TER 206 User manual

OPERATING MANUAL English GB

GB

1. DECLARATION OF CONFORMITY

TER SRL - Via Leopardi, 13 - 36030 Caldogno (VI) Italy

declares that the machines descripted in this manual must be use

solely for professional purposes in an industrial environment and they

are manufactured in compliance with the instructions contained in

the harmonized standard:

2006/95/CE (LDV) – 2004/108/CE (EMC) – 2002/95 (RoHs)

and with the instructions contained in the harmonized standard,

if applicable:

EN 60974-1 EN 60974-2 EN 60974-3 EN 60974-5 EN 60974-7

EN 60974-10 EN 60974-12

Date 31/01/2012 Maurizio Terzo

General Manager

IN CASE OF BAD OPERATION YOU DEMAND

THE

ATTENDANCE OF QUALIFIED STAFF

The equipment don’t compiles with EN/ IEC 61000-3-12.

The installer or the user must be sure that it can be connected to the public low voltage power line,

if necessary, in consultation with the network distributor.

OPERATING MANUAL Inglese GB

GB

TER 206 SERIES

This manual must be completed by the “CE Operating and service maual” Edition of 29/07/2015 Rev.00

OPERATING MANUAL English GB

GB

1. DECLARATION OF CONFORMITY

TER SRL - Via Leopardi, 13 - 36030 Caldogno (VI) Italy

declares that the machines descripted in this manual must be use

solely for professional purposes in an industrial environment and they

are manufactured in compliance with the instructions contained in

the harmonized standard:

2006/95/CE (LDV) – 2004/108/CE (EMC) – 2002/95 (RoHs)

and with the instructions contained in the harmonized standard,

if applicable:

EN 60974-1 EN 60974-2 EN 60974-3 EN 60974-5 EN 60974-7

EN 60974-10 EN 60974-12

Date 31/01/2012 Maurizio Terzo

General Manager

IN CASE OF BAD OPERATION YOU DEMAND

THE

ATTENDANCE OF QUALIFIED STAFF

The equipment don’t compiles with EN/ IEC 61000-3-12.

The installer or the user must be sure that it can be connected to the public low voltage power line,

if necessary, in consultation with the network distributor.

OPERATING MANUAL Inglese GB

GB

TER 206 SERIES

This manual must be completed by the “CE Operating and service maual” Edition of 29/07/2015 Rev.00

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

WARNING

IMPORTANT: BEFORE STARTING THE EQUIPMENT, READ THE CONTENTS OF THIS MANUAL, WHICH MUST

BE STORED IN A PLACE FAMILIAR TO ALL USERS FOR THE ENTIRE OPERATIVE LIFE-SPAN OF THE MACHI-

NE.THIS EQUIPMENT MUST BE USED SOLELY FOR WELDING OPERATIONS.

1. Conformity declaration

The machines descripted in this manual, TER 166/186, must be used solely for professional purposes in an industrial

environment and they are manufactured in compliance with the instructions contained in the harmonized standard

EN50199 (electromagnetic compatibility) and EN60974-1.

IN CASE OF BAD OPERATION YOU DEMAND THE ATTENDANCE OF QUALIFIED STAFF.

1.1 RAEE Norm

The symbol on the product or on its packaging indicates that this product may not be treated as household waste.

Instead it shall be handed over to the applicable collection point for the recycling of electrical and electronic equip-

ment. By ensuring this product is disposed of correctly, you will help prevent potential negative consequences for the

environment and human health, which could otherwise be caused by inappropiate waste handling of this product. For

more detailed information about recycling of this product, please contact your local city ofce, your household waste

disposal service or the shop where you purchased the product.

2. SAFETY PRECAUTIONS

WELDING AND ARC CUTTING CAN BE HARMFUL TO YOURSELF AND OTHERS. The user must therefore be edu-

cated against the hazards, summarized below, deriving from welding operations.

ELECTRIC SHOCK – May be fatal.

Install and earth the welding machine according to the applicable regulations.

Do not touch live electrical parts or eletrodes with bare skin, gloves or wet clothing.

Isolate yourselves from both the earth and the workpiece.

Make sure your working position is safe.

FUME AND GASES – May be hazardous to your health.

Keep your head away from fumes.

Work in the presence of adequate ventilation, and use ventilators around the arc to prevent gases from

forming in the work area.

ARC RAYS – May injure the eyes and burn the skin.

Protect yuor eyes with welding masks tted with ltered lenses, and protect your body with appropiate

safety garments.

Protect others by installing adequate shields or curtains.

RISK OF FIRE AND BURNS

Sparks (sprays) may cause res and burn the skin; you should therefore make sure there are no

ammable materials in the area, and wear appropriate protective garments.

NOISE

This machine does not directly produce noise exceeding 80dB. The plasma cutting/welding procedure

may produce noise levels beyond said limit; users must therefore implement all precautions required by

law.

PACEMAKERS

The magnetic elds created by high currents may affect the operation of pacemakers. Wearers of vital

electronic equipment (pacemakers) should consult their physician before beginning any arc welding,

cutting, gouging or spot welding operations.

EXPLOSIONS

Do not weld in the vicinity of containers under pressure, or in the presence of explosive dust, gases or

fumes. All cylinders and pressure regulators used in welding operation should be handled with care.

3. General description

This machine is a constant direct current power source, designed for welding electrically conductive materials (metals

and alloys) using the electical arc procedure.

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

WARNING

IMPORTANT: BEFORE STARTING THE EQUIPMENT, READ THE CONTENTS OF THIS MANUAL, WHICH MUST

BE STORED IN A PLACE FAMILIAR TO ALL USERS FOR THE ENTIRE OPERATIVE LIFE-SPAN OF THE MACHI-

NE.THIS EQUIPMENT MUST BE USED SOLELY FOR WELDING OPERATIONS.

1. Conformity declaration

The machines descripted in this manual, TER 166/186, must be used solely for professional purposes in an industrial

environment and they are manufactured in compliance with the instructions contained in the harmonized standard

EN50199 (electromagnetic compatibility) and EN60974-1.

IN CASE OF BAD OPERATION YOU DEMAND THE ATTENDANCE OF QUALIFIED STAFF.

1.1 RAEE Norm

The symbol on the product or on its packaging indicates that this product may not be treated as household waste.

Instead it shall be handed over to the applicable collection point for the recycling of electrical and electronic equip-

ment. By ensuring this product is disposed of correctly, you will help prevent potential negative consequences for the

environment and human health, which could otherwise be caused by inappropiate waste handling of this product. For

more detailed information about recycling of this product, please contact your local city ofce, your household waste

disposal service or the shop where you purchased the product.

2. SAFETY PRECAUTIONS

WELDING AND ARC CUTTING CAN BE HARMFUL TO YOURSELF AND OTHERS. The user must therefore be edu-

cated against the hazards, summarized below, deriving from welding operations.

ELECTRIC SHOCK – May be fatal.

Install and earth the welding machine according to the applicable regulations.

Do not touch live electrical parts or eletrodes with bare skin, gloves or wet clothing.

Isolate yourselves from both the earth and the workpiece.

Make sure your working position is safe.

FUME AND GASES – May be hazardous to your health.

Keep your head away from fumes.

Work in the presence of adequate ventilation, and use ventilators around the arc to prevent gases from

forming in the work area.

ARC RAYS – May injure the eyes and burn the skin.

Protect yuor eyes with welding masks tted with ltered lenses, and protect your body with appropiate

safety garments.

Protect others by installing adequate shields or curtains.

RISK OF FIRE AND BURNS

Sparks (sprays) may cause res and burn the skin; you should therefore make sure there are no

ammable materials in the area, and wear appropriate protective garments.

NOISE

This machine does not directly produce noise exceeding 80dB. The plasma cutting/welding procedure

may produce noise levels beyond said limit; users must therefore implement all precautions required by

law.

PACEMAKERS

The magnetic elds created by high currents may affect the operation of pacemakers. Wearers of vital

electronic equipment (pacemakers) should consult their physician before beginning any arc welding,

cutting, gouging or spot welding operations.

EXPLOSIONS

Do not weld in the vicinity of containers under pressure, or in the presence of explosive dust, gases or

fumes. All cylinders and pressure regulators used in welding operation should be handled with care.

3. General description

This machine is a constant direct current power source, designed for welding electrically conductive materials (metals

and alloys) using the electical arc procedure.

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

PLC - Power Line Controller

The machine with PLC has a key socket in the back panel.

Held one copy of the key in a safe place (if both the key are lost, the complete key block must be replaced).

The domestic (inside houses) power supply

is limited at 16A; to use the machine in that

condition, t set the key on 16A position.

Use the key to select the power supply

range.

Note: The plug used in the supply cable of the machine must be an industrial plug ≧25A, when the machine is

used at maximum power. The PLC key must be positioned on 25 A (industrial applications).

Don’t use the 16A plug for industrial applications.

The key must be removed from the machine after the power supply setting.

PLC FUNCTION

The Ter 166 and Ter 186 series are industrial power sources for light/medium applications; the duty cycle is very

high and the design of the power inverter allows hight current rates. When the machines are connected to the

domestic (house) power supply a plug 16A should be mounted; the input current must be less than average 16A in

order to avoid the switching-o of the main switch protecting the power line.

The PLC feature controls the input current, automatically inhibiting the welding process when the power input rise

the limit of the main line switch (16A).

The power of the machine isn’t reduced, only the welding time (duty cycle) is concerned when the current is

highter than the available one from net, as shown in the picture below, where we compare the available welding

time in function of the welding current between industrial (red plot) and domestic (green plot) for a mig setting.

LIMITATION OF THE WELDING TIME WITH PLC

10

100

1000

100 110 120 130 140 150 160 170 180 190 200

CURRENT

sec.

PLC curves

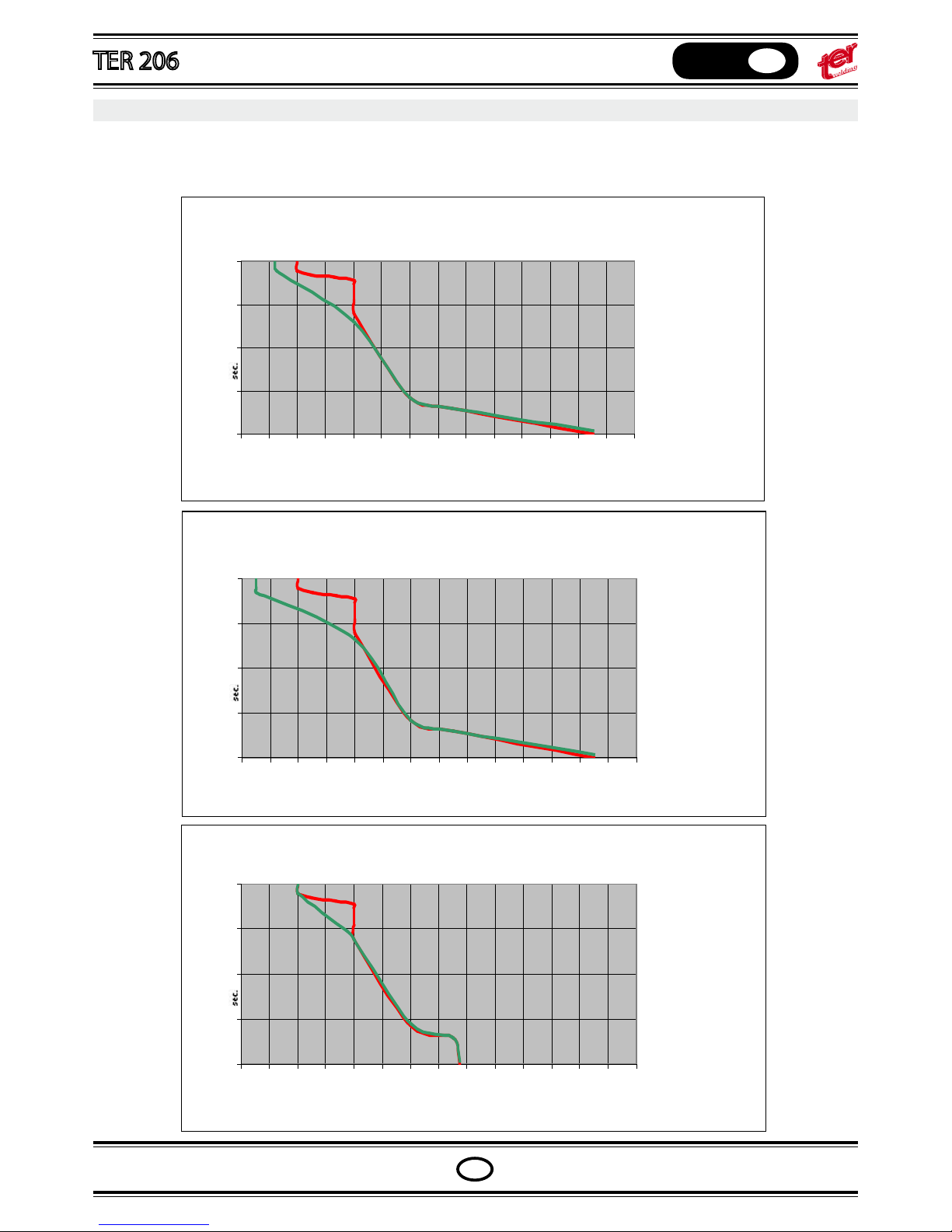

The following three curves shown the reduced data for the applications of the machine in MMA, Mig and Tig.

The red plots are for industrial applications and the green ones are for domestic with the PLC key turned in 16A

position.

MIG PULS MIG PLC

0,1

1

10

100

1000

100 120 140 160 180 200 220 240 260 280 300 320 340 360 380

CURRENT

ELCTRODE PLC

0,1

1

10

100

1000

100 120 140 160 180 200 220 240 260 280 300 320 340 360 380

CURRENT

TIG TIG PULSE PLC

0,1

1

10

100

1000

100 120 140 160 180 200 220 240 260 280 300 320 340 360 380

CURRENT

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

PLC - Power Line Controller

The machine with PLC has a key socket in the back panel.

Held one copy of the key in a safe place (if both the key are lost, the complete key block must be replaced).

The domestic (inside houses) power supply

is limited at 16A; to use the machine in that

condition, t set the key on 16A position.

Use the key to select the power supply

range.

Note: The plug used in the supply cable of the machine must be an industrial plug ≧25A, when the machine is

used at maximum power. The PLC key must be positioned on 25 A (industrial applications).

Don’t use the 16A plug for industrial applications.

The key must be removed from the machine after the power supply setting.

PLC FUNCTION

The Ter 166 and Ter 186 series are industrial power sources for light/medium applications; the duty cycle is very

high and the design of the power inverter allows hight current rates. When the machines are connected to the

domestic (house) power supply a plug 16A should be mounted; the input current must be less than average 16A in

order to avoid the switching-o of the main switch protecting the power line.

The PLC feature controls the input current, automatically inhibiting the welding process when the power input rise

the limit of the main line switch (16A).

The power of the machine isn’t reduced, only the welding time (duty cycle) is concerned when the current is

highter than the available one from net, as shown in the picture below, where we compare the available welding

time in function of the welding current between industrial (red plot) and domestic (green plot) for a mig setting.

LIMITATION OF THE WELDING TIME WITH PLC

10

100

1000

100 110 120 130 140 150 160 170 180 190 200

CURRENT

sec.

PLC curves

The following three curves shown the reduced data for the applications of the machine in MMA, Mig and Tig.

The red plots are for industrial applications and the green ones are for domestic with the PLC key turned in 16A

position.

MIG PULS MIG PLC

0,1

1

10

100

1000

100 120 140 160 180 200 220 240 260 280 300 320 340 360 380

CURRENT

ELCTRODE PLC

0,1

1

10

100

1000

100 120 140 160 180 200 220 240 260 280 300 320 340 360 380

CURRENT

TIG TIG PULSE PLC

0,1

1

10

100

1000

100 120 140 160 180 200 220 240 260 280 300 320 340 360 380

CURRENT

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

PLC signals

When the PLC inhibit the welding, the current supply is breaked immediately, and the front panel shows the PLC

timer count down.

When the timer arrive to 0, the welding can restart.

Please refer to the plots in order to avoid unexpected welding interruptions when the machine is used on dome-

stic lines.

VRD - Voltage Reduction Device

IThis function reduces the output no load voltage at a value less than 25V in a very short time.

It increases the safety conditions of the machine user: the no load voltage is not dangerous but contact trough

human body and live parts of earth cable and electrode holder can cause a shock with lost of equilibrium control

or similar.

The simbol“VRD” lighting on means that VRD protection is active with an output no load voltage equal to 15V.

When“VRD” feature is o, an icon led shows voltage greather than 25V.

Setting:

when VRD is o, press the“CYCLE”pushbutton for 7

seconds; once the“VRD” led start ashing release the

button pressure.

when VRD is on, press the“CYCLE” pushbutton for 7 se-

conds until the VRD icon ligth o.

In the meantime the icon U2>25LV should light on.

The machine stops its main functions when it is not continuosly used, in order to reduce the power consumption

at 10W, and “STANDBY” icon lights.

The fan works only when the machine need to be cooled down; during ligth applications, the fan normally doesn’t work.

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

PLC signals

When the PLC inhibit the welding, the current supply is breaked immediately, and the front panel shows the PLC

timer count down.

When the timer arrive to 0, the welding can restart.

Please refer to the plots in order to avoid unexpected welding interruptions when the machine is used on dome-

stic lines.

VRD - Voltage Reduction Device

IThis function reduces the output no load voltage at a value less than 25V in a very short time.

It increases the safety conditions of the machine user: the no load voltage is not dangerous but contact trough

human body and live parts of earth cable and electrode holder can cause a shock with lost of equilibrium control

or similar.

The simbol“VRD” lighting on means that VRD protection is active with an output no load voltage equal to 15V.

When“VRD” feature is o, an icon led shows voltage greather than 25V.

Setting:

when VRD is o, press the“CYCLE”pushbutton for 7

seconds; once the“VRD” led start ashing release the

button pressure.

when VRD is on, press the“CYCLE” pushbutton for 7 se-

conds until the VRD icon ligth o.

In the meantime the icon U2>25LV should light on.

The machine stops its main functions when it is not continuosly used, in order to reduce the power consumption

at 10W, and “STANDBY” icon lights.

The fan works only when the machine need to be cooled down; during ligth applications, the fan normally doesn’t work.

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

The machine stops its main functions when it is not continuosly used, in order to

reduce the power consumption at 10W, and “STANDBY” icon lights.

The fan works only when the machine need to be cooled down; during ligth

applications, the fan normally doesn’t work.

Power supply control

The machine can be used with motogenerator power supply and/or long supply cables; the supply voltage should

run between 180V and 270V limits.

When the supply voltage overlaps those limits, the machine functions stop and the main panel lights the last sup-

ply voltage, like picture shows.

Functions can be recovered switching the machine o and than on again.

STAND BY

Means “Power Supply” 169V was the voltage before the

machine shut down

MMA WELDING: MANUAL MODE SETTING

Connect the electrode holder and the earth clamp plugs to the correct machine polarities, according to the

electrode manufacturer specs.

Negative polarity Positive polarity

Press the rst pushbutton and select the icon “STICK”

Press the second pushbutton and select icon“MANUAL”

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

The machine stops its main functions when it is not continuosly used, in order to

reduce the power consumption at 10W, and “STANDBY” icon lights.

The fan works only when the machine need to be cooled down; during ligth

applications, the fan normally doesn’t work.

Power supply control

The machine can be used with motogenerator power supply and/or long supply cables; the supply voltage should

run between 180V and 270V limits.

When the supply voltage overlaps those limits, the machine functions stop and the main panel lights the last sup-

ply voltage, like picture shows.

Functions can be recovered switching the machine o and than on again.

STAND BY

Means “Power Supply” 169V was the voltage before the

machine shut down

MMA WELDING: MANUAL MODE SETTING

Connect the electrode holder and the earth clamp plugs to the correct machine polarities, according to the

electrode manufacturer specs.

Negative polarity Positive polarity

Press the rst pushbutton and select the icon “STICK”

Press the second pushbutton and select icon“MANUAL”

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

Set with pushbuttons“+” or“-”the required welding current

start the welding

THE DYNAMIC OF THE ARC

It can be changed according to the electrode type.

Example: stainless steel and rutil electrodes must have a“soft dynamic” (close to 0), basic and the majority of the

industrial electrode applications need a “medium dynamic” (10-12), while cellulosic needs a high one.

Setting:

Press the second level pushbutton: the icon “HS” lights and its value appears on the display.

The icon ash for two seconds and durig this time, pressing the pushbuttons“+” and“-”adjust the value.

Two seconds after the last touching the display sort out from setting mode.

ANTI-STICKING

During the MMA welding process, the electrode may stick on the workpiece; thanks to the anti-sticking feature the

current is inhibited until the electrode unstick.

Once active, the“Antisticking”icon ash on the front panel.

ANTISTICKING

Any setting in the MMA (stick) manual mode, once xed, is considered like a user program; it means once the user

select the stick manual mode again, the last adjustment is recovered and proposed.

Again, if the machine is turned o, for any reason, the last mode and setting are proposed in the front panel.

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

Set with pushbuttons“+” or“-”the required welding current

start the welding

THE DYNAMIC OF THE ARC

It can be changed according to the electrode type.

Example: stainless steel and rutil electrodes must have a“soft dynamic” (close to 0), basic and the majority of the

industrial electrode applications need a “medium dynamic” (10-12), while cellulosic needs a high one.

Setting:

Press the second level pushbutton: the icon “HS” lights and its value appears on the display.

The icon ash for two seconds and durig this time, pressing the pushbuttons“+” and“-”adjust the value.

Two seconds after the last touching the display sort out from setting mode.

ANTI-STICKING

During the MMA welding process, the electrode may stick on the workpiece; thanks to the anti-sticking feature the

current is inhibited until the electrode unstick.

Once active, the“Antisticking”icon ash on the front panel.

ANTISTICKING

Any setting in the MMA (stick) manual mode, once xed, is considered like a user program; it means once the user

select the stick manual mode again, the last adjustment is recovered and proposed.

Again, if the machine is turned o, for any reason, the last mode and setting are proposed in the front panel.

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

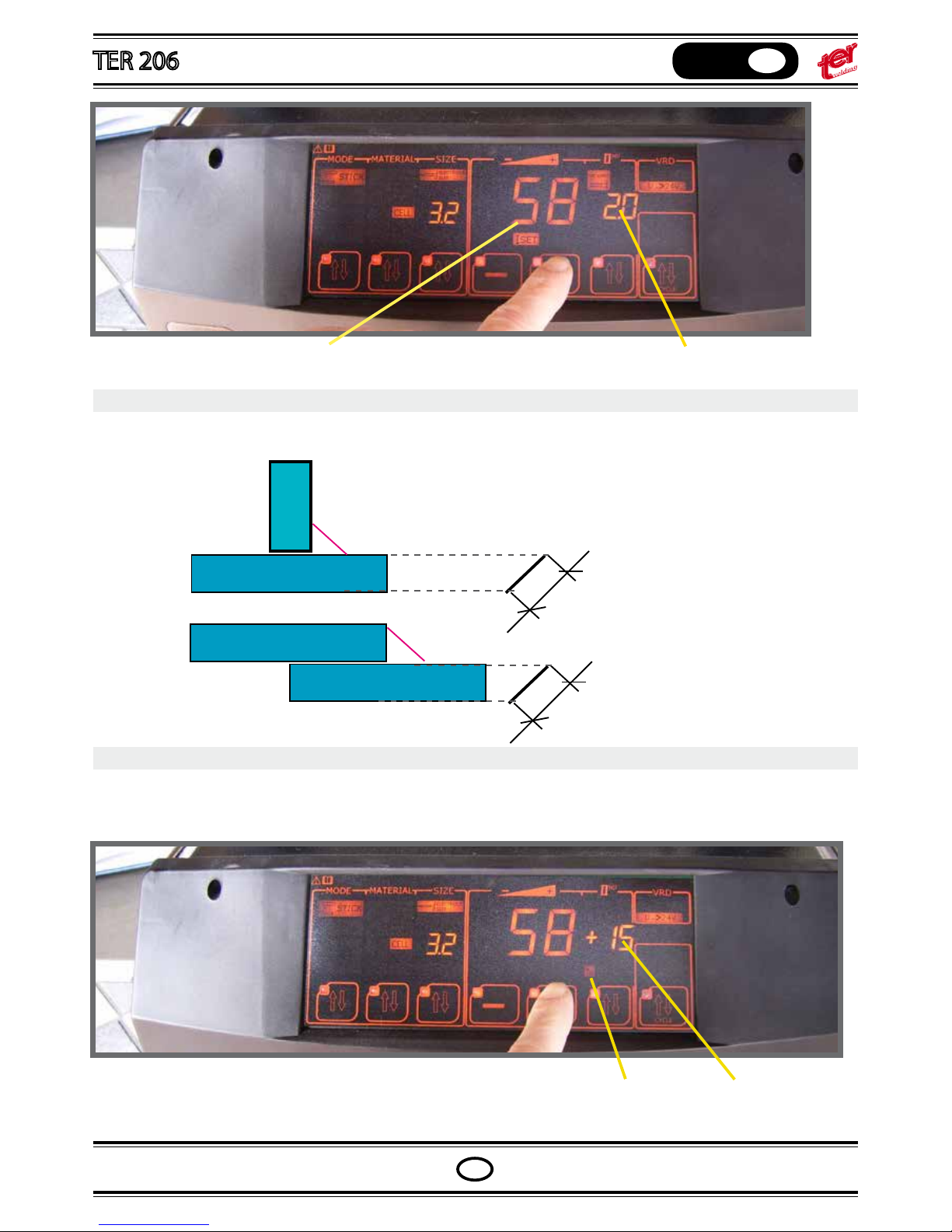

MMA WELDING: SYNERGIC MODE SETTING

MMA electrode synergic mode is an exclusive and powerfull solution to approach the MMA welding avoiding

setting mistakes.

Even professional welders can use the synergic mode in order to approach faster new settings.

Press the rst pushbutton and select the icon “STICK”

Press the second pushbutton and select the material type

With the third pushbutton select the electrode diameter

Set with pushbuttons“+” or“-”the required wel-

ding current or workpiece tickness

The workpiece thickness is shown and

helps the user with the current setting

NOTE:

The workpiece thickness is based over a standard orizontal welding.

In case of dierent joints or positions, increase or decrease the current/thickness values.

equivalent thickness

equivalent thickness

ARC DYNAMIC

It is already set with an optimal value according to the choosed basic material and electrode but it can be adju-

sted as shown on chapter“The dynamic of the arc”.

The adjustment works in % value over the program setting

Dynamic icon selected Increase dynamic by 15%

Once settings are given, they are stored as default programs for MMA synergic mode. The modied personalized

setting will be proposed as default program during the following stick synergic setting mode.

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

MMA WELDING: SYNERGIC MODE SETTING

MMA electrode synergic mode is an exclusive and powerfull solution to approach the MMA welding avoiding

setting mistakes.

Even professional welders can use the synergic mode in order to approach faster new settings.

Press the rst pushbutton and select the icon “STICK”

Press the second pushbutton and select the material type

With the third pushbutton select the electrode diameter

Set with pushbuttons“+” or“-”the required wel-

ding current or workpiece tickness

The workpiece thickness is shown and

helps the user with the current setting

NOTE:

The workpiece thickness is based over a standard orizontal welding.

In case of dierent joints or positions, increase or decrease the current/thickness values.

equivalent thickness

equivalent thickness

ARC DYNAMIC

It is already set with an optimal value according to the choosed basic material and electrode but it can be adju-

sted as shown on chapter“The dynamic of the arc”.

The adjustment works in % value over the program setting

Dynamic icon selected Increase dynamic by 15%

Once settings are given, they are stored as default programs for MMA synergic mode. The modied personalized

setting will be proposed as default program during the following stick synergic setting mode.

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

TIG WELDING – machine setting

Connect the tig torch to the negative

polarity

Connect the auxiliary plug (if the

machine is provided with the remote

control socket)

Connect the torch gas hose to the

output nipple (if the machine is

equipped with gas control)

Connect the argon gas bottle to

the input gas nipple located on the

machine back side and adjust the

gas ow between 5 to 7 liters per

minute

Connect the

workpiece earth

cable to the positive

polarity

LIFT ARC MODE

Push the torch switch. If the solenoid gas valve is not

controlled by the torch switch, open the gas ow.

Slow down the torch until the ceramic nozzle touch the

workpiece; in this phase held the torch and avoid any

contact between tungsten and workpiece.

Keeping the nozzle in contact, turn the torch until the

tungsten enters in contact with the workpiece

Maintaining the nozzle-work piece contact, turn back

the torch to the original position; the arc strikes and the

welding can be performed.

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

TIG WELDING – machine setting

Connect the tig torch to the negative

polarity

Connect the auxiliary plug (if the

machine is provided with the remote

control socket)

Connect the torch gas hose to the

output nipple (if the machine is

equipped with gas control)

Connect the argon gas bottle to

the input gas nipple located on the

machine back side and adjust the

gas ow between 5 to 7 liters per

minute

Connect the

workpiece earth

cable to the positive

polarity

LIFT ARC MODE

Push the torch switch. If the solenoid gas valve is not

controlled by the torch switch, open the gas ow.

Slow down the torch until the ceramic nozzle touch the

workpiece; in this phase held the torch and avoid any

contact between tungsten and workpiece.

Keeping the nozzle in contact, turn the torch until the

tungsten enters in contact with the workpiece

Maintaining the nozzle-work piece contact, turn back

the torch to the original position; the arc strikes and the

welding can be performed.

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

HIGH FREQUENCY MODE

Approach the work piece with the torch up to a dinstance of

3-5 mm. from tungsten.

Push the torch switch to strike the arc; if the arc doesn’t ignit,

the high frequency impulse stops after 4 seconds. Drive again

the torch switch.

In particular environment conditions such as hospitals, aerports, active nuclear plants, etc. the high frequency

should be forbitten.

In that case, deselect the high frequency and use only lift arc start.

Press “+” and“-” pushbuttons to select or

deselect the high frequency mode

Press the second level pushbutton up to

the icon“HF”ash

CURRENT SETTING – Manual

Press the rst pushbutton and select “TIG”or“TIG PULSE”

Press the second pushbutton and select “MANUAL”

With the third pushbutton select the electrode diameter

Set with pushbuttons“+” or“-”the required welding current

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

HIGH FREQUENCY MODE

Approach the work piece with the torch up to a dinstance of

3-5 mm. from tungsten.

Push the torch switch to strike the arc; if the arc doesn’t ignit,

the high frequency impulse stops after 4 seconds. Drive again

the torch switch.

In particular environment conditions such as hospitals, aerports, active nuclear plants, etc. the high frequency

should be forbitten.

In that case, deselect the high frequency and use only lift arc start.

Press “+” and“-” pushbuttons to select or

deselect the high frequency mode

Press the second level pushbutton up to

the icon“HF”ash

CURRENT SETTING – Manual

Press the rst pushbutton and select “TIG”or“TIG PULSE”

Press the second pushbutton and select “MANUAL”

With the third pushbutton select the electrode diameter

Set with pushbuttons“+” or“-”the required welding current

OPERATING MANUAL

OPERATING MANUAL

English GB

English GB

GB

GB

SWITCH CYCLES – Setting

TIMER

The current stops

after the set time;

can restart with a

new arc strike.

Available both

with lift and HF

arc strike mode

TWO STEPS

The current starts

when the torch

switch drives the

cycle and stops

when it is relea-

sed. Up and down

slopes are not

allowed

TWO STEP

SLOPE

The current starts

when the torch

switch drives the

cycle and stops

with a down slope

when the torch

switch is released

FOUR

STEPS

The current starts

when the torch

switch drives the

cycle and stops

when the torch

switch is pressed

again

FOUR

STEPS SLO-

PE

The current starts

at level 1 at the

rst torch switch

pressure; slope

rise up releasing

the torch switch.

Down slope to

current I3 at

second switch

pressure and

stop with switch

release.

NOTES:

In manual tig setting certain parameters can be adjusted by the user while others are xed:

PREGAS x at 0,1 sec

UP slope automatic depending from down slope

CURRENT 1 (initial current) xed

CURRENT 3 (craterller nal current) xed

DOWN slope variable and synergic (select the icon with second level pushbutton)

POST GAS variable and synergic (select the icon with second level pushbutton)

PULSE FREQUENCYvariable and sinergyc (select the icon with second level pushbutton)

PULSE BALANCE variable and sinergyc (select the icon with second level pushbutton)

TIMER variable and sinergyc (select the icon with second level pushbutton)

PULSE PEAK automatic

PULSE LOW CURRENT automatic

TIG SYNERGIC MODE - Setting

With the second pushbutton select the material type

With the third pushbutton select the tungsten size

Set with pushbuttons“+” or“-”the required wel-

ding current. Current level limits depend from

the choosed program

The basic material thickness setting is strictly

connected with the selected current and

material type

Table of contents

Other TER Welding System manuals

Popular Welding System manuals by other brands

Miller Weldmaster

Miller Weldmaster 112 Extreme manual

Lincoln Electric

Lincoln Electric SP-100T Operator's manual

ProMeister

ProMeister MIG 200 Translation of original operating instructions

Thermal Dynamics

Thermal Dynamics CUTMASTER 60i operating manual

Oerlikon

Oerlikon CITOSTEEL III 420 Instruction for operation and maintenance

Telwin

Telwin INVERPULSE 320 MIG-TIG-MMA instruction manual