Application 1 cold threshold 33

Application 2 hot threshold 33

Application 2 cold threshold 33

Application 3 hot threshold 34

Application 3 cold threshold 34

NO/NC ON time 34

IND-Thermal-90 emissivity 34

Application 2 centered area size 34

Application 2 moving average size 35

Application 3 ROI size 35

Temperature choice 35

Configurable Flags (Coil Inputs) 36

NO/NC enabled/disabled 36

NO/NC timer based 36

NO/NC selected 36

NPN/PNP selected 37

Application 3 uni-directional counter 37

Application 1 (alarm) enabled/disabled 37

Application 2 (alarm) enabled/disabled 38

Application 3 (alarm) enabled/disabled 38

Master reading 38

Asynchronous reconstruction of Frame by using ‘Master reading’ flag 39

Application 1 limited FoV flag 40

Application 1 and 3 moving average 40

Clear NO/NC 41

Application 3 reset uni-directional counter 41

Discrete Inputs (Read-Only) 41

NO/NC active 41

Alarm triggered 41

Application 1 alarm triggered 42

Application 2 alarm triggered 42

Application 3 alarm triggered 42

Default factory reset 42

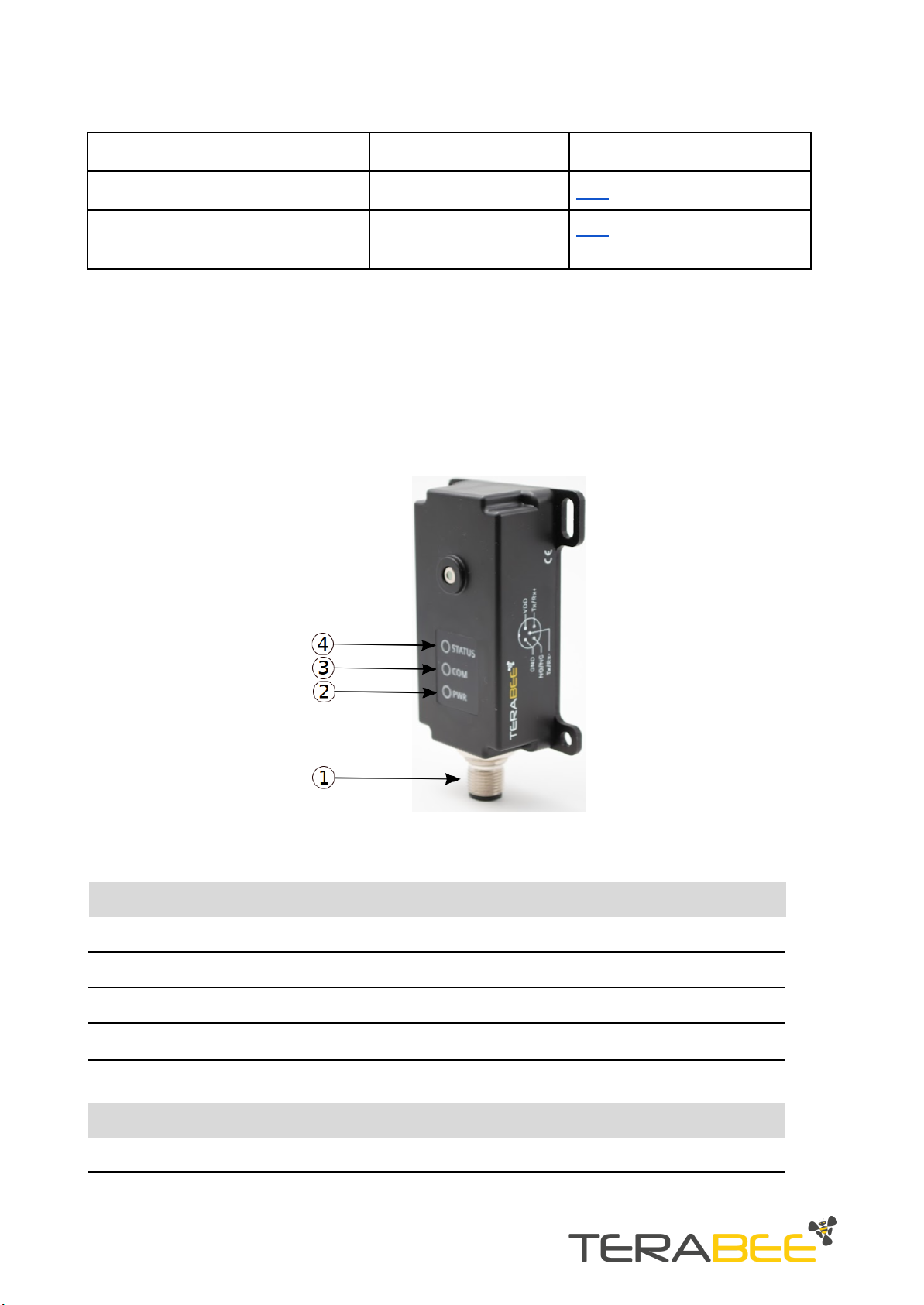

Connection example: input to a PLC 43

PNP connection 43

NPN connection 44

Connection to PC (Windows) 45

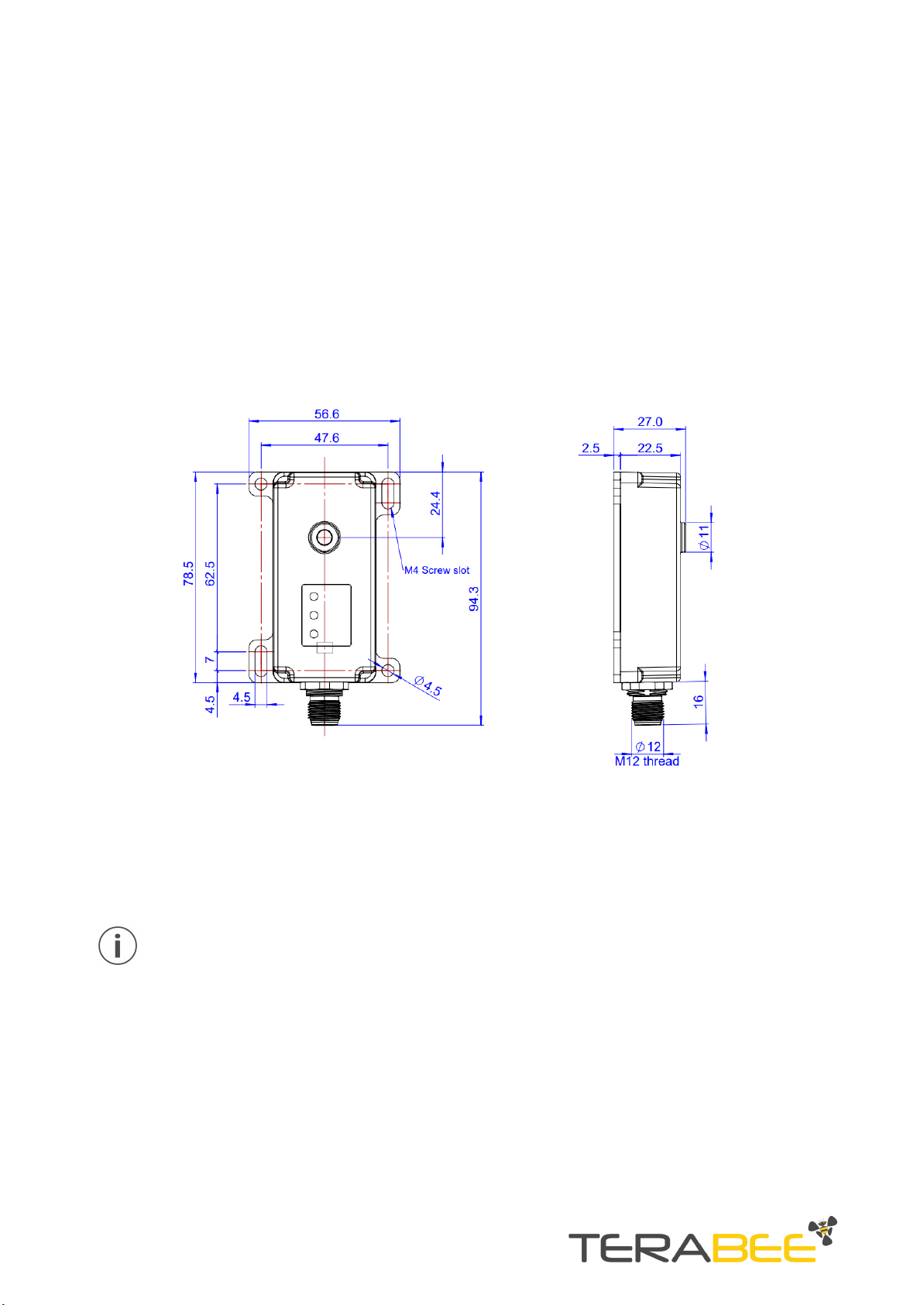

Hardware setup 45

Software setup 47

MODBUS Doctor software configuration 47

Basic IND-Thermal-90 camera parameter configuration 48