Tense RGM-12S User manual

RGM-12S

USER MANUAL

www.tense.com.tr

www.tenseenerji.com

ELEKTRİK - ELEKTRONİK SAN.TİC.A.Ş.

1

About RGM-12S

RGM-12S reactive power control relay is designed to reduce inductive powers not used by

loads but drawn from the network. If inductive reactive power is drawn from the network, it

intervenes by activating capacitors of appropriate value. In this way, it tries to bring the Cos fi

value to the desired level.

Index

1

1

About RGM-12S

8

Program (Intervention Logic) Change

10

9

Current Transformer Test

Determining the Step Count

11

Current Transformer Ratio

12

Step Measurement

13

Cosine Set Value

13

Cosine Tolerance Value

14

Step Drive Time

14

15

15

16

16

17

17

18

18

18

19

20

21

22

22

Step Release Time

Step Discharge Time

Over Compensation

Low Compensation

Harmonic Voltage

Harmonic Current

High Voltage

Blocking Access to Settings

Returning to Factory Settings

Fan and Alarm Output

Capacitor Calculation Table According to Connection Type

Factory Set Values

Dimensions

Technical Specifications

Contact Informations

11

Step Values

Considerations in Current Transformer Selection and Connection 3

3

4

5

6

7

Device Maintenance

Connection Diagram

Screen Introduction

Measurement Screens

Setting Screens

Matters to be Considered in Power Factor Correction

2

2

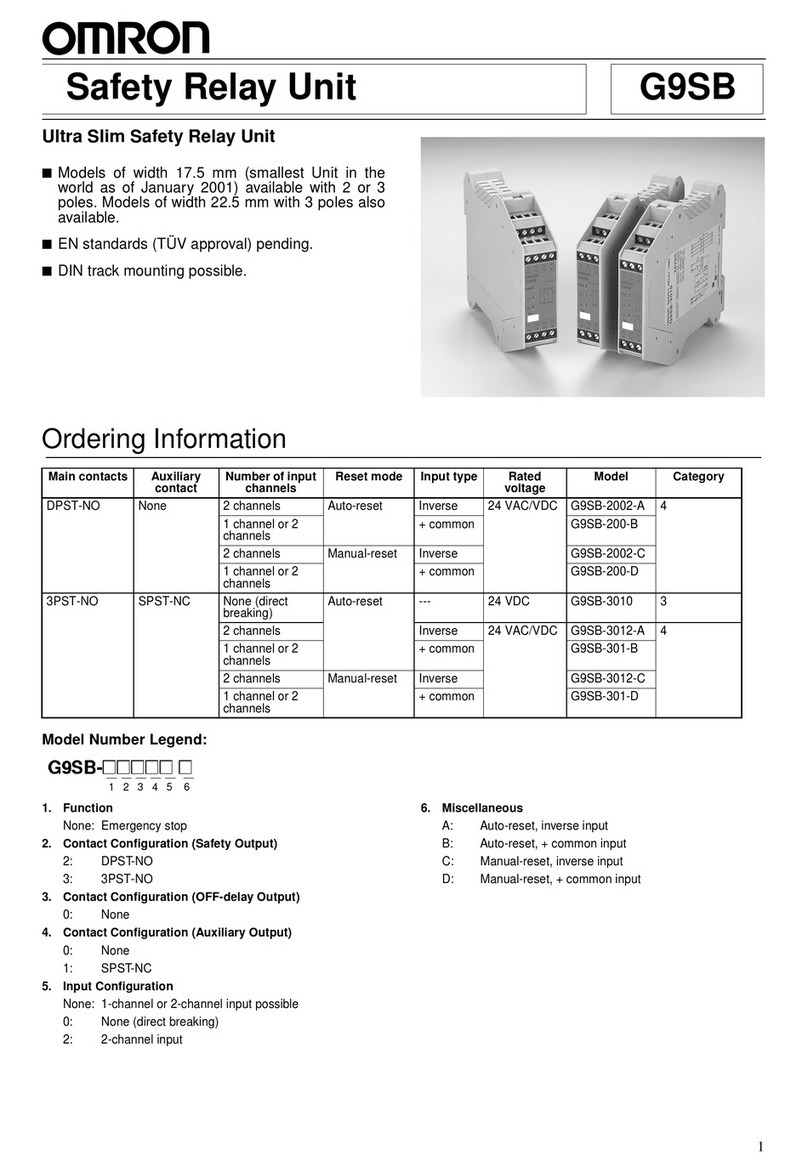

Features

Settings

Warnings

Easy to Install and Use with 20mm. 4 Digit Led Display

7 Different Compensation Programs

Manual Compensation Option

Can Only Compensate Inductive Systems

Automatic Step Measurement

Voltage and Current Harmonic Alarm Values Adjustable

Over and Under Compensation Alarm Values Can Be Set

Voltage, Harmonic Voltage/Current, Over and Under Compensation Alarm Output

Step Drive, Release and Discharge Times are Adjustable

Up to the 15th harmonic THD-I Can Be Monitored

Voltage, Current and Frequency Values Can Be Monitored

Active Power, Reactive Power and Apparent Power Values Can be Monitored

Up to the 15th harmonic THD-V Can Be Monitored

Cosine Value Can Be Monitored

Power Factor Value Can Be Monitored

Capacitive/Active and Inductive/Active Ratios Can Be Monitored

Automatic Fan Output

Step Values Can Be Monitored

Same Aging in Steps (In Certain Compensation Programs)

Features

1

About RGM-12S

RGM-12S reactive power control relay is designed to reduce inductive powers not used by

loads but drawn from the network. If inductive reactive power is drawn from the network, it

intervenes by activating capacitors of appropriate value. In this way, it tries to bring the Cos fi

value to the desired level.

Index

1

1

About RGM-12S

8

Program (Intervention Logic) Change

10

9

Current Transformer Test

Determining the Step Count

11

Current Transformer Ratio

12

Step Measurement

13

Cosine Set Value

13

Cosine Tolerance Value

14

Step Drive Time

14

15

15

16

16

17

17

18

18

18

19

20

21

22

22

Step Release Time

Step Discharge Time

Over Compensation

Low Compensation

Harmonic Voltage

Harmonic Current

High Voltage

Blocking Access to Settings

Returning to Factory Settings

Fan and Alarm Output

Capacitor Calculation Table According to Connection Type

Factory Set Values

Dimensions

Technical Specifications

Contact Informations

11

Step Values

Considerations in Current Transformer Selection and Connection 3

3

4

5

6

7

Device Maintenance

Connection Diagram

Screen Introduction

Measurement Screens

Setting Screens

Matters to be Considered in Power Factor Correction

2

2

Features

Settings

Warnings

Easy to Install and Use with 20mm. 4 Digit Led Display

7 Different Compensation Programs

Manual Compensation Option

Can Only Compensate Inductive Systems

Automatic Step Measurement

Voltage and Current Harmonic Alarm Values Adjustable

Over and Under Compensation Alarm Values Can Be Set

Voltage, Harmonic Voltage/Current, Over and Under Compensation Alarm Output

Step Drive, Release and Discharge Times are Adjustable

Up to the 15th harmonic THD-I Can Be Monitored

Voltage, Current and Frequency Values Can Be Monitored

Active Power, Reactive Power and Apparent Power Values Can be Monitored

Up to the 15th harmonic THD-V Can Be Monitored

Cosine Value Can Be Monitored

Power Factor Value Can Be Monitored

Capacitive/Active and Inductive/Active Ratios Can Be Monitored

Automatic Fan Output

Step Values Can Be Monitored

Same Aging in Steps (In Certain Compensation Programs)

Features

2

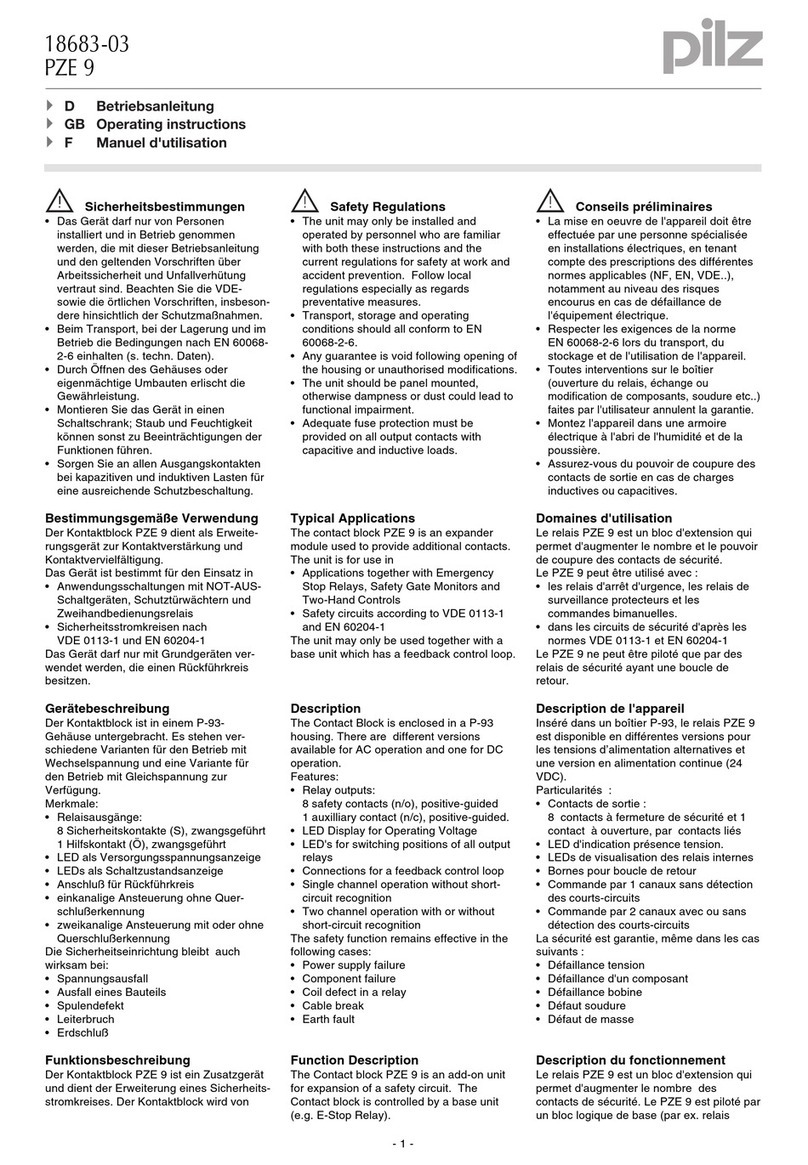

Make sure that there is no rapid load change in the system while performing current

transformer test and step measurement.

Compensation begins with the balanced arrangement of the load distribution in the electrical

installation of the system.

For the current transformer test, connect three phase capacitors in 1/40 (*) of the current

transformer value to the first two (C1 and C2) stages of the device.

( * : The total value of the first two steps.)

While preparing the compensation panel, make sure that new steps can be easily added for

changes that may occur later.

It is recommended to add new stages with the same value in terms of the lifetime of contactors

and capacitors in frequently used stages.

Matters to be Considered in Power Factor Correction

Select the fuse current values used in the steps according to the capacitor power

and mark the connection as a lifting element.

Use separate fuses for supply coils of step contactors.

Use compensation contactors and discharge coils in the steps.

Single phase connection in three phase systems is only suitable for balanced load draws.

Otherwise, the desired rates will not be achieved.

Warnings

Use the device in accordance with the instructions set by us.

After the device is mounted, leave a space of at least 10 cm. behind it.

Fix the device to the front cover of the panel with the accompanying apparatus.

Balance the inside and outside temperature in metal panels. Otherwise, water droplets are

formed on the ceiling of the panel due to the temperature difference in humid environments

and this is dangerous for open connected busbars.

Keep the switch and circuit breaker close to the device and within easy reach of the operator.

Mark the switch or circuit breaker as the disconnection element of the device.

Include a switch or circuit breaker in the assembly.

During installation, there should be no electricity in the connection cables.

Shielded and twisted cord cables should be used in input and output lines that are not

connected to the network. These cables should not be passed near high power lines and devices.

3

Maintenance of the Device

Power off the device and disconnect it from the connections. Clean the body of the device

with a slightly damp or dry cloth. Do not use conductors or other chemicals that could damage

the device as cleaning agents. After the device is cleaned, make its connections and make sure

that the device is powered and working.

Considerations in Current Transformer Selection and Connection

Make sure that the current transformer value is higher than the maximum current drawn

from the system.

It is recommended that the class of the current transformers to be used in compensation

systems should be 0.5.

Only X/5A current transformers can be connected to the RGM-12S.

Make sure that there is no load before the current transformers. Otherwise, there will be

differences in consumption and rates between the device and the electricity meter.

The current transformer must be connected to the phase from which the voltage input of the

device is received. Otherwise, the device will not be able to perform the current transformer test.

Current transformer output cables should not be close to the high voltage line.

It is recommended to use minimum 1.5mm² of cables to be connected to current transformer

output ends. As the distance gets longer, it is recommended to thicken the cable or to use a

current transformer with high output power.

Fix the current transformer to the busbar, cable or rail so that it does not shake.

The cable connected to the current transformer output ends should be made as one piece as

possible. Otherwise, there may be errors in the measurements and the current transformer

test may not be performed.

2

Make sure that there is no rapid load change in the system while performing current

transformer test and step measurement.

Compensation begins with the balanced arrangement of the load distribution in the electrical

installation of the system.

For the current transformer test, connect three phase capacitors in 1/40 (*) of the current

transformer value to the first two (C1 and C2) stages of the device.

( * : The total value of the first two steps.)

While preparing the compensation panel, make sure that new steps can be easily added for

changes that may occur later.

It is recommended to add new stages with the same value in terms of the lifetime of contactors

and capacitors in frequently used stages.

Matters to be Considered in Power Factor Correction

Select the fuse current values used in the steps according to the capacitor power

and mark the connection as a lifting element.

Use separate fuses for supply coils of step contactors.

Use compensation contactors and discharge coils in the steps.

Single phase connection in three phase systems is only suitable for balanced load draws.

Otherwise, the desired rates will not be achieved.

Warnings

Use the device in accordance with the instructions set by us.

After the device is mounted, leave a space of at least 10 cm. behind it.

Fix the device to the front cover of the panel with the accompanying apparatus.

Balance the inside and outside temperature in metal panels. Otherwise, water droplets are

formed on the ceiling of the panel due to the temperature difference in humid environments

and this is dangerous for open connected busbars.

Keep the switch and circuit breaker close to the device and within easy reach of the operator.

Mark the switch or circuit breaker as the disconnection element of the device.

Include a switch or circuit breaker in the assembly.

During installation, there should be no electricity in the connection cables.

Shielded and twisted cord cables should be used in input and output lines that are not

connected to the network. These cables should not be passed near high power lines and devices.

3

Maintenance of the Device

Power off the device and disconnect it from the connections. Clean the body of the device

with a slightly damp or dry cloth. Do not use conductors or other chemicals that could damage

the device as cleaning agents. After the device is cleaned, make its connections and make sure

that the device is powered and working.

Considerations in Current Transformer Selection and Connection

Make sure that the current transformer value is higher than the maximum current drawn

from the system.

It is recommended that the class of the current transformers to be used in compensation

systems should be 0.5.

Only X/5A current transformers can be connected to the RGM-12S.

Make sure that there is no load before the current transformers. Otherwise, there will be

differences in consumption and rates between the device and the electricity meter.

The current transformer must be connected to the phase from which the voltage input of the

device is received. Otherwise, the device will not be able to perform the current transformer test.

Current transformer output cables should not be close to the high voltage line.

It is recommended to use minimum 1.5mm² of cables to be connected to current transformer

output ends. As the distance gets longer, it is recommended to thicken the cable or to use a

current transformer with high output power.

Fix the current transformer to the busbar, cable or rail so that it does not shake.

The cable connected to the current transformer output ends should be made as one piece as

possible. Otherwise, there may be errors in the measurements and the current transformer

test may not be performed.

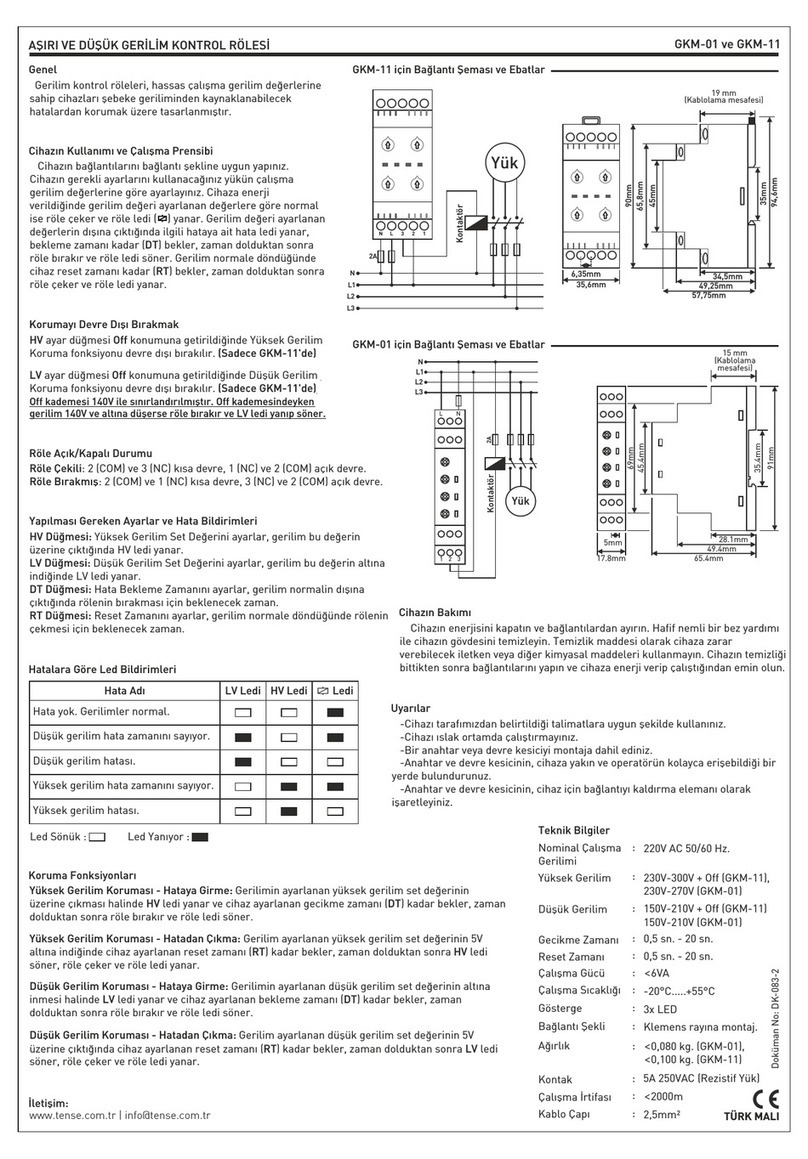

Single Phase Connection Diagram (L-N)

4

Pr2: Step Values (kVar) / Step Test

Pr5: Step Drive Time (sec)

Pr6: Step Release Time (sec)

Pr7: Step Discharge Time (sec)

Pr3: Cosine Set

Pr4: Cosine Tolerance (%)

Pr12: High Voltage Set (V)

Pr11: THD-I Set (%)

Pr10: THD-V Set (%)

Pr9: Low Compensation

Pr8: Over Compensation

Pr1: Current Transformer Ratio

Current (A)

P (kW)

Q (kVAr)

S (kVA)

Voltage (V)

PF

Q/P (%Ind)

-Q/P (%Cap)

F (Hz)

COS φ

THD-I (%)

THD-V (%)

5s

DOWN ESC

+

(C.T. TEST)

UP ESC

+

(STEP COUNT)

SET

UP

DOWN

ESC 5s

(MODE)

RGM-12S Monophase Power Factor Controller

FAN

5s

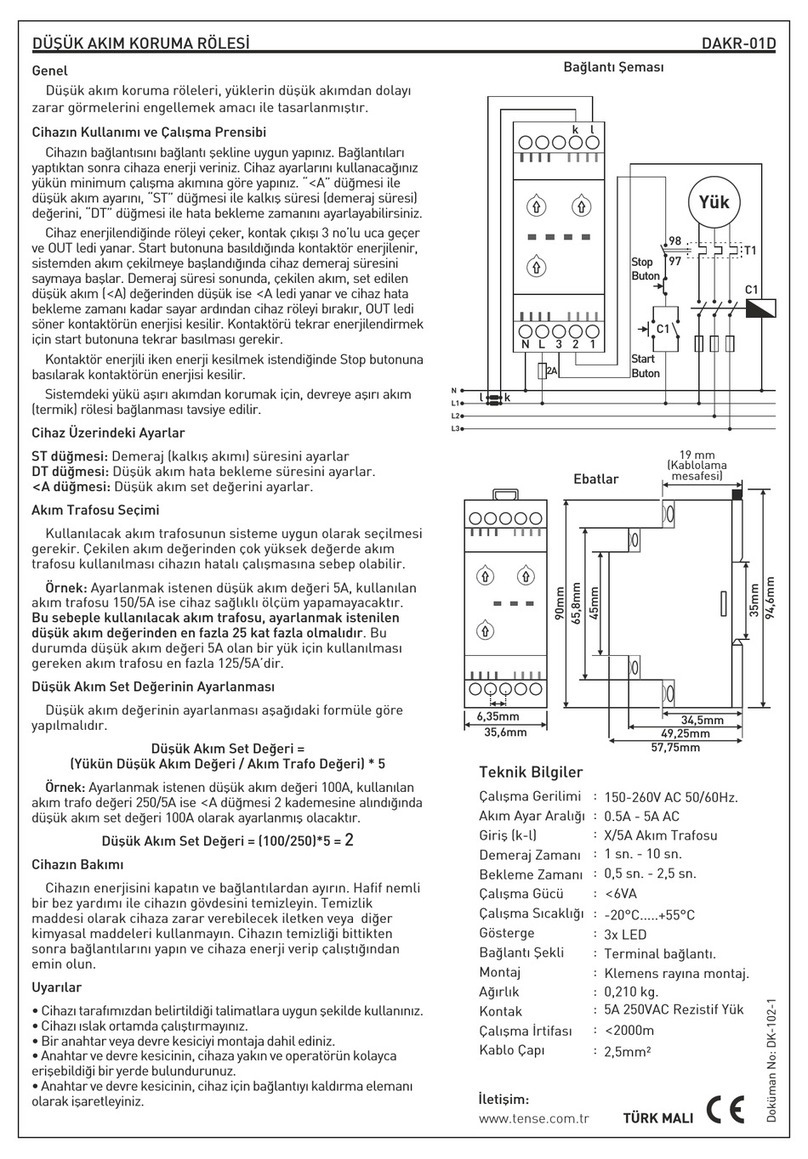

Screen Introduction

5

1

32

6

7

8

9

1- Step LEDs: These are the LEDs that light up when the steps are active.

5- Fan LED: It is the LED that lights up to inform the user when the fan output is active.

6- Alarm LED: It is the LED that lights up to warn the user in alarm situations.

2- LED Display: It is the screen where all measurements, settings and notifications regarding

the device are transferred to the user.

3- Status LEDs: Compensation status notification LEDs.

OVER: If the cosine value is above the overcompensation value, this LED turns on.

LOW: If the cosine value is below the undercompensation value, this LED turns on.

NORMAL: If the cosine value is between the over and under compensation values, this LED will light.

7- Buttons: They are used for monitoring measurements and making settings.

8- Measurments & Settings LEDs: Indicates that the device is in the measurement or setting menu.

9- Value & Parameter LEDs: When the device is in the measurement menu, it informs that the

measured value is displayed on the screen, and the parameter is displayed while in the setting menu.

4- Compensation Mode LED: Indicates the compensation mode of the device.

ESC Button: When pressed while in the menu, it returns to the upper menu without saving the

values. When pressed outside the menu (on the measurement screens) it always brings up the

Cosine measurement screen. When pressed for 5 seconds, Compensation Mode screen is entered.

SET Button: Enters the menu/parameter. If the parameter has been changed, it will save and

exit the parameter.

UP Button: Scrolls through measured values outside the menu. Switches between parameters

while in the menu. Increases the selected value while inside the parameters.

DOWN Button: Scrolls through measured values o utside the menu. Switches between parameters

while in the menu. Decreases the selected value while inside the parameters.

UP + ESC Button: Step Count screen is entered when these two buttons are pressed together for 5 sec.

DOWN + ESC Button: C.T. test screen is entered when these two buttons are pressed together for 5 sec.

4

5

N

L1

L2

L3

N

VoltageCurrent

2A

L

l1k1

Steps (1 to 7)

Harmonic Filter

Capacitor

Thermal

A2

2A

6A

A1

L C1 C2 C3 C4 C5 C6

Steps (8 to 12)

L C8 C9 C10C11C12

Harmonic Filter

Capacitor

Thermal

A2

2A

6A

A1

C7

Fan and Alarm Outputs

LFAN

6A

A2

2A

A1

ALR

Fan

A2

2A

A1

Alarm

Contactor

Contactor

Contactor

Contactor

To Load

Single Phase Connection Diagram (L-N)

4

Pr2: Step Values (kVar) / Step Test

Pr5: Step Drive Time (sec)

Pr6: Step Release Time (sec)

Pr7: Step Discharge Time (sec)

Pr3: Cosine Set

Pr4: Cosine Tolerance (%)

Pr12: High Voltage Set (V)

Pr11: THD-I Set (%)

Pr10: THD-V Set (%)

Pr9: Low Compensation

Pr8: Over Compensation

Pr1: Current Transformer Ratio

Current (A)

P (kW)

Q (kVAr)

S (kVA)

Voltage (V)

PF

Q/P (%Ind)

-Q/P (%Cap)

F (Hz)

COS φ

THD-I (%)

THD-V (%)

5s

DOWN ESC

+

(C.T. TEST)

UP ESC

+

(STEP COUNT)

SET

UP

DOWN

ESC 5s

(MODE)

RGM-12S Monophase Power Factor Controller

FAN

5s

Screen Introduction

5

1

32

6

7

8

9

1- Step LEDs: These are the LEDs that light up when the steps are active.

5- Fan LED: It is the LED that lights up to inform the user when the fan output is active.

6- Alarm LED: It is the LED that lights up to warn the user in alarm situations.

2- LED Display: It is the screen where all measurements, settings and notifications regarding

the device are transferred to the user.

3- Status LEDs: Compensation status notification LEDs.

OVER: If the cosine value is above the overcompensation value, this LED turns on.

LOW: If the cosine value is below the undercompensation value, this LED turns on.

NORMAL: If the cosine value is between the over and under compensation values, this LED will light.

7- Buttons: They are used for monitoring measurements and making settings.

8- Measurments & Settings LEDs: Indicates that the device is in the measurement or setting menu.

9- Value & Parameter LEDs: When the device is in the measurement menu, it informs that the

measured value is displayed on the screen, and the parameter is displayed while in the setting menu.

4- Compensation Mode LED: Indicates the compensation mode of the device.

ESC Button: When pressed while in the menu, it returns to the upper menu without saving the

values. When pressed outside the menu (on the measurement screens) it always brings up the

Cosine measurement screen. When pressed for 5 seconds, Compensation Mode screen is entered.

SET Button: Enters the menu/parameter. If the parameter has been changed, it will save and

exit the parameter.

UP Button: Scrolls through measured values outside the menu. Switches between parameters

while in the menu. Increases the selected value while inside the parameters.

DOWN Button: Scrolls through measured values o utside the menu. Switches between parameters

while in the menu. Decreases the selected value while inside the parameters.

UP + ESC Button: Step Count screen is entered when these two buttons are pressed together for 5 sec.

DOWN + ESC Button: C.T. test screen is entered when these two buttons are pressed together for 5 sec.

4

5

N

L1

L2

L3

N

VoltageCurrent

2A

L

l1k1

Steps (1 to 7)

Harmonic Filter

Capacitor

Thermal

A2

2A

6A

A1

L C1 C2 C3 C4 C5 C6

Steps (8 to 12)

L C8 C9 C10C11C12

Harmonic Filter

Capacitor

Thermal

A2

2A

6A

A1

C7

Fan and Alarm Outputs

LFAN

6A

A2

2A

A1

ALR

Fan

A2

2A

A1

Alarm

Contactor

Contactor

Contactor

Contactor

To Load

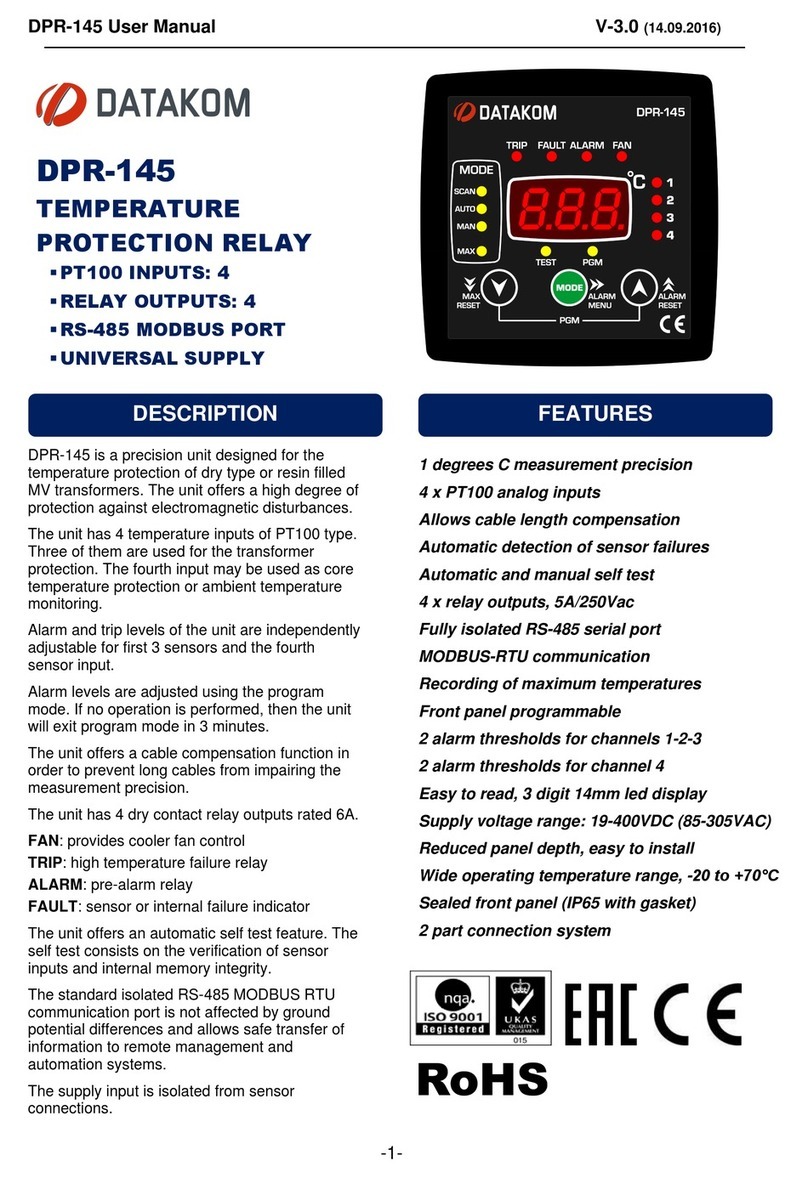

Measurement Screens

6

8888-985

... . 8 8 8 83 5 0

.. . . 8 8 8 82 3 0

.. . .

Figure φ)-1 (Cos Figure-2 (Current (A)) Figure-3 (Voltage (V))

Figure-4 (F (Hz))Figure-12 (PF)

8 8 8 85 0

.. . .

8 8 8 87 9 2 9

.. . .

8 8 8 81 3 8 9

.. . .

8 8 8 88 0 5 0

.. . .

8 8 8 85

.. . .

88888

.. . .

88881 3

.. . .

88882

.. . .

88880850

... .

UP

DOWN

Figure-5 (P (kW))Figure-11 (THD-I (%))

Figure-6 (Q (kVAr))Figure-10 (THD-V (%))

Figure-7 (S (kVA))Figure-8 (-Q/P (%Cap))Figure-9 (Q/P (%Ind))

While on the measurement screen, the

"MEASUREMENTS" led on the device lights up.

While this LED is on, the values shown on the

screen are the values of the measurements. If you

move by pressing the down button while the

MEASUREMENTS led is on, the following

measurement values will be displayed

sequentially. Pressing the up button will display

the previous measurement parameter. While

showing these values, the led for the related

measurement value lights up.

Figure-1: It shows the cosine value.

Figure-2: It shows the current value.

Figure-3: It shows the voltage value.

Figure-4: It shows the frequency value.

Figure-5: It shows the active power value.

Figure-6: It shows the reactive power value.

Figure-7: It shows the apparent power value.

Figure-8: It shows the capacitive/active ratio (%)

value.

Figure-9: It shows the inductive/active ratio (%)

value.

Figure-10: It shows the THD-V (%) value.

Figure-11: It shows the THD-I (%) value.

Figure-12: It shows the power factor value.

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

7

8 8 8 8- 9 8 5

... .

Figure-1

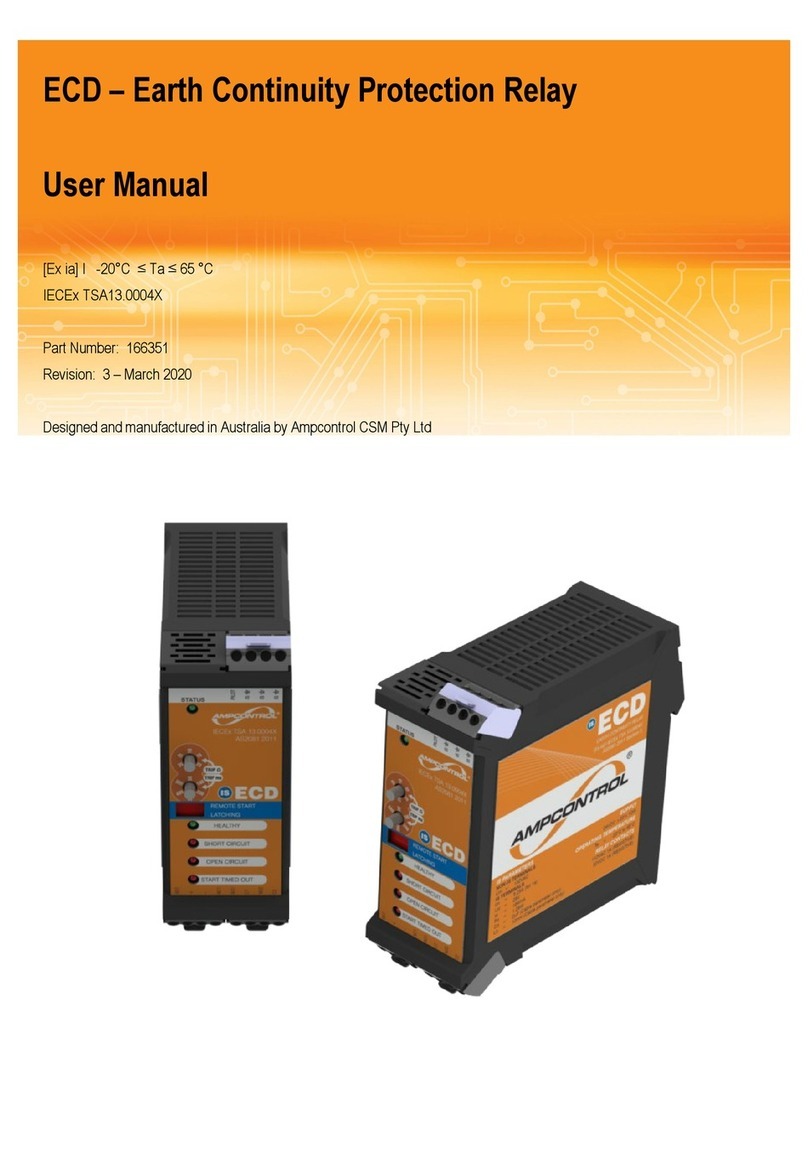

Setting Screen

8 8 8 82 5 0 0

... . 8 8 8 80 9 4 0

... .

8 8 8 82 0

.. . .

8 8 8 80 0 1 0

... .

8 8 8 80 0 1 0

... .

8 8 8 81 0

.. . .

8 8 8 83 0

.. . .

8 8 8 82 5 0

.. . .

8 8 8 8- 9 8 5

.. . .

Figure-13 (Pr.1) Figure-14 (Pr.2) Figure-15 (Pr.3)

8 8 8 81 0

.. . .

Figure-16 (Pr.4)

Figure-24 (Pr.12)

8 8 8 83

.. . .

Figure-17 (Pr.5)

Figure-23 (Pr.11)

8 8 8 83

.. . .

Figure-18 (Pr.6)

Figure-22 (Pr.10)

Figure-19 (Pr.7)Figure-20 (Pr.8)Figure-21 (Pr.9)

In order to enter the setting screen, “SET”

button must be pressed for 2 seconds while in the

measurements screen. “SETTINGS” led on the

device lights up while on the setting screen. While

this LED is on, the values shown on the screen are

the values of the device settings. If you move by

pressing the down button while the SETTINGS led

is on, the values of the following setting

parameters will be displayed sequentially. While

showing these values, the led for the related

measurement value lights up. To change the value

of a parameter in the menu, enter the menu and

reach the relevant parameter with the help of up /

down buttons. Then press the SET button to enter

the relevant parameter, when you enter the

parameter, the led of the parameter will start to

blink. Then adjust the value you want with the up /

down buttons and press the SET button to save it.

The device will save the value and return to the

upper menu. After this process, the parameter led

will stop flashing and turn on steady.

Figure-13: Pr1: Current Transformer Ratio

Figure-14: Pr2: Step Values

Figure-15: Pr3: Cosine Set Value

Figure-16: Pr4: Cosine Tolerance Value

Figure-17: Pr5: Step Drive Time (sec.)

Figure-18: Pr6: Step Release Time (sec.)

Figure-19: Pr7: Step Discharge Time (sec.)

Figure-20: Pr8: Over Compensation Value

Figure-21: Pr9: Under Compensation Value

Figure-22: Pr10: THD-V Set Value (%)

Figure-23: Pr11: THD-I Set Value (%)

Figure-24: Pr12: High Voltage Set Value

8 8 8 81 0 0

... .

SET

The device shows the Cosine value on the measurements screen on the

left. While on any measurement screen, the SET button is pressed for 2

seconds in order to enter the menu.

(2sec.)

DOWN

UP

DOWN

UP

DOWN

UP

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

DOWN

UP

Measurement Screens

6

8888-985

... . 8 8 8 83 5 0

.. . . 8 8 8 82 3 0

.. . .

Figure φ)-1 (Cos Figure-2 (Current (A)) Figure-3 (Voltage (V))

Figure-4 (F (Hz))Figure-12 (PF)

8 8 8 85 0

.. . .

8 8 8 87 9 2 9

.. . .

8 8 8 81 3 8 9

.. . .

8 8 8 88 0 5 0

.. . .

8 8 8 85

.. . .

88888

.. . .

88881 3

.. . .

88882

.. . .

88880850

... .

UP

DOWN

Figure-5 (P (kW))Figure-11 (THD-I (%))

Figure-6 (Q (kVAr))Figure-10 (THD-V (%))

Figure-7 (S (kVA))Figure-8 (-Q/P (%Cap))Figure-9 (Q/P (%Ind))

While on the measurement screen, the

"MEASUREMENTS" led on the device lights up.

While this LED is on, the values shown on the

screen are the values of the measurements. If you

move by pressing the down button while the

MEASUREMENTS led is on, the following

measurement values will be displayed

sequentially. Pressing the up button will display

the previous measurement parameter. While

showing these values, the led for the related

measurement value lights up.

Figure-1: It shows the cosine value.

Figure-2: It shows the current value.

Figure-3: It shows the voltage value.

Figure-4: It shows the frequency value.

Figure-5: It shows the active power value.

Figure-6: It shows the reactive power value.

Figure-7: It shows the apparent power value.

Figure-8: It shows the capacitive/active ratio (%)

value.

Figure-9: It shows the inductive/active ratio (%)

value.

Figure-10: It shows the THD-V (%) value.

Figure-11: It shows the THD-I (%) value.

Figure-12: It shows the power factor value.

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

7

8 8 8 8- 9 8 5

... .

Figure-1

Setting Screen

8 8 8 82 5 0 0

... . 8 8 8 80 9 4 0

... .

8 8 8 82 0

.. . .

8 8 8 80 0 1 0

... .

8 8 8 80 0 1 0

... .

8 8 8 81 0

.. . .

8 8 8 83 0

.. . .

8 8 8 82 5 0

.. . .

8 8 8 8- 9 8 5

.. . .

Figure-13 (Pr.1) Figure-14 (Pr.2) Figure-15 (Pr.3)

8 8 8 81 0

.. . .

Figure-16 (Pr.4)

Figure-24 (Pr.12)

8 8 8 83

.. . .

Figure-17 (Pr.5)

Figure-23 (Pr.11)

8 8 8 83

.. . .

Figure-18 (Pr.6)

Figure-22 (Pr.10)

Figure-19 (Pr.7)Figure-20 (Pr.8)Figure-21 (Pr.9)

In order to enter the setting screen, “SET”

button must be pressed for 2 seconds while in the

measurements screen. “SETTINGS” led on the

device lights up while on the setting screen. While

this LED is on, the values shown on the screen are

the values of the device settings. If you move by

pressing the down button while the SETTINGS led

is on, the values of the following setting

parameters will be displayed sequentially. While

showing these values, the led for the related

measurement value lights up. To change the value

of a parameter in the menu, enter the menu and

reach the relevant parameter with the help of up /

down buttons. Then press the SET button to enter

the relevant parameter, when you enter the

parameter, the led of the parameter will start to

blink. Then adjust the value you want with the up /

down buttons and press the SET button to save it.

The device will save the value and return to the

upper menu. After this process, the parameter led

will stop flashing and turn on steady.

Figure-13: Pr1: Current Transformer Ratio

Figure-14: Pr2: Step Values

Figure-15: Pr3: Cosine Set Value

Figure-16: Pr4: Cosine Tolerance Value

Figure-17: Pr5: Step Drive Time (sec.)

Figure-18: Pr6: Step Release Time (sec.)

Figure-19: Pr7: Step Discharge Time (sec.)

Figure-20: Pr8: Over Compensation Value

Figure-21: Pr9: Under Compensation Value

Figure-22: Pr10: THD-V Set Value (%)

Figure-23: Pr11: THD-I Set Value (%)

Figure-24: Pr12: High Voltage Set Value

8 8 8 81 0 0

... .

SET

The device shows the Cosine value on the measurements screen on the

left. While on any measurement screen, the SET button is pressed for 2

seconds in order to enter the menu.

(2sec.)

DOWN

UP

DOWN

UP

DOWN

UP

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

UP

DOWN

DOWN

UP

Settings EProgram (Intervention Logic) Change

8888Auto

.. . . Auto: It intervenes according to the step values. It activate the

required step. Works in accordance with same aging. While the device

is in this program, the "Auto" led turns on.

8

8888rot1

.. .. Rotation-1: In this mode, all steps must have the same value. It is

sufficient to measure only the 1st step in step measurement. It

automatically saves the next steps at the value of this step and

compensates accordingly. (For example: If the first step is 5kVAr, it

records all other steps as 5kVAr.) It works in accordance with same

aging. When the device is in this mode, the "Auto" led turns on.

8888rot2

.. .. Rotation-2: In this mode, the 2nd and subsequent steps must have

the same value and twice the value of the 1st step. It is sufficient to

measure only the 1st step in step measurement. It automatically

saves the next steps at 2 times the value of the 1st step and

compensates accordingly. (For example: If the first stage is 10kVAr, it

records all other steps as 20kVAr.) It works in accordance with same

aging. When the device is in this mode, the "Auto" led turns on.

8888rot3

.. .. Rotation-3: In this mode, the 2nd step should be 2 times the value of the 1st

step and the 3rd and next steps must be twice the value of the 2nd step. It is

sufficient to measure only the 1st step in step measurement. It automatically

saves the next steps according to the above rule and compensates accordingly.

(For example: If the 1st step is 5kVAr, it records the 2nd step as 10kVAr and all

the other stages as 20kVAr.) It works in accordance with same aging. When the

device is in this mode, the "Auto" led turns on.

Changing the Program: The device has 7 different compensation programs. The first 6 of these

modes operate automatically and when one of these modes is activated, the "AUTO" led on the

device turns on. The 7th mode is manual program and works in manual mode. When this mode is

active, the "MANUAL" led on the device lights up.

In order to change the program, when you press the "ESC" button for 5 seconds while on the

measurement screen (while MEASUREMENTS led is on), it enters the compensation program

selection screen and the default compensation program is displayed on the screen. While the

compensation program is displayed on the screen (auto, rot.1, rot.2, rot.3, rot.4, babb or noAt

(manual)), you can switch between programs with the Down and Up buttons. While the program you

want to select as a compensation program is displayed on the screen, you can save the selection by

pressing the SET button. After the compensation program selection is saved, the device returns to

the cosine screen and starts compensation according to the selected compensation program.

8888rot4

.. .. Rotation-4: In this mode, the 2nd step must be 2 times the 1st step,

the 3rd step must be 2 times the 2nd step, the 4th step and the next

steps must be 2 times the 3rd step. It is sufficient to measure only the

1st step in step measurement. It automatically saves the next steps

according to the above rule and compensates accordingly. (For

example: If the 1st level is 5kVAr, it records the 2nd step as 10kVAr,

the 3rd step as 20kVAr, the 4th step and all the other steps as

40kVAr.) It works in accordance with same aging. When the device is

in this mode, the "Auto" led turns on.

After the program selection,

the 1st step measurement

should be done.

!

After the program selection,

the 1st step measurement

should be done.

!

After the program selection,

the 1st step measurement

should be done.

!

After the program selection,

the 1st step measurement

should be done.

!

9

Settings EProgram (Intervention Logic) Change

Determining the Step Count to be Used: It determines with how

many steps the device will compensate. In order to determine the step

count to be used, while the device is on the measurement screen

(while MEASUREMENTS led is on). When you press the “ESC” and

“UP” buttons together for 5 seconds, it enters the step count

determination screen and the default step count (current setting of

the device) is displayed on the screen. With the DOWN and UP buttons

you can determine the step count to be used. While the step count to

be used is displayed on the screen, you can save the selection by

pressing the SET button or exit without saving by pressing the ESC

button. After the selection is saved, the device returns to the cosine

screen and starts compensation according to the selected step count.

For example: If you save by pressing the SET button while St.8 is

written on the screen, the device starts to compensate with only the

first 8 steps. It does not use other steps.

8 8 8 8b A b b

.. . . Start Over and Drop Mode: In this mode, steps should be at the lowest

value in the first step and at the highest value in the last step. (From small to

large value) Compensation is not made according to the step value,

therefore there is no need for step measurement. When the step is to be

activated, it always starts with the first step and activates the other steps one

by one. When the step is to be deactivated, it always starts with the first step

and deactivates the other steps one by one. It does not works in accordance

with same aging. When the device is in this mode, the "Auto" led turns on.

8 8 8 8n o A t

.. . . Manuel Mode: In this mode, the cosine value is displayed on the

screen. Each time the "UP" button is pressed, one step is activated,

starting from the first step. Whenever the "DOWN" button is pressed,

one step is deactivated sequentially, starting from the last activated

step. It does not works in accordance with same aging. When the

device is in this mode, the "Manuel" led turns on.

Note: When the manual mode is selected, if there are steps that are

activated, these steps are deactivated sequentially.

Not2: In this mode, the "ESC" button should be used to switch

between measurement screens.

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 8S t 1 2

.. . .

(5sec.)

8 8 8 8s t 8

.. . .

Settings EDetermining the Step Count

UP

ESC

+

UP

DOWN

Settings EProgram (Intervention Logic) Change

8888Auto

.. . . Auto: It intervenes according to the step values. It activate the

required step. Works in accordance with same aging. While the device

is in this program, the "Auto" led turns on.

8

8888rot1

.. .. Rotation-1: In this mode, all steps must have the same value. It is

sufficient to measure only the 1st step in step measurement. It

automatically saves the next steps at the value of this step and

compensates accordingly. (For example: If the first step is 5kVAr, it

records all other steps as 5kVAr.) It works in accordance with same

aging. When the device is in this mode, the "Auto" led turns on.

8888rot2

.. .. Rotation-2: In this mode, the 2nd and subsequent steps must have

the same value and twice the value of the 1st step. It is sufficient to

measure only the 1st step in step measurement. It automatically

saves the next steps at 2 times the value of the 1st step and

compensates accordingly. (For example: If the first stage is 10kVAr, it

records all other steps as 20kVAr.) It works in accordance with same

aging. When the device is in this mode, the "Auto" led turns on.

8888rot3

.. .. Rotation-3: In this mode, the 2nd step should be 2 times the value of the 1st

step and the 3rd and next steps must be twice the value of the 2nd step. It is

sufficient to measure only the 1st step in step measurement. It automatically

saves the next steps according to the above rule and compensates accordingly.

(For example: If the 1st step is 5kVAr, it records the 2nd step as 10kVAr and all

the other stages as 20kVAr.) It works in accordance with same aging. When the

device is in this mode, the "Auto" led turns on.

Changing the Program: The device has 7 different compensation programs. The first 6 of these

modes operate automatically and when one of these modes is activated, the "AUTO" led on the

device turns on. The 7th mode is manual program and works in manual mode. When this mode is

active, the "MANUAL" led on the device lights up.

In order to change the program, when you press the "ESC" button for 5 seconds while on the

measurement screen (while MEASUREMENTS led is on), it enters the compensation program

selection screen and the default compensation program is displayed on the screen. While the

compensation program is displayed on the screen (auto, rot.1, rot.2, rot.3, rot.4, babb or noAt

(manual)), you can switch between programs with the Down and Up buttons. While the program you

want to select as a compensation program is displayed on the screen, you can save the selection by

pressing the SET button. After the compensation program selection is saved, the device returns to

the cosine screen and starts compensation according to the selected compensation program.

8888rot4

.. .. Rotation-4: In this mode, the 2nd step must be 2 times the 1st step,

the 3rd step must be 2 times the 2nd step, the 4th step and the next

steps must be 2 times the 3rd step. It is sufficient to measure only the

1st step in step measurement. It automatically saves the next steps

according to the above rule and compensates accordingly. (For

example: If the 1st level is 5kVAr, it records the 2nd step as 10kVAr,

the 3rd step as 20kVAr, the 4th step and all the other steps as

40kVAr.) It works in accordance with same aging. When the device is

in this mode, the "Auto" led turns on.

After the program selection,

the 1st step measurement

should be done.

!

After the program selection,

the 1st step measurement

should be done.

!

After the program selection,

the 1st step measurement

should be done.

!

After the program selection,

the 1st step measurement

should be done.

!

9

Settings EProgram (Intervention Logic) Change

Determining the Step Count to be Used: It determines with how

many steps the device will compensate. In order to determine the step

count to be used, while the device is on the measurement screen

(while MEASUREMENTS led is on). When you press the “ESC” and

“UP” buttons together for 5 seconds, it enters the step count

determination screen and the default step count (current setting of

the device) is displayed on the screen. With the DOWN and UP buttons

you can determine the step count to be used. While the step count to

be used is displayed on the screen, you can save the selection by

pressing the SET button or exit without saving by pressing the ESC

button. After the selection is saved, the device returns to the cosine

screen and starts compensation according to the selected step count.

For example: If you save by pressing the SET button while St.8 is

written on the screen, the device starts to compensate with only the

first 8 steps. It does not use other steps.

8 8 8 8b A b b

.. . . Start Over and Drop Mode: In this mode, steps should be at the lowest

value in the first step and at the highest value in the last step. (From small to

large value) Compensation is not made according to the step value,

therefore there is no need for step measurement. When the step is to be

activated, it always starts with the first step and activates the other steps one

by one. When the step is to be deactivated, it always starts with the first step

and deactivates the other steps one by one. It does not works in accordance

with same aging. When the device is in this mode, the "Auto" led turns on.

8 8 8 8n o A t

.. . . Manuel Mode: In this mode, the cosine value is displayed on the

screen. Each time the "UP" button is pressed, one step is activated,

starting from the first step. Whenever the "DOWN" button is pressed,

one step is deactivated sequentially, starting from the last activated

step. It does not works in accordance with same aging. When the

device is in this mode, the "Manuel" led turns on.

Note: When the manual mode is selected, if there are steps that are

activated, these steps are deactivated sequentially.

Not2: In this mode, the "ESC" button should be used to switch

between measurement screens.

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 8S t 1 2

.. . .

(5sec.)

8 8 8 8s t 8

.. . .

Settings EDetermining the Step Count

UP

ESC

+

UP

DOWN

Settings ECurrent Transformer Test

8888-985

.. . .

8888truE

.. . .

8888tEst

.. . .

DOWNESC

+(5sec.)

Performing Current Transformer Test: For the current transformer

test, it is necessary to enter the Current Transformer Ratio first.

Please examine the section "Current Transformer Ratio" in the

manual to enter the current transformer ratio.

In order to make a current transformer test, when you press the "ESC"

and "DOWN" buttons together for 5 seconds while on the measurement

screen (while MEASUREMENTS led is on), "test" written will appear on

the screen. When you press the "SET" button, the device starts the

current transformer test. SETTINGS led and Pr1: Current Transformer

led turns on steadily. The device performs the current transformer

connection test by activating and deactivating the 1st and 2nd stages

respectively. If there is no problem in the connection (reverse connection

of current transformer k-l terminals is not important) "true" written is

displayed on the screen. Press the SET button to save the test and press

the ESC button to return to the previous menu without saving.

8888Err0

.. . .

8888Err1

.. . .

Err0 Error: If you get an "Err0" error in the current transformer

test, it means the voltage value that feeds the device is lower than

160V. Check the connections and perform a current transformer test

again after eliminating the error.

Err1 Error: If you get an "Err1" error in the current transformer

test, there may be a loose contact in the current transformer output

connections (s1 (k) and s2 (l). Check the connections and perform a

current transformer test again after eliminating the error.

8888Err3

.. . . Err3 Error: If you get an "Err3" error in the current transformer test, it

means there is an error in the current and voltage sequence. The phase to

which the current transformer is connected and the phase that feeds the

device may not be the same. In addition, fast load changes in the system,

defective contactors/capacitors, loose connections at the current

ends/steps outputs may also cause this error Check the connections and

perform current transformer test again after eliminating the error.

8888Err2

.. . . Err2 Error: If you get an "Err2" error in the current transformer test,

it means that the step current is insufficient. In order for the current

transformer test to be completed successfully, the total value of the

1st and 2nd step must be 1 in 40 of the current transformer value.

(For example: For a 50 / 5A current transformer, the total value of the

capacitors connected to the 1st and 2nd step must be at least 1.2kVAr

(three phase).)

For the Err2 error, please make sure that; The life of the capacitors

may be over, the capacitors may not be energized, the capacitor

feeding may have been taken before the current transformer, the

current transformer ratio may not be entered to the device.

10

Settings ECurrent Transformer Ratio

Entering Current Transformer Ratio: In order to change the

Current Transformer Ratio, press the “SET” button for 2 seconds

while on the measurement screen (while MEASUREMENTS led is on).

When you enter the setting menu, the MEASUREMENTS led will turn

off and the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. While this parameter is

displayed on the screen, the led (Pr1: Current Transformer Ratio) of the

parameter also lights up steadily. To change the value of this parameter,

press the "SET" button and see that the led for the parameter is blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the

ESC button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value

is displayed on the screen and the parameter led does not blink, it

lights up steadily.

Example: If the Current Transformer Value is 100/5A, the ratio value

to be entered in Pr1 is "20". (100/5 = 20)

Monitoring Step Values: In order to see the step values that the

device measures automatically, press the “SET” button for 2 seconds

while on the measurement screen (while MEASUREMENTS led is on).

When you enter the setting menu, the MEASUREMENTS led will turn

off and the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on

the screen is Pr1: Current Transformer Ratio. Press the DOWN button

to access Pr2: Step Values parameter. To see the step values, press

the "SET" button and see that the led of the Pr2 parameter is blinking.

While the parameter led is blinking, you can see the step values by

using the DOWN and UP buttons. While the step value is displayed on

the screen, the information of which step this value belongs to is

associated with the step leds on the top of the screen. Press the

DOWN and UP buttons to switch between the step values and press

the ESC button to return to the previous menu.

NOTE: When entering this menu, the device deactivates the activated

steps one by one.

Settings EMonitoring Step Values

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 81

.. . .

SET (2sec.)

8 8 8 82 0

.. . .

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 80 5 0 0

... .

SET (2sec.)

8 8 8 82 5 0 0

... .

11

UP

DOWN

UP

DOWN

Settings ECurrent Transformer Test

8888-985

.. . .

8888truE

.. . .

8888tEst

.. . .

DOWNESC

+(5sec.)

Performing Current Transformer Test: For the current transformer

test, it is necessary to enter the Current Transformer Ratio first.

Please examine the section "Current Transformer Ratio" in the

manual to enter the current transformer ratio.

In order to make a current transformer test, when you press the "ESC"

and "DOWN" buttons together for 5 seconds while on the measurement

screen (while MEASUREMENTS led is on), "test" written will appear on

the screen. When you press the "SET" button, the device starts the

current transformer test. SETTINGS led and Pr1: Current Transformer

led turns on steadily. The device performs the current transformer

connection test by activating and deactivating the 1st and 2nd stages

respectively. If there is no problem in the connection (reverse connection

of current transformer k-l terminals is not important) "true" written is

displayed on the screen. Press the SET button to save the test and press

the ESC button to return to the previous menu without saving.

8888Err0

.. . .

8888Err1

.. . .

Err0 Error: If you get an "Err0" error in the current transformer

test, it means the voltage value that feeds the device is lower than

160V. Check the connections and perform a current transformer test

again after eliminating the error.

Err1 Error: If you get an "Err1" error in the current transformer

test, there may be a loose contact in the current transformer output

connections (s1 (k) and s2 (l). Check the connections and perform a

current transformer test again after eliminating the error.

8888Err3

.. . . Err3 Error: If you get an "Err3" error in the current transformer test, it

means there is an error in the current and voltage sequence. The phase to

which the current transformer is connected and the phase that feeds the

device may not be the same. In addition, fast load changes in the system,

defective contactors/capacitors, loose connections at the current

ends/steps outputs may also cause this error Check the connections and

perform current transformer test again after eliminating the error.

8888Err2

.. . . Err2 Error: If you get an "Err2" error in the current transformer test,

it means that the step current is insufficient. In order for the current

transformer test to be completed successfully, the total value of the

1st and 2nd step must be 1 in 40 of the current transformer value.

(For example: For a 50 / 5A current transformer, the total value of the

capacitors connected to the 1st and 2nd step must be at least 1.2kVAr

(three phase).)

For the Err2 error, please make sure that; The life of the capacitors

may be over, the capacitors may not be energized, the capacitor

feeding may have been taken before the current transformer, the

current transformer ratio may not be entered to the device.

10

Settings ECurrent Transformer Ratio

Entering Current Transformer Ratio: In order to change the

Current Transformer Ratio, press the “SET” button for 2 seconds

while on the measurement screen (while MEASUREMENTS led is on).

When you enter the setting menu, the MEASUREMENTS led will turn

off and the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. While this parameter is

displayed on the screen, the led (Pr1: Current Transformer Ratio) of the

parameter also lights up steadily. To change the value of this parameter,

press the "SET" button and see that the led for the parameter is blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the

ESC button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value

is displayed on the screen and the parameter led does not blink, it

lights up steadily.

Example: If the Current Transformer Value is 100/5A, the ratio value

to be entered in Pr1 is "20". (100/5 = 20)

Monitoring Step Values: In order to see the step values that the

device measures automatically, press the “SET” button for 2 seconds

while on the measurement screen (while MEASUREMENTS led is on).

When you enter the setting menu, the MEASUREMENTS led will turn

off and the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on

the screen is Pr1: Current Transformer Ratio. Press the DOWN button

to access Pr2: Step Values parameter. To see the step values, press

the "SET" button and see that the led of the Pr2 parameter is blinking.

While the parameter led is blinking, you can see the step values by

using the DOWN and UP buttons. While the step value is displayed on

the screen, the information of which step this value belongs to is

associated with the step leds on the top of the screen. Press the

DOWN and UP buttons to switch between the step values and press

the ESC button to return to the previous menu.

NOTE: When entering this menu, the device deactivates the activated

steps one by one.

Settings EMonitoring Step Values

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 81

.. . .

SET (2sec.)

8 8 8 82 0

.. . .

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 80 5 0 0

... .

SET (2sec.)

8 8 8 82 5 0 0

... .

11

UP

DOWN

UP

DOWN

SettingsEStep Measurement

Making Automatic Step Measurement: In order to make an

automaticly step measurement, press the “SET” button for 2 seconds

while on the measurement screen (while MEASUREMENTS led is on).

When you enter the setting menu, the MEASUREMENTS led will turn

off and the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on

the screen is Pr1: Current Transformer Ratio. Press the DOWN button

to access Pr2: Step Values parameter. To see the step values, press

the "SET" button and see that the led of the Pr2 parameter is blinking.

8888-985

... .

8888-985

.. . .

88880500

... .

SET (2sec.)

8888-985

.. . .

8888st12

.. . .

8888All

.. . .

8888S t

.. . .

2 Measuring a Single Step: If you press the SET button while the step

value is on the screen, the device starts measuring the step for the

selected step. When step measurement is started, on the screen

shows the information for which step the measurement was made.

(For example: St.1 = means 1st step.) After the step measurement is

completed for the selected step, the step value is displayed on the

screen. Press the SET button to save the measured value, then exit

the menu by pressing the ESC button. Also, press the ESC button to

cancel the operation during the measurement and return to the

previous menu without saving the value after the measurement is

completed.

Measuring All Steps: To have all the steps measured, switch

between the steps by pressing the DOWN button. When you press the

DOWN button again after the 12th step, "ALL" will appear on the

display. When you press the SET button while the word "ALL" is

displayed on the screen, the device starts from the 1st step and

activates all the steps one by one and makes the step measurement.

After each step measurement, the measured value is displayed on the

screen for 2 seconds, and then the measurement is made for the next

step. After the measurement is completed for all steps, press the SET

button to save the measured step values, then exit the menu by

pressing the ESC button. Also, press the “ESC” button to cancel the

operation during the measurement and return to the previous menu

without saving the value after the measurement is completed.

NOTE: The lowest capacitor value that can be connected to a step is

90 VAR and the highest is 250 kVAR.

NOTE: When entering this menu, the device deactivates the activated

steps one by one.

12

UP

DOWN

UP

DOWN

SettingsECosine Set Value

Adjusting the Cosine Set Value: The target cosine set value for

compensation is set with this parameter. In order to change the cosine

value, press the “SET” button for 2 seconds while on the measurement

screen (while MEASUREMENTS led is on). When you enter the setting

menu, the MEASUREMENTS led will turn off and the SETTINGS led will

light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to

access Pr3: Cosine Set p arameter. To see the parameter value, press

the "SET" button and see that the led of the Pr3 parameter is blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the ESC

button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value is

displayed on the screen and the parameter led does not blink, it lights

up steadily.

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 80 9 5 0

... .

SET (2sec.)

8 8 8 80 9 6 0

... .

13

SettingsECosine Tolerance Value

Adjusting the Cosine Tolerance Value: It is the movement area that will be

given to the device in inductive and capacitive directions in order to ensure less

on/off in order to extend the life of contactors, capacitors and reactors in the

steps. The device will not change its current intervention for reactive power

changes within the Cosine SET Value ± Cosine Tolerance Value area.

In order to change the cosine tolerance value, press the “SET” button for 2

seconds while on the measurement screen (while MEASUREMENTS led is

on). When you enter the setting menu, the MEASUREMENTS led will turn off

and the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to access

Pr4: Cosine Tolerance p arameter. To see the parameter value, press the

"SET" button and see that the led of the Pr4 parameter is blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the ESC

button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value is

displayed on the screen and the parameter led does not blink, it lights

up steadily.

Example: If the SET value is 0.940 and the tolerance value is ± 10, the device

will not change its current intervention for reactive power changes between

the cosine value of 0.930 and 0.950. If it is out of this value, the device

continues its intervention if there is an appropriate step value in the system

according to the drawn reactive power.

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 81 0

.. . .

SET (2sn.)

8 8 8 81 5

.. . .

UP

DOWN

UP

DOWN

SettingsEStep Measurement

Making Automatic Step Measurement: In order to make an

automaticly step measurement, press the “SET” button for 2 seconds

while on the measurement screen (while MEASUREMENTS led is on).

When you enter the setting menu, the MEASUREMENTS led will turn

off and the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on

the screen is Pr1: Current Transformer Ratio. Press the DOWN button

to access Pr2: Step Values parameter. To see the step values, press

the "SET" button and see that the led of the Pr2 parameter is blinking.

8888-985

... .

8888-985

.. . .

88880500

... .

SET (2sec.)

8888-985

.. . .

8888st12

.. . .

8888All

.. . .

8888S t

.. . .

2 Measuring a Single Step: If you press the SET button while the step

value is on the screen, the device starts measuring the step for the

selected step. When step measurement is started, on the screen

shows the information for which step the measurement was made.

(For example: St.1 = means 1st step.) After the step measurement is

completed for the selected step, the step value is displayed on the

screen. Press the SET button to save the measured value, then exit

the menu by pressing the ESC button. Also, press the ESC button to

cancel the operation during the measurement and return to the

previous menu without saving the value after the measurement is

completed.

Measuring All Steps: To have all the steps measured, switch

between the steps by pressing the DOWN button. When you press the

DOWN button again after the 12th step, "ALL" will appear on the

display. When you press the SET button while the word "ALL" is

displayed on the screen, the device starts from the 1st step and

activates all the steps one by one and makes the step measurement.

After each step measurement, the measured value is displayed on the

screen for 2 seconds, and then the measurement is made for the next

step. After the measurement is completed for all steps, press the SET

button to save the measured step values, then exit the menu by

pressing the ESC button. Also, press the “ESC” button to cancel the

operation during the measurement and return to the previous menu

without saving the value after the measurement is completed.

NOTE: The lowest capacitor value that can be connected to a step is

90 VAR and the highest is 250 kVAR.

NOTE: When entering this menu, the device deactivates the activated

steps one by one.

12

UP

DOWN

UP

DOWN

SettingsECosine Set Value

Adjusting the Cosine Set Value: The target cosine set value for

compensation is set with this parameter. In order to change the cosine

value, press the “SET” button for 2 seconds while on the measurement

screen (while MEASUREMENTS led is on). When you enter the setting

menu, the MEASUREMENTS led will turn off and the SETTINGS led will

light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to

access Pr3: Cosine Set p arameter. To see the parameter value, press

the "SET" button and see that the led of the Pr3 parameter is blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the ESC

button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value is

displayed on the screen and the parameter led does not blink, it lights

up steadily.

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 80 9 5 0

... .

SET (2sec.)

8 8 8 80 9 6 0

... .

13

SettingsECosine Tolerance Value

Adjusting the Cosine Tolerance Value: It is the movement area that will be

given to the device in inductive and capacitive directions in order to ensure less

on/off in order to extend the life of contactors, capacitors and reactors in the

steps. The device will not change its current intervention for reactive power

changes within the Cosine SET Value ± Cosine Tolerance Value area.

In order to change the cosine tolerance value, press the “SET” button for 2

seconds while on the measurement screen (while MEASUREMENTS led is

on). When you enter the setting menu, the MEASUREMENTS led will turn off

and the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to access

Pr4: Cosine Tolerance p arameter. To see the parameter value, press the

"SET" button and see that the led of the Pr4 parameter is blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the ESC

button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value is

displayed on the screen and the parameter led does not blink, it lights

up steadily.

Example: If the SET value is 0.940 and the tolerance value is ± 10, the device

will not change its current intervention for reactive power changes between

the cosine value of 0.930 and 0.950. If it is out of this value, the device

continues its intervention if there is an appropriate step value in the system

according to the drawn reactive power.

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 81 0

.. . .

SET (2sn.)

8 8 8 81 5

.. . .

UP

DOWN

UP

DOWN

14

SettingsEStep Drive Time

Adjusting the Step Drive Time: It determines the step drive

(activation) time to intervene in the power change in the system. In

order to change this value, press the “SET” button for 2 seconds while

on the measurement screen (while MEASUREMENTS led is on). When

you enter the setting menu, the MEASUREMENTS led will turn off and

the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to

access Pr5: Step Drive Time p arameter. To see the parameter value,

press the "SET" button and see that the led of the Pr5 parameter is

blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the ESC

button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value is

displayed on the screen and the parameter led does not blink, it lights

up steadily.

8888-985

... .

8888-985

.. . .

88883

.. . .

SET (2sec.)

88885

.. . .

SettingsEStep Release Time

Adjusting the Step Release Time: It determines the time to release

the active step in order to intervene in the power change in the system.

In order to change this value, press the “SET” button for 2 seconds

while on the measurement screen (while MEASUREMENTS led is on).

When you enter the setting menu, the MEASUREMENTS led will turn off

and the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to

access Pr6: Step Release Time p arameter. To see the parameter value,

press the "SET" button and see that the led of the Pr6 parameter is

blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the ESC

button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value is

displayed on the screen and the parameter led does not blink, it lights

up steadily.

8888-985

... .

8888-985

.. . .

88883

.. . .

SET (2sec.)

88885

.. . .

UP

DOWN

UP

DOWN

SettingsEStep Discharge Time

Adjusting the Step Discharge Time: It determines the capacitor

discharge (reactivate the same step) time. In order to change this value,

press the “SET” button for 2 seconds while on the measurement screen

(while MEASUREMENTS led is on). When you enter the setting menu,

the MEASUREMENTS led will turn off and the SETTINGS led will light

up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to

access Pr7: Step Discharge Time p arameter. To see the parameter

value, press the "SET" button and see that the led of the Pr7 parameter

is blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the ESC

button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value is

displayed on the screen and the parameter led does not blink, it lights

up steadily.

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 82 0

.. . .

SET (2sec.)

8 8 8 82 5

.. . .

15

SettingsEOver Compensation

Adjusting the Over Compensation Value: In case the Cosine value stays

above the Over Compensation Value for 3 minutes although the device

disables all steps, it enters an overcompensation error, the alarm relay is

energized, the OVER led flashes while the alarm and SETTINGS leds are

constantly lit. When the cosine value returns to the normal level for 10

seconds, the device disables the overcompensation error, the alarm relay is

deactivated, the alarm and OVER led turn off, the cosine led turns on.

In order to change this value, press the “SET” button for 2 seconds while

on the measurement screen (while MEASUREMENTS led is on). When you

enter the setting menu, the MEASUREMENTS led will turn off and the

SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to

access Pr8: Over Compensation p arameter. To see the parameter value,

press the "SET" button and see that the led of the Pr8 parameter is blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the value of

the parameter, press the SET button to save and press the ESC button to

return to the previous menu without saving.

8 8 8 8- 9 8 5

... .

8 8 8 8- 9 8 5

.. . .

8 8 8 80 0 1 0

... .

SET (2sec.)

8 8 8 80 0 1 5

... .

When the changed parameter value is saved by pressing the SET button, the device returns to the previous

menu, the parameter value is displayed on the screen and the parameter led does not blink, it lights up steadily.

Example: Let Cosine set: 0.940, Cosine tolerance: 10 and overcompensation: 10. If the cosine value

stays above 0.960 for 3 minutes even though it deactivates all steps, this error occurs. If the cosine

value goes below 0.950 for 10 seconds after the error, the error situation will disappear.

NOTE: This feature is disabled in manual mode.

UP

DOWN

UP

DOWN

14

SettingsEStep Drive Time

Adjusting the Step Drive Time: It determines the step drive

(activation) time to intervene in the power change in the system. In

order to change this value, press the “SET” button for 2 seconds while

on the measurement screen (while MEASUREMENTS led is on). When

you enter the setting menu, the MEASUREMENTS led will turn off and

the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to

access Pr5: Step Drive Time p arameter. To see the parameter value,

press the "SET" button and see that the led of the Pr5 parameter is

blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the ESC

button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value is

displayed on the screen and the parameter led does not blink, it lights

up steadily.

8888-985

... .

8888-985

.. . .

88883

.. . .

SET (2sec.)

88885

.. . .

SettingsEStep Release Time

Adjusting the Step Release Time: It determines the time to release

the active step in order to intervene in the power change in the system.

In order to change this value, press the “SET” button for 2 seconds

while on the measurement screen (while MEASUREMENTS led is on).

When you enter the setting menu, the MEASUREMENTS led will turn off

and the SETTINGS led will light up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to

access Pr6: Step Release Time p arameter. To see the parameter value,

press the "SET" button and see that the led of the Pr6 parameter is

blinking.

When the parameter led is blinking, you can change the value of the

parameter by using the DOWN and UP buttons. After changing the

value of the parameter, press the SET button to save and press the ESC

button to return to the previous menu without saving.

When the changed parameter value is saved by pressing the SET

button, the device returns to the previous menu, the parameter value is

displayed on the screen and the parameter led does not blink, it lights

up steadily.

8888-985

... .

8888-985

.. . .

88883

.. . .

SET (2sec.)

88885

.. . .

UP

DOWN

UP

DOWN

SettingsEStep Discharge Time

Adjusting the Step Discharge Time: It determines the capacitor

discharge (reactivate the same step) time. In order to change this value,

press the “SET” button for 2 seconds while on the measurement screen

(while MEASUREMENTS led is on). When you enter the setting menu,

the MEASUREMENTS led will turn off and the SETTINGS led will light

up.

After entering the settings menu, the first parameter displayed on the

screen is Pr1: Current Transformer Ratio. Press the DOWN button to

access Pr7: Step Discharge Time p arameter. To see the parameter

value, press the "SET" button and see that the led of the Pr7 parameter

is blinking.