Telpro PaneL Lift 439 User manual

OPERATOR’S MANUAL

MADE BY

®

Covered by one or more of the following patents: 3,828,942 5,368,429 5,586,619 5,984,605 7,556,464 7,726,901 Other patents pending.

© 2013 Telpro Inc. All Rights Reserved.Form 42-04-00-00 version 2b

Read and become familiar with this manual BEFORE operating unit.

WARNING

For Model 439

Before operating this equipment, thoroughly read this set of instructions, make sure you

understand them, and only then follow the step-by-step directions. Failure to do so could

result in serious property damage and / or serious bodily injury.

Warning

Read and follow these warnings and the instructions that follow. Failure to do so could

result in serious property damage and/or serious bodily injury.

• Use and maintenance of the PANELLIFT®Drywall Lift shall be

limited to authorized personnel who are trained in the proper

techniques for its safe operation and maintenance and who are

familiar with the various hazards of overhead material handling.

• As with any lifting equipment, ALWAYS WEAR A HARD HAT

when operating the PANELLIFT®Drywall Lift and keep children

away from the work area. Failure to do so could result in serious

bodily injury.

• DO NOT ATTEMPT TO USE YOUR PANELLIFT®Drywall Lift

IF ANY PART IS MISSING, DAMAGED OR WORN. ORDER A

REPLACEMENT PART IMMEDIATELY. Using a PANELLIFT®

Drywall Lift with missing, damaged or worn components can

result in failure of the unit and possibly severe property damage

and/or serious bodily injury.

• INSPECT THE CHAIN ASSEMBLIES BEFORE EACH USE.

REPLACE AT THE FIRST SIGN OF DAMAGE OR WEAR. A

worn, damaged or improperly installed chain can fail resulting in

a sudden and rapid lowering of the lift and the load and possibly

resulting in serious property damage and/or serious bodily injury.

Inspect the chains by extending the lift fully and examining the

full length of each lift chain for signs of damage or wear.

• The weight capacity of the PANELLIFT®Drywall Lift is 200

lbs. (90 kg). DO NOT load the unit beyond this limit. When

loading wallboard (or similar building panels), load only

one sheet of wallboard at a time. Failure to follow this warning

can result in an unstable load and/or damage to the PANELLIFT®

Drywall Lift contributing to a sudden failure of the machine and

serious property damage and/or serious bodily injury.

• DO NOT TAMPER WITH OR ADJUST the torque setting on

the load limiting clutch of the PANELLIFT®Drywall Lift. This is

factory preset for the load range of the intended use of the lift.

Altering this factory setting can subject the drive, lift, and brake

mechanisms of the lift to stresses and loads that they were not

designed to carry. This can result in failure of the unit which

may include a sudden and rapid lowering of the lift and the load

possibly resulting in serious property damage and/or serious

bodily injury.

• DO NOT ROLL a loaded PANELLIFT®Drywall Lift while the

load is raised. Always keep the load lowered until the lift is in

place beneath the space in which the load will be installed. Rolling

a PANELLIFT®Drywall Lift while the load is raised can result

in tipping the lift and load possibly resulting in serious property

damage and/or serious bodily injury.

• Operate the PANELLIFT® Drywall Lift only on hard, flat, level sur-

faces free of obstructions, debris, clutter, pits, holes or openings.

Failure to follow this warning can result in tipping the lift and/or

load possibly resulting in serious property damage and/or serious

bodily injury.

• The PANELLIFT®Drywall Lift is designed exclusively as

a material lift and shall be used for no other purpose. The

PANELLIFT®Drywall Lift is not a personnel lift or platform and

shall not be used as such. Using the PANELLIFT®Drywall Lift for

purposes other than a material lift can subject the unit to stresses

and loads that it was not designed to carry. This can result in

failure of the unit which may include a sudden and rapid lowering

of the lift and the load possibly resulting in serious property

damage and/or serious bodily injury.

• The PANELLIFT®Drywall Lift is made of steel which conducts

electricity. Keep the unit away from live electrical wires. Failure to

do so could result in electrocution.

• Use only factory authorized replacement parts. Installation of

other parts can compromise the safe design of the PANELLIFT®

Drywall Lift and may cause failure of the unit possibly resulting in

serious property damage and/or serious bodily injury.

• Moving the PANELLIFT®Drywall Lift from a cold environment to

a warm one may cause condensation to form on metal surfaces

creating a potential for malfunction. Such malfunction could

possibly result in serious property damage and/or serious bodily

injury: Allow the unit to reach working room temperature and

check to make sure that the winch brake drum is clean and dry

before operating.

• CAUTION: When the winch brake is released the winch will

rotate backward and cradle will rapidly descend. If the winch is

allowed to free-wheel backward, the winch handle can develop

a great deal of rotational speed and potential for injury. To avoid

possible serious personal injury or property damage always

control the winch wheel firmly with the right hand before releasing

the brake. SEE INSTRUCTIONS ON PAGE 6

• DO NOT pass your hand through the spokes on the winch

when operating the unit as this could result in serious bodily

injury.

• Keep hands, hair, and clothing away from chains and movable

telescoping sections.

• BEFORE operating this equipment, thoroughly read

this set of instructions, make sure you understand them,

and only then follow the step-by-step directions.

FAILURE TO READ AND FOLLOW THESE

INSTRUCTIONS could result in failure of the

equipment. Failure of the equipment while the lift is

raised can include a sudden and rapid lowering of

the lift and load possibly resulting in serious property

damage and/or serious bodily injury.

Questions? - Call Telpro Inc. Customer Service at 1-800-448-0822 or 701-775-0551

- 1 -

USER COMPONENTS & SPECIFICATIONS

- 2 -

SEE PAGE 1 FOR IMPORTANT OPERATIONAL WARNINGS

NET WEIGHT

LOADING HEIGHT

MAxIMUM HEIGHT 14’ 5” (439 cm)

15’ 11” (485 cm) w/ optional 18” extension

LOAD RATING 200 lbs. (90 kg) DO NOT EXCEED.

SHEET QUANTITY CAPACITY Single

37” (94 cm)

Approximately 124 lbs. (56 kg)

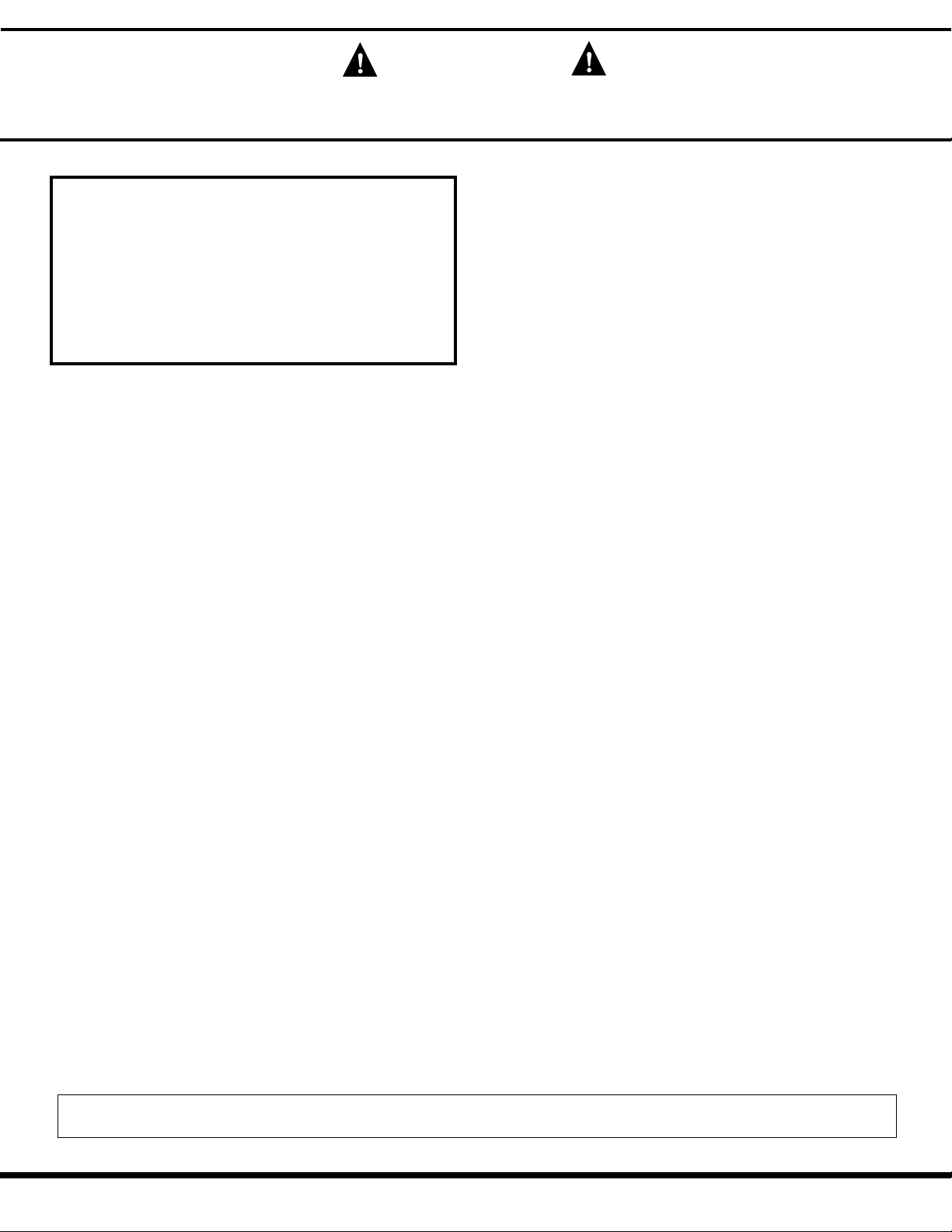

A

B

C

D

A. Cradle Assembly - less detachable cross arms

B. Cradle Cross arms ( 1 pair )

C. Frame Assembly with winch and telescoping sections

D. Tripod Base Assembly

AB

DC

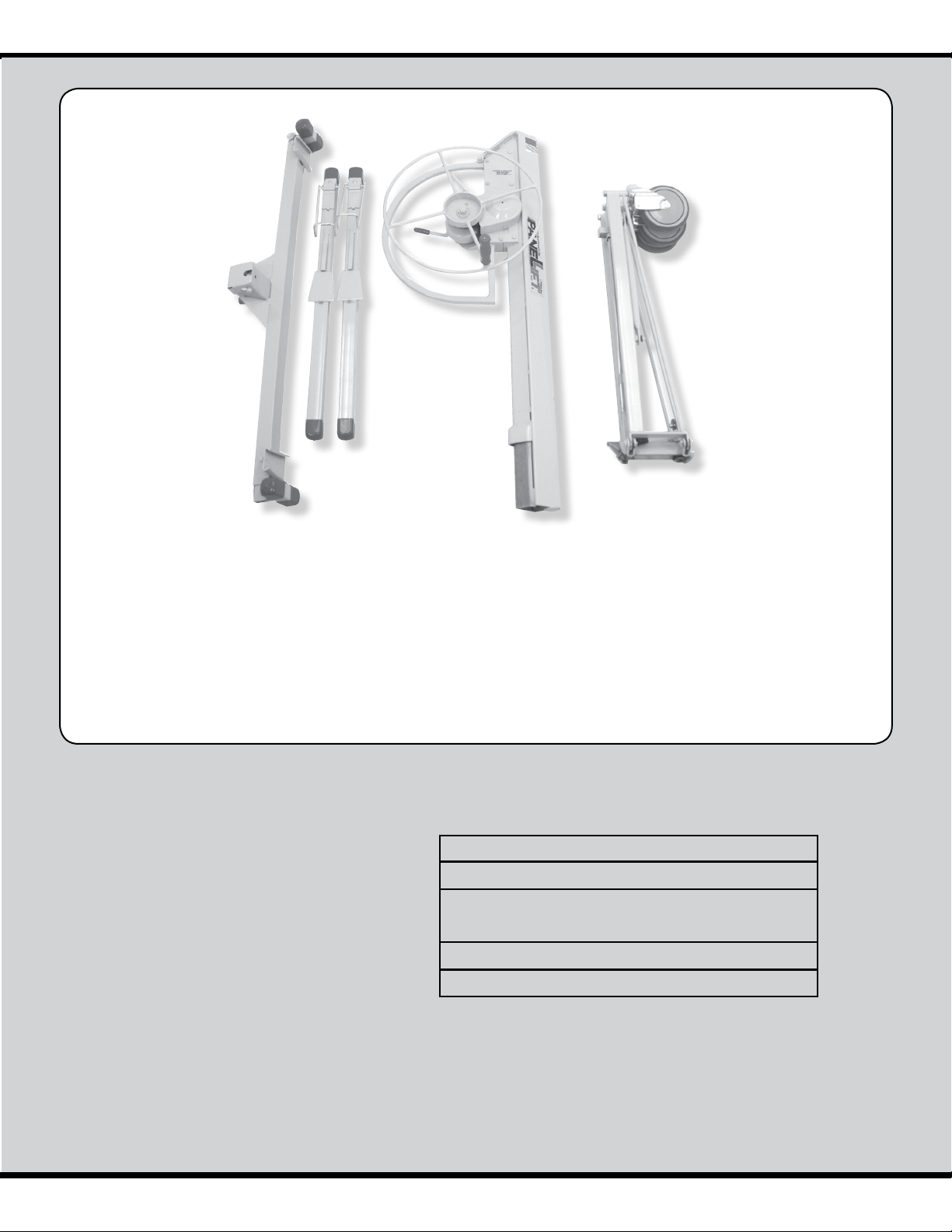

1. Begin by setting up the tripod base: press down on the

slide yoke pin clip and swing the outer legs out until they lock

in the working position (note the holes on the bottom of the

slide tube).

2. Set the backstop as shown to hold the tripod in place

when attaching the frame.

3A. Place the frame assembly on the tripod base.

ASSEMBLY

- 4 -

3B. Pocket “A” slides OVER angle “B” while angle “C”

slides INSIDE angle “D”.

3C. When the frame is correctly positioned on the tripod

base release the backstop.

4A. Release the telescoping section retaining hook by rotating

the winch wheel forward with your right hand while raising the

brake arm with your left hand.

ASSEMBLY continued

- 5 -

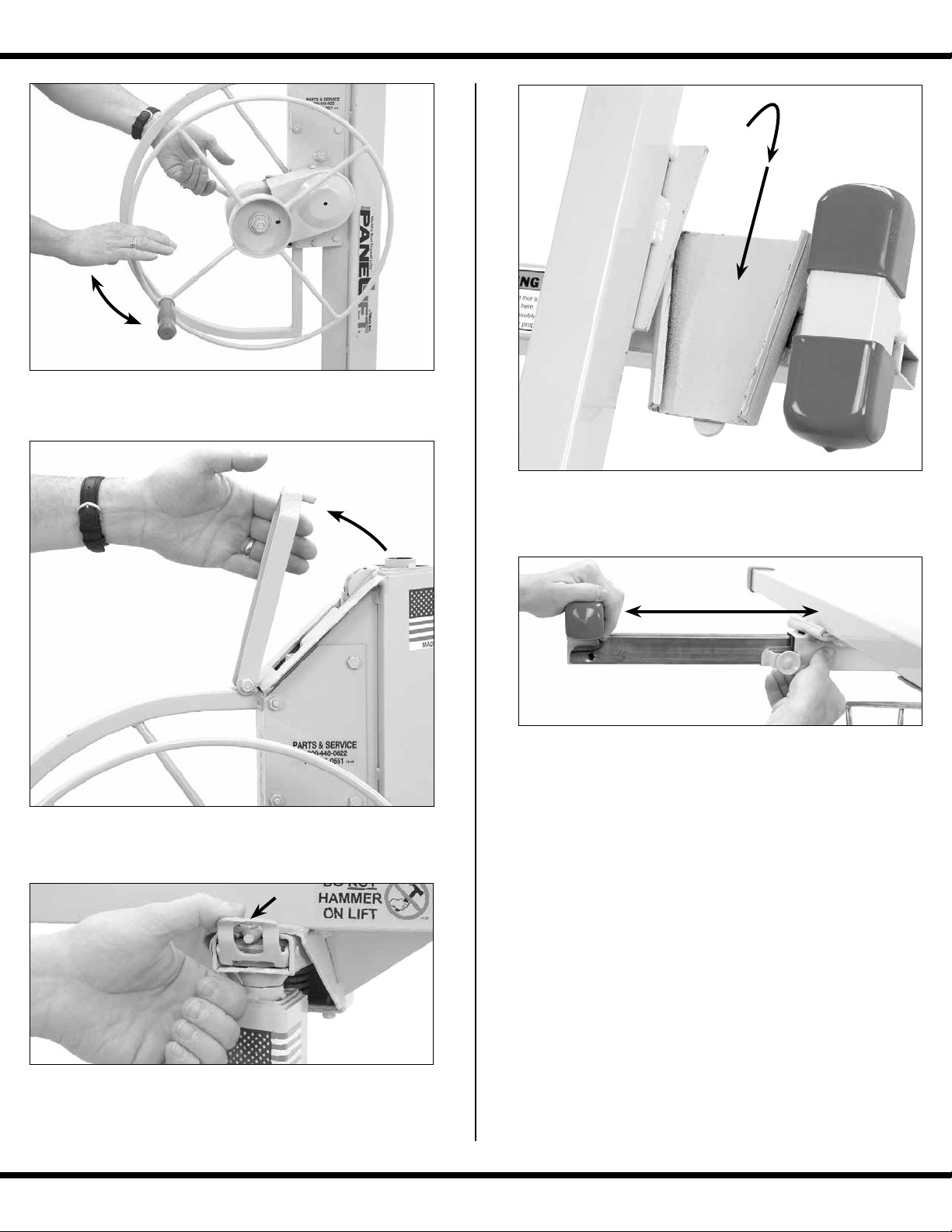

4B. Hold the brake arm in the raised position and allow

the winch wheel to find a neutral position.

Pull

6. Place the tapered plates of the cross arms into the

tapered sockets on the cradle. The spring tab on the

back of the cross arm will lock it into place.

7. To extend the outriggers for use, pull out on the outrig-

ger lock pin with your right hand and slide the outrigger

out with your left hand as shown. The lock pin will engage

at three different points on the outrigger: fully retracted,

extended 21”, or extended 33”. MAKE SURE that the lock

pins are engaged in one of these three positions before

loading the unit. DO NOT use the PANELLIFT®with the

outriggers extended beyond the 33” point.

Retract the outriggers when storing or transporting

the unit.

4C. Release the brake arm and swing the retaining hook

to the open position.

5. Mount the cradle on top of the telescoping section.

Flip out the tilt latch to allow the cradle to tilt for loading

and for hanging drywall on sidewalls and sloped ceilings.

Table of contents

Other Telpro Lifting System manuals

Popular Lifting System manuals by other brands

probst

probst SDH-H-15 operating instructions

Bruno

Bruno OUTDOOR ELITE CRE-2110E Operator's manual

matev

matev FPS Mounting Assembly Installation Guide

Vestil

Vestil CYL-HLT Series instruction manual

Butts Tools

Butts Tools BXS0002 operating instructions

Safelift

Safelift MoveAround MA60 Original instructions

R. Beck Maschinenbau

R. Beck Maschinenbau HS 600 operating manual

Nova Technology International, LLC

Nova Technology International, LLC NAS Series quick start guide

Genie

Genie Z-60/34 Operator's manual

Screen Technics

Screen Technics INTERFIT Vertical Up Lift instructions

Drive

Drive DUPONT SAMERY Hermes user manual

Custom Equipment

Custom Equipment Hy-Brid 3 Series MAINTENANCE & TROUBLESHOOTING MANUAL