EcoInsight I, O & M Guide

Telkonet, Inc.

For Use with Firmware Version 2.x

20800 Swenson Drive, Suite 175

EcoSmart Energy Management System

Waukesha, WI 53186

Revision 4.2

(414) 302-2299

Page 3 www.telkonet.com

EcoSmart Energy Management System

The EcoSmart Energy Management System is designed to reduce HVAC energy consumption without interfering

with an occupant’s comfort.

EcoSmart thermostats such as the EcoInsight will automatically learn and adapt to the heating and cooling

patterns of each room. For example, a room on the east side of a building will receive direct sunlight in the

morning and will either need less HVAC heating or more HVAC cooling. However, as the day progresses, the

room will need more HVAC heating or less HVAC cooling as it moves into the shade. An EcoSmart thermostat

will continually monitor the room, learn its patterns, and adjust its heating and cooling profiles accordingly.

EcoSmart thermostats also learn and adapt to occupant schedules. When a room is unoccupied, an EcoSmart

thermostat will enter an energy saving mode, allowing the room to drift away from the desired set point.

During this drift period, the thermostat will operate the HVAC unit less often, reducing energy costs. When the

room becomes occupied again, the EcoSmart Recovery Time™ technology built into each thermostat will return

the room to the set point without the occupant noticing.

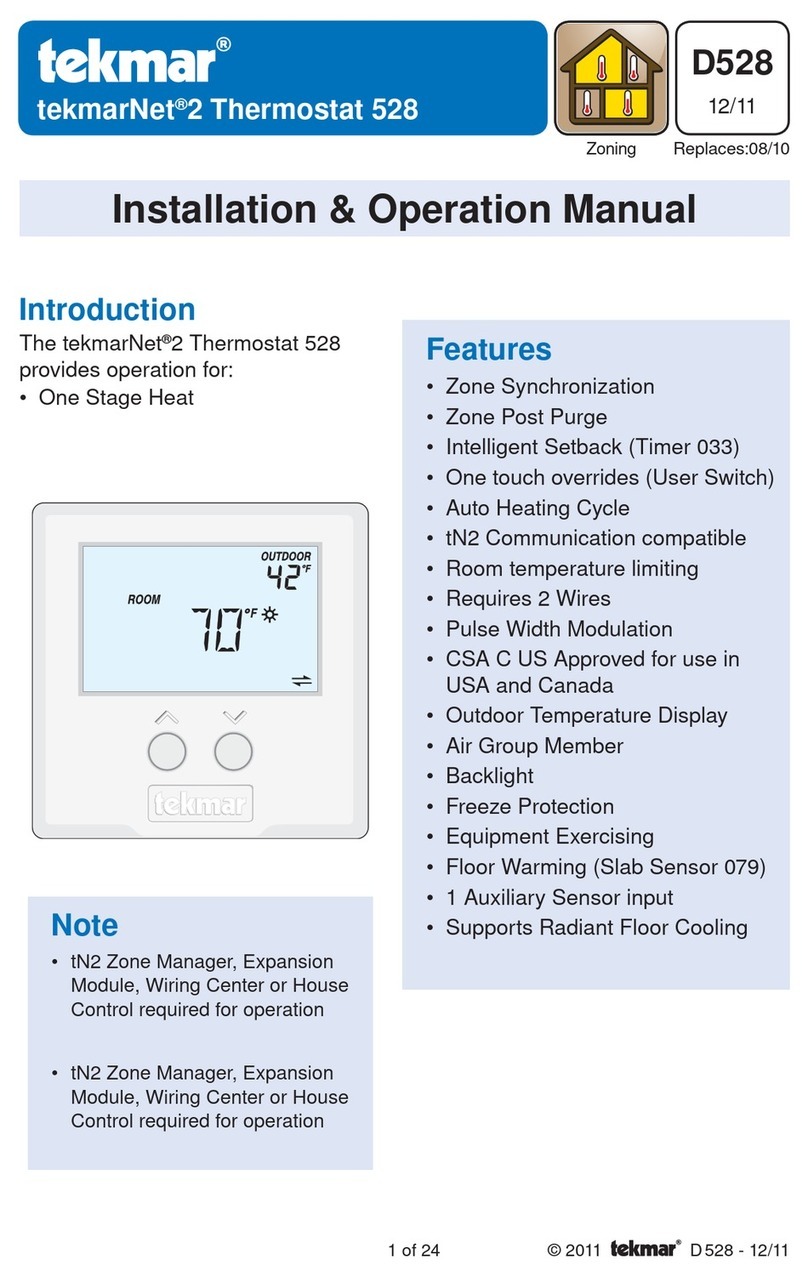

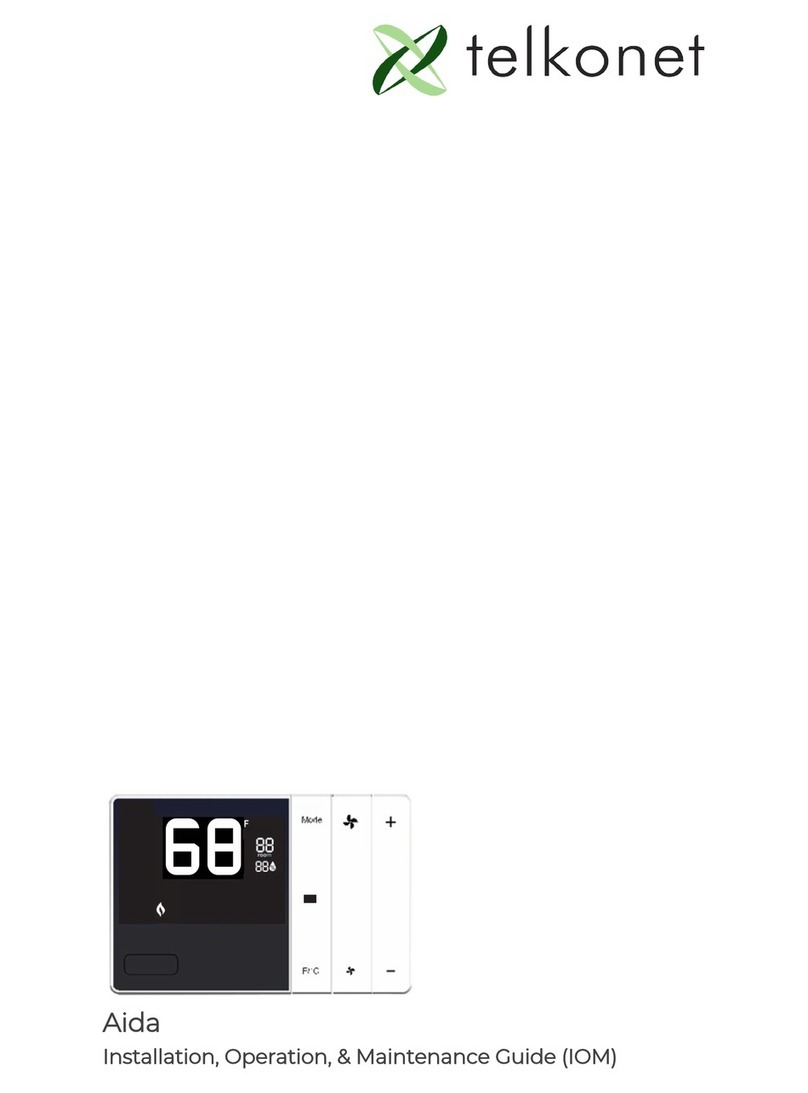

The EcoInsight is available in several possible configurations, to address specific requirements of multiple

applications including hotel, classroom, office, university dormitory, military residence hall, retail, public

area, convention center, and a wide variety of commercial and industrial spaces.

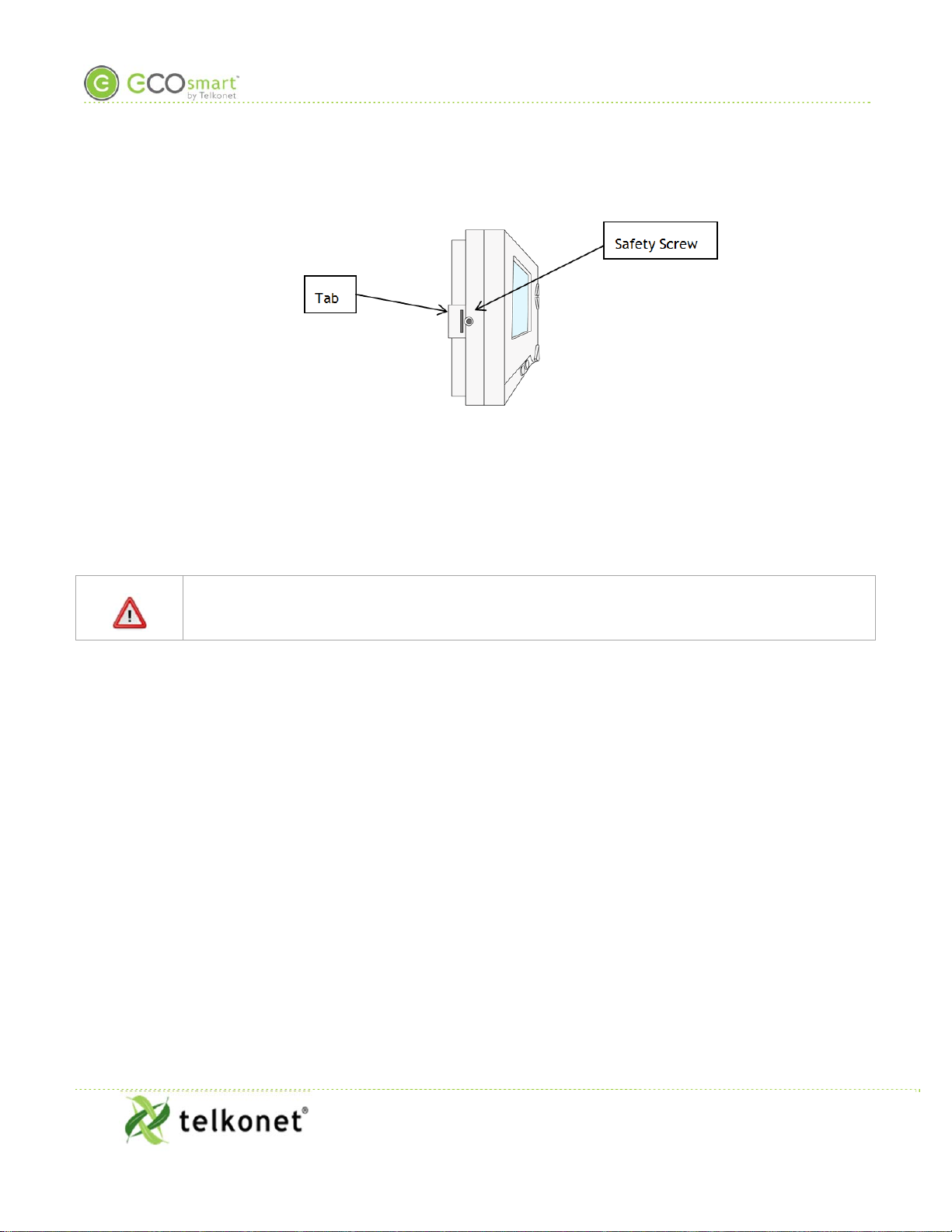

The form factor of all non-networked models is identical, as are the form factors of the networked versions.

Networking options may be added to the base units at any time via a simple retrofit module process.

Additional controls generally used during installation, maintenance, and troubleshooting are available in the

on-screen Maintenance menu.

Regulatory Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

FCC Notice

This equipment has been tested and found to comply with the limits for a class B digital device pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If the equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Consult the dealer or experienced radio/TV technician for help.

In order to maintain compliance with FCC regulations, shielded cables must be used with this equipment.

Operation with non-approved equipment is likely to result in interference to radio and TV reception. The user

is cautioned that changes and modifications made to the equipment without the approval of the manufacturer

could void the user’s authority to operate the equipment.