2

PRODUCT DESCRIPTION

1

TVNRG868E04

Control unit with integrated radio receiver for the remote control of tubular motors up to 450W, with built-in limit switch, for rolling shutters and rolling doors.

FEATURES

- Compact plastic case with easy fixing

- Front cover with buttons for up/stop/down commands and

LED for alarms status

- Integrated LED courtesy light

- Wireless control via radio transmitters

- Wireless safety edge with auto-test

- Bidirectional communication: door status is shown by the

transmitter LED with different colour

- Alarm function, in combination with shock sensor (TVSSH868A01 and

BST25S) and integrated speaker

W

i

r

e

l

e

s

s

s

y

s

t

e

m

e

a

s

y

t

o

c

o

n

n

e

c

t

W

i

r

e

l

e

s

s

s

a

f

e

t

y

s

y

s

t

e

m

F

r

o

n

t

c

o

v

e

r

w

i

t

h

u

p

/

s

t

o

p

/

d

o

w

n

b

u

t

t

o

n

s

O

p

t

i

o

n

a

l

a

l

a

r

m

b

u

z

z

e

r

t

o

b

e

fi

t

t

e

d

i

n

t

h

e

c

a

s

e

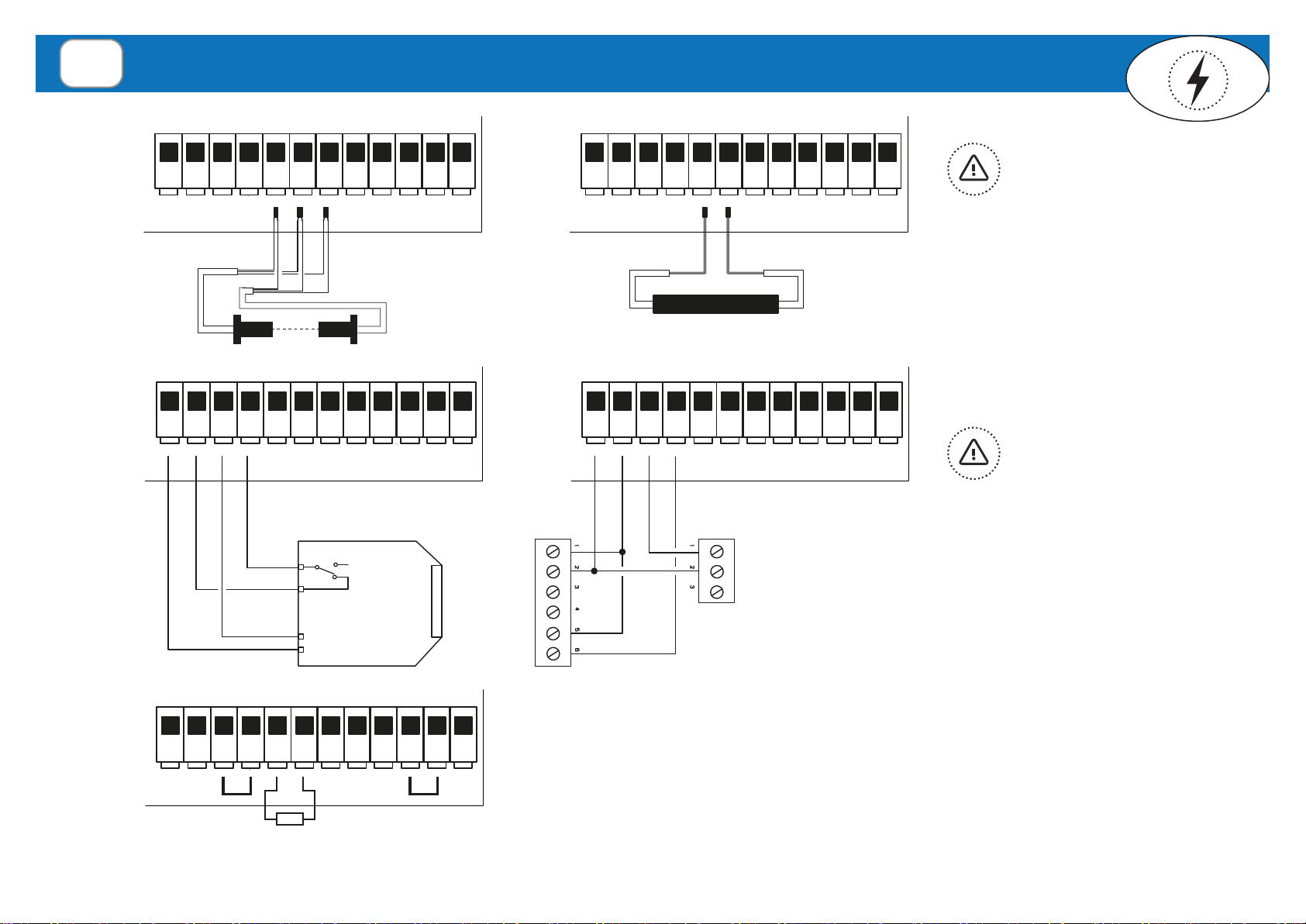

CONNECTIONS & FUNCTIONING

- Wired inputs for safety edge (both resistive 8K2 and infrared)

- Wired inputs for command push-button and emergency STOP push-button

- Possibility to connect an external 240Vac courtesy light

- 2 Functioning modes: semi-automatic (automatic opening + hold-to-run

closing) and automatic

- Automatic closing with programmable pause time

- Exclusion of the safety edge in the last part of the closure, in case of bumpy

floor

- Motor torque control

- “Holiday mode” to lock the control unit with the front cover

INDEX

1. Product description ----------------------------------------------------------------page 2

2. Installation -----------------------------------------------------pages 3 - 8

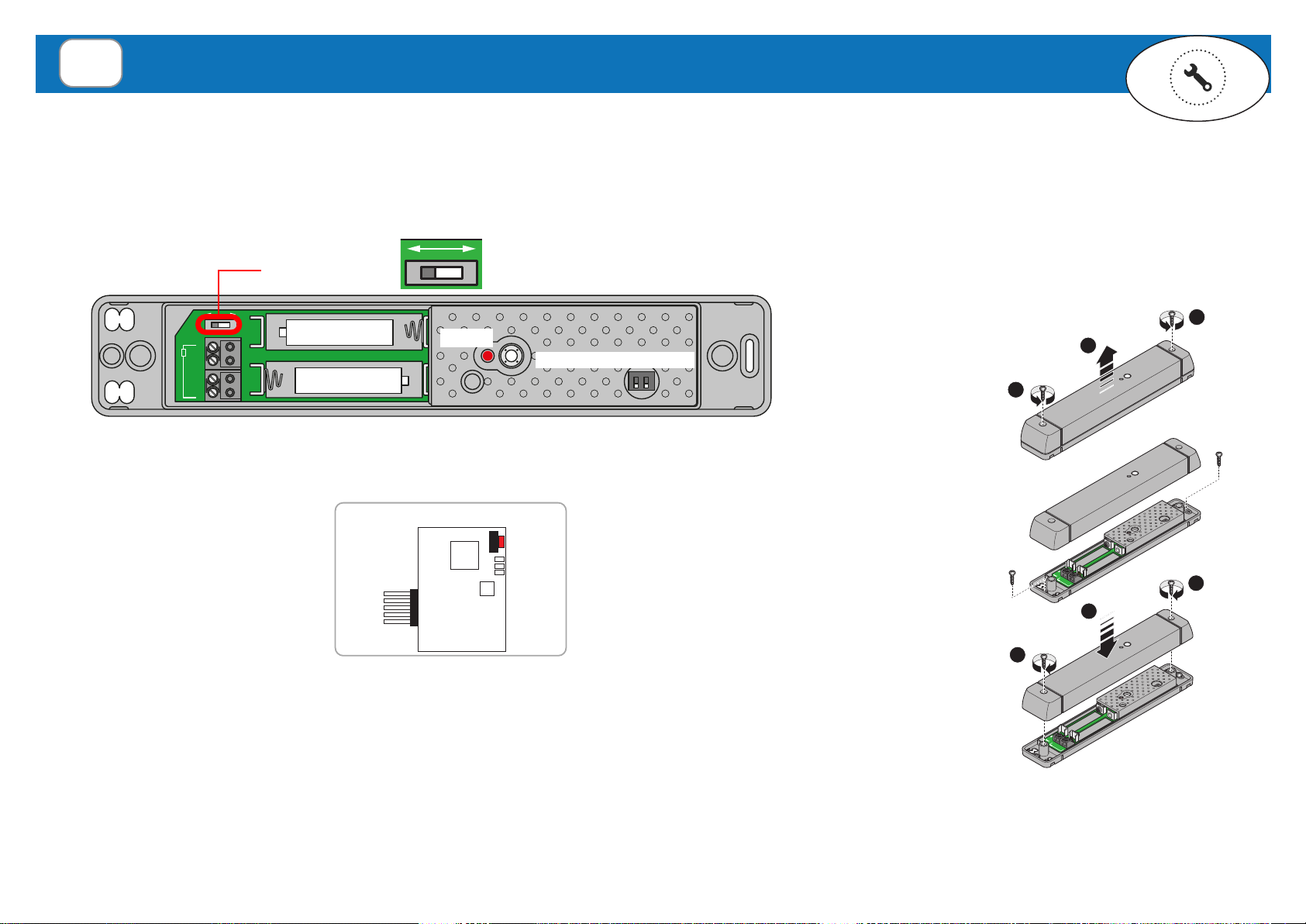

2.1 Mounting the product

2.2 Control Unit diagram

2.3 Electrical connections

2.4 Wired safety device connections

2.5 Mounting the wireless “shock” safety system (BST26)

3. Preliminary check and initial start-up ---------------------------------------------pages 9 - 10

3.1 Limit switch configuration and direction check

3.2 Matching of the wireless safety device system & Activation/Deactivation

3.3 Functioning mode

3.4 Exclusion of safety edge

4. Transmitters & memorization -----------------------------------------------------pages 12 - 15

4.1 Radio codes memorization

4.2 Single channel: door status request (ask)

4.3 Alarm function: shock sensor memorization

4.4 Remote memorization of the first transmitter

4.5 Remote memorization of further transmitters

5. Transmitters deletion --------------------------------------page 16

5.1 Remote deletion of a transmitter

6. Time setting ----------------------------------------------------------------page 17

6.1 Auto close time setting

6.2 Courtesy light time setting

7. Other programming --------------------------------------------------------page 18

7.1 Motor torque control

7.2 “Holiday mode”

8. Troubleshooting --------------------------------------------------------page 19

Technical specification