2

Connection

• Connect the motor securely according to the motor connection method

explained in the AR Series Driver OPERATING MANUAL. Failure to do

so may result in fire or electric shock.

• Do not forcibly bend, pull or pinch the cables. Doing so may result in fire

or electric shock.

Repair, disassembly and modification

• Do not disassemble or modify the motor. This may cause electric shock or

injury. Refer all such internal inspections and repairs to the branch or sales

office from which you purchased the product.

Caution

Handling the product without observing the instructions that accompany a

“Caution” symbol may result in injury or property damage.

General

• Do not use the motor beyond its specifications, or electric shock, injury or

damage to equipment may result.

• Do not touch the motor during operation or immediately after stopping.

The surface is hot and may cause a skin burn(s).

Transportation

• Do not hold the motor output shaft or motor cable. This may cause injury.

Installation

• Provide a cover over the rotating parts (output shaft) of the motor to

prevent injury.

• To prevent the risk of damage to equipment, leave nothing around the

motor that would obstruct ventilation.

Operation

• Do not touch the rotating parts (output shaft) of the motor during operation.

This may cause injury.

• Provide an emergency stop device or emergency stop circuit external to

the equipment so that the entire equipment will operate safely in the event

of a system failure or malfunction. Failure to do so may result in injury.

• The motor’s surface temperature may exceed 70 °C

(158 °F), even under normal operating conditions. If a

motor is accessible during operation, post a warning

label shown in the figure in a conspicuous position to

prevent the risk of skin burn(s).

Warning label

• For the power supply input to the electromagnetic brake, use a DC power

supply with reinforced insulation on the primary side.

Maintenance and inspection

• To prevent the risk of electric shock, do not touch the terminals while

measuring the insulation resistance or conducting a voltage-resistance test.

Disposal

• To dispose of the motor, disassemble it into parts and components as much

as possible and dispose of individual parts/components as industrial waste.

Precautions for use

• Conduct the insulation resistance measurement or withstand

voltage test separately on the motor and the driver.

Conducting the insulation resistance measurement or withstand voltage test

with the motor and driver connected may result in injury or damage to

equipment.

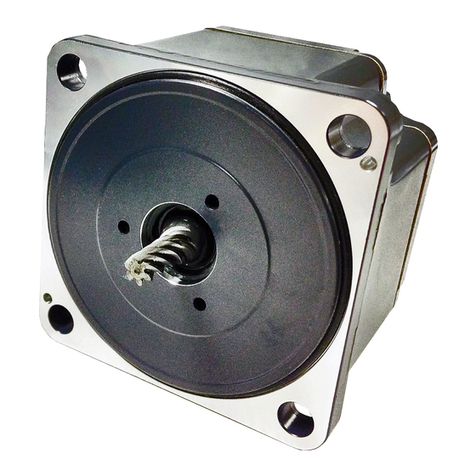

• Do not apply an overhung load and thrust load in excess of the

specified permissible limit.

Operating the motor under an excessive overhung load and thrust load may

damage the motor bearings (ball bearings). Be sure to operate the motor

within the specified permissible limit of overhung load and thrust load. See

page 4 for details.

• Use the motor in conditions where its surface temperature will not

exceed 100 °C (212 °F).

The driver has an overheat-protection function, but the motor has no such

feature. The motor case’s surface temperature may exceed 100 °C (212 °F)

under certain conditions (ambient temperature, operating speed, duty cycle,

etc.). To prevent the motor bearings (ball bearings) from reaching its usable

life quickly, use the motor in conditions where its surface temperature will

not exceed 100 °C (212 °F).

Use the harmonic geared type motor in a condition where the gear case

temperature does not exceed 70 °C (158 °F), in order to prevent deterioration

of grease in the gear.

If the motor is to be operated continuously, install the motor in a location

where heat dissipation capacity equivalent to a level achieved with a heat

sink [made of aluminum, 250 × 250 × 6 mm (9.84 × 9.84 × 0.24 in.)] is

ensured.

• Maximum static torque at excitation

Maximum static torque at excitation represents a value obtained when the

motor is excited using a rated current. When combined with a dedicated

driver and while the motor is stopped motor temperature increases are

suppressed due to a current reduction of approximately 50% by the current

cutback function. Acceleration and operation at the maximum static torque at

excitation is possible in start-up, but it has approximately 50% holding power

after it has stopped. When selecting a motor for your application, consider the

fact that the holding power will be reduced to approximately 50% after the

motor has stopped.

• Do not use the electromagnetic brake to reduce speed or as a

safety brake.

Do not use the electromagnetic brake as a means to decelerate and stop the

motor. The brake hub of the electromagnetic brake will wear significantly

and the braking force will drop. The electromagnetic brake is of power-off

activated type. This means that although it helps maintain the position of the

load in the event of power outage, etc., this brake cannot securely hold the

load in place. Accordingly, do not use the electromagnetic brake as a safety

brake. To use the electromagnetic brake to hold the load in place, do so after

the motor has stopped.

• Double shaft motor

Do not apply load torque, overhung load or thrust load to the output shaft on

the opposite side of the motor output shaft.

• Preventing electrical noise

See AR Series Driver OPERATING MANUAL for measures with regard to

noise.

• Maximum torque of geared type motor

Always operate the geared type motor under a load not exceeding the

maximum torque. If the load exceeds the maximum torque, the gear will be

damaged.

• About grease of geared motor

On rare occasions, a small amount of grease may ooze out from the geared

motor. If there is concern over possible environmental damage resulting from

the leakage of grease, check for grease stains during regular inspections.

Alternatively, install an oil pan or other device to prevent leakage from

causing further damage. Oil leakage may lead to problems in the customer’s

equipment or products.