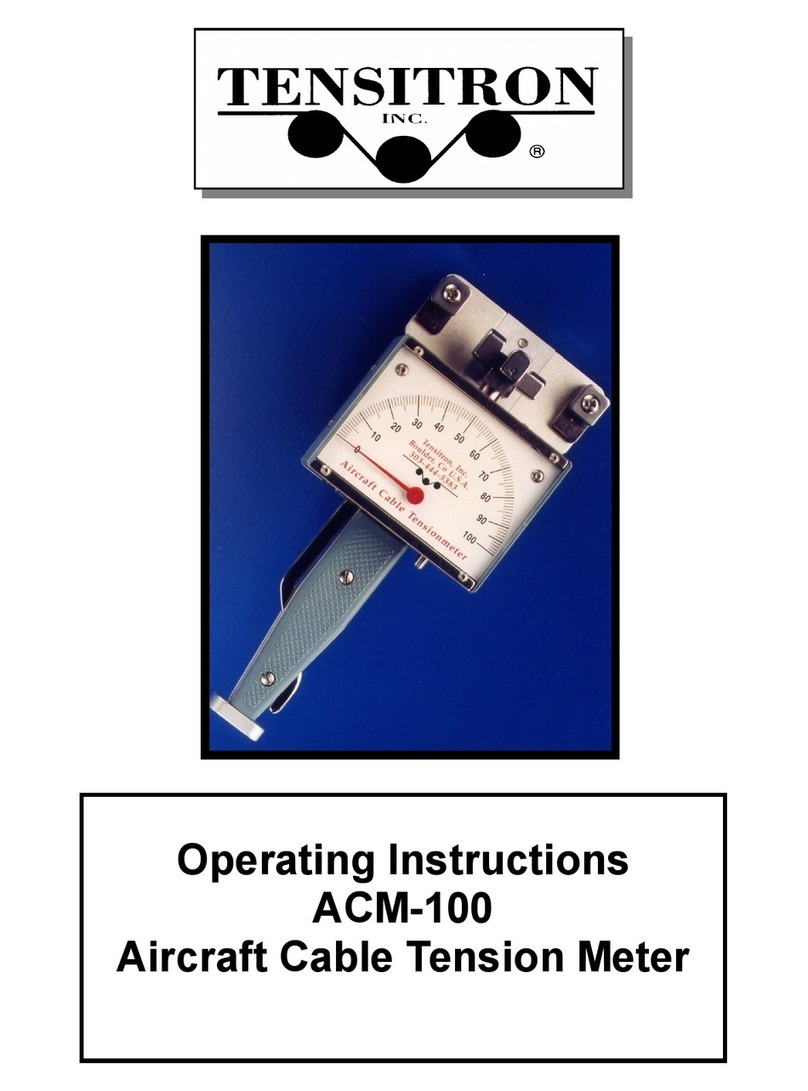

clamp.) Note how much the pointer moves as you rotate the calibrating ramp. It should

move slightly -- about 5 lb at a time. Retighten clamping screw.

Reset dial/bezel to zero setting. If necessary, readjust as outlined above.

To reposition the pointer after calibrating ramp is reset, rotate the dial/bezel to top center of

the indicator. Then loosen the four 8-32 cap screws fastening the indicator plate. Move

plate and indicator until pointer straddles 0 / Maximum reading on the dial.

Retighten all four cap screws. Recheck readings.

ACCURACY CHECK ONLY:

Check at 1/4, 1/2, 3/4, and 100% of your meter range. If adjustments are necessary, either

following the above calibration instructions or return the instrument to Tensitron for service

and repair.

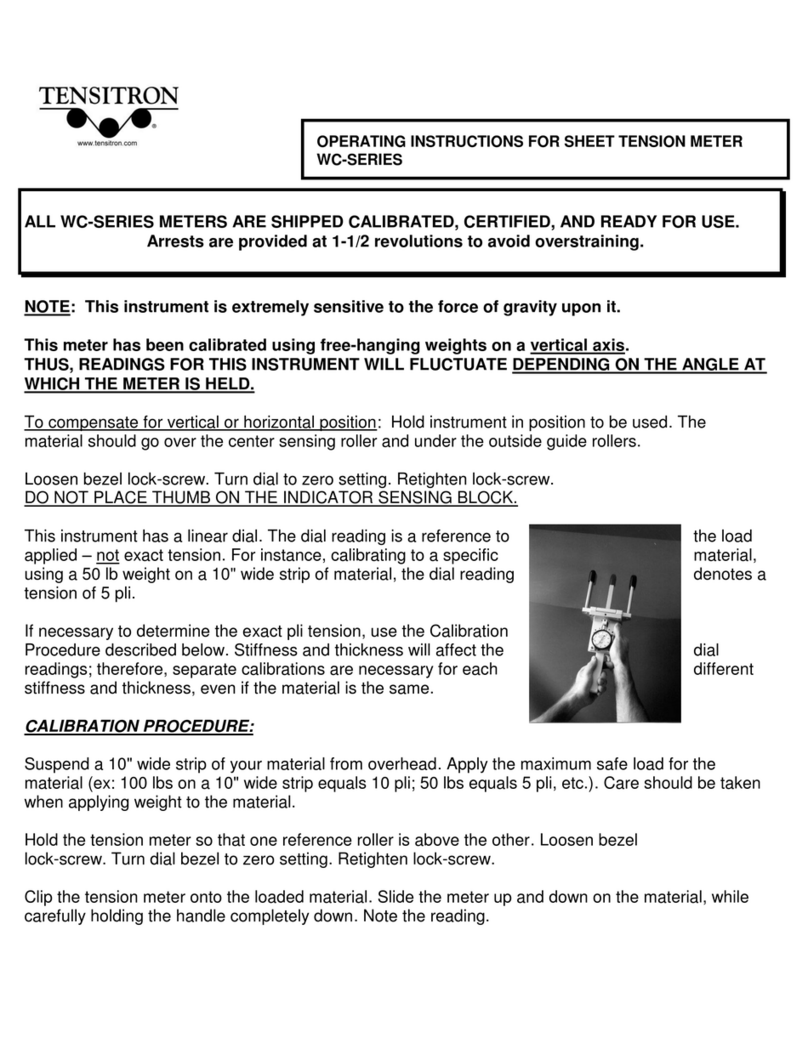

TO COMPENSATE FOR VERTICAL OR HORIZONTAL POSITION:

Hold instrument in position to be used. Loosen bezel lock-screw. Turn dial to zero setting.

Retighten lock-screw. AVOID PUTTING THUMB ON THE INDICATOR SENSING BLOCK.

CARE AND MAINTENANCE:

•Do not apply pressure to indicator sensing block. Keep clean and free of dust.

•If handle becomes stiff, apply a slight drop of oil or grease on point of contact.

•If meter has been dropped or otherwise damaged, return it to Tensitron for repair.

•Tensitron recommends calibration by the manufacturer at one-year intervals, or

sooner if the meter is worn, damaged, or reading incorrectly. However, it is the

responsibility of the user to establish a suitable calibration interval, considering such

factors as the user’s accuracy requirements, requirements set by contract or

regulation, and environmental factors such as frequency and conditions of the

meter’s use.

DO NOT OIL DIAL INDICATOR OR ROLLER BEARINGS.

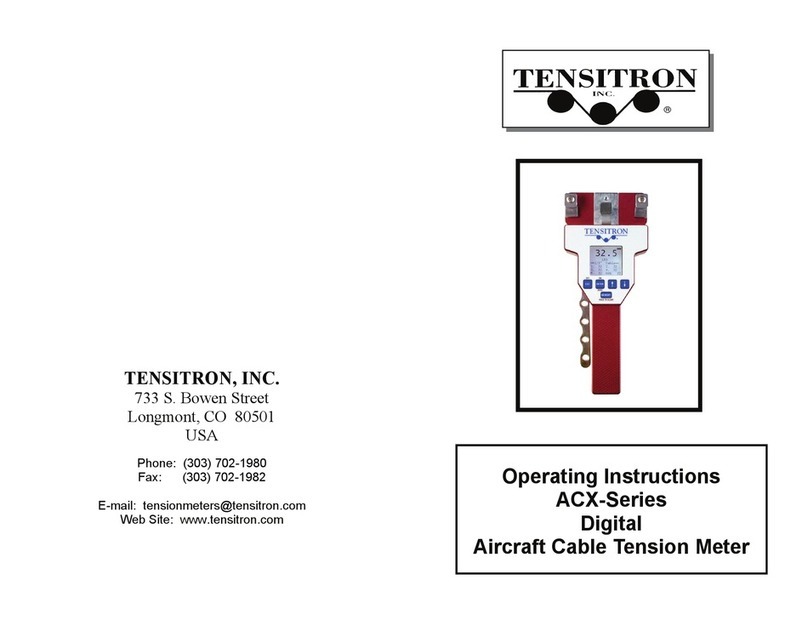

If service is required, return to:

Tensitron Tel: (303) 702-1980

733 South Bowen Street Fax: (303) 702-1982