low (NC) will

be active. The functions selectable in the two boxes are identical. Notice that the status of the Digital Input 1 can be read in the Input and Output Statusfield. Following function can be selected.

Analogue Output Moving Average: The time constant defines how long the averaging is. The value can be from 0 to 2000 ms.

Measurement functions:

DIS: Disabled output. Output is disabled, i.e. constantly de-energised.

FBB: First Beam Blocked. Position of the first beam blocked.

FBM: First Beam Made. Position of the first beam made.

LBB: Last Beam Blocked. Position of the last beam blocked.

LBM: Last Beam Made. Position of the last beam made.

MBB: Middle Beam Blocked. Position of the (FBB+LBB)/2 rounded to nearest integer

TBB: Total Beams Blocked. Total number of beams blocked.

TBM: Total Beams Made. Total number of beams made.

CBB: Contiguous Beams Blocked. Reads out the number of beams in the largest group of adjacent

beams blocked.

CBM: Contiguous Beams Made. Reads out the number of beams in the largest group of adjacent

beams made.

TRN: Number of Transitions. The number of transitions in the beam pattern between made beams and blocked beams.

OD: Outside dimensions. Reads out LBB - FBB+1, corresponding to the size of a single object contained in the beam pattern, counted in beam breaks.

ID: Inside dimensions. Reads out the count of beams made between first beam broken and last beam broken. This corresponds to the size of a hole in a single solid object in the light curtain.

CFBB: Contiguous First Beam Blocked. Reads out the number of the first beam in the largest group of adjacent beams blocked.

CLBB: Contiguous Last Beam Blocked. Reads out the number of the last beam in the largest group of adjacent beams blocked.

Force Set Enable: Marking the checkbox Force Set Enable disables all measurements and enables the user to set the output value in the textbox next to Analogue Output Value.

This function can be used for test and calibration purposes.

SD: Speed and Direction. Reads out the velocity of an object. The input box ‘minimum speed’ is used to define the velocity that corresponds to 4 mA/ 0 V. The input box ‘maximum speed’ is used to

define the velocity that corresponds to 20 mA / 10 V. Notice that both negative and positive values in the interval between -40 m/s and +40 m/s can be used. If objects are moving in direction of larger

beam numbers the beam number the velocity is positive. If the objects are moving in the direction of smaller beam numbers the velocity is negative.

Note: The beams are counted starting with one from the end of the cable entry.

Note: Unintended use of pre-filtering, i.e. hole detection or Maximum Area of adjacent beams blocked set different from 0 can lead to unexpected results!

If crossed beam setting is used, the effective beam number is increase by a factor of 2.

SS02 - USER MANUAL

Space Scan Series

Photoelectric measurement light curtains

Website: www.telcosensors.com

Warning

V 1.6 Part Number: L40-0666220746

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

April 2019 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

Page 6 of 7

tel

!

EN

Functions -> Overview –> Digital Output tabs

The Digital Output 1 tab, selected under Function->Overview,it is possible to define the operation of Digital Output 1.

If the light curtain is equipped with multiple digital outputs, the other outputs can be configured by using the other identical digital output tabs.

The digital output tab contains 3 marked areas: Digital Output, Digital Output Function and Set Digital Output.

Digital Output: To Enable Output and Disable Output.

Digital Output Function:

A digital output can read out only two values which are associated with the Boolean values true and false; the output is either high = true or low= false.

The output value is the result of the evaluation of a Boolean expression, that here is set up using the two pull down-boxes and text input box.

The first box contains the same list of functions as available under Analogue Output Function, plus the ABBA function.

The second box contains a list of comparison operators.

The third box is used to type in a number. If the expression is true, the out will be high, and if the expression is false, the output will be low.

The selection “Any Beam Blocked in Area” has two values minimum and maximum. The output is high if one or more beams are broken with beam numbers that are larger than or equal to

Minimum and smaller than or equal to Maximum.

With the selection “Signal Alarm” the output is set high if the signal is not OK.

Set Digital Output

Marking the checkbox Force Set Enable disables the Digital Output Function and enables the user to set the digital output high by selecting Output Forced High or low by selecting Output Forced

Low. The function is primarily intended for test purposes.

Output delay:On-delay specify the time between the expression becomes true and the output is switched accordingly. Off-delay specify the time between the expression becomes false and the output

is switched. On-delay and off-delay is selectable between 0 and 10 s.

Functions -> System information

System information contains the information displayed in the figure below. The MODBUS address can be modified using the Change MODBUS Address button.

SS02 - USER MANUAL

Space Scan Series

Photoelectric measurement light curtains

Website: www.telcosensors.com

Warning

V 1.6 Part Number: L40-0666220746

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

April 2019 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

Page 7 of 7

tel

!

EN

Functions -> Status Messages

Selecting Functions -> Status messages makes the window below appears. Status messages and error messages are logged and displayed. The log can be cleared by pressing the button Clear

Status Messages.

Table of contents

Other Telco Sensors Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

ADJUST-A-WINGS

ADJUST-A-WINGS HELLION DE Setup instructions

Good Earth Lighting

Good Earth Lighting SE1093-BP2-01LF0-G quick start guide

MELINERA

MELINERA 271551 Operation and safety notes

Anslut

Anslut 422-525 User instructions

MJ LED LIGHTNING

MJ LED LIGHTNING MJ-1025 instruction manual

Kelu

Kelu RODI user manual