TENSITRON ACM-100 User manual

ACM Series Instrument www.tensitron.com pg. 1

Operating Instructions

ACM and CWT Series Mechanical

Aircraft Cable Tension Meters

ACM Series Instrument www.tensitron.com pg. 2

TABLE OF CONTENTS

1. WARRANTY POLICY ..................................................................................................... 3

2. SPECIFICATIONS .......................................................................................................... 4

3. SAFETY......................................................................................................................... 5

4. INSTRUMENT DETAILS................................................................................................. 5

Standard Instruments, cable diameters, accuracy ................................................. 5

Features of all Instruments .................................................................................... 6

5. BASIC OPERATION....................................................................................................... 6

Before Use.............................................................................................................. 6

Selecting the Riser.................................................................................................. 6

Engaging Instrument onto Cable............................................................................ 7

Saving a Reading Using Memory Lock Feature....................................................... 8

Converting Readings to Tension Values with Calibration Chart ............................. 9

Maintaining Your Meter....................................................................................... 10

6. ADVANCED OPERATION ............................................................................................ 10

Checking Accuracy................................................................................................ 10

Recalibrating ........................................................................................................ 11

7. APPENDICES .............................................................................................................. 12

Appendix 1: RISER USAGE CHARTS....................................................................... 12

Appendix 2: BLANK CALIBRATION CHARTS........................................................... 12

oACM-100.......................................................................................................... 12

oACM-200.......................................................................................................... 13

oACM-300.......................................................................................................... 13

oACM-600.......................................................................................................... 14

oCWT-150.......................................................................................................... 14

oCWT-300.......................................................................................................... 15

Appendix 3: TROUBLESHOOTING ......................................................................... 15

ACM Series Instrument www.tensitron.com pg. 3

Proprietary Notice

This document contains proprietary information which may not be

reproduced in whole or in part without the written permission of

Tensitron, 733 South Bowen Street, Longmont, CO 80501.

Tensitron reserves the right to make instrument changes and

improvements which may not be reflected in this document. Portions

of this document may have been updated to include the latest

hardware or firmware version, if applicable. We recommend that this

document be read in its entirety before any attempt is made to

operate the instrument.

Thank You . . .

For purchasing another fine product from Tensitron.

If you have any questions or need assistance, please call us at

303-702-1980 or find us online at www.tensitron.com

1. WARRANTY POLICY

STANDARD EQUIPMENT WARRANTY

Tensitron warrants that all Tensitron-manufactured equipment will be free of any defect in materials or

workmanship for the period of (1) year. Warranty begins from the date of shipment from a Tensitron facility.

The warranty is extended to customers and applies to all Tensitron-manufactured equipment purchased,

installed, and used for the purpose for which such equipment was originally designed. The above warranties

cover only defects arising under normal use and donot include malfunctions orfailures resulting from misuse,

abuse, neglect, alteration, problems with electrical power, usage not in accordance with product instructions,

acts of nature, or improper installation or repairs made by anyone other than Tensitron or a Tensitron-

authorized, third-party service provider. Shipping costs to and from Tensitron are not included in the warranty

coverage.

ACM Series Instrument www.tensitron.com pg. 4

2. SPECIFICATIONS

Dimensions (L x W x D)

All ACM models except ACM-600: 8.24” x 3.38” x 1.56”

ACM-600 only: 8.24” x 5.20” x 1.56” (See Figure 1)

Full Scale Accuracy

ACM-100, ACM-200 and ACM-150-CWT: 4%

ACM-300, ACM-400 and ACM-300-CWT: 6%

ACM-600: 8%

Accuracy for custom calibrations is material specific

Operating Temperature

32º F to 120 º F.

Storage Temperature

20º F to 158º F.

Ambient Humidity

10% to 90% non-condensing

Weight

1.5 lb

Environment:

Indoor or outdoor use, dust-free environment.

Figure 1: ACM Dimensions

All ACM and Models

except ACM-600

ACM-600 only

ACM Series Instrument www.tensitron.com pg. 5

3. SAFETY

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE. Before use,

ensure all users read and understand this manual, as well as any labels

packaged with or attached to the instrument.

Know your instrument. Read this manual carefully to learn your tension

meter’s applications and limitations, as well as the potential hazards

associated with this type of instrument.

Use the right tool or instrument. Do not use this instrument to do a job for

which it is not recommended.

Check for damaged parts. Inspect instrument before use. Check for any

binding of moving parts, improper mountings, broken parts and any other

condition that may affect operation. Do not use a damaged instrument.

Tag damaged instrument “DO NOT USE” until repaired.

Maintain instrument carefully. Keep handles dry, clean and free from oil

and grease. Do not lubricate. All roller bearings are sealed.

Do not use instrument if it has received a sharp blow, been dropped or

damaged in any way. Do not disassemble. Incorrect reassembly may

damage the instrument.

If instrument is damaged return it to Tensitron for repair.

4. INSTRUMENT DETAILS

Standard Instruments, cable diameters, accuracy

Model #

Cable Selection

Full Scale

Accuracy

(+/-)

Total error

allowed (+/-)

ACM-100

1/16”, 3/32”, 1/8”, 5/32”

4%

4 lbs.

ACM-200

1/16”, 3/32”, 1/8”, 5/32”, 3/16”, 1/4”

4%

8 lbs.

ACM-300

3/32”, 1/8”, 3/16”, 1/4”

6%

18 lbs.

ACM-400

3/32”, 1/8”, 5/32”, 3/16”

6%

24 lbs.

ACM-600

1/8”, 5/32”, 3/16”, 1/4”

8%

48 lbs.

ACM-150-CWT

(formerly CWT-150)

5, 10, 15, 20 & 25 CWT cables

4%

6 lbs.

ACM-300-CWT

(formerly CWT-300)

10, 15, 20 & 25 CWT cables

6%

18 lbs.

ACM Series Instrument www.tensitron.com pg. 6

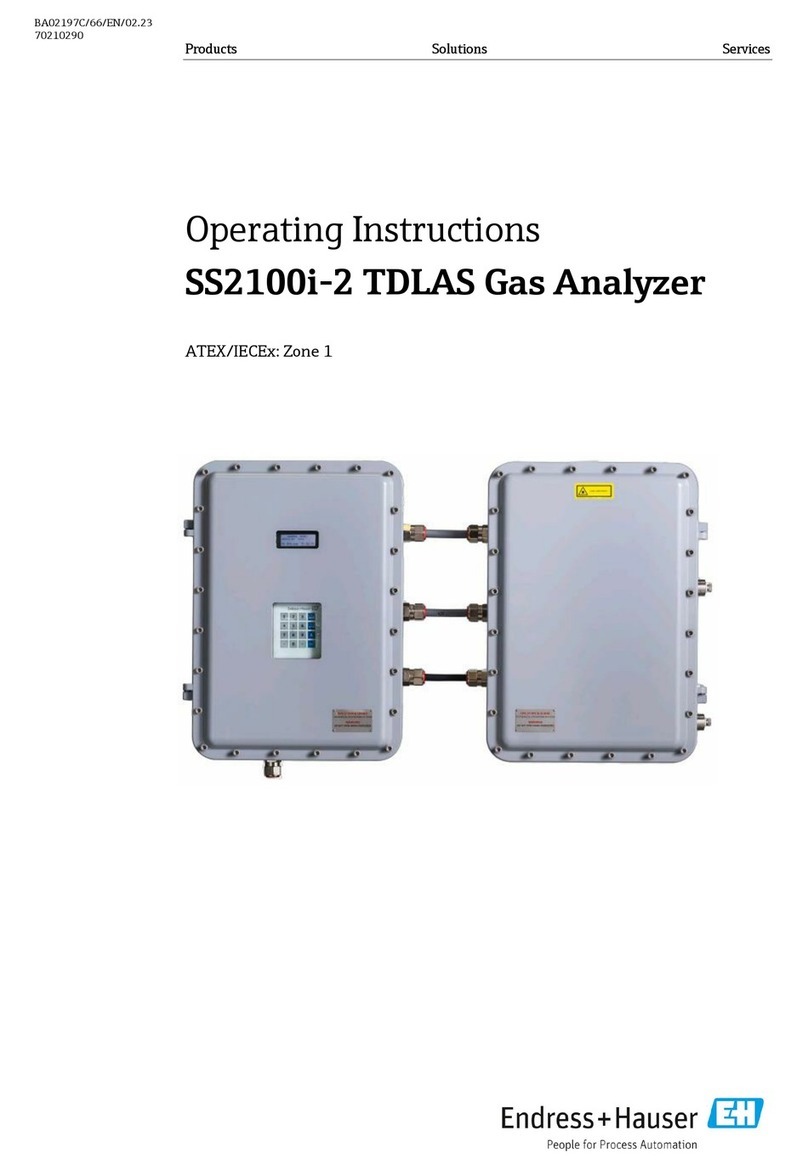

Features of all Instruments

Memory Lock feature on all models.

All models are typically available from stock.

All models are factory calibrated and ready for use.

All calibration values are traceable to National Standards.

Calibration certificate is included.

Durable, lightweight carrying case with protective foam inserts included.

(See Figure 2)

5. BASIC OPERATION

Before Use

1. Verify that the serial number on the instrument and the calibration chart are

the same, since readings may vary among instruments.

2. Check that the calibration and certification are current.

3. The Memory Lock feature should be OFF (pushed down). (See “Memory Lock

Feature” below.)

4. The pointer must be resting at 0 on the dial. If it is not, the calibration should

be checked. (See “Checking Accuracy” in Section 6 below.)

Selecting the Riser

1. Determine the diameter of the cable to be checked. (See Figure 3)

1/16" = .0625" 5-CWT = .076"

3/32" = .0938" 10-CWT = .106"

1/8" = .1250" 15-CWT = .141"

5/32" = .1562" 20-CWT = .155"

3/16" = .1875" 25-CWT = .170"

7/32" = .2188"

1/4" = .2500"

Standard

Aircraft Cables

CWT

Aircraft Cables

Cable Dimensions

Figure 2:

Carrying case

with

instrument and

calibration

certification

Figure 3:

Cable

Dimensions

ACM Series Instrument www.tensitron.com pg. 7

2. Determine the correct riser for your cable by referring to the Calibration Chart

on the back of the meter. (See also Riser Usage Chart in Appendix 1)

3. Rotate the riser so the correct setting faces the front (dial side) of the meter

and clicks into place.

Example: Selecting Riser

Assuming your cable diameter is 1/8”:

If the meter is an ACM-100, rotate the riser so the number 1/8 faces front

If the meter is an ACM-200, rotate the riser so the number 2 faces front

If the meter is an ACM-300, rotate the riser so the number 2 faces front

If the meter is an ACM-400, rotate the riser so the number 2 faces front

If the meter is an ACM-600, rotate the riser so the letter A faces front

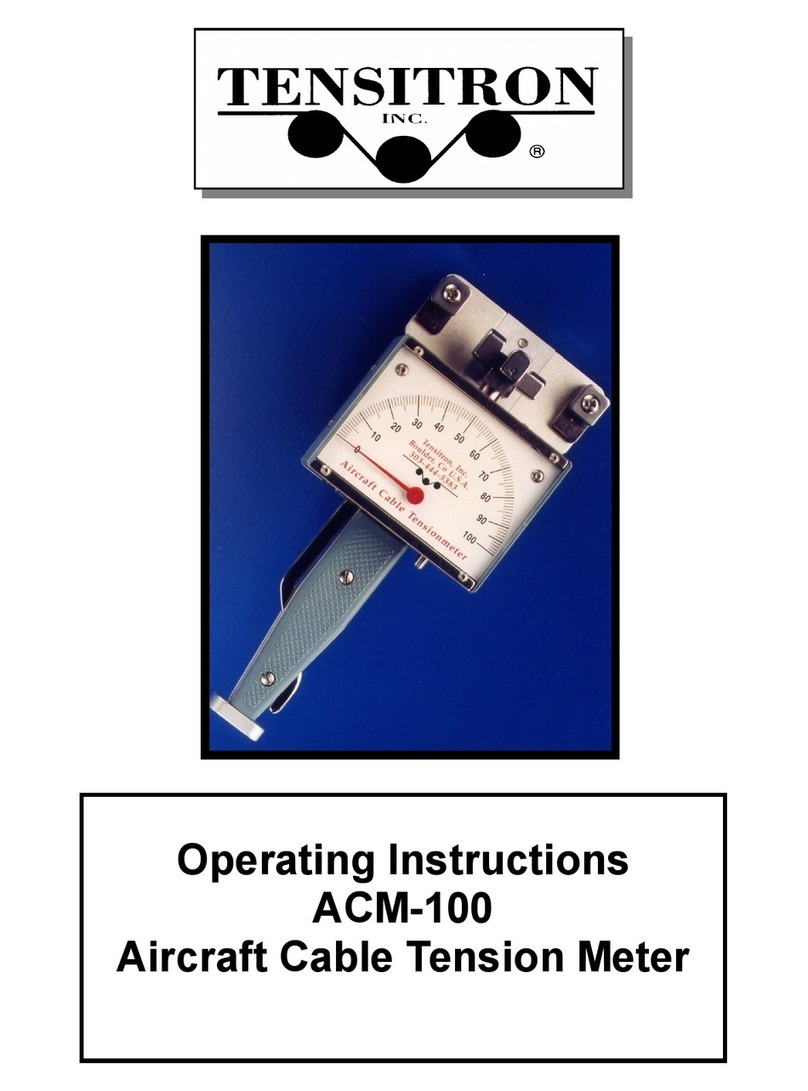

Engaging Instrument onto Cable

Warning:

Do not force the engagement lever or

exceed the maximum tension range of the instrument

or you will damage your meter!

1. To engage the instrument on the cable, first rotate the engagement lever away

from the instrument, raising the outer cable contacts. Next position your cable

so it rests on top of the (center) riser and beneath the outer cable contacts.

(See Figure 4)

2. Once the cable is in place, squeeze the engagement lever shut until it locks

into position parallel with the instrument handle. (See Figure 5) Note: Do NOT

try to force the lever closed, or damage may occur. If the lever does not close

Ready the instrument to

accept cable by rotating

engagement lever away

from handle.

Figure 4: Instrument ready to engage cable

Position cable below the

outer cable contacts.

Position cable above the riser.

ACM Series Instrument www.tensitron.com pg. 8

easily, STOP, and refer to the Troubleshooting Guide at the end of these

instructions

3. Note the reading on the display.

Saving a Reading Using Memory Lock Feature

Each ACM instrument has a Memory Lock feature. This feature can be used to

save readings taken in areas (such as confined spaces or behind obstructions)

where the operator cannot see the dial face while engaging the instrument on the

cable. To use this feature:

1. Begin by making sure the Memory Lock feature is OFF. Do this by pushing the

memory lock shaft all the way DOWN, so the red line is no longer visible. (See

Figure 6)

2. Engage the instrument onto the cable as described in “Engaging Instrument

onto Cable,” above.

Turn OFF the Memory Lock feature

by pushing the memory lock shaft

DOWN until the red line is no

longer visible.

Figure 6: Memory Lock feature

OFF / disengaged

Note the routing of the Cable.

Once cable is properly routed,

gently squeeze the

engagement lever back toward

the handle until it locks into the

engaged position, parallel to

the instrument handle.

Don’t over torque!

Figure 5: Instrument engaged

onto cable

ACM Series Instrument www.tensitron.com pg. 9

3. Save your reading by turning the Memory Lock feature ON. Do this by pushing

the memory lock shaft UP as far as possible, so the red stripe on the shaft is

visible. (See Figure 7)

4. Disengage and remove the meter from the cable. The pointer will remain

locked in position so you can note the reading.

5. To clear the reading and return the pointer to zero, turn the Memory Lock

feature OFF (see step #1 above).

6. If you engage the Memory Lock with no tension load, you may see the needle

move slightly off zero. However, this small amount of travel will not materially

affect the accuracy of tension readings taken when the Memory Lock feature

is correctly used.

7. Do not try to measure tension with the Memory Lock feature already ON. Only

turn the Memory Lock feature on AFTER engaging the meter on the cable.

Converting Readings to Tension Values with Calibration Chart

The number on the dial is NOT the tension. You must convert the reading on

the dial to a tension value by using the chart on the back of the meter.

1. Once the meter is engaged onto the cable, note the reading (where the pointer

is on the dial).

2. Refer to the calibration chart on the back of the instrument and locate the

column for the cable diameter you are testing.

3. Find the number in this column that most closely corresponds to the pointer’s

reading.

4. Follow this number’s row all the way to the left until you reach a number in the

“TENSION IN LBS” column. This number is the true tension of the cable.

5. Tensions may differ along the length of an aircraft cable because cable shape

and thickness may vary. For greater accuracy, it is best to take multiple

readings along the cable and average these readings.

Turn ON the Memory Lock feature

by pushing the memory lock shaft

UP until the red line is visible.

Figure 7: Memory Lock

ON / engaged

ACM Series Instrument www.tensitron.com pg. 10

Maintaining Your Meter

Return your meter to Tensitron for service when:

Pointer does not reset at 0 with memory lock "off."

Instrument has been dropped or otherwise damaged.

When using on aircraft, the instrument should be calibrated at intervals

not to exceed 12 months.

6. ADVANCED OPERATION

Checking Accuracy

1. To verify the accuracy of your instrument, hang a 5’ length of your cable

vertically. Suspend a known weight from the end. (Make sure the weight does

not exceed the maximum tension range of your instrument.) Engage the

instrument on the cable. See if the tension value matches the suspended

weight. (See Figure 8)

2. NOTE: Tension on a cable can be defined as the exact value of a suspended

weight from the cable. For example, a 100 lb. weight hanging freely from a

cable will tension the cable to exactly 100 lbs.

3. When performing this test, use a micrometer to measure your cable diameter

and ensure it is dimensionally within tolerance, +/- .003” of size, and not out of

round.

4. Only use free-hanging weights which are traceable to National Standards on

correctly-sized cables.

5. Never use any tensioning device that attempts to convert rotational torque

values into tension loads, as these types of systems are highly inaccurate.

Also, any load cell system must be routinely checked for accuracy using

traceable weights as these types of systems are also highly inaccurate and

generally do not meet the minimum repeatable accuracy standards required

by ISO-17025.

6. NEVER SIMULATE TENSION LOADS ON THESE INSTRUMENTS BY

USING A CALIBRATION BAR!

Figure 8:

Simulating

cable tension

using free-

hanging weight

ACM Series Instrument www.tensitron.com pg. 11

Recalibrating

Tensitron provides prompt turnaround service for its instruments needing

repair and/or re-certification. All values tested are traceable to national

standards, and serviced instruments meet or exceed all civilian and military

specifications. A calibration certification listing all calibration data and

values is included with each instrument.

If you would like to calibrate your instrument yourself, follow the procedure below.

*IMPORTANT: This procedure should only be performed by a qualified

calibration facility using certified and traceable dead weights.

Do not use this procedure for a simple accuracy check.

1. Prepare blank charts: Photocopy the blank calibration chart to use for the

new values you will be collecting. (See Appendix 2 for blank calibration charts

that are correctly sized to fit on the back of your instrument.)

2. Adjust zero: If the pointer is not resting at the 0 position on the dial, unscrew

the socket plug located on the bottom left of the instrument body. Using a

small screwdriver, gently adjust the zero adjust screw until the pointer

indicates 0. After adjustment apply torque-seal or paint to lock the screw

head.

3. Perform a Dead Weight Calibration:

a. For each cable to be tested:

i. Set the correct riser for the cable diameter as described in

“Selecting the Riser” above.

ii. Simulate a tension load on the cable with a dead weight by

following the procedure in step #1 under “Checking

Accuracy” above.

iii. On the calibration chart, in the column for that cable, record

the pointer reading so it lines up with the corresponding

weight in the CABLE TENSION LBS column.

iv. Repeat this process with different weights.

b. Do not attempt to measure cable diameters larger than those for

which the meter was designed. See Appendix 1, Riser Usage Charts,

for the appropriate cables for each instrument.

c. If a tension value for a particular cable is considered “critical”, remove

the cable from the aircraft and perform this dead weight calibration

procedure on that cable, rather than relying on a comparable sample.

d. Repeat this process for each cable.

4. Complete Chart: Make sure to sign and date your new calibration chart, and

attach it to the back of the instrument.

ACM Series Instrument www.tensitron.com pg. 12

7. APPENDICES

Appendix 1: RISER USAGE CHARTS

Note: ACM-150-CWT was formerly known as CWT-150, and ACM-300-CWT was

formerly known as CWT-300.

Appendix 2: BLANK CALIBRATION CHARTS

oACM-100

DIAMETER 1/16" 3/32" 1/8" 5/32" 3/16" 1/4"

ACM-100 1/16 3/32 1/8 5/32

ACM-200 1 2 2 3 3 4

ACM-300 1 2 3 4

ACM-400 1 2 3 3

ACM-600 A B C D

DIAMETER 5 10 15 20 25

ACM-150-CWT 510 15 20 20

ACM-300-CWT 10 15 20 20

MODEL #

MODEL #

RISER USAGE & CABLE DIAMETER - Inch

RISER USAGE & CABLE DIAMETER - Carat Weight (CWT)

Use Riser #:

Use Riser #:

ACM-100 Serial No.

If Cable Size is: 1/16" 3/32" 1/8" 5/32"

USE RISER 1/16 RISER 3/32 RISER 1/8 RISER 5/32

CABLE TENSION

LBS = 5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100 TENSITRON, INC.

CAL. BY: _________________________

733 S. Bowen St., Longmont, CO 80501

Date: See Cal Sticker

TEL: (303) 702-1980 FAX: (303) 702-1982

ACM Series Instrument www.tensitron.com pg. 13

oACM-200

oACM-300

Model ACM-300 Serial No.

If Cable Size is:

3/32" 1/8" 3/16" 1/4"

USE RISER 1 RISER 2 RISER 3 RISER 4

CABLE TENSION

LBS = 40

50

60

70

80

90

100

120

140

160

180

200

220

240

260

280

300 TENSITRON, INC.

CAL. BY: _______________ 733 S. Bowen St., Longmont, CO 80501

Date: See Cal Sticker

TEL: (303) 702-1980 FAX: (303) 702-1982

ACM Series Instrument www.tensitron.com pg. 14

oACM-600

oACM-150-CWT (formerly CWT-150)

ACM-600 Serial No.

If Cable Size is:

1/8" 5/32" 3/16" 1/4"

USE RISER A RISER B RISER C RISER D

Actual Tension on

Cable in LBS =

40

60

80

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

420

440

460

480

500

520

540

560

580

600

TENSITRON, INC.

CAL. BY: _________________________

733 S. Bowen St., Longmont, CO 80501

Date: See Cal Sticker

TEL: (303) 702-1980 FAX: (303) 702-1982

Model CWT-150 Ser. No.:

IF CABLE SIZE IS:

5 CWT 10 CWT 15 CWT ACTUAL 20 CWT 25 CWT

USE USE USE TENSION USE USE

RISER 5 RISER 10 RISER 15 LBS. RISER 20 RISER 20

10

20

30

40

50

60

70

80

90

100

N/A N/A 110

N/A N/A 120

N/A N/A 130

N/A N/A 140

N/A N/A 150

DATE: SEE CAL. STICKER

CAL. BY: __________________ TENSITRON, INC.

733 S. Bowen St., Longmont, CO 80501

TEL: (303) 702-1980 FAX: (303) 702-1982

ACM Series Instrument www.tensitron.com pg. 15

oACM-300-CWT (formerly CWT-300)

Appendix 3: TROUBLESHOOTING

TROUBLESHOOTING

PROBLEM

POSIBLE CAUSE

POSIBLE SOLUTION

The engagement

lever is difficult to

rotate closed.

1. Using the incorrect riser for

the cable diameter.

1. See Appendix 1, and

use correct riser.

2. Trying to measure

excessive tension.

2. Do not exceed meter’s

maximum tension

The tension

readings are not as

expected

1. Reading chart incorrectly.

See “Converting Readings

to Tension Values with

Calibration Chart” above

2. The meter has been

dropped and is damaged

3. Return to Tensitron for

service

The instrument

needle will not

return to zero

The Memory Lock is engaged

Disengage the memory

Lock. See “Saving a

Reading Using Memory

Lock Feature “ above

The instrument

needle will not

hold a stable

reading.

The meter has been dropped

and is damaged

Return to Tensitron for

service

Model CWT-300 Serial No. 224

If Cable Size is:

1/16" 10 15 5/32" 20 25

USE RISER RISER 1 10 15 RISER 3 20 20

CABLE TENSION

LBS = 40

50

60

70

80

90

100

120

140

160

180

200

220

240

260

280

300

300 TENSITRON, INC.

CAL. BY: _______________

- Boulder, CO 80301

733 S. Bowen St., Longmont, CO 80501

Date: See Cal Sticker TEL: (303) 702-1980 FAX: (303) 702-1982

733 S. Bowen Street

Longmont, CO 80501

USA

Phone: (303) 702-1980

Fax: (303) 702-1982

Web Site: www.tensitron.com

Other manuals for ACM-100

1

This manual suits for next models

8

Table of contents

Other TENSITRON Measuring Instrument manuals

TENSITRON

TENSITRON ACM-100 User manual

TENSITRON

TENSITRON WC SERIES User manual

TENSITRON

TENSITRON TX-125-1 User manual

TENSITRON

TENSITRON ACX-100-1 User manual

TENSITRON

TENSITRON LX-50-1 User manual

TENSITRON

TENSITRON BTM SERIES User manual

TENSITRON

TENSITRON WX-1 Series User manual

TENSITRON

TENSITRON ACX-Series User manual

TENSITRON

TENSITRON BTX-1 Series User manual

TENSITRON

TENSITRON TX-125 User manual