Temelsan KN-40 S-MN User manual

KN-40 S-MN BUTT WELDING

MACHINE USER MANUAL

Congratulation to your new TEMELSAN Butt Welding Machine KN-40 S-MN

P a g e | 1

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

INDEX

BASIC INFORMATIONS........................................................................................................................3

APPROPRIATE USE........................................................................................................................3

WARRANTY AND LIABILITY...........................................................................................................4

SAFETY.............................................................................................................................................4

QUALIFIELD PERSONNEL .............................................................................................................4

PLANNING ANG SET-UP................................................................................................................4

OPERATIONS...................................................................................................................................4

SAFETY DEVICES ...........................................................................................................................4

AREAS OF USAGE..........................................................................................................................5

MAINTENANCE................................................................................................................................5

ISSUES..............................................................................................................................................5

SAFETY MEASURED RELATED WITH THE MACHINE...............................................................6

TRANSPORTATION - STORAGE - PACKAGING .....................................................................7

STANDART ACCESSORIES...........................................................................................................9

OPTIONAL ACCESSORIES ............................................................................................................9

REQUIREMENTS OF WORKING PLACE......................................................................................9

FIRST CONNECTIONS........................................................................................................................11

POWER SUPPLY (WIRING DRAW SEE AT FOLLOWING PAGE)............................................11

PRESS-AIR REQUIREMENTS......................................................................................................13

FIRST INSTALLATION AND ADJUSTMENTS.....................................................................................13

FIRST CLEANING ..........................................................................................................................13

OPERATOR PANEL AND BUTTONS...........................................................................................14

GENELRAL USE OF BUTTONS ON KEYBOARD.......................................................................14

START-UP THE MACHINE............................................................................................................15

CALIBRATION OF JAW SPACE ...................................................................................................16

BASIC SETTING OF STOPPERS AND SUPPORT PLATE LEVEL ...........................................16

SERVICING THE JAWS ( PLEASE SERVICE THE JAWS FREQUENTLY )............................18

CLAMPİNG JAW GRİNDİNGİNSTRUCTİONS

.........................................................................19

INSTALLATİON OF CLAMPİNG JAWS .......................................................................................19

CLAMPİNG DEVİCE

...................................................................................................................19

UPSET PRESSURE .......................................................................................................................20

USING THE ADJUSTMENT HANDLE .................................................................................................21

JAW LEVEL CALIBRATION (CLAMPING JAW ANNEALING PRESSUREPOINT)..................22

CLAMPING JAW CALIBRATION BY CARBON PAPER..............................................................27

SUMMARY OF FUNCTIONALITY TYPES.........................................................................................29

WELDING STOP POINT

....................................................................................................................30

P a g e | 2

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

QUICK MANUAL CHART.....................................................................................................................31

MACHINE SERVICE............................................................................................................................32

CLAMPING JAW SERVICING / GRINDING INSTRUCTIONS.............................................................32

SYSTEM DRAWINGS..........................................................................................................................33

SPARE PART DRAWINGS..................................................................................................................42

P a g e | 3

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

BASIC INFORMATIONS

This manual user guide is prepared to be useful in order to get familiar with the machine and

the functions of the machine. By the help of this manual guide, the operator becomes a

capable to use the machine in an optimal way in order to operationalize safely, ergonomically

and properly.

This manual user guide allows the operators not to take risk, minimize the idle and repair time.

It also helps to increase lifetime of the machine.

This manual user guide should be kept in a proper place and be accessible easily when

needed. The local regulations included safety and environmental requirements must be

followed in addition to the statements based on this manual user guide.

In case of an issue, complaint, request, demand on spare parts etc. please note the following

information along with the below message

Concerning following Object:

Machine Model:

TEMELSAN KN-40 S-MN

Mfg. year: 2018

Serial Number:

APPROPRIATE USE

The machine is designed to weld the steel and band saw blades min. 6x0.65mm and max.

41x1.10mm.

In the event of using the machine rather than described in which case the machine would be out

of warranty situation of Temelsan.

Upset welding

/resistance butt welding is a welding technique that produces coalescence

simultaneously over the entire area of abutting surfaces or progressively along a joint, by the

heat obtained from resistance to electric current through the area where those surfaces are in

contact. Pressure is applied before heating is started and is maintained throughout the heating

period. The equipment used for upset welding is very similar to that used for flash welding.

Flash welding

is a type of resistance welding that does not use any filler metals. The pieces of

metal to be welded are set apart at a predetermined distance based on material thickness,

material composition, and desired properties of the finished weld. Current is applied to the

metal, and the gap between the two pieces creates resistance and produces the arc required

to melt the metal. Once the pieces of metal reach the proper temperature, they are pressed

together, effectively forging them together. You will be faced with technical words like Upset

Pressure, Weld-Space, Welding-Ready Position. This will be explained later in this Manual.

(Some Text here is copied from Wikipedia, which explains very well the Butt Welding procedure, many

thanks to the writer)

P a g e | 4

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

WARRANTY AND LIABILITY

In the event of involving a personal injury or physical damages are not covered by the warranty if the

following events occur as below.

-

Using the machine for a purpose rather than intended

-

Technically, improper installation, start-up operation or maintenance of the machine

-

In the act of using the machine while any of safety equipment is a broken or

protective device inappropriately running.

-

Making constructional changes on running parameters.

-

Insufficient control of abrasion parts

-

Inappropriate repairs

-

The catastrophic failures due to the action of foreign objects / Bodies and excessive force applied

SAFETY

Below safety requirements must be applied without skipping anything and priority case to carry

out.

QUALIFIELD PERSONNEL

Certain tasks must be carried out on the machine by a professional qualified personnel. Not

third parties neither the children should be near the machine working area.

PLANNING ANG SET-UP

Planning, transportation, installation, programming, start-up, maintenance, repairs and other

works must be done by qualified personnel. Authorized technician must check it also.

The following matters must be noted:

-

Technical data and details concerning the permissible use of the machine and its

accessories.

-

General and specific local preparation and safety measures.

-

Personal usage and the use of general safety equipment must be related the norms.

-

Especially listed on this manual guide but specifically not listed in the operating instructions

that has been explicitly forbidden. Such as a handicapped to use the machine is such

cases it is necessary to contact the manufacturing company.

OPERATIONS

Dangers hidden in disregards of safety regulations.

SAFETY DEVICES

The machine is equipped with the safety devices corresponding to current state of the art. In the

matter of safety equipment, the machine may not be disabled, removed, dismantled, damaged.

It applies in particular to:

-

Safety switches (Emergency Stop Button)

-

Electrical and electronic fuses

P a g e | 5

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

AREAS OF USAGE

The butt-welding machine Temelsan KN40S-MN is used for low-alloyed and high-alloyed steel

bands and band saw blades or bi-metal or carbide tipped band saw blades.

The welding capacity for Band Saw Blades is from minimum 6x0.65mm up to a maximum 41

x1.10mm. The machine is capable to weld all kinds of band saw blades which are called

carbon, wood, bi-metal, CT Work on the electrical power supply is only to be done by

professional electrician.

The machine is a single piece and no need to be assembled.

The machine can be set-up by the customer’s own staff if officially approved by Temelsan.

Please read the following sections thoroughly and carefully before the initial start-up and ensure

that you clearly understand it.

MAINTENANCE

In order to insure a safe operation on the machine and prevent accidents, the job listed in the

section “Servicing” must be carried out regularly. If the owner of machine is not in a position to

do that also must be arranged by an authorized service agent.

ISSUES

The machine must be switched off at once in case of any problem occurs during the operation

and then locked for not being restarted accidently by an unauthorized person.

The machine must be switched off in this case.

-

Unusual sounds, vibrations, smells

-

Unusual operations on the monitoring device

-

Increased temperatures or power consumption

-

Unusual reaction during the manual or automatic operation

-

Strange behavior and error messages displayed

WARNING!

Only suitably qualified personnel must service the machine!

EMERGENCY

P a g e | 6

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

ATTENTION!

Note the following at emergent cases (fire, water, explosions, breakage):

•

Cut the machine off from the mains power supply at an external main switch or external

fuses

•

Switch off the compressed air supply

•

Use the fire extinguishers of a suitable type to deal with the fire

SAFETY MEASURED RELATED WITH THE MACHINE

WEAR PROTECTIVE GLASSES!

Welding beads produced during welding work could damage your eyes.

WEAR GLOVES!

The sharp edges of the blades can cause hand injuries.

DANGER OF FIRE!

Easily inflammable materials could be set alight if they come in to contact with

welding sparks

SWITCH OFF THE MACHINE!

Cut off machine from the main supply before carrying out setting-up maintenance

and servicing work on the machine. Kind of inflammable materials should keep far

away from welding area constantly during the operation!

DANGEL OF BEING CRUSHED!

There is a degree of danger if being crushed when in the proximity of the

clamping jaws during inserting parts. There is a degree of danger being crushed

between the clamping jaws during the setting-up operations.

ATTENTION!

It’s dangerous when contacting parts of the power supply, control and transformer.

IN CASE OF EMERGENCY;

Push the emergency stop button.

The emergency stop button is to use by emergency issues only!

P a g e | 7

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TRANSPORTATION - STORAGE - PACKAGING

The machine may not be handled with special care in transport so as to prevent damage from

impacts to careless loading and unloading. The measures listed below are essential. The

following measures that must be taken only cover the transport within the company. Road, rail,

airline transport and sea transport require additional measures to be taken.

Transport in assembled state (see figure below)

•

Use only the lifting eyelets for transport by crane (Picture below)

P a g e | 8

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

•The use by forklift (pictured blow)

Attention:RISK OF TIPPING OVER

The higher center of gravity requires a special view for transportation even the

Machine should be fixed by screws to the pallet.

CENTER OF GRAVITY

P a g e | 9

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

STANDART ACCESSORIES

6-41mm Width Bi-Metal and CT-Band welding capacity

10-50mm Width Wood-Band welding capacity

One type jaws Both side usable and turn able for small widths

Adjustable Manuel stoppers for cambered band saw blades

3 Program Memories For 3 fully range of band saw blade dimensions

Air Pistol For manual cleaning

Support Tools Pre-Adjustment tools

OPTIONAL ACCESSORIES

1 Set Spare Upper and Lower Jaws (2 pcs of upper + 2 pcs of lower jaws)

Please check the Packing when arrived before unloading the machine from truck.

Do not accept the delivery if packaging is damaged or broken by transportation.

In case of broken or damaged packing of machine, it’s possible with agreement of Transportation

Company to unpack and check the machine condition before down loading

As soon you unload the machine, you accept the condition of machine, you take any responsibility for

damages and eventually repairs.

REQUIREMENTS OF WORKING PLACE

-Flat and smooth desk

-Required big enough area around the machine

-Environmental conditions

-The running of the machine is not permitted if flammable liquids and objects are near to welding

machine

-Enough air circulation is required

-The client is obliged to local electrical distributor notified technical requirements

P a g e | 11

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

FIRST CONNECTIONS

POWER SUPPLY (Wiring draw see at following page)

A qualified electrician must do the connection.

The input voltage (standard norm) is 400V AC (3 Phase + Neutral + Ground) 50Hz.

The input voltage (US Norm) is 600 V AC (3 phase + Neutral + Ground) 60 Hz. (optional)

The recommended fusing for power supply is

40 Amp fuse

,

sluggish type

The Diameter of each wire for power supply it's very important, please use the chart by

selecting the Machine Type

Do not switch ON the machine before the all setup instruction is read and work performed

Pay special attention to protect yourself from the energized cables moreover the

control panel

while operating the machine. Keep closed the cover of electrical control panel

and do not forget

to take out all the foreign objects in the cabinet which might cause short circuit.

-

Working on the electrical power supply has to be only done by professional electrician.

-

The electrical equipment of the machine must be checked regularly

-

Always keep the switching cabinet locked. Access is only permitted to authorized personnel

with the key or special tool.

-

Remove at once any loose or worncables

-

If it is essential to work on parts carrying a current there must be a second person present to

turn off the main switch in case of anemergency

-

The customer is required to comply with the technical conditions and requirements of the

relevant electrical power supplycompany

Make sure that the main switch of the machine is on OFF

position and prevent to be turned on by an accident.

ATTENTION!

WARNING!

P a g e | 13

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

PRESS-AIR REQUIREMENTS

The machine needs dry and clean air pressure, which needs 6-8 bars.

After some time the air becomes wet and dirty, then please clean the conditioner of air right

behind the machine.

Connect air hose supply coming from the compressor through at the rear side of the machine.

FIRST INSTALLATION AND ADJUSTMENTS

Authorized professionals, who must read this user guide, must do first installation and

adjustments. In case of questions, is an immediately contact with manufacturer/supplier

required.

FIRST CLEANING

Unpainted parts on the machine are slushed with conservation oil and have to be cleaned

before the operation can start. Especially the jaws and around them must be cleaned properly.

Check Points

1.

Power is connected through the instructions above, All fuses are ON also inside the

electrocabinet

2. Air is connected and adjusted with 8 Bar

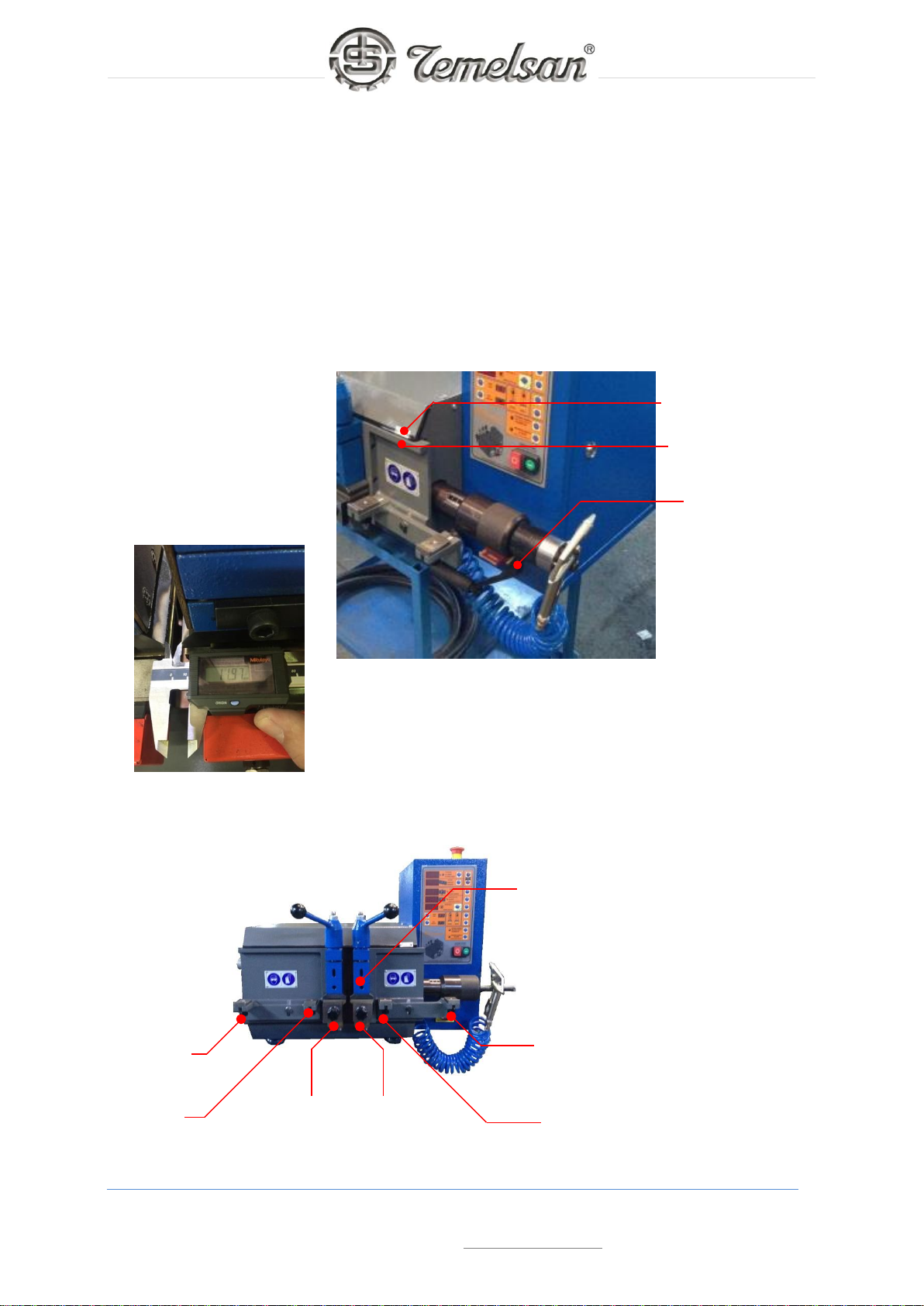

EMERGENCY STOP BUTTON

OPERATOR KEYBOARD

HAND WHEEL FOR JAW SPACING

ELECTRIC CABINET

MAIN POWER SWITCH

JAWS

BLUE START BUTTON

RIGHT SIDE CLAMPING HANDLE

LEFT SIDE CLAMPING

HANDLE

P a g e | 14

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

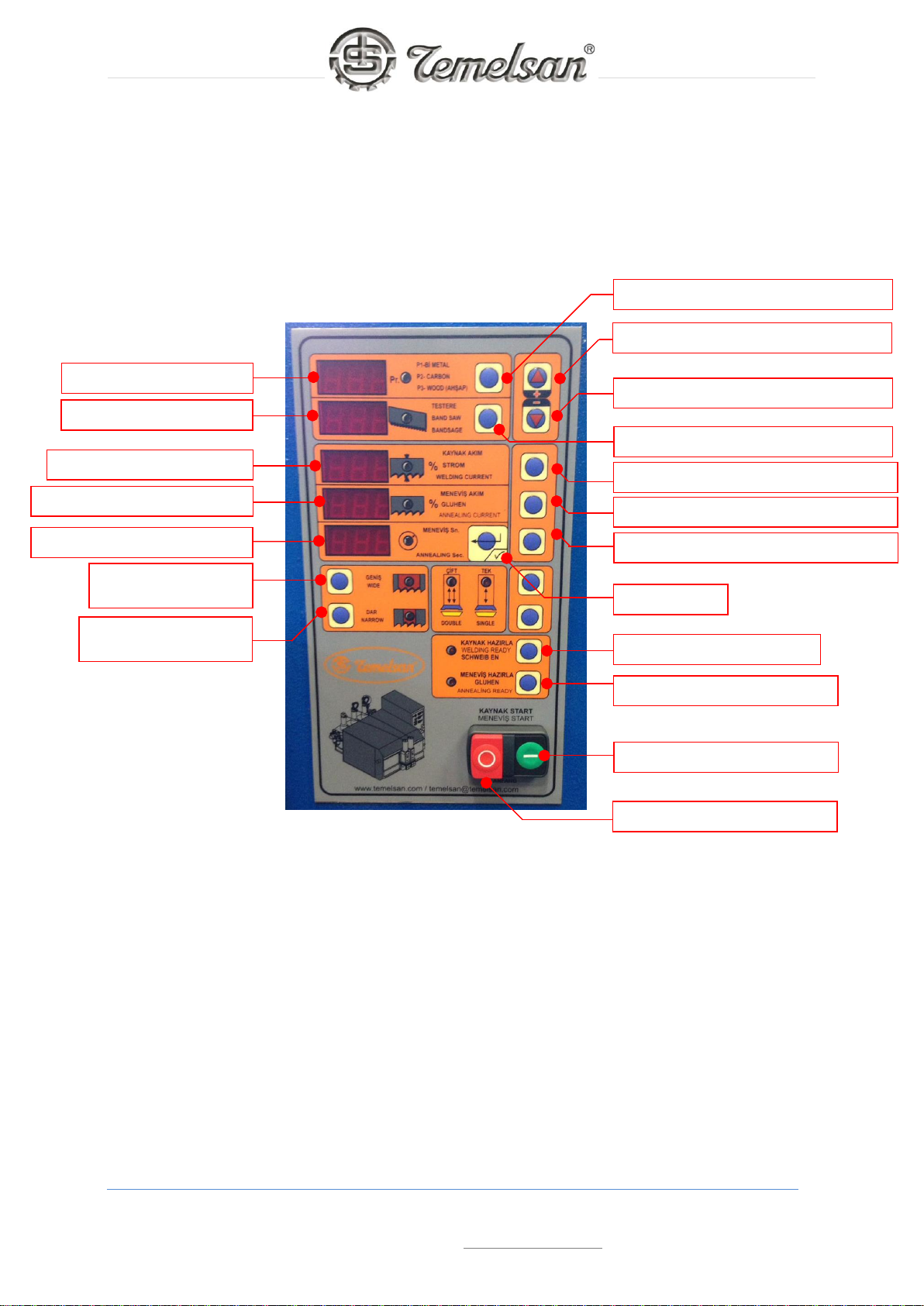

OPERATOR PANEL AND BUTTONS

GENELRAL USE OF BUTTONS ON KEYBOARD

Push the button (Program, Bandsaw, Welding Current, Annealing Current, Annealing Timer) to

make selection on which value you want to change. When you press the selection buttons the screen

next to button the light will blink. While screen is blinking you can adjust with “VALUE ADJUSTMENT

BUTTON (+) or (-)”. When you reach the value, press the “SET BUTTON”to save your settings.

PROGRAM SELLECTION BUTTON

VALUE ADJUSTMENT BUTTON (+)

VALUE ADJUSTMENT BUTTON (-)

BANDSAW SELLECTION BUTTON

WELDING CURRENT SELL. BUTTON

ANNEALING CURRENT SELL. BUTTON

ANNEALING TIMER SELL. BUTTON

SET BUTTON

WELDING READY BUTTON

ANNEALING READY BUTTON

OPERATION START BUTTON

OPERATION STOP BUTTON

PROGRAM SCREEN

BANDSAW SCREEN

WELDING CURR. SCREEN

ANNEALING CURR. SCREEN

ANNEALING TIMER SCREEN

WIDE ANNEALING

SPACE BUTTON

NARROW ANNEALING

SPACE BUTTON

P a g e | 15

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

START-UP THE MACHINE

(Very important to follow step by step, do not proceed to next step when check point is not

confirmed for proper functionality)

1.

Turn the main power switch to

ON

2.

Check and unlock the Emergency Stop Button (to unlock turn on Button to left side)

3.

Press the

“BLUE RESET BUTTON”

to start the machine.

4.

Press the

“PROGRAM SELLECTION BUTTON”

and use

“(+) or (-) VALUE ADJUSTMENT

BUTTONS”

to find your program and press the

“SET BUTTON”

5.

Press the

“BANDSAW SELLECTION BUTTON”

and use

“(+) or (-) VALUE ADJUSTMENT

BUTTONS”

to find your band saw type and press the

“SET BUTTON”

6.

Press the

“WELDING CURRENT SELLECTION BUTTON”

and use

“(+) or (-) VALUE

ADJUSTMENT BUTTONS”

to find your current value and press the

“SET BUTTON”

7.

Press the

“ANNEALING CURRENT SELLECTION BUTTON”

and use

“(+) or (-) VALUE

ADJUSTMENT BUTTONS”

to find your current value and press the

“SET BUTTON”

8.

Press the

“ANNEALING TIMER SELLECTION BUTTON”

and use

“(+) or (-) VALUE

ADJUSTMENT BUTTONS”

to find your timer value and press the

“SET BUTTON”

9.

Choice your annealing space and press the button

“WIDE ANNEALING”

or

“NARROW

ANNEALING”

button to set it.

10.

Push on Operator Keyboard the Button "

WELDING READY

" The right jaw should move on

position

11.

Check the space between the Jaws; it should be same as on indicator

12.

Push on Operator Keyboard the Button "Annealing Ready"

Congratulation, your Machine is correct connected and is ready to Calibrate several

following equipment

a.

StopperPositions

b.

Jaw Level and spacing

P a g e | 16

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

CALIBRATION OF JAW SPACE

1.

Adjust the space of jaws by turning the hand wheel to 10mm (use a caliper) Hand Wheel

can be only turned when jaws are in Welding Ready Position!

2.

Adjust the space indicator also to 10mm by using a screwdriver Check the indicator

frequently.

BASIC SETTING OF STOPPERS AND SUPPORT PLATE LEVEL

Turn the CSL and CSR stoppers to find proper adjustment for band saw teeth size.

HAND WHEEL FOR JAW SPACING

SPACE INDICATOR

SCREW TO ADJUST INDICATOR

Adjust the space between the Jaws in Welding Ready

Position to a specific slot width and measure it proper.

Position on Space indicator should be same.

PLEASE CONTROL THIS FREQUENTLY!

MSR

OSR

OSL

MSL

JAW LEVEL

ADJUSTMENT HOLE

Outside Stopper Left

Center Stopper Left

Center Stopper Right

Outside Stopper Right

Middle Stopper Right

Middle Stopper Left

OSL

CSL

CSR

OSR

MSR

MSL

CSR

CSL

P a g e | 17

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

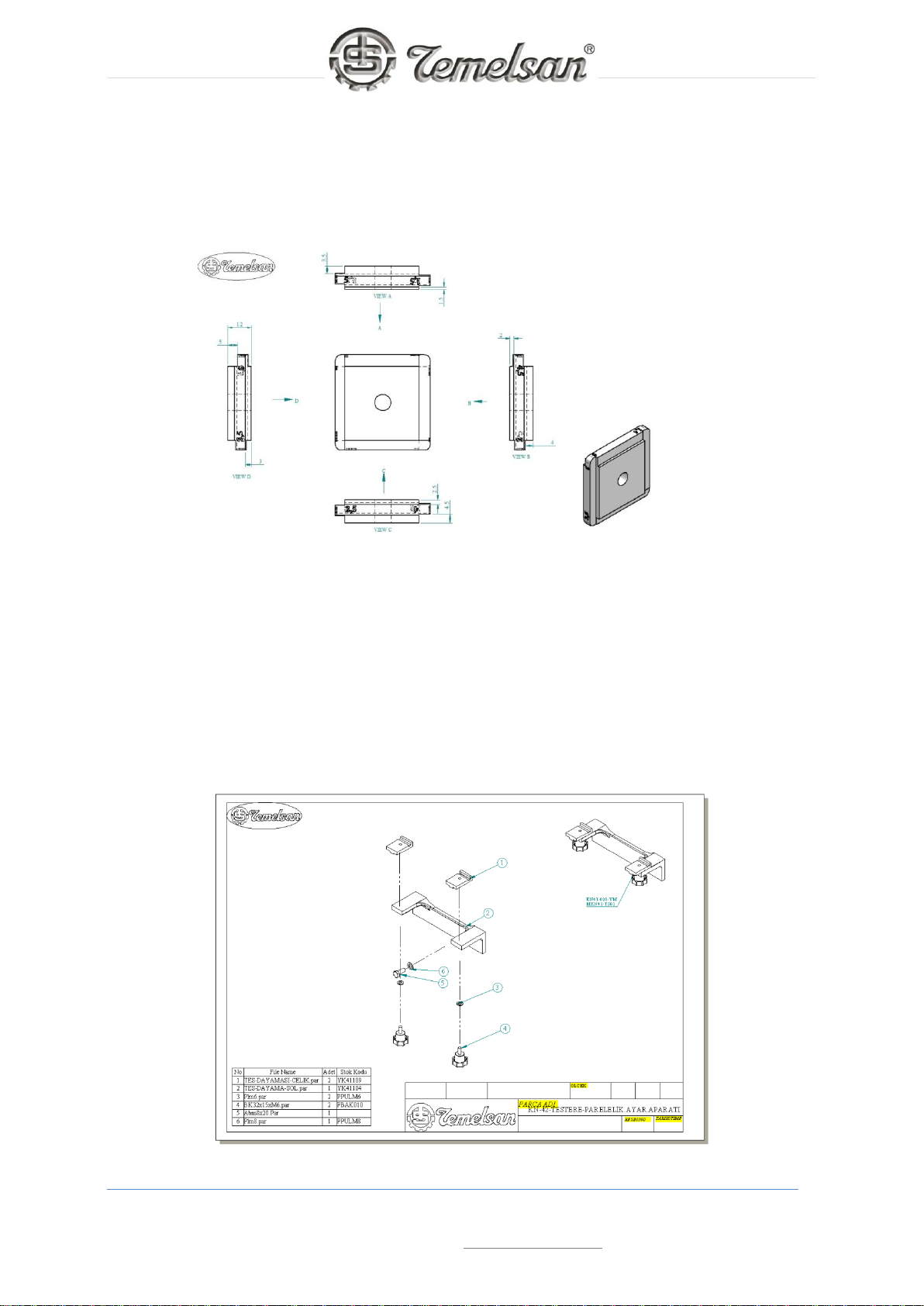

CSL AND CSR STOPPERS DRAWING

Unscrew the OSL, OSR, MSL and MSR stoppers to be free move.

Put the Band saw be sure the teeth of band saw touch the stoppers on proper way.

Turn the clamping handles to clamp.

Set the OSL, OSR, MSL and MSR stoppers to touch the band saw.

Screw the OSL, OSR, MSL and MSR stoppers.

Please check and service the Stoppers frequently!

P a g e | 18

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

SERVICING THE JAWS (PLEASE SERVICE THE JAWS FREQUENTLY )

3.

unscrew the "Lower Jaw retaining screw (3)"

4.

move up the Lower Jaw block (1)

5.

pull out the "Lower Jaw”to front

6.

unscrew the “Upper Jaw retaining screw”

7.

move down the Upper Jaw block (2)

8. pull out the “Upper Jaw to front”

JAW LEVEL ADJUSTMENT TOOL

UPPER JAW (STEEL)

P a g e | 19

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

9.

CLAMPING JAW GRINDINGINSTRUCTIONS

The lowerjaws (Bronze) -just to grind on top surface until any crack on weld edge is out

-Both lower jaws have to be same thickness; it's

recommended to grind it together as a pair

The upperjaws (Steel) -just to grind on bottom surface until any crack on weld edge

is out

-Both upper jaws should have the same thickness

We recommend to grind the surface of jaws frequently, that has the advantage of

-Better power connectivity

-Straight surface

-Higher weld precision

As earlier you take it out to grind, as less material have to be grinded, the life of jaws will

increase.

10. INSTALLATION OF CLAMPING JAWS

Please make sure that the touch points between Jaws and Jaw-blocks are clean and

free from grease.

When you place the Jaw to position it, check if all surface has contact, very clean

between. Do not create the contact by tighten the screws.

When fixing the screws, not too tight please!

11.

CLAMPING DEVICE

The clamping devices are Manual system to clamp Metal Band or Band Saw Blade

for butt-welding procedure.

.

Table of contents