TENSITRON WX-1 Series User manual

Operating Instructions

WX-1 Series Digital

Web Tension Meter

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 2

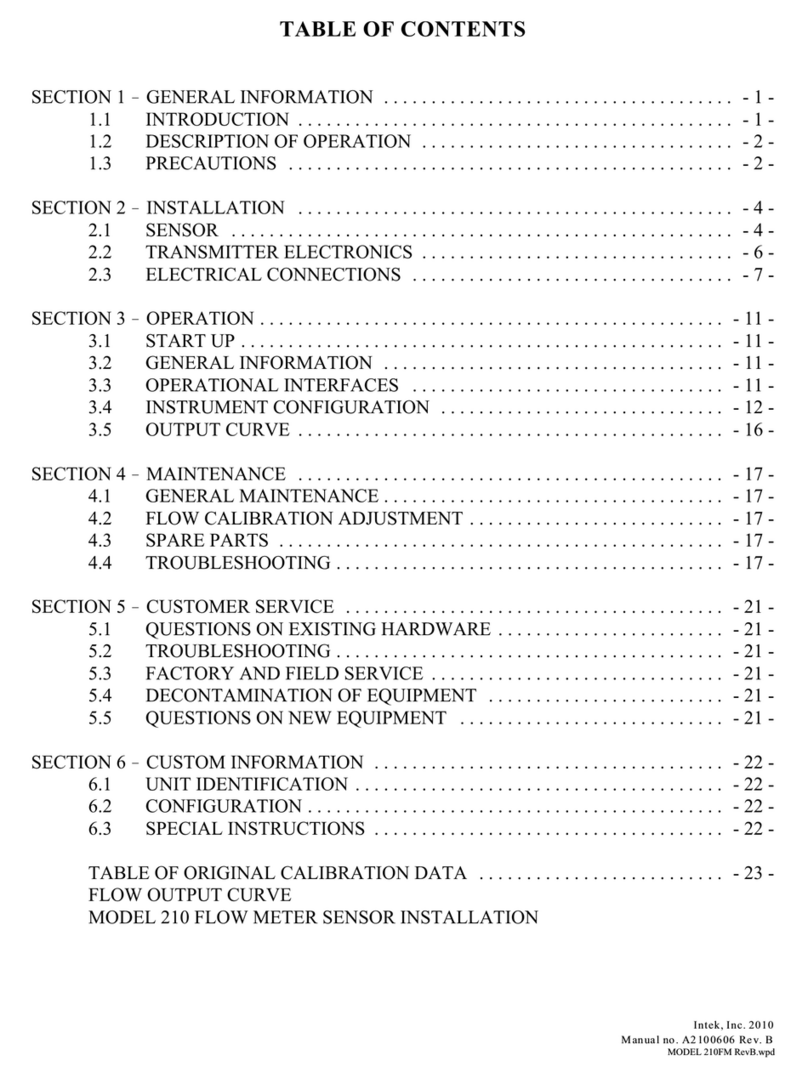

TABLE OF CONTENTS

1. WARRANTY POLICY ..................................................................................................... 3

2. SPECIFICATIONS .......................................................................................................... 4

3. SAFETY AND MAINTENANCE ....................................................................................... 5

4. INSTRUMENT FEATURES ............................................................................................. 6

•Calibration and Accuracy........................................................................................ 6

•Add-On Options...................................................................................................... 6

o- A Analog Output option................................................................................ 6

o- E RS-232 Serial Output option ...................................................................... 6

•Features of all Instruments .................................................................................... 6

5. BASIC OPERATION....................................................................................................... 7

•Charging Instrument Batteries ............................................................................... 7

•Quick Start Instructions.......................................................................................... 8

•Engaging Instrument onto Web ............................................................................. 9

6. DISPLAY SCREENS...................................................................................................... 10

•SETUP Screen ....................................................................................................... 10

oLCD Refresh Rate............................................................................................. 10

oData Averaging ................................................................................................ 10

oCustom Names ................................................................................................ 10

oRe-Cal Tension: See description at the end of this booklet............................. 11

oAudio ............................................................................................................... 11

oBacklight.......................................................................................................... 11

oSet-Point Menu ............................................................................................... 11

oVersion ............................................................................................................ 11

•DATA LOGGING Screen......................................................................................... 12

oView Data Stats ............................................................................................... 12

oView Data Log.................................................................................................. 12

oClear Single Point Log ...................................................................................... 12

•TENSION UNITS Screen......................................................................................... 12

•SELECT MATERIAL Screen..................................................................................... 12

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 3

7. ADVANCED OPERATION............................................................................................ 12

•General Calibration Precautions .......................................................................... 12

•Check Accuracy .................................................................................................... 13

•Calibrate Instrument ............................................................................................ 13

Proprietary Notice

This document contains proprietary information which may not be

reproduced in whole or in part without the written permission of

Tensitron, 733 South Bowen Street, Longmont, CO 80501.

Tensitron reserves the right to make instrument changes and

improvements which may not be reflected in this document. Portions

of this document may have been updated to include the latest

hardware or firmware version, if applicable. We recommend that this

document be read in its entirety before any attempt is made to

operate the instrument.

Thank You . . .

For purchasing another fine product from Tensitron

If you have any questions or need assistance, please call us at

303-702-1980 or find us online at www.tensitron.com

1. WARRANTY POLICY

STANDARD EQUIPMENT WARRANTY

Tensitron warrants that all Tensitron-manufactured equipment will be free of any defect in materials or

workmanship for the period of (1) year. Warranty begins from the date of shipment from a Tensitron facility.

The warranty is extended to customers and applies to all Tensitron-manufactured equipment purchased,

installed, and used for the purpose for which such equipment was originally designed. The above warranties

cover only defects arising under normal use and donot includemalfunctions orfailures resulting from misuse,

abuse, neglect, alteration, problems with electrical power, usage not in accordance with product instructions,

acts of nature, or improper installation or repairs made by anyone other than Tensitron or a Tensitron-

authorized, third-party service provider. Shipping costs toand from Tensitron are not included in the warranty

coverage.

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 4

2. SPECIFICATIONS

Full Scale Accuracy

For the accuracy of each WX-1 model, see Section 4.

Power Requirements

For Instrument Input: 9 VDC…2.2A

For AC Adapter: 100-240V~50-60Hz 0.48A

Power Supply operates with input voltages from 100 –240V and includes several interchangeable

adapters allowing use with European, U.S., Australian, English and other plug configurations.

Battery

Battery: Rechargeable NiMH, custom proprietary design

Battery lasts approximately 8 hours between charges, depending on backlighting intensity.

Operating Temperature

Recommended operating temperature range for WX-1 meters is -20 to 65 C (-4 to 149 F).

Recommended charging temperature range for WX-1 meters is 0 to 45 C (32 to 113 F).

Storage Temperature

20º F to 158º F. (Instrument and Charger)

Ambient Humidity

10% to 90% non-condensing

Weight, Dimensions

WX-1: Weight 3.1 lb. Dimensions 5.7” x 14.7” x 4.6” (See Figure 1)

Environment

Indoor or outdoor use, dust-free environment.

Figure 1: WX-1 Dimensions

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 5

3. SAFETY AND MAINTENANCE

WARNING: When using cordless, electronic instruments, always follow basic safety

precautions to reduce the risk of fire, electric shock and personal injury

USE ONLY A TENSITRON POWER SUPPLY TO AVOID DAMAGE

TO INSTRUMENT.

READ AND SAVE ALL INSTRUCTIONS. Before use, ensure all users read

and understand this manual, as well as labels packaged with or attached to the

instrument.

•Know your instrument. Read this manual carefully to learn your tension meter’s

applications and limitations, as well as potential hazards associated with this type

of instrument.

•Avoid dangerous environments. Do not use your instrument in explosive

atmospheres (gaseous fumes, dust or flammable materials). Do not submerge your

instrument in liquids.

•Use the right tool or instrument. Do not use this instrument to do a job for which it is

not recommended.

•Check for damaged parts. Inspect instrument before use. Check for any binding of

moving parts, improper mountings, broken parts and any other condition that may

affect operation. Do not use a damaged instrument. Tag damaged instrument “DO

NOT USE” until repaired. For repair, send instruments directly to Tensitron.

•Guard against electric shock.

•Maintain instrument carefully. Keep handles dry, clean and free from oil and

grease. Do not lubricate. All roller bearings are sealed.

•Do not use instrument if it has received a sharp blow, been dropped or damaged in

any way. Do not disassemble. Incorrect reassembly may result in damage to the

instrument and risk of electric shock and fire. Return damaged instruments to

Tensitron for repair.

•WARNING: Only use battery pack assemblies provided by Tensitron with your

meter. Other types of batteries might explode, causing personal injury and

damage. Unplug charger when not in use.

•Tensitron recommends calibration by the manufacturer at one-year intervals, or

sooner if the meter is worn, damaged, or reading incorrectly. However, it is the

user’s responsibility to establish a suitable calibration interval, considering the

user’s accuracy requirements, requirements set by contract or regulation, and

environmental factors such as frequency and conditions of the meter’s use.

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 6

4. INSTRUMENT FEATURES

•Calibration and Accuracy

WX-1 series instruments are calibrated to customer-supplied materials to ensure the

greatest possible accuracy for each application. When ordering, please provide Tensitron

with a sample (approximately 10”-wide, 10’-long) of each material you’d like included in

the menu.

WX-1 meters display tension per 10” width of material. Readings that equal PLI can

be provided instead, but the accuracy of each reading will be reduced.

Accuracy is material-specific. Typical accuracy for WX-1 instruments is summarized in

the table below, but actual accuracy may differ, depending on the properties of the

material used in the calibration:

Typical WX-1 Accuracy

Model

Range (lb)

Resolution

(lb)

Full-Scale

Accuracy

WX-50-1

5-50

0.5

2%

WX-100-1

5-100

0.5

2%

WX-250-1

5-250

0.5

2%

WX-500-1

25-500

1.0

2%

•Add-On Options

Instruments can be configured with either of these options:

o- A Analog Output option

Data output at 40 Hz.

0-5 VDC or 4-20 mA with Software-definable ending sequences.

Provided with 10’ web to interface with your receiving device.

o- E RS-232 Serial Output option

Select data sampling rate from 1, 2 or 5 Hz.

Provided with 10’ web to interface with your receiving device.

•Features of all Instruments

•Rollers: WX-1 meters come standard with 1” contact elements at the end

of 4” extensions.

•Color graphic display:

oLarge and easy to read, with adjustable backlighting.

oShows Tension, Battery Charge Level, and Web Material and

Size Selected.

oIncludes user-definable tension set points.

•Data Statistics: Monitor your process by viewing count, average,

minimum/maximum, and standard deviation values of your logged data.

•Selectable Tension Units: Choose to display tension in Lb, Kg or daN.

•Up to ten calibrations can be programmed into the instrument. (Password-

protected to provide due diligence against unauthorized changes.)

•Adjustable LCD refresh rates allow for stable digital readings.

•Automatic shutoff after several minutes of non-use.

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 7

•All models are typically available from stock.

•All models are factory calibrated and ready for use.

•All calibration values are traceable to National Standards.

•Calibration certificate is included.

•Continuous operation while connected to power supply.

•Durable, lightweight carrying case with protective foam inserts included.

(See Figure 2)

5. BASIC OPERATION

•Charging Instrument Batteries

1. Use only a Tensitron power supply to avoid damage to instrument.

2. Connect power supply to the instrument. Plug the power supply into a

power source with input voltages between 100 –240 VAC.

3. A full charge of the battery assembly requires several hours of

charging.

4. Battery pack assembly cannot be overcharged.

5. Instrument will remain on while connected to its power supply.

6. Battery charge level is indicated in upper, right-hand corner of display.

Figure 2: Carrying case with instrument, calibration

certificate, charger, adapters, and operating instructions.

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 8

•Quick Start Instructions

1. Power unit on by pressing ON button. Main display will indicate:

Tension, Material, Min and Max readings and other information. (See

Figure 3.)

2. Select a screen:

a. Move between screens by using the up (↑) and down (↓)

buttons.

b. Make or enter a selection by pressing the Enter/Zero button.

c. Exit a setting by pressing the Escape (ESC) button.

3. Log Data:

a. Press the STORE button to store tension readings along

with the Minimum and Maximum of these values.

b. Clear the data displayed on the Main Screen by pressing

and holding the STORE button, or power the instrument off.

c. For additional information on logging and viewing data, refer

to Sec 6 Display Screens - Data Logging.

4. Read Tension: Variations in webbing (material, thickness and width)

affect tension readings. It is essential to select the correct material

and size before use, or tension values may be incorrect.

Instrument Operation Panel

Main Display

Operation Buttons:

Off / Escape

On / Enter / Zero

Arrow Up

Arrow Down

Store

Main Display

Battery Charge Level

Selectable Units in Kg, daN, Lbs.

Set Point Display

Select Web Size –Instrument

automatically adjusts calibration

Store and Display Max and Min Tension

Readings.

Figure 3: Instrument Operation Panel and Display

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 9

5. Select Tension Units:

a. Using the up or down arrows, scroll to TENSION UNITS,

then press ENTER.

b. Next, select from: Kilograms, DecaNewtons, or LBS, and

then press ENTER.

6. Select Material:

a. Using the up or down arrows, scroll to SELECT MATERIAL,

then press ENTER.

b. Next scroll through the web descriptions until the correct

web size/material is highlighted, then press ENTER. Your

main display will indicate the web size selected. (See Figure

4)

c. If your specific material is not listed, add it to the menu by

following the calibration instructions included at the end of

these instructions. Or, send a 10’ sample of your

material/web and the instrument to Tensitron and ask to

have it added to the menu.

7. Zero Instrument: Hold the instrument in the attitude your reading will

be taken before you engage it to the tensioned web. Then, press

ZERO.

•Engaging Instrument onto Web

▪To engage the instrument onto the tensioned web, start with the

meter’s lever released, so the center sensor roller is lowered.

▪Position the meter so the webbing passes under the two outer guide

rollers and over the center sensor roller. Do not exceed the

maximum tension range of the instrument or damage will occur.

(See Figure 5)

▪Squeeze the lever gently shut until the rollers close onto the material.

Note: If it takes a lot of force to close the lever, STOP! Closing the

lever with excessive force will damage the instrument.

▪Note the tension reading on the display. (See Figure 5)

Select web size –

Instrument automatically

adjusts calibration

Figure 4:

Select Material Screen

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 10

6. DISPLAY SCREENS

•SETUP Screen

oLCD Refresh Rate

To either speed up or slow down the instrument’s LCD refresh rates:

▪Scroll to SETUP and press ENTER.

▪Scroll to LCD REFRESH RATE and press ENTER.

▪Select your preference: 1, 2 or 5 Hz and press ENTER.

Note: This feature is unrelated to Data Averaging

oData Averaging

Use the Data Averaging feature to adjust the stability of your displayed

tension readings in processes where the material to be checked is

constantly moving. This feature averages all of the readings taken over

a user-selected duration, then posts that average to the display, in an

ongoing, rolling average. The duration can be set at 1, 2, 5 and 10

seconds.

Examples: The meter takes ~300 readings per second, so if a 1-second

duration is selected, the meter will average all 300 readings before

posting the average of those readings to the display. Likewise, if a 10-

second duration is selected, the meter will average all 3000 readings

before posting the average of those 3000 readings to the display.

oCustom Names

Custom calibrations, listed as Custom 0 –9, can be renamed so your

material appears as a selection on the Main Display. To rename a

Custom Calibration:

▪Scroll to SETUP and press ENTER.

▪Scroll to CUSTOM NAMES and press ENTER.

▪Scroll to the description to rename and press ENTER.

▪Input your custom name by using the up and down arrows to

select each number, letter, or character, followed each time

by ENTER.

Note the routing of the web (under

the outer guide rollers and over the

center sensor roller) and the

tension reading on the display.

Figure 5: Instrument engaged onto

webbing.

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 11

▪Continue pressing ENTER until all spaces in the description

have values, including blank spaces.

▪Once your new name has been entered you will automatically

be returned to the SETUP screen.

oRe-Cal Tension: See description at the end of this booklet.

ONLY PERFORM THIS IF YOU ARE A QUALIFIED CALIBRATION HOUSE USING NIST-CERTIFIED

CALIBRATION WEIGHTS.NOT USED FOR CHECKING ACCURACY.TO CHECK ACCURACY,REFER TO

SEC.7: CHECK ACCURACY.

oAudio

To turn the Beep ON or OFF:

▪Scroll to SETUP and press ENTER.

▪Scroll to AUDIO and press ENTER.

▪Select ON or OFF and press ENTER.

oBacklight

To adjust the visual intensity of the LCD screen.

▪Scroll to SETUP and press ENTER.

▪Scroll to BACKLIGHT and press ENTER

▪Select Low, Medium or Full intensity and press ENTER.

oSet-Point Menu

This feature displays tension as a colored bar on the main display. The

colored bar advances as tension increases, and retracts as tension

decreases. You can define a safe operating tension range. For tension

measurements within this range, the bar is green. Below the range, the

bar is amber. Above the range, the bar is red.

To adjust the Set Point Menu:

▪Scroll to SETUP and press ENTER.

▪Scroll to SETPOINT MENU and press ENTER.

▪Follow and enter the prompts to turn this feature on or off, or

to edit your high and low values. (See Figure 6)

oVersion

Press this button to determine what Model the instrument is set at in the

firmware as well as to see what level of firmware is downloaded to the

Instrument.

Set Point Setup Screen

See High and Low threshold values

Settings:

On / Off

Edit High Point Threshold

Edit High Point Threshold

Figure 6: Setpoint Setup

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 12

•DATA LOGGING Screen

Each time the instrument’s STORE button is pressed, a log of that web tension

will be stored into memory for later review.

oView Data Stats

This feature allows the operator to view the basis statistics of the

logged data (Count, Average, Minimum/Maximum, and Standard

Deviation).

oView Data Log

When data is logged to the instrument memory, that data and the

statistics of that data log (Count, Average, Minimum/Maximum, and

Standard Deviation) can be seen under the Data Logging / View Data

Stats screen. To view this logged data:

▪Scroll to DATA LOGGING and press ENTER.

▪Scroll to VIEW DATA LOG and press ENTER.

oClear Single Point Log

To clear stored data, scroll to CLEAR SINGLE PT LOG, press ENTER,

and follow the prompts.

•TENSION UNITS Screen

To change the unit of measure in which tension readings are logged:

▪Scroll to Tension Units and press ENTER.

▪Use the Up and Down arrows to select Kilograms,

DecaNewtons or Pounds and press ENTER.

•SELECT MATERIAL Screen

Press ENTER while this display is shown to show the available options for the

material types. Use the up or down arrow to scroll to the option you want and

press ENTER to select it.

7. ADVANCED OPERATION

•General Calibration Precautions

1. To verify the accuracy of your instrument, check the tension on a sample

length of web by suspending known weights from the opposite end.

2. When performing this test, use a micrometer to measure your web

thickness and ensure it is dimensionally within tolerance.

3. Only use free-hanging weights which are traceable to National Standards

on correctly-sized webs. (See Figure 7.)

4. Never use any tensioning device that attempts to convert rotational torque

values into tension loads, as these types of systems are highly inaccurate.

Also, any load cell system must be routinely checked for accuracy using

traceable weights as these types of systems are also highly inaccurate

and generally do not meet the minimum repeatable accuracy standards

required by ISO-17025.

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 13

•Check Accuracy

1. Confirm that the size web you’re working with is the same as the one

selected in your WX’s display.

2. Before engaging the WX-1 instrument onto the web, zero the instrument

by holding it in the same attitude you’ll be taking the readings and press

the “Enter” or “Zero” button. This will eliminate any small tare effects.

3. Take readings along the web. FOR BEST RESULTS ALWAYS TAKE

SEVERAL READINGS OF THE WEB TENSION BY DISENGAGING AND

THEN RE-ENGAGING THE INSTRUMENT FROM THE WEB ITSELF.

4. Verify the tension value. For example, if your suspended weight is 40.0 lb.

your instrument should also indicate 40.0 lb. +/- the full-scale accuracy

percentage of the specific instrument model listed in Section 4, once

properly engaged to the web. This procedure confirms the instrument’s

accuracy and it is now ready for use.

Note: Accuracy Specification: NOTE, ACCURACY IS MODEL

DEPENDENT. For an instrument with a full-scale range of 250 lb., this

translates into +/- 5 lb., and for an instrument with a full-scale range of

500 lb., accuracy is +/- 10.0 lb. (with a 2% Accuracy Specification).

If you have additional questions, please contact Tensitron for help.

•Calibrate Instrument

*IMPORTANT: THIS FEATURE SHOULD ONLY BE USED BY A CALIBRATION FACILITY USING CERTIFIED AND

TRACEABLE DEAD WEIGHTS.DO NOT USE THIS FEATURE FOR A SIMPLE ACCURACY CHECK.

If you want to verify or check the accuracy of a Web go to: “Check

Accuracy” in Section 7: Advanced Operation.

When calibrating these instruments tension values must be entered in

Lbs. Note: If your dead weight standards are in Kilograms, convert their

values into Lbs: 1 KG = 2.2046 Lbs

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 14

Follow these instructions to update the calibration for an existing web on

the menu or to add a calibration for a new web. If you would like to add a

new web, first create a name for it by following the instructions under

“Custom Names” in Section 6, above.

1. Scroll to SETUP and press ENTER. Next, scroll to RE-CAL TENSION and press

ENTER. The screen will now display: SETUP, RE-CALIBRATE TENSION,

ENTER PASSWORD, CAL DATA WILL BE LOST!

2. Enter Password. Contact Tensitron at service@tensitron.com for the password.

3. The display now indicates: SETUP RE-CALIBRATE TENSION with a list of the

calibration names and custom names programmed into the instrument. Scroll to

the description you wish to recalibrate, highlight it and then press ENTER.

4. The next screen will indicate: CALIBRATE TENSION, NUMBER OF POINTS.

Using the up and down arrows select the number of calibration points to which you

will be tensioning the web. The minimum is 5 points. Zero is a calibration point

already set, so you will need to define a minimum of 4 increasing tension values

such as: 50, 100, 150 and 200. If desired you can define more than 5 weight

points, with a maximum of 10 points total. If 10 calibration points were selected the

entries could look something like this: 10, 20, 30, 40, 50, 60, 70, 80, 90.

Figure 7: Free hanging weight

simulating web tension.

WX-1 Series Instrument Revised: 10.3.19 www.tensitron.com pg. 15

5. ENTER WEIGHT. After selecting the number of calibration points, you need to

define these weight values. Using the up or down arrows select your first tension,

or weight calibration point and press ENTER. Do not use 0 (zero) as this value is

already programmed into the instrument. Next, use the up or down arrows to select

your weight 2 value, making sure the value entered is greater than the entry in

weight 1. Next, select increasing weight values for the additional weight points,

without exceeding the maximum tension range of the instrument.

6. CALIBRATE TENSION. Next you will calibrate the instrument using the weight

values you previously selected. To properly simulate these tensions, suspend a

single length of your web from above and suspend known weights onto the web in

the values you’ve previously selected, when prompted. (See Figure 7.)

a. CALIBRATE TENSION, NUMBER OF POINTS __, ZERO UNIT.

Without any web engaged to the instrument, hold it in the attitude

you will be taking the reading in and press ENTER to calibrate

zero weight. Next the display will prompt you to suspend the

weight value you previously selected in step 5. If, for example

you selected 50 lb. for your first weight value the instrument will

indicate: PLACE WEIGHT 50.

b. Suspend the exact weight value from your web that you’ve

previously selected (In this example it would be 50 lb.)

c. Next, engage the instrument to your tensioned web, then press

ENTER once the reading has stabilized.

d. Repeat steps b. and c. for the remaining weight points by

suspending additional weights onto your web in the values

previously selected and entering these readings.

e. Once the last weight value is entered, the instrument will return

to the SETUP menu. Press the ESCAPE button to return to the

main display.

f. The main display will now indicate the web/material description

you just finished calibrating. If the material name on the display

is not the material you just recalibrated, you have re-

programmed the incorrect description. If this happens, you will

need to recalibrate both the material indicated on the display

along with the material you thought you were calibrating.

g. After completing a calibration always recheck the values. Refer

to “Check Accuracy” in Section 7.

733 S. Bowen Street

Longmont, CO 80501

USA

Phone: (303) 702-1980

Fax: (303) 702-1982

E-mail: [email protected]

Web Site: www.tensitron.com

This manual suits for next models

4

Table of contents

Other TENSITRON Measuring Instrument manuals

TENSITRON

TENSITRON BTX-1 Series User manual

TENSITRON

TENSITRON WC SERIES User manual

TENSITRON

TENSITRON TX-125-1 User manual

TENSITRON

TENSITRON LX-50-1 User manual

TENSITRON

TENSITRON ACX-100-1 User manual

TENSITRON

TENSITRON STX-1 Series User manual

TENSITRON

TENSITRON ACM-100 User manual

TENSITRON

TENSITRON ACM-100 User manual

TENSITRON

TENSITRON ACX-Series User manual

TENSITRON

TENSITRON TX-125 User manual