Tencor AlphaStep 200 User manual

Tencor Alphastep 200 Automatic Step Profiler

Contents

1. Introduction

2. System Description

2.1 General

2.2 Specifications

2.3 Data Display

2.4 Keyboard

3. Operating Procedures

3.1 Setting Scan Parameters

3.2 Scanning a Sample

4. Manipulating Data

4.1 Overriding Vertical Auto-Ranges

4.2 Measurement Cursors - Measuring Profile Features

4.3 Leveling the Plot

4.4 Plotting Individual Profile Features - Zoom

4.5 Average Difference Mode

4.6 Printing

APPENDIX A Printer Paper Change

1. Introduction

The Alphastep 200 is a computerized step profiler with a programmable X-Y stage, and a

9" video monitor which displays a magnified view of the sample and stylus during the

scan, as well as scan profiles and a summary of scan data. The system has three

operating modes: "manual" for single scans; "semiautomatic" for multi-point scans; and

"automatic" for repeated multi-point scans. The system allows the operator to set, and

store if desired, a variety of scan parameters such as scan direction, scan length/sampling

rate and vertical units (kA vs. Mm). Measurement cursors are used to level plots,

obtain a variety of data, and/or to zoom in on a particular section of a scan profile. A

printer is built into the system for hard copies of screen scan profiles and data.

This manual will describe operation of this system in manual mode "only". For

information on programming the stage, semiautomatic and automatic operating modes, or

menu storage, please refer to the manufacturer's user operation manual available from the

staff in the cleanroom office.

2. System Description

2.1. General

The figure in the hard copy manual shows the main features of the system.

The top half of the system houses the printer, video monitor and its controls. The lower

half has the sample chuck and the keyboard, by which the sample and data are

manipulated.

2.2. Specifications

Mechanical profilometer

Scanning Stylus: 12.5-micron radius

Zoom Video Microscope 40x to 120x Magnification

5 Angstrom Vertical Resolution

400 Angstrom Horizontal Resolution

Tracking Force - User adjustable 1 to 25 mg

Maximum Sample Dimensions - 16.5 mm thickness, 162 mm diameter

2.3. Data Display

The Alphastep 200 digitizes measurement data and stores it in memory during the

scan. When the scan has been completed, a plot of the scan is displayed along with

pertinent data and information on the scan characteristics. The cursors displayed on the

plot are positioned by the operator to level the plot and/or obtain the desired data.

The figure in the hard copy manual shows what the display looks like.

The following describes the data display as read from top to bottom:

ID# Optional identifier for sample assigned by the user. Can be up to 7 characters.

Pressing # when the system is NOT in "Enter Mode" (see below) will allow the user

to enter a number. Pressing ENT, PRINT or initiating a scan will terminate the entry.

VERT Total vertical scale on plot in kA or Mm (specified by operator)

L Profile height at intersection with left cursor.

R Profile height at intersection with right cursor.

Highlighted Value Calculated difference between heights at cursors.

Avg Average profile height between cursors measured relative to the baseline.

TIR Total Indicator Runout - difference between maximum and minimum profile

heights for section of plot between measurement cursors.

R Arithmetic Average Roughness, see a manufacturer's manual for details.

Area Cross-sectional area of a profile above the base line, displayed in Mm2. The

base line is that line which extends between the intersections of the two

measuring cursors and the profile. Only those parts of the profile above the

line are included in the measurement. See section 2.3 for details on how to

display the area and the baseline.

HORIZ Total horizontal scale on plot (scan length)

L Position at left cursor on horizontal scale

R Position at right cursor on horizontal scale

Highlighted Value Difference between horizontal positions.

Directly under the data described above are the chosen scan length/sample density

specifications, scan time, scan direction, stylus force, and the vertical units.

2.4. Keyboard

There is a figure showing the keyboard in the hard copy manual. A brief description

of key functions follows. For further information on using the keyboard, see the

detailed operating procedures in Section 3.

ENT "Enter" Pressing this button will initiate/terminate "Enter Mode" in which

the operator can change parameters in the scan menu.

VID "Video" Toggles the screen between the sample display and the scan menu.

O Moves the stage out from under the stylus to the "home" position, for loading or

unloading of samples.

- Holding this key down when a plot is on the video screen displays the cross

sectional area of the profile as described under Area in Section 2.2 (Data

Display) above.

. Holding this key down when a plot is on the video screen displays the

baseline of the profile as described under Avg in Section 2.2 (Data Display)

above.

Numeric Pad Used when programming stage. Please see manufacturer's manual for

more details.

RESET If pressed prior to a scan, will return measurement cursors to their

position during the previous scan. Used for other miscellaneous

operations, such as setting the time clock.

Stage Keys These include the 4 arrow keys and the NXT (next) key in the center.

The arrows indicate the direction in which the stage, (not the stylus),

will move when pressed. They are used to move the sample stage and

during stage programming. The stage has two speeds in each direction:

0.13 mm/sec and 13 mm/sec. Pressing the NXT key before the desired

arrow key causes the stage to move at the faster rate.

RANGE Allows the user to set the scan length/sample density. The

highlighted values change as either the ^ or “down arrow” key is

pressed.

PLOT Used to zoom in on a section of a profile between the measurement

cursors, or to level a profile.

CUR This key and its associated <- and -> keys allow the operator to set scan

direction and place the measurement cursors.

LEVEL Used to level the baseline of a profile.

TABLE The ^ and “down arrow” keys will move the sample chuck up and down

respectively.

PRINT Guess.

FEED Printer paper feed.

START/STOP Starts/stops the scan.

3. Operating Procedure

3.1. Setting Scan Parameters

Up to 9 scan menus containing scan parameters can be stored in the system. It is

usually convenient, however, to simply bring up the default menu and modify it to suit

your needs, as follows.

1. Make sure the power is on. Turn up the brightness.

2. Press VID to bring up a menu.

3. Press ENT to initiate "Enter Mode". You will see a message at the bottom of the

screen "SCAN MENU may now be changed".

4. Use the RANGE keys to select the desired scan length and sampling rate. Note

how the scan time changes as you move through the options.

5. Use the CUR (cursor) arrow keys to indicate desired scan direction. Note: this is

the direction in which the stylus will move, not the substrate.

6. Use the CUR key to toggle the vertical units (MODE) between kA and Mm.

7. Once all the parameters are set as you want them, press ENT to leave "Enter

Mode". Press VID to toggle the screen display back to the sample. You are now

ready to start your scan.

3.2. Scanning a Sample

1. Press the TABLE key to lower the substrate table. Make sure that there is enough

room for your sample to clear the stylus housing when it is mounted on the chuck.

2. Press "0" to bring the stage to the home position (i.e., out from under the stylus).

3. Place your sample on the chuck and turn on the vacuum toggle.

4. Use the NXT and stage arrow keys to bring your sample under the stylus.

5. Press TABLE ^ key and watch the screen. You should see your sample come

into view, and the stylus lower and come to rest on the surface of your substrate. If

you continue to press TABLE ^, the stylus will retract. Thus the TABLE ^ button

toggles the stylus between its fully retracted and lowered position. Always retract the

stylus when moving the sample.

6. Use the zoom knob to adjust the magnification of your sample. Use the stage arrow

keys to move the sample to the desired scan location.

7. With the sample in position and the desired Scan Menu parameters set, press

START/STOP to initiate the scan. The sample table will automatically rise if it is

not already in the up position. If it must rise more than the amount it lowered after

the last scan, it will stop and START/STOP must be pressed again.

The stylus will first make a short pass "away" from the section of the sample to be

scanned. It will then reverse direction so that it is traveling in the direction

specified in the Scan Menu. Data collection will begin when the stylus passes

the point where it was positioned prior to starting to scan. When finished, the table

will lower so the sample can be removed.

8. To interrupt a scan, press START/STOP. The data collected to that point will be

displayed in the usual manner.

4. Manipulating Data

After the scan, the profile is plotted on the screen with a summary of the data

displayed next to it. For many applications, this initial display will contain all

required information. When further analysis is needed, it can be performed in the

instrument's computer without having to re-scan. If the profile appears tilted,

proceed to Section 4.3 before taking any measurements.

4.1. Overriding Vertical Auto-Ranges

To change the vertical range after the scan, press the RANGE ^ or “down arrow”

key. The range is indicated in the data summary, next to the label VERT. When

the desired range is selected, press PLOT to redraw the image. The profile will

be centered vertically where it intersects the left cursor. Some of the profile

may spill of the screen at higher magnifications.

4.2. Measurement Cursors - Measuring Profile Features

On the edges of the profile are two dashed vertical lines. These are the

measurement cursors, used to make horizontal and vertical measurements off the

plot. Cursor-derived measurement data is continuously displayed in the data

summary on the left side of the screen.

The CUR button selects the cursor to be moved. You can see the active cursor

indicator appear over each cursor in turn, and then over both as you repeatedly

press this button. When both cursors are active, they will remain a fixed distance

apart as they move simultaneously. The arrow buttons will move the cursor(s)

in the direction indicated. Holding down these buttons causes the cursors to

automatically speed up for long moves.

The cursors can be returns to the ends of the scan by pressing CUR followed by

ABT. This also undoes all zooming (see below), returning to the plot displayed

immediately after the scan.

Vertical measurements are shown in the data summary under the heading

VERT. Profile heights at the cursors appear directly beneath the label. The

highlighted area directly below shows the difference between the heights. Thus to

measure a step height, simply position one cursor so that it intersects the

substrate at the base of the step. Position the other so that it intersects the profile

on top of the step. The vertical difference shown in the highlighted area

under VERT is the step height.

Horizontal measurements are shown in the data summary under the heading

HORIZ. Scan positions at the cursors appear directly beneath the label. The

highlighted area directly below shows the distance between the cursors. To

measure the width of a feature, position on cursor on each side of it and

read the horizontal distance shown in the highlighted

area under HORIZ.

Once positioned, the cursors will retain those positions for subsequent scans.

They will not move unless forced to do so by a change in scan length or they are

moved by the operator. If a batch of similar samples is to be tested, the cursors

can be left in position and the measurement can be read directly from the data

summary with minimum operator intervention.

4.3. Leveling the Plot

When the profile is plotted after a scan, a leveling program aligns the trace to the

two axes to facilitate accurate measurement. Leveling cursors, vertical lines

normally invisible to the user, are used to indicated two points on the profile

whose heights are equal. The leveling program re-computes the measurement

data to make these heights equal on the display. The rest of the profile is

displayed relative to these points.

The leveling cursor are normally located at the ends other scan. If one cursor is

on a surface feature higher or lower than the other cursor, the substrate

will appear tilted when the program makes both cursor heights equal.

The condition described above can be corrected by moving the leveling cursors

to places on the profile where the heights are equal. Ideally, these should

both be on the substrate, near the ends of the scan, although any equally high

points may be used.

If the message "SCAN MENU may now be changes" is displayed, press ENT to

terminate "Enter Mode".

1. Press the orange LEVEL key. The screen will show the leveling cursors

which are dotted vertical lines, instead of the dashed lines used for measurement

cursors. The following message will appear at the bottom of the screen:

"MANUAL LEVELING may now be changed".

2. Position the cursor so the actual profile height is the same at each cursor.

Ignore the indicate profile height. The leveling cursor are moved using the <- and

-> keys in conjunction with CUR as described in Section 4.2.

3. Press the PLOT or ENT key. The profile will be redrawn with the points

under the cursors at equal heights. The horizontal positions of the leveling cursors

are shown in the lower left corner of the screen.

4.4. Plotting Individual Profile Features - Zoom

Any portion of a profile can be magnified for close examination. Using the

procedures of the previous section, position the cursors so that they bracket the

feature of interest. Press the yellow PLOT button. The display will zoom in

on the bracketed region. The horizontal and vertical scales will each auto-range

to provide the greatest magnification that the feature's size will allow.

The cursors will still be located at the same points on the profile after the image

is re-plotted. The profile will be positioned to place the left cursor at

the left edge of the screen. The right cursor will appear in the right half of the

screen after the zoom.

To return to the previous magnification after zooming, press PLOT again without

moving the cursors. the cursors will remain in their most recent position.

Pressing PLOT again will not cause zooming until a cursor has been moved.

To return to the screen showing the entire profile, press ABT. This undoes all

zooming, but leaves the cursors at their most recent positions on the profile.

Pressing CUR then ABT undoes all zooming and returns the cursors to the ends

of the scan.

4.5. Average Difference Mode

In Average Difference mode, the system computes the difference between

average height measurements. When this mode is entered the currently displayed

average is stored as a reference reading. The instrument displays the

difference between this reference and all subsequent average height

measurements. This mode remains in effect until it is exited, even if another

scan is taken.

1. Level the plot if necessary (see Section 4.3).

2. Position the measurement cursors on the section of the profile to be stored as

the reference reading.

3. Press ENT, then the "dot" key [+].

The vertical height field will be re-labeled "dAv" for average difference. It

will read "0" until the cursors are moved.

The difference between cursor heights is not shown in this mode, since the

cursors are typically placed at the same profile height when an average is being

taken.

The reference profile section is marked with vertical lines called the average

reference cursors. These cursors are drawn with large dashes and connected by

bars at the top and bottom of the screen to distinguish them from the other

cursors.

1. Position the measurement cursors on the profile section to be compared to

the reference.

The field labeled "Avg" will show the average profile height between the

measurement cursors. The field labeled "dAv" will now show the difference

between this value and the reference reading.

When the measurement cursors are moved, the average height and average

difference will be updated.

2. To exit Average Difference mode, press CUR then ABT. The vertical

height field will now display the difference between the cursor heights. See

the hard copy manual for a figure showing the Average Difference Mode

display.

4.6. Printing

There are three available printing modes: "Screen" in which the entire contents

of the screen, including the plot of the profile, is printed; "Summary Data"

prints out only the data shown on the left side of the screen; "Data Send"

sends all data to the RS-232C

serial output instead of the printer.

Screen and Summary Data print modes are used to make print-outs on the

internal printer or on the optional remote printer. Data Send uses the RS-

232C serial output to send the data to an external device such as

an 80-column serial printer or a host computer.

Your choice of printer mode remains in effect until changed. A printout or

data send can be initiated whenever the results of a scan are are displayed on

the screen.

1. Initiate "Enter Mode" by hitting the ENT key if you have not already done

so.

2. Press the white print button to change the print mode. The selection will

be highlighted in reverse video.

3. With the desired mode selected, press ENT to leave the Scan Menu, or

press START/STOP to leave the Scan Menu and begin a scan.

4. To print, press the PRINT button. To abort a printout before it is complete,

press ABT.

APPENDIX A

Printer Paper Change

(1) Remove the printer cover by lifting at the front and disengaging the tab at the

rear of the cover.

(2) Pull forward on the small lever located on the right of the printer in front of

the rubber roller. This will release any paper remaining in the printer.

(3) Remove the old spool from the printer.

(4) Place the new spool in the printer, orienting it so that the paper unwinds from

underneath as it leaves the spool. (This is thermal paper; if you do not have the

correct side facing the printer, nothing will be printed on the paper.)

(5) Insert the paper underneath the rubber roller from behind. (This is easier if the end

of the paper is cut so that it tapers to a point.)

(6) The paper will emerge at the top of the rubber roller, aiming back. Pull

out several inches of paper.

(7) Push the small lever back to engage the rubber roller against the paper. (The

paper will not feed unless the roller is engaged.) Caution: Do not pull on the paper

once the roller is engaged.

(8) Carefully replace the cover, threading the paper through the slot.

Table of contents

Popular Laboratory Equipment manuals by other brands

KoamTac

KoamTac SKXPro quick guide

Hettich

Hettich UNIVERSAL 320 operating instructions

Terra Universal

Terra Universal Ductless Exhaust Fume Hood Installation and operating guide

Fluidigm

Fluidigm Juno Getting started guide

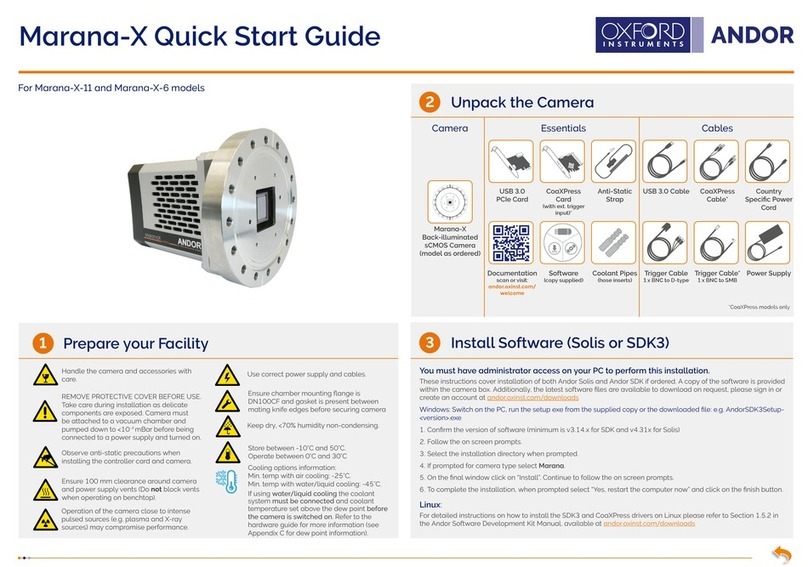

Oxford Instruments

Oxford Instruments Andor Marana-X-11 quick start guide

Thermo Scientific

Thermo Scientific 2860 Service manual