Telpro PARAGON PRO TROLL 112 User manual

Model 112

53.5 In.

overall

height

28.5 - 51 In.

18 In. overall width

2 Inch shoe

Slide clamp will

handle a load

size from 28.5

to 51 inches.

The Troll®Panel Handler Model 112 makes light work of hustling drywall,

plywood and other heavy building panels around the work site. Its unigue

design locks the load vertically for easy mobility. Patented omni-directional

design makes fast, safe handling of building loads in tight quarters a snap.

The 250 lb. capacity hauls 4 sheets of half-inch board as well as large

banquet tables and solid core doors.

Position the Troll®in the middle of the

load with the SLIDE CLAMP up and

the LEG PIPE down. Lift one end of the

load and place it in the shoe of The

Troll®.

Move the SLIDE CLAMP down on the

SLIDE POLE to secure the load.

Hold the SLIDE CLAMP down with

one hand and use your other hand

to pull up on the SLIDE POLE. This

raises the stand.

Using the Troll®Model 112

SAVES YOUR BACK +

SPEEDS YOUR WORK =

MAKES YOU MONEY!

If you have questions about your Troll®

Model 112, please call us toll free at 1-

800-448-0222. We can also be reached

on the web at www.telproinc.com or by

mail at Telpro Inc., 7251 South 42nd

Street, Grand Forks, ND 58201. Thank

you for choosing the Troll®,

we hope you’re happy with

your purchase.

Step 1

Step 2

Step 3

Just tilt the Troll® back on the swivel

caster, pull it away from the wall and

you’re off. You can use this same tilting

action to position the Troll®for easy

off-loading when you reach your

destination.

Step 5

You’re now ready to roll.

Step 4

Form 42-12-00-00.07-10-02 3DUDJRQ3UR0DQXIDFWXULQJ6ROXWLRQV$OO5LJKWV5HVHUYHG

Parts Breakdown

1. 45-00 UPRIGHT FRAME

2. 45-01 WHEEL BASE ASSEMBLY

(with fasteners)

3. 45-02 FLOOR PLATE(with fasteners)

4. 45-03 LEG PIPE

5. 45-04 SLIDE PIPE (with knob)

6. 45-05 SLIDE CLAMP (with fasteners)

7. 45-06 5” WHEEL (with fasteners)

8. 45-07 5” CASTER (with fasteners)

1

6

5

4

7

2

3

8

Attach the FLOOR PLATE to the

WHEEL BASE.

Fasten the wheeel base to the UP-

RIGHT FRAME using three 1/4” x 3/4”

bolts and 1/4” lock nuts. Finger tighten

only at this time.

Fasten the FLOOR PLATE to the

UPRIGHT FRAME using four 1/4” x 1/2”

bolts and 1/4” lock nuts. Inserting the

bolts will be easier if done in the order

shown. Tighten these bolts securely

using wrenches and do the same for

all other bolt assemblies that are still

only finger tightened.

1st

2nd

2nd

Fasten the FLOOR PLATE to the

WHEEL BASE using two 1/4” x 3/4”

bolts and 1/4” lock nut. Inserting the

bolts will be easier if done in the order

shown. Finger tighten only at thie time.

1st

2nd

Attach the WHEEL BASE, aligning the

holes as shown.

Unpack box and check for assembly

components. (Youwill need two 7/16

wrenches)

1.UPRIGHT FRAME

2. WHEEL BASE

3. FLOOR PLATE

4. LEG PIPE

5. SLIDE PIPE with SLIDE CLAMP

ASSEMBLY

6. HARDWARE

(5) 1/4” x 1/2” (1 extra)

(6) 1/4” x 3/4” (1 extra)

(11) 1/4” locknut (2 extra)

4

5

3

2

1

6

Insert the SLIDE PIPE assembly into

the UPRIGHT FRAME with the KNOB

and CLAMP at the handle end of the

UPRIGHT FRAME.

Retract the LEG ASSEMBLY into the

UPRIGHT FRAME before proceeding to

the next step.

1ST

2ND

Begin by clipping

the LEG PIPE onto

the SLIDE PIPE in the

UPRIGHT FRAME assembly.

Clip the two pieces fully together and

slide the leg assembly fully into the

UPRIGHT FRAME.

the LEG PIPE onto

the SLIDE PIPE in the

3RD

4TH

5TH

6TH

7TH

8TH

9TH

Parts Breakdown

1. 45-00 UPRIGHT FRAME

2. 45-01 WHEEL BASE ASSEMBLY

(with fasteners)

3. 45-02 FLOOR PLATE(with fasteners)

4. 45-03 LEG PIPE

5. 45-04 SLIDE PIPE (with knob)

6. 45-05 SLIDE CLAMP (with fasteners)

7. 45-06 5” WHEEL (with fasteners)

8. 45-07 5” CASTER (with fasteners)

1

6

5

4

7

2

3

8

Attach the FLOOR PLATE to the

WHEEL BASE.

Fasten the wheeel base to the UP-

RIGHT FRAME using three 1/4” x 3/4”

bolts and 1/4” lock nuts. Finger tighten

only at this time.

Fasten the FLOOR PLATE to the

UPRIGHT FRAME using four 1/4” x 1/2”

bolts and 1/4” lock nuts. Inserting the

bolts will be easier if done in the order

shown. Tighten these bolts securely

using wrenches and do the same for

all other bolt assemblies that are still

only finger tightened.

1st

2nd

2nd

Fasten the FLOOR PLATE to the

WHEEL BASE using two 1/4” x 3/4”

bolts and 1/4” lock nut. Inserting the

bolts will be easier if done in the order

shown. Finger tighten only at thie time.

1st

2nd

Attach the WHEEL BASE, aligning the

holes as shown.

Unpack box and check for assembly

components. (Yow will need two 7/16

wrenches)

1.UPRIGHT FRAME

2. WHEEL BASE

3. FLOOR PLATE

4. LEG PIPE

5. SLIDE PIPE with SLIDE CLAMP

ASSEMBLY

6. HARDWARE

(5) 1/4” x 1/2” (1 extra)

(6) 1/4” x 3/4” (1 extra)

(11) 1/4” locknut (2 extra)

4

5

3

2

1

6

Insert the SLIDE PIPE assembly into

the UPRIGHT FRAME with the KNOB

and CLAMP at the handle end of the

UPRIGHT FRAME.

Retract the LEG ASSEMBLY into the

UPRIGHT FRAME before proceeding to

the next step.

1ST

2ND

Begin by clipping

the LEG PIPE onto

the SLIDE PIPE in the

UPRIGHT FRAME assembly.

Clip the two pieces fully together and

slide the leg assembly fully into the

UPRIGHT FRAME.

the LEG PIPE onto

the SLIDE PIPE in the

3RD

4TH

5TH

6TH

7TH

8TH

9TH

Model 112

53.5 In.

overall

height

28.5 - 51 In.

18 In. overall width

2 Inch shoe

Slide clamp will

handle a load

size from 28.5

to 51 inches.

The Troll®Panel Handler Model 112 makes light work of hustling drywall,

plywood and other heavy building panels around the work site. Its unigue

design locks the load vertically for easy mobility. Patented omni-directional

design makes fast, safe handling of building loads in tight quarters a snap.

The 250 lb. capacity hauls 4 sheets of half-inch board as well as large

banquet tables and solid core doors.

Position the Troll®in the middle of the

load with the SLIDE CLAMP up and

the LEG PIPE down. Lift one end of the

load and place it in the shoe of The

Troll®.

Move the SLIDE CLAMP down on the

SLIDE POLE to secure the load.

Hold the SLIDE CLAMP down with

one hand and use your other hand

to pull up on the SLIDE POLE. This

raises the stand.

Using the Troll®Model 112

SAVES YOUR BACK +

SPEEDS YOUR WORK =

MAKES YOU MONEY!

If you have questions about your Troll®

Model 112, please call us toll free at 1-

800-448-0222. We can also be reached

on the web at www.telproinc.com or by

mail at Telpro Inc., 7251 South 42nd

Street, Grand Forks, ND 58201. Thank

you for choosing the Troll®,

we hope you’re happy with

your purchase.

Step 1

Step 2

Step 3

Just tilt the Troll® back on the swivel

caster, pull it away from the wall and

you’re off. You can use this same tilting

action to position the Troll®for easy

off-loading when you reach your

destination.

Step 5

You’re now ready to roll.

Step 4

Form 42-12-00-00.07-10-02 © 2002, Telpro Inc. All Rights Reserved

Chemical Hazard CAS# % By Weight

Arsenic Cancer 7440-38-2 Trace

Cadmium Develpmental 7440-43-9 Trace

Chromium Cancer, Developmental 7440-47-3 Trace

Ethylbenzene Cancer 100-41-4 Trace

Lead Cancer 7439-92-1 Trace

Methanol Developmental 67-56-1 Trace

Methylene Chloride (Dichloromethane) Cancer 75-09-2 Trace

Nickel Cancer 7440-02-0 Trace

Propylene glycol monobutyl ether Cancer 5131-66-8 Trace

Toluene Developmental 108-88-3 Trace

This product contains trace amounts of the following items which are known to cause

cancer and/or developmental harm in the state of California.

These chemicals are not hazardous under product's intended use.

Please review CAS# for PRUHLQIRUPDWLRQ

Questions? Contact Us:

www.industrialproducts.com

888-243-3339

sales@industrialproducts.com

Other Telpro Lifting System manuals

Popular Lifting System manuals by other brands

Nexus 21

Nexus 21 L-75ix installation manual

Blue Giant

Blue Giant H7012 Installation & technical manual

Denios

Denios XH manual

FACAL

FACAL CAPO-1 Use and maintenance handbook

Pinguely-Haulotte

Pinguely-Haulotte HA20PX Operating and maintenance instructions

Extreme Max

Extreme Max 5001.5041 operating instructions

AUTOLIFT PRODUCTION

AUTOLIFT PRODUCTION EASYLift 1500 manual

3M

3M DBI SALA Pro Series User instructions

AccessRec

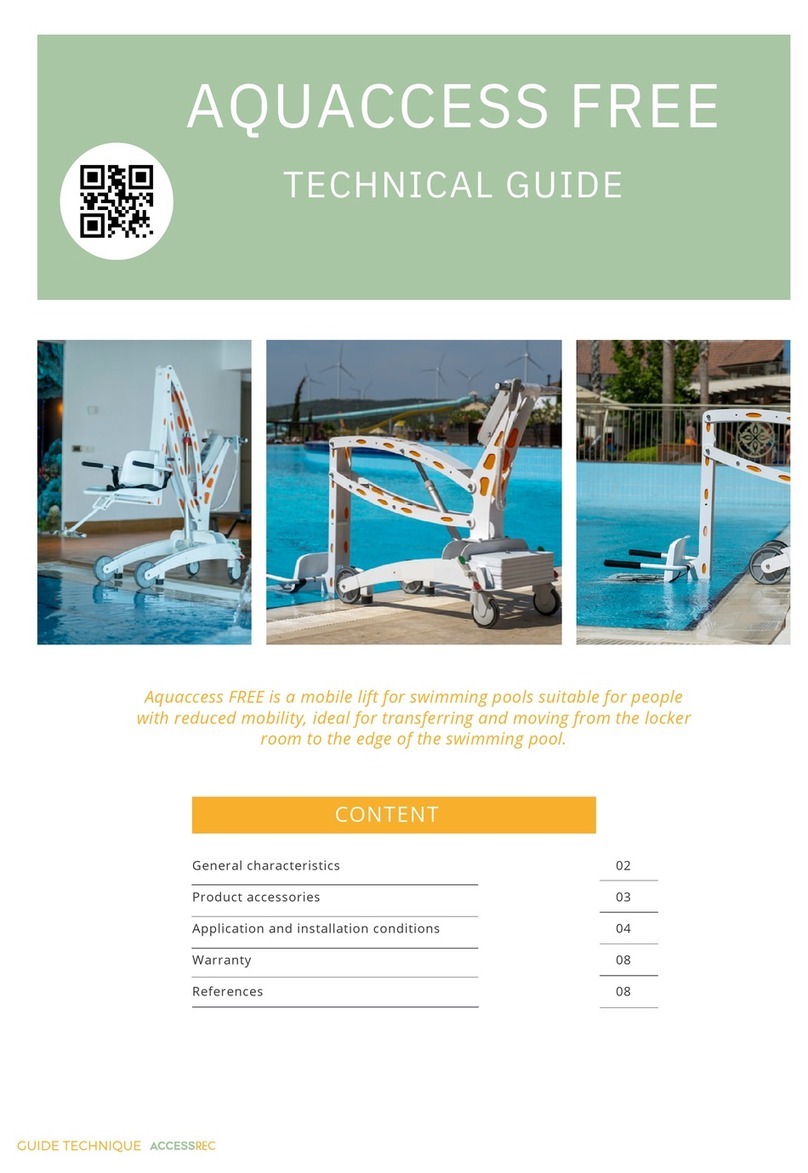

AccessRec AQUACCESS FREE Technical guide

Avanti

Avanti SWP L02 CE-AECO Service manual

U-Line

U-Line Presto Lifts P3 All Around Installation, operation and service manual

Guldmann

Guldmann GLS5.2 user manual