TEN EDA 2 User manual

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 1

USER MANUAL

EDA 2

The contents of this user manual and EDA 2 software are the intellectual property of Test Equipment

Nederland B.V. Each way of duplication of this manual or software is not allowed. Test Equipment Nederland B.V is

not responsible for any direct or indirect damage arising from the use of the apparatus or manual. The EDA 2

is tested and approved according the EMC directive 89/336/EC .

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 2

Contents

1 Introduction......................................................................................................................................................... 3

2 Preparations ....................................................................................................................................................... 4

3 Smoke test.......................................................................................................................................................... 6

4 Official test.......................................................................................................................................................... 8

5 Messages ......................................................................................................................................................... 10

6 Maintenance ..................................................................................................................................................... 10

7 Specifications.................................................................................................................................................... 12

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 3

1 Introduction

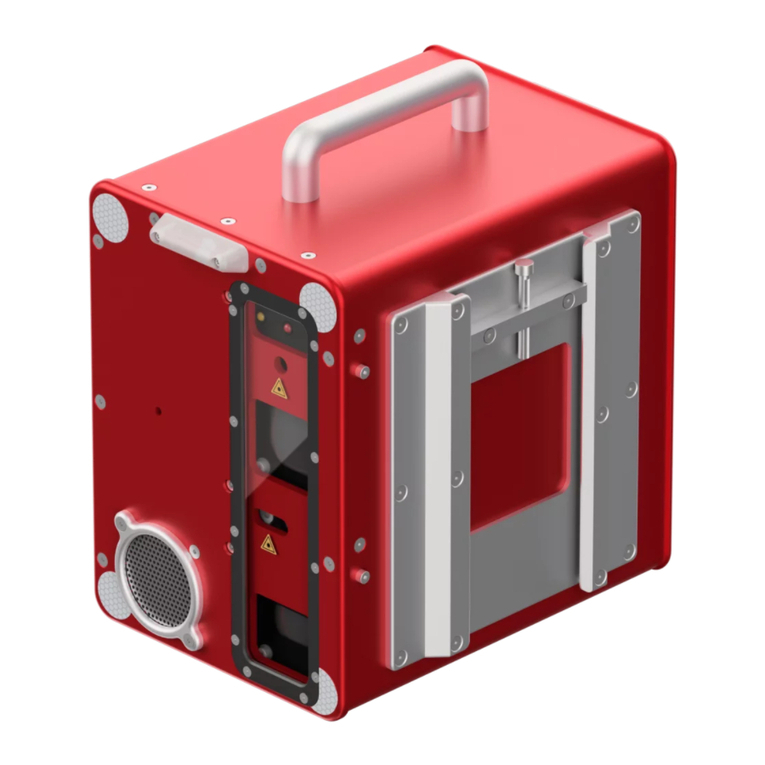

Thank you for purchasing the smoke meter TEN EDA 2.The EDA2 smoke head is developed and produced by TEN

Automotive.

Due to the smart design, the EDA 2 offers you a wide range of possibilities for measuring the smoke emissions of

diesel passenger and commercial vehicles.

The new model smoke head is compact and provided with the latest microcontroller controlled electronics. The

smoke chamber is completely made of aluminum and uses the so called unique ‘natural flow’ system that

guarantees a minimum of maintenance.

In this user manual we describe the combination of the EDA2 smoke head and the INNOVA500 . The INNOVA 500

has digital LED displays and a thermal printer to provide you all necessary information during a emission test.

Before using the EDA 2, it’s absolutely necessary to read this user manual carefully !

If you have any questions about the EDA 2, please don’t hesitate to us :

Dealer name

T: + xxxxxxxxxxxx

F: + xxxxxxxxxxxx

Warning !

During operation, the temperature of the smoke

chamber is 100 ºC!

Always wear protection gloves when you touch the

smoke chamber or sample probe!

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 4

2 Preparations

RPM

The RPM of the vehicle is recorded by a optional piëzo clamp or RPM adapter. The standard piëzo clamp has a

diameter of 6 mm and suitable for most European vehicles. Dismount the engine cover plates of the vehicles.

- Find a location were injection pipe is straight.

-Take care take this piece of pipe is clean and dry.

- If necessary, use sand paper to clean the injection pipe.

- Mount the piëzo clamp around the injection pipe.

- Tighten the knob of the clamp but don’t overdo.

- Place the black crocodile clamp (ground) at the injection pipe near the piëzo.

Check that the RPM is recorded correctly. If not, repeat the procedure mentioned above at a different location of the

injection pipe.

Figure 2. Placing the piëzo clamp

Remark: the piëzo clamp can not be used for all types of diesel vehicles, for example common rail diesels. Here for

you need a special RPM adapter. If you use an adapter, always follow the instructions given by the manufacturer.

Oil temperature sensor

Take care that the length of the sensor is not longer than the length of the dip stick. Move the adaptation rubber

until the length of the sensor is correct. Now place the temperature sensor in the dip stick holder of the engine.

Figure 2. The oil temperature sensor

After testing you have to remove the temperature sensor from the engine. Clean wasted oil from the engine and

temperature sensor with a clean towel. Don’t forget to place back the dip stick !

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 5

Sample probe

Always use the correct sample probe. Probe 1 has a diameter of 10 mm and is used for exhausts with a diameter

smaller than 70 mm. Probe 2 has a diameter of 27 mm and used for exhausts with a diameter equal or larger than

70 mm.

Place the probe a far as possible in the exhaust. Take care the gas flow in probe is correct. Avoid sharps curves or

bending .

Figure 3. Placing the sample probe.

The temperature of the sample probe can rise up to 200 ºC during a smoke test. Always wear protection

gloves while you are touching the exhaust or sample probe.

During a zero calibration of the smoke meter, the sample probe must be removed from exhaust or the

engine must be switched off!

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 6

3 Smoke test

From standby mode you press the function key and select the menu item ‘DIESEL’ with the up or down keys.

Confirm your selection with the enter key. Now the following screen will appear.

Figure 4. Smoke test

This screen will only appear if the smoke cell temperature is over 80 ºC. If the temperature is lower than 80 ºC the

INNOVA 500 will display the message ‘EDA heating’ and only the cell temperature is displayed.

If the opacity and max.opacity display shows the message ‘----‘, you need to perform a zero calibration. Press the

zero calibration key to activate a zero calibration.

Figure 5. Zero calibration of the smoke head

Important!

We advise you to perform a zero calibration regularly. Take care that during a zero calibration the sample is

removed from the exhaust of the vehicle.

Printing

If you wish to print the actual values of the smoke meter, you can press the print key. The thermal printer of the

INNOVA 500 prints all relevant information including the date, time etc at a piece of thermal paper.

Warning: thermal paper has a restricted lifetime. Don’t store thermal paper near ‘hot’ sources.

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 7

Settings

During the smoke test the operator can change various settings or read the status of the smoke head. After

pressing the function key the operator can select one of the following menus:

RESET Reset the max. opacity.

UNIT Select opacity in % (percent) or m-1 (light absorption coefficient).

Normally during a test always use %.

MODE Select mode A (not filtered) or mode B (filtered). Normally during a test

always use mode B.

PROBE Select sample probe 1 or 2.

Probe 1 = Ø 10 mm, exhaust diameter < 70 mm (passenger cars).

Probe 2 = Ø 27 mm, exhaust diameter >= 70 mm (large commercial vehicles).

DIVISION Here you can set the division ratio for the RPM, for example 1,2,3,4 etc.

DISPLAY Select what you want to display at the display at the right bottom, RPM or oil temperature.

STATUS Menu to check the status of the EDA2 smoke head.

VERSION Software version of the smoke head EDA2, for example 9.01

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 8

CS_A CS_B The corresponding checksum of the software.

SERIAL The serial number of the smoke head.

CURR.DATE Current date.

CAL.DUE Calibration due date.

CNT. Calibration counter. After each calibration this counter automatically increments.

FILTER Dynamic test to check the low-pass filter-time constant. First a zero calibration is performed. After

this the EDA 2 checks the rise time from 0 till 90% opacity. Than the EDA displays ‘time 1.00’. This

value must be between 0,95 and 1,05 seconds. Normally the time is 1,00 seconds.

During this test the sample probe must be removed from the exhaust. Don’t influence the smoke

meter in any way!

Remark: the ‘STATUS’ menu is only used for checking purposes.

4 Official test

During the smoke test just press the Enter key to start the official test. The official test is a series of 3 free

accelerations to measure the maximum emission of a diesel vehicle.

First the EDA 2 performs a zero calibration. Be sure that during a zero calibration the sample is removed from the

exhaust tail pipe. After the zero calibration you insert the probe in exhaust of the vehicle.

Then the oil temperature is measured. The EDA 2 waits until a temperature of 60 ºC is reached. As soon as the

engine temperature reaches 60 ºC, the EDA automatically continues. If the temperature of 60 ºC is not reached or

you just want to continue, press the Enter key. Now the INNOVA 500 will proceed with the next program part.

After measuring the temperature the operator must be prepared to perform the free accelerations

Between each acceleration the operator can see a down counter of 6 seconds. During the count down the throttle of

the vehicle is not touched.

After the count down the INNOVA shows ‘THROTTLE UP’ which means that the operator has to press the pedal

completely until the maximum engine speed is reached. Maintain this situation for maximum 2 seconds. Then

release the pedal and let the engine speed come back to idle. The SMOKE METER light blinks.

After 4 seconds the INNOVA 500 shows ‘RELEASE THROTTLE’. These 4 seconds are the maximum throttle up

time for vehicle with a ‘slow’ engine (large commercial vehicles). For passenger cars just maintain the maximum

engine speed for 2 seconds !

After each acceleration the EDA 2 displays the result of the test for 3 seconds. After this the INNOVA 500 starts a

new count down for the next acceleration.

After completing the official test, the EDA 2 shows the result of the test, the calculated average of the opacity of the

3 free accelerations, at the opacity display. If the result is out of limits, more than 50%, the display blinks.

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 9

Press the print key to get a full report of the official test with all recorded values.

Press the escape key to close the official test and return to the normal smoke test.

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 10

5 Messages

During operation, the EDA 500 can display different messages. The following messages can occur:

EDA2 No communication between the IINOVA 500 and EDA2 smoke head. Check the communication

OFF-LINE cable connection. Check that the EDA2 is switched on.

EDA2 The smoke cell temperature is below 80 ºC. The smoke cell is heating up.

HEATING

ERROR This message can occur during a zero calibration. Reason for the error can be:

a) Receiver needs to be cleaned, see Chapter 12.

b) The halogen light source is defect, see Chapter 12.

c) The smoke head is located in a location with to much direct sun light.

Move the smoke head to another location.

6 Maintenance

Cleaning

Clean the outside of the INNOVA 500 and smoke head with a soft towel and eventually with a non aggressive liquid

like Glassex. Before cleaning the unit always switch off the INNOVA 500 and remove the mains plug. Let the smoke

head cool down till ambient temperature.

Replacing the printer paper

Open the printer by pulling the lit at the cover forwards. Remove the old roll and place the new roll in the printer. Let

a piece of paper of approximately 10 cm hang out of the printer. Press with both hands at the printer cover to close

the printer. Press a the paper feed key to check the paper transport.

Replacing the fuses

Before you change the fuses always switch off the INNOVA 500, remove the power lead and let the smoke head

cool down until ambient temperature. Open the little lit of the main switch at the rear of the EDA, no. 12 of figure 2.

Take out the fuses and place the new fuses in the holders of the lit. Use 230 V 2AT fuses. Close the lit.

In the smoke head the fuse holder is located at the bottom of the EDA 2, no. 5 of figure 3. Press and open the

holder by turning it counter clockwise. Take of the holder with the fuse. Replace the fuses. Use 230 V 2AT fuses.

Close the fuse holder by pressing it and turning it clockwise. If you have to change the fuses frequently, please

contact our service department!

Calibration

The EDA 500 must be calibrated once every 12 month. The calibration can only be performed by authorized

technicians from your supplier. We advise you to take a service contract including the annual calibration.

Cleaning the optical components of the smoke head

If the receiver gets polluted, the receiver voltage will go down and the smoke meter will show ‘ERROR’ during a

zero calibration at the displays. Switch off the INNOVA 500 and let the smoke head cool down until ambient

temperature. Loosen the right mounting ring of the smoke chamber and take out the cone. Now take the receiver

support out of the cone. Clean the front surface of the receiver with a clean and soft cotton towel. Don’t touch this

surface, the lens, with your fingers. Put the support back to its position and place cone into the smoke chamber.

Tighten the mounting ring. Switch on the smoke meter and perform a zero calibration. Check that the smoke meter

is not showing the error message again.

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 11

Figure 7. Cleaning the receiver of the smoke meter.

Replacing the light source

If it’s necessary to replace the light source of smoke head, place carefully follow the next steps:

Switch of the smoke meter and let the smoke head cool down until ambient temperature. Loosen the left mounting

ring and take out the cone from the smoke chamber. Take out the bulb support and remove the light source.

Open the plastic cover of the new light source at the bottom, but leaf the plastic around the bulb. Carefully press the

new light source with its two pins at the bottom into the holder of the support. Remove the plastic cover. Never

touch the light source with you fingers! Place the support into the cone and put the cone into the smoke chamber.

Tighten the mounting ring. Switch on the smoke meter and perform a zero calibration. Check that the smoke meter

is not showing the error message again.

Figure 8. Replacing the light source.

The EDA smoke head is equipped with a special halogen light source. Never use equivalent light sources, only the

original. Please contact your supplier for these original spare parts.

TEN

Test Equipment Nederland B.V. (C) Version 3.0 February 2008 Pagina 12

7 Specifications

Voltage 230V/50Hz with PE (or 110V/50Hz with PE on request)

Power dissipation Max. 330 Watt

Weight smoke cell 7 Kg

Effective length smoke cell 430 mm

Material Aluminum

Diameter 55 mm

Light source Halogen 6V/10W 3200 ºKelvin

Receiver Siemens BPW21 with Vfilter

Sample probe 10 mm, 1 meter length

Optional:

16 mm, 2.5 meter length

27 mm, 1 meter length (trucks)

27 mm, 3.5 meter length (trucks)

Ranges:

Opacity 0-99,9%

0-9,99 m-1

Oil temperature 0-150 ºC

Cell temperature 0-150 ºC

RPM 300-9990 1/min

Resolution:

Opacity 0,1 %

0.01 m-1

Oil temperature 1 ºC

Cell temperature 1 ºC

RPM 10 1/min

Table of contents