TELECO AUTOMATION TVRDS868B01 User guide

Control system for garage doors

Installer’s instruction manual

Product:

TVRDS868B01

Doc:

T763.03

Date:

13/11/18

2

INDEX

1. PRODUCT DESCRIPTION --------------------------------------------------------------- p. 3

2. INSTALLATION ----------------------------------------------------------------------- p. 4 - 7

2.1 Mounting the product

2.2 Mounting the wireless safety system (BST24/BST25/BST25S)

2.3 Control unit diagram

2.4 Electrical connections

2.5 Wired safety device connections

3. PRELIMINARY CHECK AND INITIAL START-UP --------------------------------------- p. 8 - 10

3.1 Limit switch configuration

3.2 Deactivation of wireless safety system

3.3 Exclusion of safety edge in the last 5cm of the closure

3.4 Light output mode

4. TRANSMITTERS MEMORIZATION ------------------------------------------------------- p. 11 - 13

4.1 Single channel memorization

4.2 Double channel memorization

4.3 Single channel: Courtesy light ON/OFF

4.4 Four channels memorization

4.5 Remote memorization of the first transmitter

4.6 Remote memorization of further transmitters

4.7 Alarm function: shock sensor memorization

4.8 Single channel: door status request (“ASK”)

5. TRANSMITTERS DELETION ------------------------------------------------------- p. 14

5.1 Deleting a single transmitter

5.2 Deleting all the transmitters

5.3 Remote deletion of a transmitter

6. TIME SETTINGS ----------------------------------------------------------------------- p. 15

6.1 Auto close time setting

6.2 Courtesy light time setting

7. OTHER PROGRAMMING ------------------------------------------------------- p. 16

7.1 “Holiday mode”

7.2 Control unit reset

8. TECHNICAL SPECIFICATIONS ------------------------------------------------------- p. 17

8.1 WARNINGS

9. TROUBLESHOOTING (What to do if...) ----------------------------------------------- p. 18 - 19

3

TVRDS868B01

Control unit with integrated radio receiver for the remote control of tubular motors up to

700W, with built-in limit switch, for rolling shutters and rolling doors.

W

i

r

e

l

e

s

s

s

a

f

e

t

y

s

y

s

t

e

m

F

r

o

n

t

c

o

v

e

r

w

i

t

h

b

u

t

t

o

n

s

a

n

d

L

E

D

1. PRODUCT DESCRIPTION

FEATURES

Compact plastic case with easy fixing and LED for alarms/status

Front cover with buttons for programming and up/stop/down commands

Integrated LED courtesy light

Wireless control via radio transmitters

Wireless safety edge with auto-test.

Bidirectional communication: door status is shown by the transmitter LED with different colour

Alarm function, in combination with shock sensor (TVSSH868A01 and BST25S) and integrated

speaker

CONNECTIONS & FUNCTIONING

Wide room for wiring and easy cable lock without need of cable glands

Wired inputs for photocells and safety edge (both resistive 8K2 and infrared)

Wired inputs for command push-button and emergency STOP push-button

Possibility to connect an external 230V~ flashing light (activated just during the manoeuvre) or

courtesy light.

2 Functioning modes: semi-automatic (automatic opening + hold-to-run closing) and automatic

Automatic closing with programmable pause time

Exclusion of the safety edge in the last part of the closure, in case of bumpy floor

“Holiday mode” to lock the control unit with the front cover

W

i

r

e

l

e

s

s

s

y

s

t

e

m

e

a

s

y

t

o

c

o

n

n

e

c

t

I

n

t

e

g

r

a

t

e

d

L

E

D

c

o

u

r

t

e

s

y

l

i

g

h

t

W

i

d

e

r

o

o

m

f

o

r

w

i

r

i

n

g

a

n

d

e

a

s

y

c

a

b

l

e

l

o

c

k

S

a

f

e

t

y

e

x

c

l

u

s

i

o

n

Max.

5 cm

4

2.1 Mounting the product

OPENING THE COVER

1. Remove the screw.

2. Lift the lid up.

BOX DIMENSIONS

FRONT SIDE REAR

screw

65 mm165 mm

220 mm

150 mm

130 mm

5

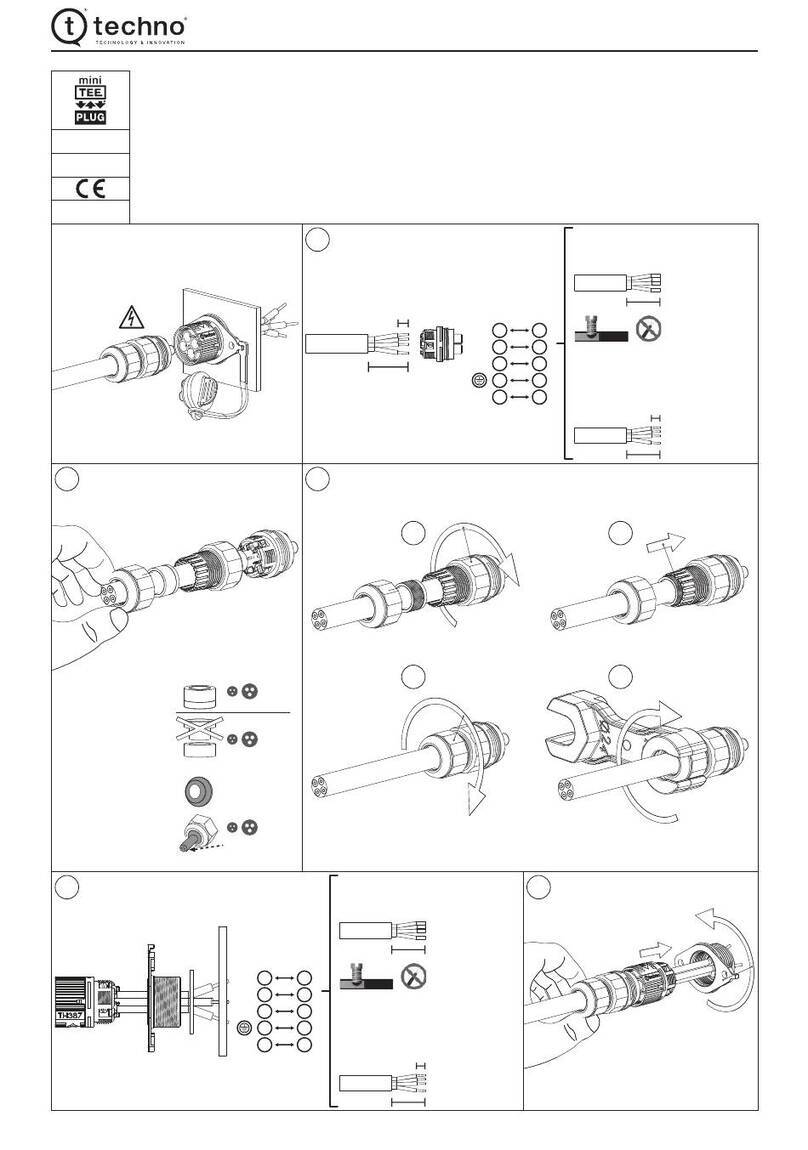

2.2 Mounting the wireless safety system (BST24/BST25/BST25S)

?

?

?

?

?

?

We recommend installing at the base of the door, on both

side of the safety edge, two rigid bumpers. In case of

uneven floors, this can avoid an accidental activation of the

safety edge. If it’s not possible use the procedure 3.3.

The system is composed by a radio card (MASTER), plugged in the control unit, and a wireless transmitter

(SLAVE) mounted on the door, usually close to the bottom slat, connected to the safety device.

The device has got infrared low-consumption barrier (both safety systems), or 8,2KOhm resistive barrier safety

edge (only for BST24/BST25). If an obstacle is detected during the closing, the SLAVE sends a signal to the

MASTER that immediately stops the door and reverses its movement. The system performs an auto-test before

any movement.

?

?

?

OK

RIGID BUMPERS

FLOOR

RADIO CARD (MASTER)

Install both the control unit and bottom slat transmitter

inside. Make sure that there are no obstructions

between devices. Check that the maximum distance

between the devices is no more than 10m.

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

1 2

2

2

1

1

BK2

2 3 4 5 6

BK2

1 2

1

1

2

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

1 2

2

2

1

1

BK2

2 3 4 5 6

BK2

1 2

1

1

2

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

1 2

2

2

1

1

BK2

2 3 4 5 6

BK2

1 2

1

1

2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1

3

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

2

a b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

+ -

- +

+

B1

-

B2

3 4 5 6

BK2

1 2

a

b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

BOTTOM SLAT TRANSMITTER (SLAVE)

Powered by:

led *

dip switches **

+

B1

-

B2

34 56

BK2

12

+-

-+

+-

-+

+

B1

-

B2

34 56

BK2

12

2 x 3.6V

Lithium batteries

2 x 1.5V

Type AA batteries

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1

3

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

2

a b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

+ -

- +

+

B1

-

B2

3 4 5 6

BK2

1 2

a

b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1

3

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

2

a b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

+ -

- +

+

B1

-

B2

3 4 5 6

BK2

1 2

a

b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

Opening the lid

1. Remove the screws.

2. Lift the lid up.

Closing the lid

1. Place the lid.

2. Tighten the screws.

Fixing the

transmitter

Use the screws and

the holes in the picture.

Insert batteries and

check polarity.

INFRARED SAFETY EDGE RESISTIVE SAFETY EDGE

1 2

ON

DIP1 = ON

1 2

ON

DIP2 = ON

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1

3

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

2

a b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

+ -

- +

+

B1

-

B2

3 4 5 6

BK2

1 2

a

b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1

3

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

2

a b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

+ -

- +

+

B1

-

B2

3 4 5 6

BK2

1 2

a

b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

1

ON

B2B1

2

++

P1

6 5 4 3

8K2

6 5 4 3

4- GREEN

5- BROWN

6- WHITE

3 4 5 6

BK2

Green

Brown

White

1 2

a

3 4 5 6

BK2

Green

Brown

White

b

1 2

P1

L3

L2

L1

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1

3

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

2

a b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

+ -

- +

+

B1

-

B2

3 4 5 6

BK2

1 2

a

b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1

3

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

2

a b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

+ -

- +

+

B1

-

B2

3 4 5 6

BK2

1 2

a

b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

1

ON

B2B1

2

++

P1

6 5 4 3

8K2

6 5 4 3

4- GREEN

5- BROWN

6- WHITE

3 4 5 6

BK2

Green

Brown

White

1 2

a

3 4 5 6

BK2

Green

Brown

White

b

1 2

P1

L3

L2

L1

1 2

ON

DIP1 = OFF

Infrared test activated for

30 s. Any beam interruption

turns the led ON .

*

*

*

(*) Only for BST24 / BST25

6

2.3 Control unit diagram

1 - High voltage terminals

2 - Low voltage terminals

3 - 5A fuse

4 - Aerial connection

5 - Programming/command buttons

6 - Dip switches

7 - Status/alarm LED

8 - LED courtesy light

9 - Socket for radio card (MASTER)

10 - Alarm buzzer output

11 - Manoeuvre relays

12 - Common relay

13 - Transformer

14 - Ground terminal

2.4 Electrical connections

High voltage terminals

# CONNECTION

1 Motor Ground

2 230V~ Power supply - Ground

3 230V~ Power supply IN - LIVE

4 230V~ Power supply IN - NEUTRAL

5 Motor - OPEN

6 Motor - COMMON

7 Motor - CLOSE

8230V~ LIGHT OUTPUT

(300W max. lamp)

9

# CONNECTION

12 Photocells power supply (+12V)

13 Safety common (COM)

14 Photocells power supply (0V)

15 N.C. contact FTC (photocells)

16 Infrared/8K2 safety edge input (brown)

17 Infrared/8K2 safety edge input (green)

18 Infrared/8K2 safety edge input (white)

19 Push-button common (COM)

20 Push-button (step-by-step, N.O.)

21 Emergency STOP push-button (N.C.)

22 Emergency STOP push-button common

Wired

infrared/8K2

safety edge

Emergency

STOP (TB)

Low voltage terminals

Push-

button

(TD)

Wired

photocells

< -- see pag. 7 for connections -- >

Open COM Close

MOTOR

230V

Line IN

GND LIGHT

output

Via dell'Artigianato, 16 - 31014 Colle Umberto (TV) ITALY

Tel. +39.0438.388511 Fax +39.0438.388536

Web site: www.telecoautomation.com

DATE: 02/03/17 REV: 1.0

ETI-MORS-RDSB02

Da stampare a colori

L N

1

4

5

2

3

6

7

8

9 10

11 13

12

14 3 4 5 6 7 8 9 12 13 14 15 16 17 18 19 20 21 22

TB COM

COM TD

Via dell'Artigianato, 16 - 31014 Colle Umberto (TV) ITALY

Tel. +39.0438.388511 Fax +39.0438.388536

Web site: www.telecoautomation.com

DATE: 02/03/17 REV: 1.0

ETI-MORS-RDSB02

Da stampare a colori

7

2.5 Wired safety device connections

Infrared (IR) safety edge 8.2Kohm resistive safety edge

Connect a 8K2 resistor between terminals 16 and 17.

Terminals 14 and 15 must be closed by a jumper.

Terminals 21 and 22 must be closed by a jumper.

If no wired safety edge is used, connect a 8K2 resistor between terminals 16 and 17.

Reflex photocell Pair of standard photocells (N.C.)

If no photocells are used, terminals 14 and 15 must be closed by a jumper.

NO WIRED SAFETY DEVICE CONNECTED

12 13 14 15 16 17 18 19 20 21 22 23

16- BROWN

17- GREEN

18- WHITE

12 13 14 15 16 17 18 19 20 21 22 23

8K2

0V

12V

24V

N.O.

COM

N.C.

0V

12V

24V

12 13 14 15 16 17 18 19 20 21 22 23 12 13 14 15 16 17 18 19 20 21 22 23

RX FTC010

TX FTC010

REFLEX

+

-

COM

N.C.

12Vdc - 15Vdc

12 13 14 15 16 17 18 19 20 21 22 23

8K2

8

3. PRELIMINARY CHECK AND INITIAL START-UP

• Step 1: motor limit switch setting

Once the limit switches are set connect the motor to control unit and start the system up.

The buzzer emits 3 quick sounds if the memory is empty or 1 long sound if the memory has radio codes in.

• Step 2: motor connection and powering the board up

After the power-on, the control unit executes only opening commands until the door is fully opened.

Check the direction of the door; if the door is travelling in the wrong direction:

1- STOP the manoeuvre

2- Switch the control unit off

3- Swap BLACK and BROWN motor wires over - terminals 5 & 7

4- Power the board up again

Check that the bottom slat transmitter (SLAVE) is supplied by the batteries, the voltage selector is in the right

position and all the connections are correctly made, as decribed at par. 2.2.

• Step 3: activation of the wireless safety device system

1- Push the button of the radio card (MASTER) for 2 seconds, L1 and L2 led will flash.

2- Push the button of the bottom slat transmitter (SLAVE) for 2 seconds. Its led will flash.

In case of correct memorization L1 will costantly flash.

Check the system pressing the button of the bottom slat transmitter (SLAVE) and keeping it pressed:

- Slave led solid ON = OK

- Slave led flashing = No wireless communication

- Master L1 led must costantly flash

In case of problem, the system can be totally excluded with the procedure 3.3.

WARNING: the control unit executes a brief inversion of the movement (1 second) if any error occurs.

In case that the safety devices (except for TB input) are defective or they have been activated, it is

possible to operate the door anyway, keeping pressed the command button for more than 5 seconds.

The control unit will automatically switch to hold-to-run mode.

In case of any problem, refer to the paragraph “Troubleshooting” (par. 9).

• Step 4: functioning mode

RADIO CARD

(MASTER)

BOTTOM SLAT

TRANSMITTER

(SLAVE)

button

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

1

3

1

BK2

2 3 4 5 6

BK2

1 2

1

BK2

2 3 4 5 6

BK2

Green

Brown

White

2

a b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

+ -

- +

+

B1

-

B2

3 4 5 6

BK2

1 2

a

b

+

B1

-

B2

3 4 5 6

BK2

1 2

+ -

- +

led button

1 2 3

ON

1 2 3

ON

1 2 3

ON

1 2 3

ON

A proper connection box should be used to set the limit switch before wiring the motor in the control unit

or follow the procedure described on par. 3.1.

DIP2 ON: AUTOMATIC mode.

OFF: SEMI-AUTOMATIC mode. Automatic opening and hold-to-run closing.

The automatic closure function is deactivated.

DIP2=DIP3 ON: Automatic closure function activated. Default time is 30 sec.

This function has effect only when the door is totally open.

DIP3 OFF: Automatic closure function deactivated (default setting).

L3 led

L2 led

L1 led

9

3.1 Limit switches configuration

Open the door (in hold-to-run mode) in order

to set up the upper limit switch.

Close the door (in hold-to-run mode) in order

to set up the down limit switch.

hold-to-run

DEACTIVATION

P2

( 5 s)

keep it

pressed Press P2 button five times and keep it

pressed for at least 5 seconds. L7 starts

flashing.

Press P2 button twelve times and keep it

pressed for 5 seconds. The buzzer emits 1

beep and L7 flash fast.

L7 flashes

slow

...

( 5 s)

keep it

pressed

HOLD TO RUN

L7 FLASH FAST

( 5 s)

keep it

pressed

L7 flashes

slow

...

( 5 s)

keep it

pressed

Press P2 button five times and keep it

pressed for at least 5 seconds. L7 starts

flashing slow.

Press P2 button thirteen times and keep

it pressed for 5 seconds. The buzzer emit

2 beeps.

hold-to-run

5x

12x

5x

13x

WITHIN 30 SEC.

FROM POWER-ON

P2

P2

P2

Procedure only with hold to run commands. Warning: The safety devices are excluded!

ON

1 2 3

ON

1 2 3

ON

3.2 Deactivation of wireless safety system

This function is possible ONLY within 30 seconds from the power on of the control unit.

By default DIP1 is ON (system activated).

• Switch the unit on and move DIP1 to OFF within 30 seconds.

ON to OFF

The control unit will emit 6beeps if the system has been correctly deactivated.

It is possible activate the safety system again, moving DIP1 from OFF to ON within 30 seconds from

power-on. After keeping pressed P2 button for 5 seconds, the control unit will emit 7beeps.

• Press P2 button for 5 seconds and hold it down

10

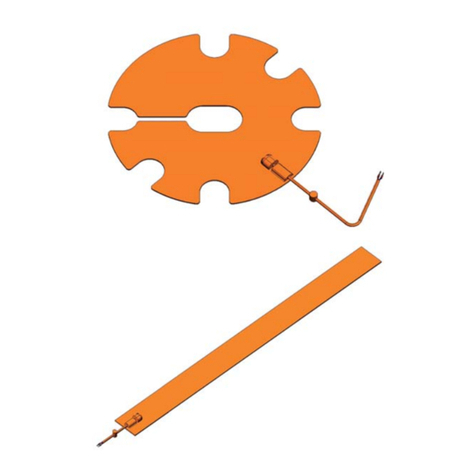

3.3 Exclusion of safety edge in the last 5 cm of the closure

In case of uneven floors, it could be necessary deactivating the safety edge in the last part of the closure (not

more than 5 cm to comply with the standards) in order to avoid any accidental activation of the safety edge.

This procedure must be performed by qualified installer only, who will take charge of its correct application.

WARNING: this procedure can be used only for doors which require more than 10 seconds each manoeuvre. The

exclusion of the safety edge is applied only if the closure starts from the upper limit switch and it is not stopped.

Open the door completely by means of

a memorized transmitter. The buzzer emits

a long beep when the upper limit switch is

reached. Put on the floor, exactely under the

door, a sturdy object not more than 5 cm high.

Close the door (in hold-to-run mode), with

no interruption. The door will stop at the

obstacle and the control unit will make a

long beep. Open the door completely and

remove the object. Close the door to verify the

correct application of the procedure.

hold-to-run

DEACTIVATION

( 5 s)

keep it

pressed Press P2 button five times and keep it

pressed for at least 5 seconds. L7 starts

flashing.

Press P2 button ten times and keep it

pressed for 5 seconds. The buzzer emits

3 beeps.

WITHIN 30 SEC.

FROM POWER-ON

L7 flashes

...

( 5 s)

keep it

pressed

( 5 s)

keep it

pressed

L7 flashes

...

( 5 s)

keep it

pressed

Press P2 button five times and keep it

pressed for at least 5 seconds. L7 starts

flashing.

Press P2 button eleven times and keep it

pressed for 5 seconds. The buzzer emits 5

beeps.

5x

10x

5x

11x

WITHIN 30 SEC.

FROM POWER-ON

P2

P2

P2

P2

max. 5 cm

X

3.4 LIGHT OUTPUT MODE Factory setting

FLASH OUTPUT

( 5 s)

keep it

pressed Press P2 button five times and keep it

pressed for at least 5 seconds.

Press P2 button fourteen times and keep

it pressed for 5 seconds. The buzzer emits

1 beep.

( 5 s)

keep it

pressed

P2

P2 14x

...

MODE: COURTESY LIGHT

( 5 s)

keep it

pressed Press P2 button five times and keep it

pressed for at least 5 seconds.

Press P2 button fifteen times and keep it

pressed for 5 seconds. The buzzer emits

2 beeps.

( 5 s)

keep it

pressed

5x

P2

P2 15x

...

MODE: FLASH OUTPUT

5x

11

4.1 Single channel memorization

Memorization of a single button of any transmitter,

with function OPEN - STOP - CLOSE

Press P2 once and keep it pressed.

The buzzer emits a continuous sound.

Press any button to memorize.

Once the memorization is successfully completed,

the buzzer emits a fast intermittent sound.

P2

continuous sound

...

( )

keep it pressed

intermittent sound

button to

memorize

OPEN - STOP - CLOSE ►

4. TRANSMITTER MEMORIZATION

In order to carry the transmitter memorization out it is necessary use the P2 button of the

front cover, entering the “programming mode” first.

WARNING: always check that L7 is flashing before carry the following memorizations out!

If no further button is pressed within 10 seconds the control unit exits automatically the programming mode.

Press P2 five times and keep it pressed

for at least 5 seconds. L7 starts flashing.

( 5 s )

keep it pressed

P2

ENTERING THE PROGRAMMING MODE

P2

(STOP)

L7 flashes

...

P2

(STOP)

5x

4.3 Single channel: courtesy light ON/OFF

Memorization of a single button of any transmitter,

with function LIGHT ON - LIGHT OFF

Press P2 three times and keep it pressed.

The buzzer emits a continuous sound.

Press any button of the pair to memorize.

Once the memorization is successfully completed,

the buzzer emits a fast intermittent sound.

continuous sound

...

( )

keep it pressed

intermittent sound

P2

4.2 Double channel memorization

Memorization of two buttons of any transmitter in one

step, with function OPEN (STOP) - CLOSE (STOP)

Press P2 twice and keep it pressed.

The buzzer emits a continuous sound.

Press any button of the pair to memorize.

Once the memorization is successfully completed,

the buzzer emits a fast intermittent sound.

continuous sound

...

( )

keep it pressed

intermittent sound

P2

button to

memorize

button to

memorize

OPEN (STOP) ►

CLOSE (STOP) ►

LIGHT ON - LIGHT OFF ►

2x

3x

12

4.4 Four channels memorization

Memorization of four button transmitter in one step.

Press P2 six times and keep it pressed.

The buzzer emits a continuous sound.

Press any button of the transmitter to memorize.

Once the memorization is successfully completed,

the buzzer emits a fast intermittent sound.

continuous sound

...

( )

keep it pressed

intermittent sound

button to

memorize

OPEN ►

CLOSE ►

STOP ►

LIGHT ON - LIGHT OFF ►

4.6 Remote memorization of further transmitters

P3

The added transmitter will have the same functions of the transmitter used for the memorization.

This procedure is compatible with any type of transmitter.

Press once P3 button (twice if

within 30 seconds from power

on) of a memorized transmitter

for 2 sec. The buzzer emits a

continuous sound.

Press the button of a transmitter

already memorized. The buzzer

stops for 1 second, then sound

continously again.

Press the button of a new transmitter to memorize

with the same functions. Once the memorization

is successfully completed, the buzzer emits a fast

intermittent sound.

P3 button is

located inside the

transmitter

1 s< 5 s

...

< 5 s

continuous

sound intermittent sound

continuous

soundmemorized new

memorized

4.5 Remote memorization of the first transmitter

The memory must to be empty in order to perform this procedure.

The added transmitter will have the double-channel function.

OPEN (STOP) ►

CLOSE (STOP) ►

P3

Press once P3 button of a transmitter for 2

sec. within 30 seconds from power on.

The buzzer emits a continuous sound.

Press any button of the pair to memorize. Once

the memorization is successfully completed,

the buzzer emits a fast intermittent sound.

P3 button is

located inside the

transmitter

< 5 s

...

continuous

sound intermittent sound

new

6x

ON

P2

13

(CH4)

In case of using bidirectional transmitters it’s possible

to receive a feedback about the door status, shown by

means of the transmitter’s LED:

- Red led: open door

- Blue led: closed door

- Flashing led: missing feedback

Warning: the remaining free buttons of the transmitter

should be memorized using the procedures 4.1, 4.2 or 4.3.

4.8 Single channel: door status request (“ASK”)

TRTXI868xx04TRTXP868x04

DOOR STATUS REQUEST (“ASK”)

ASK

Press P2 seven times and keep it pressed.

The buzzer emits a continuous sound.

Press any button of TRTXP or CH4 of TRTXI.

Once the memorization is successfully completed,

the buzzer emits a fast intermittent sound.

continuous sound

...

( )

keep it pressed

intermittent sound

button to

memorize

4.7 Alarm function: shock sensor memorization

The wireless shock sensor (optional) detects any

attempt of breaking or entering and send a signal

to the control unit that will activate the speaker

(optional) for 1 minute. L6 flashes. It is possible

to set the sensor sensitivity by means of the dip

switches (see at side). Sending any opening or

closing door command will stop the alarm.

Warning: optional speaker must be connected!

ON

2

1

Press P2 eight times and keep it pressed.

The buzzer emits a continuous sound.

Activate the shock sensor.

Once the memorization is successfully completed,

the buzzer emits a fast intermittent sound.

continuous sound

...

( )

keep it pressed

intermittent sound

DIP1 DIP2 Sensitivity

Off Off High

On Off Medium

Off On Low

On On Extra-low

TVSSH868A01

ACTIVATE THE

SHOCK SENSOR

Only for TVSSH868A01 (with BST25S is not

necessary the shock sensor memorization).

The garage door must

be completly close.

8x

7x

P2

P2

14

5. TRANSMITTERS DELETION

5.1 Deleting a single transmitter

Press P2 four times and keep it pressed.

The buzzer emits an intermittent sound.

Press the button of the transmitter to delete.

Once the deletion is successfully completed,

the buzzer emits a continuous sound.

continuous sound

...

( )

keep it pressed

intermittent sound

P2

button to

delete

5.2 Deleting all the transmitters

Press P2 five times and keep it pressed for at

least 10 seconds.

The buzzer emits an intermittent sound.

Release the button once the sound becomes

continuous.

continuous sound

...

( 10 s )

keep it pressed

intermittent sound

P2

after

10 seconds

Press 3 times P3 button of a

memorized transmitter and keep it

pressed for 2 sec. The buzzer emits a

slow intermittent sound.

Press the button of the transmitter

to delete within 5 sec.

Once the deletion is successfully completed,

the buzzer emits a continuous sound.

< 5 s

...

intermittent sound

continuous

sound

to delete

5.3 Remote deletion of a transmitter

In order to carry the transmitter deletion out it is necessary use the P2 button of the front

cover, entering the “programming mode” first.

P3

P3 button is

located inside the

transmitter

memorized

WARNING: always check that L7 is flashing before carry the following deletions out!

If no further button is pressed within 10 seconds the control unit exits automatically the programming mode.

Press P2 five times and keep it pressed

for at least 5 seconds. L7 starts flashing.

( 5 s )

keep it pressed

P2

ENTERING THE PROGRAMMING MODE

L7 flashes

...

P2

(STOP)

5x

4x

5x

3x

15

6.1 Auto close time setting

This procedure configures the time lapse between complete opening and the automatic closure (if enabled).

The default time is 30 seconds. It is possible to set the time from 5 seconds to 180 seconds.

Press P3 button of a memorized transmitter and keep it pressed for 5 seconds. The buzzer will emit one beep.

Release and press it again eight times within 5 seconds and keep it pressed for 2 seconds. The buzzer will make two

beeps at the end. In case of time-out, the control unit will sound four beeps and exit the procedure automatically.

Press once P3 to start the counting of time. The buzzer will make one beep.

Press again P3 to stop the counting after the desired lapse. The value will be memorized by the control unit.

START STOP

6.2 Courtesy light time setting

This procedure configures the time of activation of the courtesy light (internal and external, if present).

The default time is 90 seconds. It is possible to set the time from 60 seconds to 12 hours.

within 5 sec.

8x

keep it (*)

pressed

( 5 s)

Press P3 button of a memorized transmitter and keep it pressed for 5 seconds. The buzzer will emit one beep.

Release and press it again five times within 5 seconds and keep it pressed for 2 seconds. The buzzer will make three

beeps at the end. In case of time-out, the control unit will sound four beeps and exit the procedure automatically.

Press once P3 to start the counting of time. The buzzer will make one beep.

Press again P3 to stop the counting after the desired lapse. The value will be memorized by the control unit.

P3 button is

located inside the

transmitter

P3

memorized P3

memorized P3

memorized P3

memorized

keep it

pressed

( 2 s)

START STOP

5x

P3

memorized P3

memorized P3

memorized P3

memorized

within 5 sec.

keep it (*)

pressed

( 5 s)

P3 button is

located inside the

transmitter

keep it

pressed

( 2 s)

(*)The procedure can be executed only within 30 seconds from power on.

(*)The procedure can be executed only within 30 seconds from power on.

ON

ON

16

7.1 “Holiday mode”

The “Holiday mode” allows the user to temporarily lock the front cover buttons.

Note: when the mode is activated, wireless and wired input commands are still enabled.

ACTIVATION

Press the P2 button in the front cover and keep it

pressed for 5 seconds.

The buzzer makes one beep and L5 starts to flash.

DEACTIVATION

Press P2 button in the front cover and keep it pressed

for 5 seconds. In case of any transmitters have been

not memorized the deactivation is automatic. In case of

at least one transmitter has been memorized the buzzer

makes one beep and L5 starts to flash faster. Press any

button of any memorized transmitter within 10 seconds.

The buzzer makes one beep and L5 turns off.

memorized

WARNING: always check that L7 is solid ON before carry this procedure out!

7.2 Control unit reset

The following procedure configure all the parameters back to the factory settings.

The reset doesn’t include the radio code deletion.

Switch the control unit off.

Press together P1 and P2 and keep them pressed.

Switch the control unit on, keeping P1 and P2

pressed.

The buzzer makes one beep after 10s.

P2

P1

keep

pressed

...

< 10 s

5 s

...

5 s

+

10 s

17

The above mentioned product must be installed only by qualified technical personnel in compliance with

the standards of automatic openings. All connections must be rated for a single-phase power supply of

230V. For the disconnection from the power line, use an all-pole switch with contact with an opening of

at least 3.5 mm. Only suitable materials for the connections must be used to guarantee insulation that

complies with current standards on the subject of electrical safety. All the necessary safety devices are to

be seen separately. Incorrect wiring will cause incorrect functioning impairing the safety purpose for which

the product has been designed so that people injuries could occur; failure to follow instructions can cause

personal injury and/or property damage. The correct functioning of the product must be checked once a

year. Keep the 230V wires separately from the low voltage safety wires. The earth-wires must be fixed with

an additional fastening on the terminals; this fastening has to be done by qualified technical personnel during

the installation phase. The appliance has been tested with a power supply wire type H05VV-F; the power

supply wires for outdoor use have not to be lighter than the ordinary wires type H05RN-F. The safety devices

have to be in conformity with EN12978. The installation of the control unit has to be done by fixing the box

vertically with the cable glands downwards. The product is in conformity with the RAEE and RoHS directive.

The earth wire must be longer than the other wires because it must be the last to break off if the cable clamps

are slack. Remember that there are specific standards that must be complied with both as regarding the

safety of the electrical systems and as regarding the remote control of tubular motors for roller blind.

In the view of a constant development of their products, the manufacturer reserves the right for changing

technical data and features without prior notice.

8.1 WARNINGS

8. TECHNICAL SPECIFICATIONS

Power supply 230V~ - 50Hz

Operating temperature range -20°C ÷ +50°C

Protection rating IP20

Motor characteristics:

Voltage 230V~

Maximum power 700W

Maximum output power for light output 300W - resistive load (230V~)

Reception frequency 868.3MHz

Radio memory capatibility (transmitters) 32

Wireless safety system

Functioning range 10m

Answering time in manoeuvre < 100ms

Carrier frequency 2.4GHz

Power supply 2 x 1.5V AA or 2 x 3.6V lithium batteries

Consumption when transmitting 13mA

The manufacturer, Teleco Automation s.r.l, declares that the type of radio equipment is compliant with

Directive 2014/53/EU. The full text of the EU compliance declaration is available at the following Internet

address: www.telecoautomation.com/ce.

The connection between the control unit and the auxiiliary device must be done using double

insulated cables. The auxliary device connected must be a Class II device.

In case of an external aerial is connected the connections must be done using double insuleted

cables.

18

9. TROUBLESHOOTING (What to do if...)

Acoustic signals from the control unit

Sequence Meaning Solution

1 costant beep

(continuous or

intermittent)

Faulty control unit Replace the control unit

2 beeps Motor problem - Set the limit switches

- The thermal protection could be activated. Wait while the

motor cools down.

- Check the motor connection

- Test the motor separately by means of a proper tool

3 beeps at

startup

Radio receiver is empty Memorize at least one transmitter

4 beeps

(L1 = OFF)

Radio receiver is full Max. number of transmitter exceeded

4 beeps

(L1 = ON)

Safety test failure: wired

safety edge

- Check the rubber profile general condition

5 beeps

(L2 = ON)

Safety test failure:

wireless safety edge

system

Control unit checks

- The radio card (master) must be correctly inserted in the

plug: check all the pins

- The radio card (master) must be paired with the bottom slat

transmitter (slave)

Bottom slat transmitter checks

- Check type, polarity and charge level of the batteries

- Check functionality by pressing the button

- Check the DIP1 position (at par. 2.2)

- Check wiring between bottom slat transmitter and sensitive

edge (terminals and wire colour)

Sensitive edge checks

- Check the rubber profile general condition

- Check the functionality by means of the testing procedure

with DIP2 (at par. 2.2)

5 quick beeps

every 5 seconds

(L4 flashes)

Low batteries in the

bottom slat transmitter

Replace the batteries as soon as possible. Pay attention to

the polarity.

6 beeps

(L3 = ON)

Safety test failure:

emergency STOP (TB)

Check the safety device connected and the connections

8 beeps Limit switch error: the

manoeuvre exceeded

the working time.

Check the limit switches and, in case, set them again

9/10 beeps One of the relay is

defective (see the

diagram at page 6)

Replace the control unit

19

WARNING: in case that the safety devices (except for TB input) are defective or they have been

activated, it is possible to operate the door anyway, keeping pressed the command button for more

than 5 seconds. The control unit will automatically switch to hold-to-run mode.

Other possible issues

Problem Solution

None of the previous signals, but

the door doesn’t move downward

Command an opening manoeuvre until the top limit has reached.

In the closure, the door hits the

floor and opens again

- The bottom limit could be too low, adjust it upwards

- In case of uneven floor use the procedure 3.3 to deactivate the safety

edge in the last part of the closure. It is necessary to command the

closure starting from the upper limit switch in order to be effective.

The door can be operated but the

safety systems don’t activate

Check the motor direction. If wrong, swap brown and black motor wires

over (terminals 5 & 7)

The control units responds to the

commands sent by transmitters,

but the front cover is not

functioning

If L5 led flashes, the “holiday mode” is activated

The fuse blows while operating

the door

Check again the wirings

Radio card (MASTER)

Led in the front cover

L1 led Flashing: normal functioning.

ON: transmission error or drained batteries.

L2 led ON: activated safety alarm, transmission error or

drained batteries.

OFF: normal functioning.

L3 led Not used.

L3 led

L2 led

L1 led

LED Meaning

L1 Not used

L2 Safety test failure: wireless safety edge system

L3 Safety test failure: emergency STOP (TB input)

L4 Low batteries in the bottom slat transmitter

L5 “Holiday mode” activated

L6 Alarm from vibration sensor (see par. 4.7)

L7 Solid ON = powered ; Flashing = Programming mode or limit

configuration

telecoautomation.com

Branches:

Teleco Automation France - France

Teleco Automation GmbH - Germany

Teleco Automation Oceania Pty Ltd - Australia

Headquarters:

Teleco Automation Srl - Italy

Table of contents

Languages:

Other TELECO AUTOMATION Control System manuals

Popular Control System manuals by other brands

Leeson

Leeson SPEEDMASTER WASHGUARD 174102 Operation manual

Pilz

Pilz PSSu E F 2DOR 8 operating manual

Mente Marine

Mente Marine ACS R/RP user manual

Lathem

Lathem PC600 Series quick start guide

Siemens

Siemens SIMATIC 6ES7673-2CC40-0YA0 Hardware Installation and Operating Manual

Nuvation Energy

Nuvation Energy Grid Battery Controller installation guide