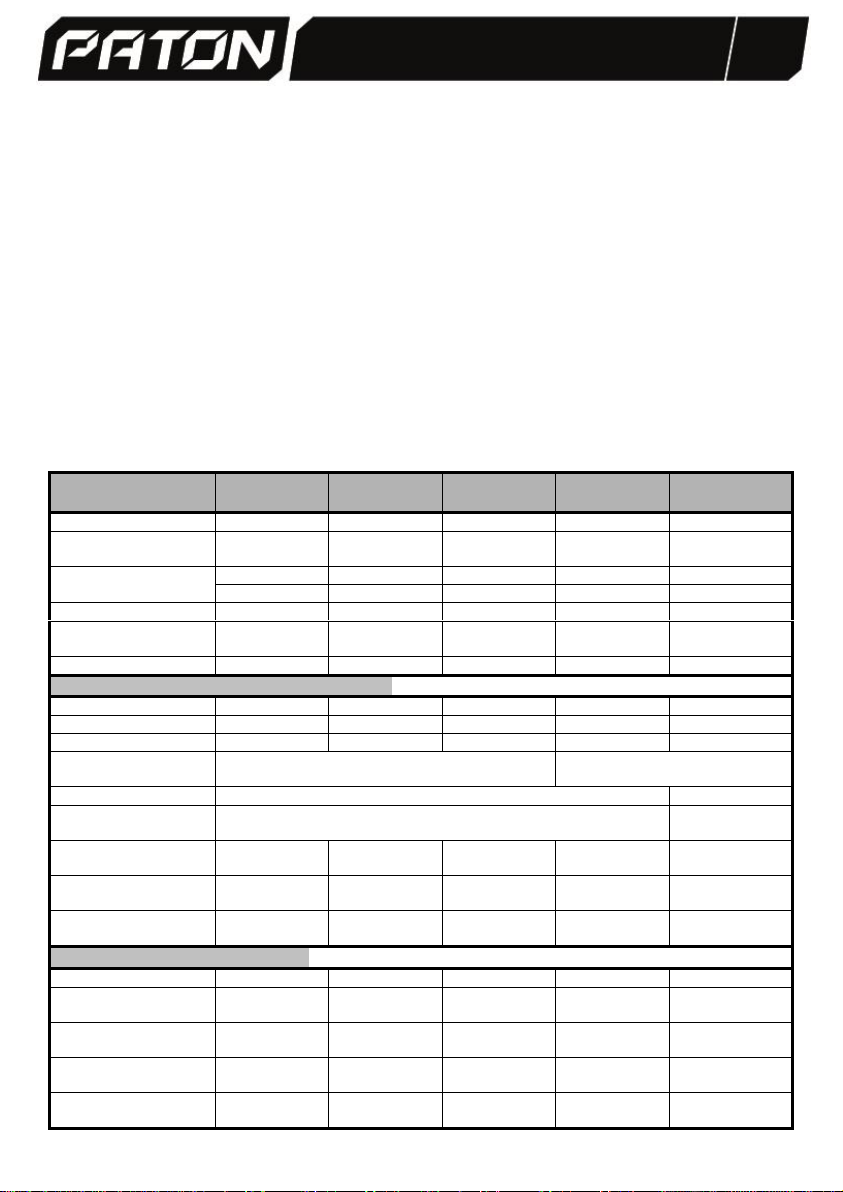

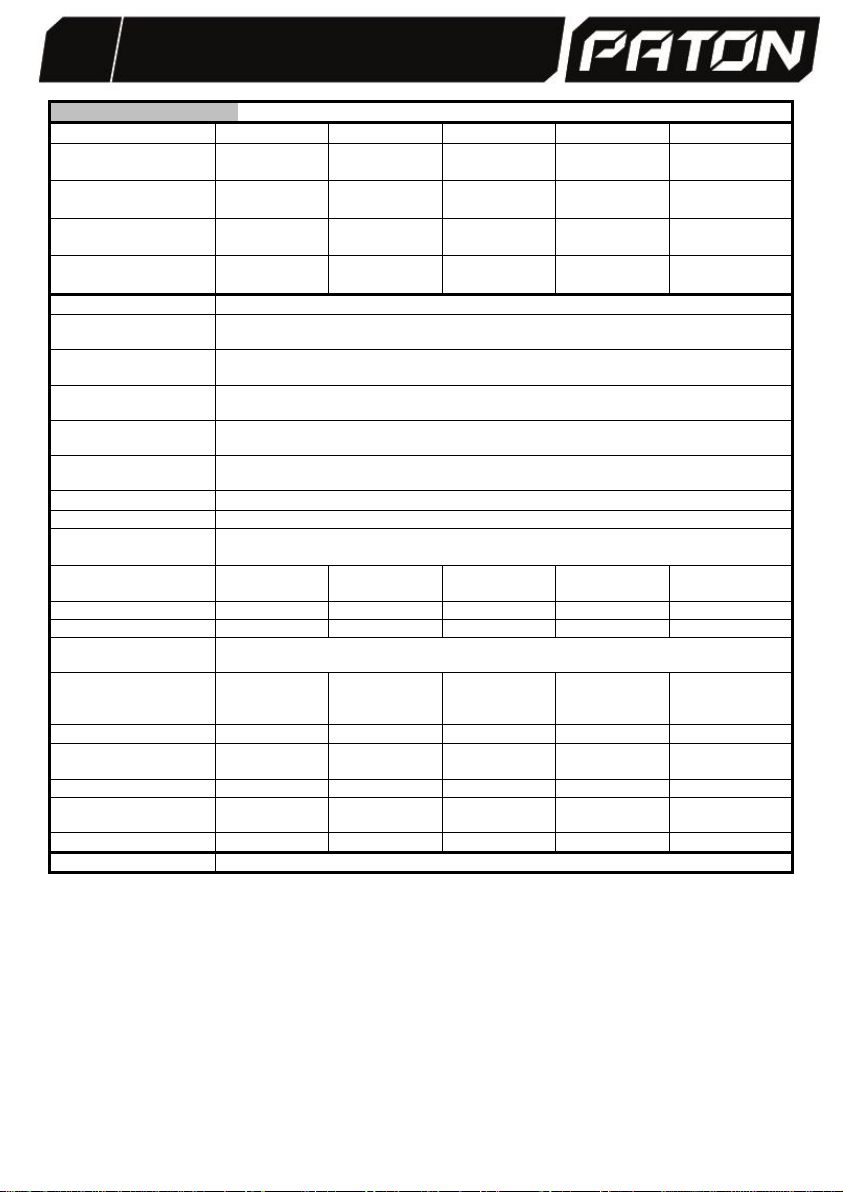

- 5 - PATON StandardMIG DC MMA/TIG/MIG/MAG

1. GENERAL PROVISIONS

The PATON™StandardMIG-160/200/250/270-400V/350-400V single-unit inverter digital semi-automatic

devices are tailored for Manual Arc Welding (MMA), Manual Tungsten Inert Gas (TIG), and Gas Metal Arc

Welding (GMAW) using direct current with protective gases and their combinations. The digital control

mechanism's primary benefit is that it avoids the limitations found in multi-function analog systems.

Analog systems are typically optimized for a specific function, making other modes less efficient. In a purely

digital setup, the control panel operates at its maximum potential, ensuring efficient performance

regardless of the selected mode.

This machine is designed for domestic and semi-industrial use. It provides a good load duration at its full

rated current of 160A/200A/250A/270A/350A respectively, which is enough to work with any electrodes

from Ф1.6 mm up to the most high-fusing Ø6mm (for StandardMIG-350-400V) and semi-automatic

welding with solid wire of Ø0.6 mm to Ø1.4 mm (for StandardMIG-350-400V). The source is initially set to

optimum values for most applications and is simple enough, if you don't go into the intricacies of additional

settings that already require a lot of skill from the welder.

Within this advanced equipment, users have the capability to effortlessly switch between the two main

polarities: Direct Current Electrode Positive (DCEP) and Direct Current Electrode Negative (DCEN). This

flexibility ensures that the welding process can be optimized for different materials and conditions,

allowing for tailored welds based on your specific requirements. The intuitive design and user-friendly

interface further simplify the polarity switching process, ensuring maximum efficiency and precision in all

welding tasks. For hazardous working conditions, there is a built-in no-load voltage reduction unit in the

MMA mode, with the possibility to switch it on and off.

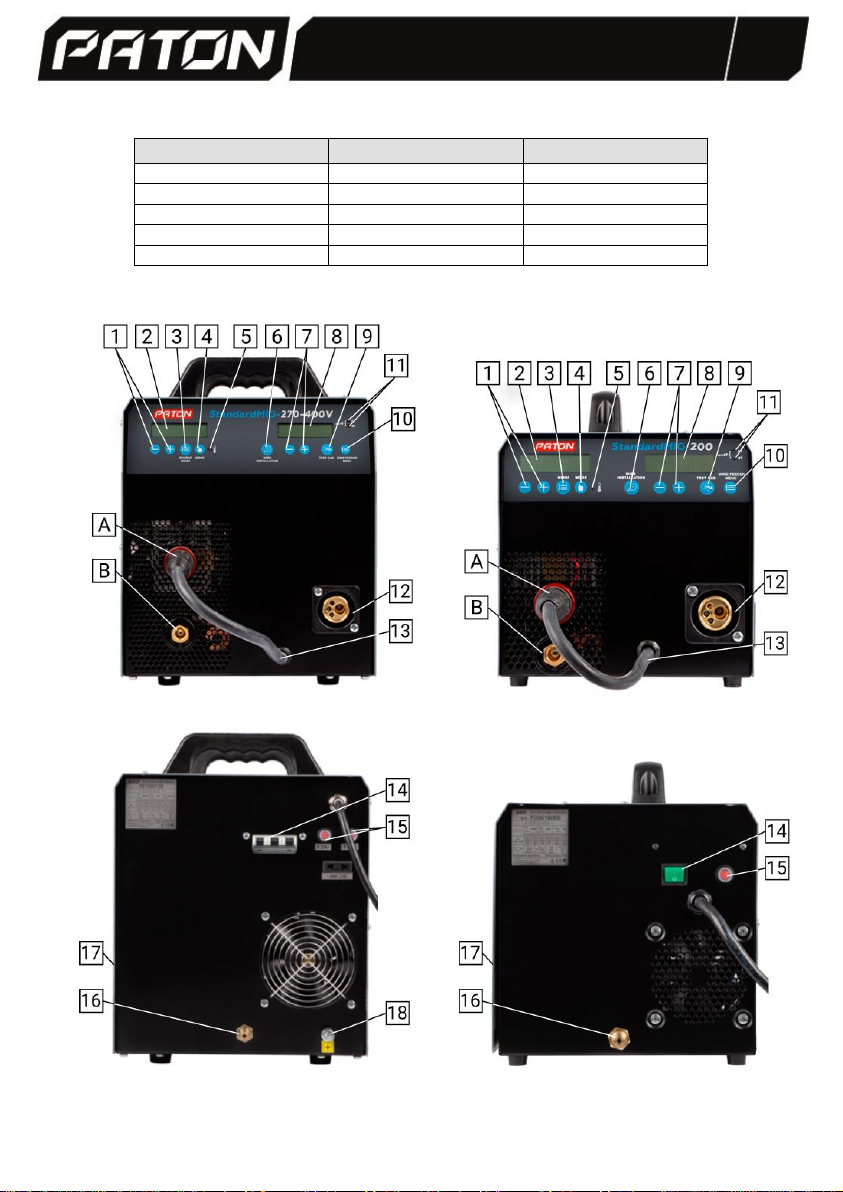

A standout feature of PATON's Standard series semi-automatic machines is their exceptionally robust,

high-quality, and hermetically sealed metal wire feeder. These machines also feature the widely adopted

KZ-2 EURO type connector, which has become a global standard, providing users the flexibility to

interchange torches according to their preferences. Notably, the StandardMIG-350-400V model boasts a

cutting-edge 4-roller feeder with full roller drive functionality, further enhancing its performance and

reliability.

The StandardMIG models from PATON™incorporates have a built-in undervoltage protection, as well as

short-term overvoltage protection. Upon shutdown, the unit retains all active settings and subsequently

restores them upon reactivation. Furthermore, the machine has the capacity to store up to 16 unique user

programs, each identifiable by its specific number, within each welding mode.

The implemented input current regulation stabilization system in the device enables compatibility with

various power sources. As a result of maintaining a consistent input current level, regardless of voltage

fluctuations originating from the power source, the welder can operate correctly and efficiently under

diverse power supply conditions like (power generator or extension cables).

Main advantages:

1. Wide possibilities of adjusting welding parameters:

a) in MMA mode –1 (basic) + 7 (additional) + 4 (for pulse mode)

b) in TIG mode –1 (basic) + 1 (additional) + 4 (for pulse mode)

c) in MIG/MAG mode –2 (basic) + 6 (additional) + 4 (for pulse mode)

2. The availability of adjustable pulse mode;

3. In addition to protection against under-volage, a system is installed to stabilize operation during large,

long-lasting voltage fluctuations in the supply from 160V to 260V (for StandardMIG-160/200/250

models) and from 320V to 440V (for StandardMIG-270-400V/350-400V models);