CONTENTS

1

3640 330580 (12--00)

CONTENTS

Page

SAFETY PRECAUTIONS 3.................

OPERATION 5..........................

OPERATOR RESPONSIBILITY 5.........

MACHINE COMPONENTS 7.............

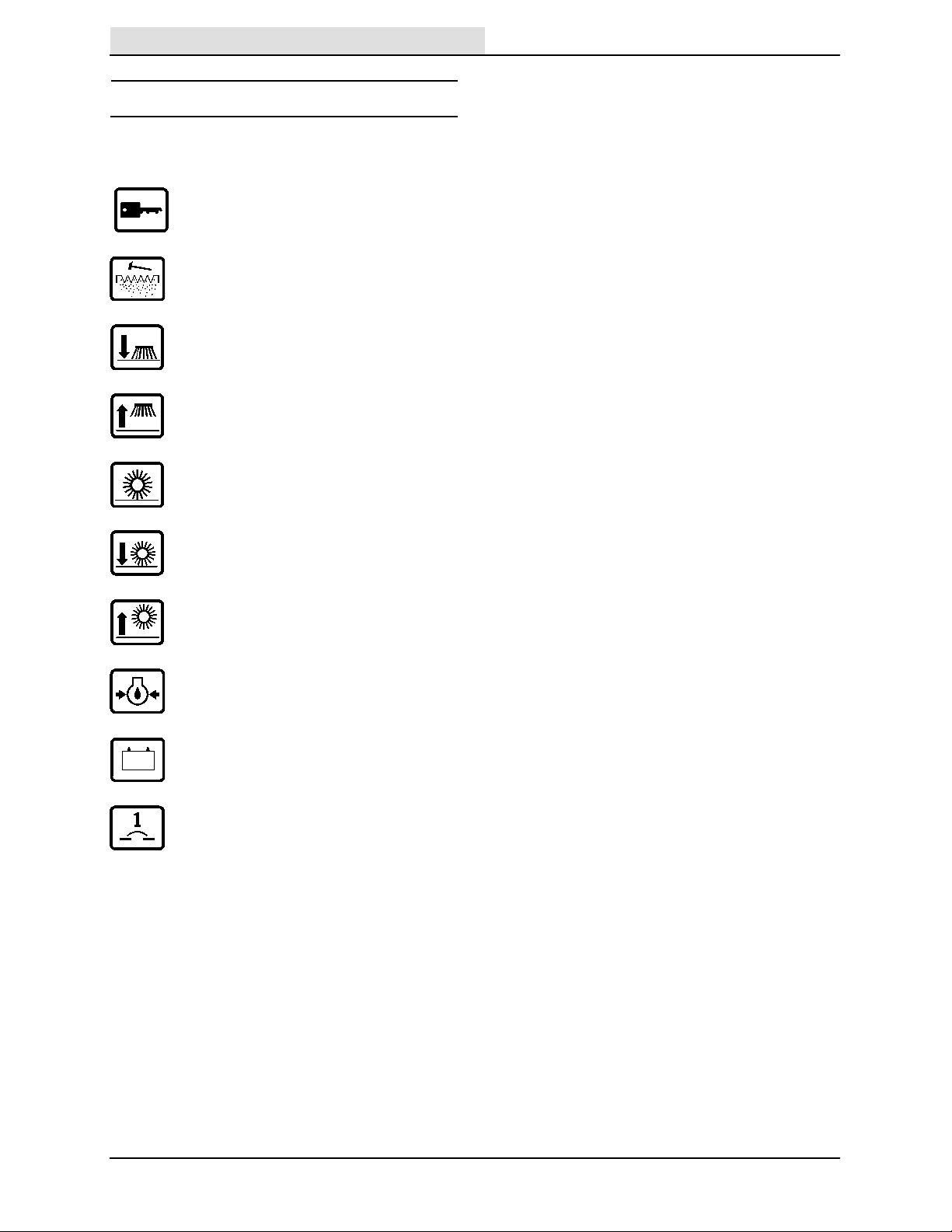

SYMBOL DEFINITIONS 8................

CONTROLS AND INSTRUMENTS 9......

OPERATION OF CONTROLS 10..........

DIRECTIONAL CONTROL LEVER 10...

CLUTCH HANDLE 12..................

MAIN BRUSH LEVER 12...............

SIDE BRUSH LEVER 13...............

ENGINE CHOKE KNOB 13.............

LOW OIL WARNING INDICATOR 13....

LOW BATTERY CHARGE

INDICATOR 14.....................

STEERING BAR 14...................

STEERING BAR ADJUSTMENT

KNOBS 14........................

IGNITION KEY SWITCH 15............

HOURMETER 15.....................

VACUUM WAND 15...................

CIRCUIT BREAKER 16................

THERMO SENTRYt16...............

FILTER SHAKER SWITCH 16..........

HOW THE MACHINE WORKS 17..........

PRE-OPERATION CHECKLIST 17.........

CHANGING AN LPG TANK 19................

STARTING THE MACHINE 21.............

SWEEPING AND BRUSH

INFORMATION 22....................

SWEEPING 23..........................

STOP SWEEPING 24....................

EMPTYING THE DEBRIS HOPPER 26.....

STANDARD HOPPER 26.................

HOPPER DUMP ASSIST

HANDLE (OPTION) 27.................

REPLACING THE BAG FILTER 28.........

CLEANING THE FILTER

COMPARTMENT 29...................

POST-OPERATION CHECKLIST 30........

OPERATION ON INCLINES 30............

OPTIONS 31..........................

WIDE TRACK TIRES AND HEAVY DUTY

CASTERS 31......................

MACHINE TROUBLESHOOTING 32.......

MAINTENANCE 33.........................

MAINTENANCE CHART 33...............

LUBRICATION 34........................

ENGINE 34..........................

HEAVY DUTY CASTERS (OPTION) 34..

FUEL SYSTEM 35.......................

FUEL FILTER AND SEDIMENT BOWL 35

GAS VALVE 35.......................

ENGINE 36..........................

AIR FILTER 36........................

SPARKPLUG 36......................

Page

SKIRTS AND SEALS 37..................

MAIN BRUSH SKIRTS 37..............

HOPPER DUST SEAL 37..............

REAR SKIRT 37......................

HOPPER LIP SKIRT 38................

FILTER COMPARTMENT

DOOR SEAL 38....................

VACUUM INLET PLATE 38................

CLEANING THE PANEL FILTER 39.........

BRUSHES 40..........................

MAIN BRUSH 40......................

REPLACING THE MAIN BRUSH 40..

CHECKING AND ADJUSTING MAIN

BRUSH PATTERN 42............

ROTATING THE MAIN BRUSH 43....

SIDE BRUSH(ES) 44..................

REPLACING THE SIDE

BRUSH(ES) 44..................

ELECTRIC MOTORS 44..................

BELTS AND CHAINS 45..................

VACUUM FAN BELT 45................

MAIN BRUSH BELT 45................

STATIC DRAG CHAIN 45..............

CLUTCH CABLE 45......................

TIRES 46...............................

PUSHING AND TRANSPORTING

THE MACHINE 47......................

PUSHING THE MACHINE 47.........

TRANSPORTING THE MACHINE 47..

STORING MACHINE 49...................

SPECIFICATIONS 50........................

GENERAL MACHINE

DIMENSIONS/CAPACITIES 50..........

GENERAL MACHINE PERFORMANCE 50...

POWER TYPE 51.........................

ELECTRIC MOTORS 51...................

TIRES 51................................

MACHINE DIMENSIONS 52................

INDEX 53...................................