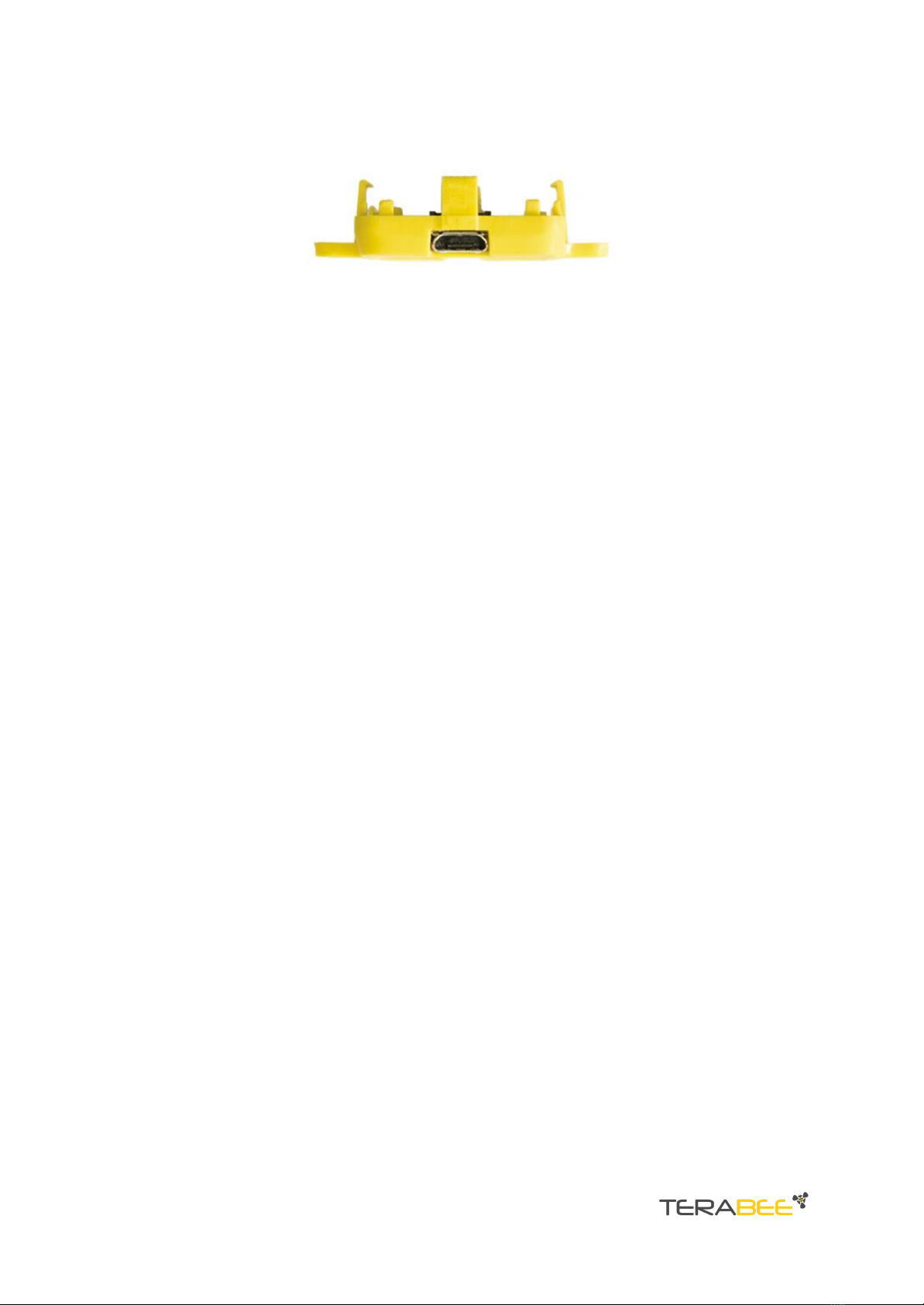

3. USB backboard use

The USB backboard comes with a standard Micro-USB connector.

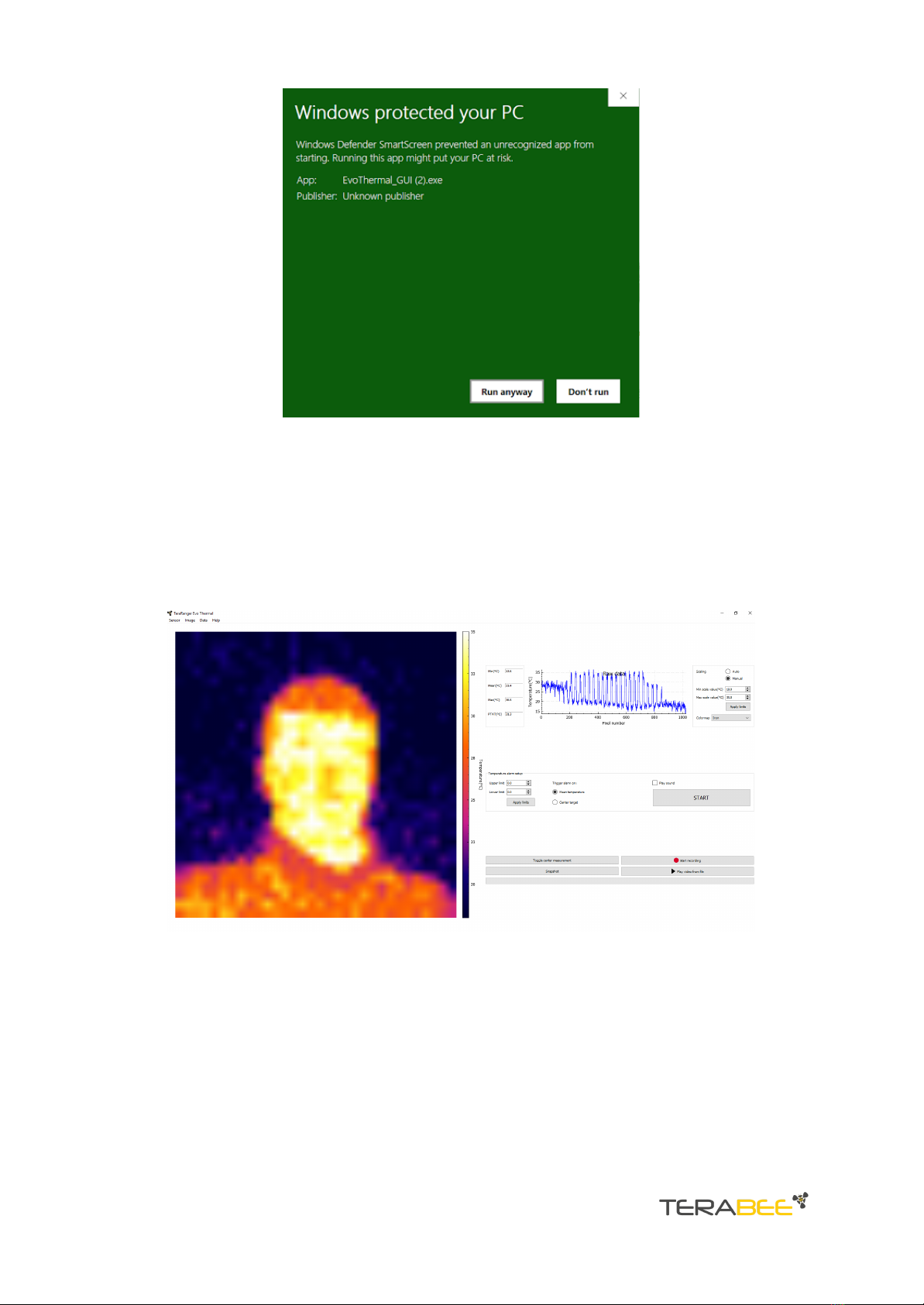

3.1. Graphical User Interface

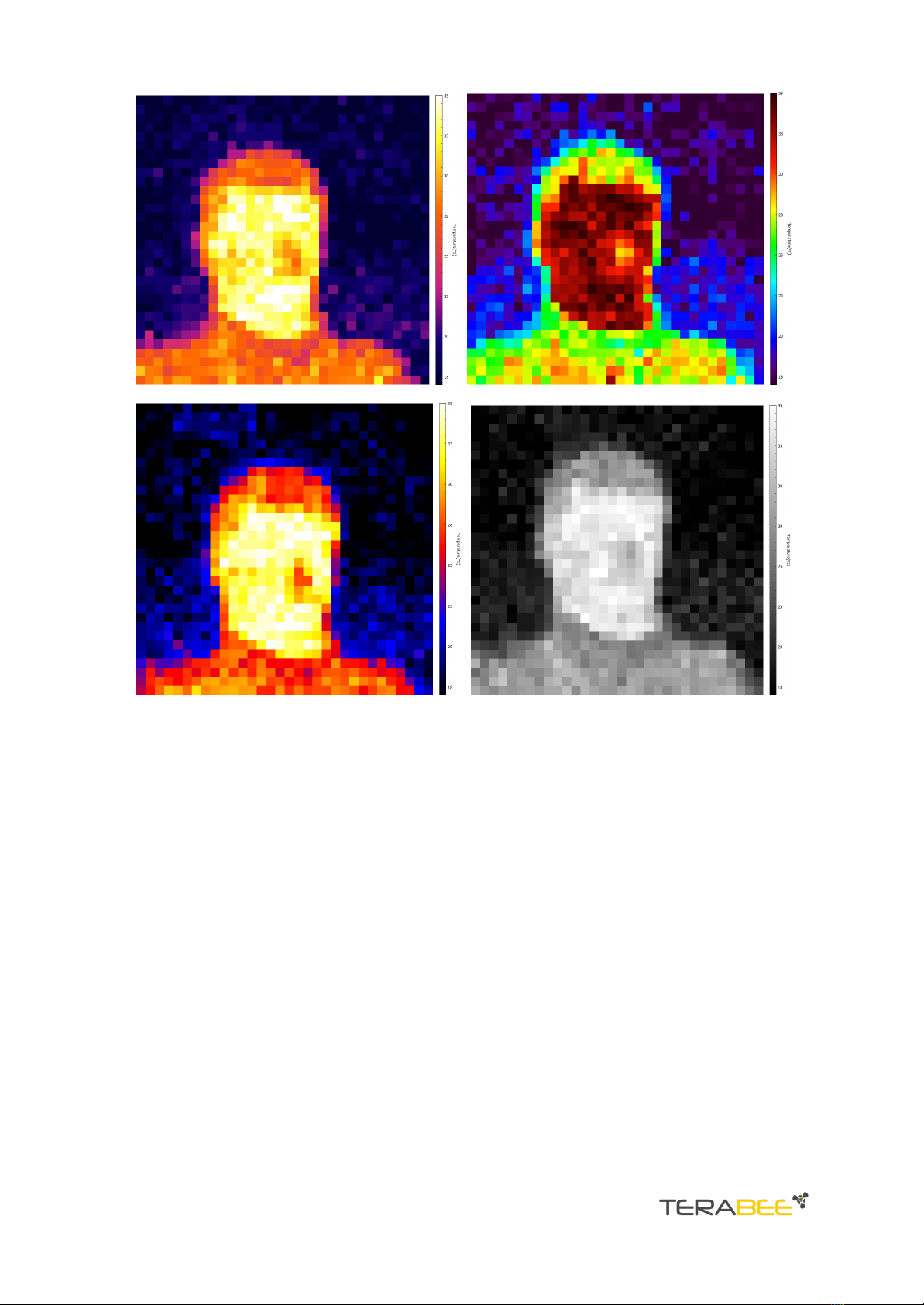

A free Graphical User Interface (GUI) is available, providing an easy way to visualize the

data from your TeraRanger Evo Thermal sensor. This is useful for demonstration,

testing purposes and checking some of the basic parameters of the sensor. It also

provides an option to easily record thermal images, export raw data and upgrade the

firmware running on the device.

The GUI is available for download here: GUI Download. (See “Downloads” section of the

TeraRanger Evo Thermal product page).

3.1.1. Prerequisites

For usage on Windows 7 and Windows 8, please download the Virtual COM Port driver

from http://www.st.com/en/development-tools/stsw-stm32102.html and follow the

”ReadMe file” instructions given by the installer . After successful installation, unplug

the interface for a few seconds, and plug it back in. The virtual COM port should now be

available on your PC.

Users of Windows 10 do not need to download this driver as the built in Windows driver

is recommended.

3.1.2. Basic operation

During installation of the GUI, you might receive a notification from Windows about an

unknown application trying to start (Figure 6). In the “Windows protected your PC”

screen select More info > Run anyway to proceed with Evo Thermal GUI installation

and please be advised that running this application will not put your PC at risk.

Copyright © Terabee 2023

Terabee, 90 rue Henri Fabre

01630 Saint-Genis-Pouilly, France (next to CERN)

TeraRanger Evo Thermal - User manual

Version 1.0