Tense MDK-02 User manual

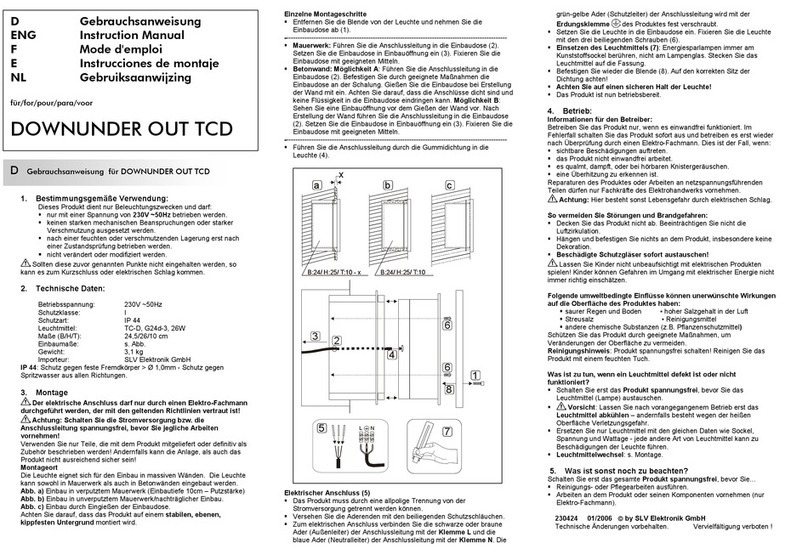

Dimensions:

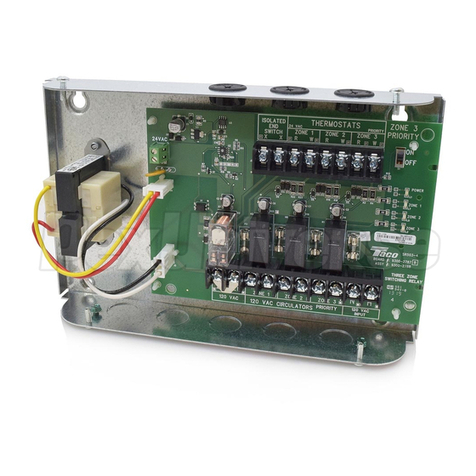

Connection Diagrams:

General:

Usage and Operating Principle of the Device:

It has been designed for controlling submersible pump motors and protecting them against adverse situations that can be arising from dry operation, high

or low voltage and high or low current.

Contacts:

Stop/Down Button: Sets the device to the start position. It is used as the

down scroll button.

Start/Up Button: Sets the device to the start position. It is used as the up scroll button in the menu.

Menu Button: It provides to enter to the menu, to browse the menu, to save the value changes and to exit from the menu.

Reset Button: It provides to reset the submersible pump manually after high or low current error and to exit from the menu.

Warnings:

When two electrodes are in use, the upper and lower electrodes are shorted

out and used together with the base electrode.

Connect the motor casing to the ground line. Otherwise, the device may

break down

Never energize the floater (Tank) terminals.

Make sure that the temperature is above 0°C in the place where the

device is mounted.

Make sure that the liquid is not flammable or explosive.

The device is connected in accordance with the connection diagram.

Before connecting the device, be sure to read the warning section. Connect the device in accordance with the connection diagram. After connecting the

device, energize it. Check whether the operating values of your motor conform to the factory values in the device menu. If they do not conform to the

factory values, you can respectively adjust; High-voltage set (P1), high current (thermic) set (P2), low-voltage set (P3), low current set (P4), current error

waiting time (P5), current auto reset time (P6), if we want it to reset itself automatically after current errors, demurrage multiplier (P7) for demurrage

(starting) flow, demurrage time (P8), current auto reset number the number (P9) in order to prevent the faults in the system and upper electrode waiting

time (P11) in order to decrease stop-start frequency of the motor.

After the device is energized, it stands-by 4 seconds in the first starting time. Then, it checks the system by considering the voltage values which are

adjusted via the menu and whether there is water in the well and whether the tank which will be filled with water is empty or not. If the water level is at the

top or in the middle, if the voltage value is within the normal values, if the tank is empty and if the device is in start position, the device starts to operate and

the led lights up which shows the motor is running. The motor starts to operate and demurrage current is observed for a few seconds. Then the motor

continues to operate under normal working current. On the monitor, the current values are displayed on the red display group and the current values are

displayed on the yellow display group.

On the Start Position: If the device is on the start position, start led (yellow) lights up on the front panel. In order to set the device to the start position,

press the start button.

On the Stop Position: When the device is on the stop position, start led does not light up. In order to set the device to the stop position, press the stop

button. When the device is on the stop position, it does not operate in any way.

As the Well is being Drained: When the water inside the well reaches to the upper electrode, the led showing that the well is full of water lights up and

the motor starts to operate. When the water level drops below the upper electrode and touches to the lower electrode, the medium level led lights up. The

motor operates. When the water level drops below the lower electrode, the led showing the well is empty lights up and the motor stops.

As the Well is being Filled: If the water level inside the well is below the lower electrode, the led showing the well is empty lights up and the motor does

not operate. When the water level reaches to the lower electrode, medium level led lights up and motor does not operate. When the water level reaches to

the upper electrode, the device stands by for the upper electrode waiting time and the led showing that the well is full of water blinks. After the time is up,

the led showing that the well is full of water lights up constantly and the motor starts to operate.

Tank: Connect the floater while the tank is empty and short out its connection. Never energize the floater terminals of the device. If you do not use the

device as a tank, please short out the floater terminals.

Tank is Empty: If the floater terminals are shorted out, the device detects the tank is empty and the led showing that the tank is full of water does

not light up.

Tank is Full: If the floater terminals are open-circuit, the device detects that the tank is full and the led showing that the tank is full of water lights up.

The device does not operate the motor in any way while the tank is full.

If the Motor does not Operate: If the led showing that the motor is operating does not light up, respectively control whether the motor is on the start

position (start led must be on) and the tank is empty; the led showing that the tank is full must not be light up, the led showing the well is full must be light

up constantly (if it blinks, the device counts the upper electrode waiting time).

Cut the energy of the device and disconnect its connections. Clean

the device casing with a slightly damp cloth. Do not use conducting or

other substances as cleaning agents that can harm to the device.

After the cleaning of the device is completed, make the connections of

it and be sure that it operates by energizing it.

Maintenance of the Device:

96,4 mm

65,6 mm

76,1 mm

96,4 mm

89,2 mm

14 mm

5,08 mm

16

15

14

13

I

k

N

L

Bottom Elect.

Low Elect.

Upper Elect.

Floater

Floater

NO

COM

17

18

19

20

21

22

23

N

L1

2A

Contactor

Tank is Full

Tank is Empty

Well

Upper Electrode

Low Electrode

Pump

Bottom Electrode

Floater

2A

C.T.

MDK-02 M

~

MONO-PHASE RELAY FOR CONTROLLING PUMP MOTOR MDK-02 ENG

Document Number: DK-020-2

<50KÙ

1A - 60A

140V - 260V AC

50 Hz.

91x91mm

<6VA

-20°C.....+55°C

2x 3digit 14mm display

5A / 250V AC (Resistive Load)

0,325Kg.

<2000meter

IP20

1,5mm²

.:Operating Voltage(Un):

Operating Frequency....:

Panel Hole Sizes..........:

Measurement Range....:

Operating Power...........:

Operating Temperature.:

Connection Type..........:

Display.........................:

Contact........................:

Sensitivity.....................:

Weight...........................:

Mounting.......................:

Operating Altitude.........:

Protection Class............:

Cable Diameter............:

Tecnical Specifications:

Panel front mounted

Plug-in terminal

MADE IN TURKEY

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Reset

Reset

Reset

Reset

Reset

Reset

Reset

Reset

Reset

Reset

Reset

Reset Parameter 1 : By pressing Up and Down buttons, you can enter the High Voltage Value. This adjusts the high

operating voltage of the motor. Slide the menu forward by pressing menu button.

Value Range..: 230V - 270V Default Value: 245V

The red display group shows the voltage value. If low or high voltage error occurs, this display group blinks.

Press menu button in order to enter menu. Firstly, (P1) will be displayed on the screen. On the menu, the red display group shows the parameter

value and the yellow display group shows the adjusted value. On the menu, you can change the value by pressing on the up and down keys. Then,

by pressing the menu button you can slide the menu forward and save the previous value if you have changed it. By pressing the reset button when

you are on any parameter, you can exit from the menu. When you press the reset button, the parameter on the screen is not saved but the

adjustments on the previous parameters are saved. As (P12) parameter is being displayed on the screen, you can also press the menu button in order

to exit from the menu. If you do not press any button when you are on the menu for about 50 seconds, the device automatically exits from the menu

and the adjustment made on the parameter displayed on the screen is not.

Menu Usage:

The yellow display group shows the current value. If low or high current error occurs, this display group blinks.

Parameter 2 : By pressing Up and Down buttons, you can enter the High Current Value. This adjusts the high

operating current (Thermic) of the motor. Slide the menu forward by pressing menu button.

Value Range..: 0V - 60A Default Value: 5A

Parameter 4 : By pressing Up and Down buttons, you can enter the Low Current Value. This adjusts the low

operating current of the motor. Slide the menu forward by pressing menu button.

Value Range..: 0V - 60A Default Value: 0A

Parameter 3 : By pressing Up and Down buttons, you can enter the Low Voltage Value. This adjusts the low

operating voltage of the motor. Slide the menu forward by pressing menu button.

Value Range..: 150V - 210V Default Value: 160V

Parameter 5 : By pressing Up and Down buttons, you can set the Current Error Waiting Time It is used to set the

time period (in seconds) at the end of which the motor will be stopped after a low or high current error occurs.

Slide the menu forward by pressing menu button. Value Range..: 0 sec. - 850 sec. Default Value: 2 sec.

Parameter 6 : By pressing Up and Down buttons, you can set the Current Auto Reset Time It is used to set the time

for automatic reactivation (reset) of the motor after it stops due to a high or low current error. When the value is on

"OFF" position, the motor should be reset manually. When a time period is set, the motor stands by for the adjusted

time period after it stops and it is reset automatically. Slide the menu forward by pressing menu button.

Value Range..: OFF - 850 sec. Default Value: OFF

Parameter 7 : By pressing Up and Down buttons, you can set the Demurrage Multiplier. During start up (demurrage),

the engine draws current at a level higher than that of the normal operating current. It indicates how many times this

drawn high-current (demurrage current) is above than the high-current set value. Slide the menu forward by pressing

menu button. Value Range..: 1 - 10 Default Value: 3

Parameter 8 : By pressing Up and Down buttons, you can set the Demurrage Time. It adjusts the start-up time of the

motor. While the motor is on the start-up process, the device allows demurrage (starting) current to flow during this

duration. Demurrage Current = High Current Set (P2) x Demurrage Multiplier (P7). Example: Assume that High

Current Set Value is 5A and Demurrage Multiplier is 3. Demurrage Current = 5 x 3 = 15A. Slide the menu forward

by pressing menu button. Value Range..:0 sec. - 850 sec. Default Value: 10 sec.

Parameter 9 : By pressing Up and Down buttons, you can set the Current Auto Reset Number. it is used to limit the

number of resets, if the motor is automatically reset constantly after a high or low voltage error occurs. If the value is

on "OFF" position, there is no limitation for the number of resets. When a value is set, the device resets the motor

automatically as much as the number set for the parameter and then the device switches to manual reset mode.

Slide the menu forward by pressing menu button. Value Range..: OFF - 200 Default Value: OFF

Parameter 11 : It indicates whether the electrodes get in contact with water or not. If the value read on the screen is

below 200, the electrode is in contact with water. And if the value is above 200, the electrode is not in contact with

water. The red display indicates the upper electrode and the yellow display indicates the lower electrode. Slide the

menu forward by pressing menu button. Value Range..: 0 - 255 Default Value: 200 (constant)

Parameter 10 : By pressing Up and Down buttons, you can set the Upper Electrode Waiting Time When the water

level within the well reaches to the upper electrode, this parameter provides the motor to operate after it stands by

during the time set beforehand. Slide the menu forward by pressing menu button.

Value Range..: 0 min. - 850 min. Default Value: 0 min.

Parameter 12 : By pressing the Up or Down button, you can select Start / Stop Memory. It is used to set whether the

device will launch in the last operating position (start or stop) or not. If you want the device to always launch in start

position, the value must be set to "1" and the device must be on start position. Otherwise, the device always

launches on stop position. By pressing the menu button, you can exit from the menu.

Value Range..: 0 - 1 Default Value: 1

Table of contents

Other Tense Relay manuals