II

Purpose of this manual

The purpose of this manual is to provide the user with detailed information necessary to properly

operate, maintain and inspect the fan.

This manual contains the following information and is intended for persons experienced in the

operation of fans, or for those who have been trained by such experienced persons. Only qualified

personnel such as electrical engineers are allowed to carry out the electrical wiring work.

Contents

1. Safety precautions·························································································································· 1-1

1.1 Types and meanings of warning terms ··················································································· 1-1

1.2 Safety precautions ·················································································································· 1-1

1.2.1. Precautions for placement and installation ······································································ 1-1

1.2.2. Precautions for operation································································································· 1-1

1.2.3. Precautions for maintenance and inspection ··································································· 1-2

1.3 Location of the warning labels································································································· 1-2

2. Configuration and overview of the fan ···························································································· 2-1

2.1 Construction and name of each part by transmission method ················································ 2-1

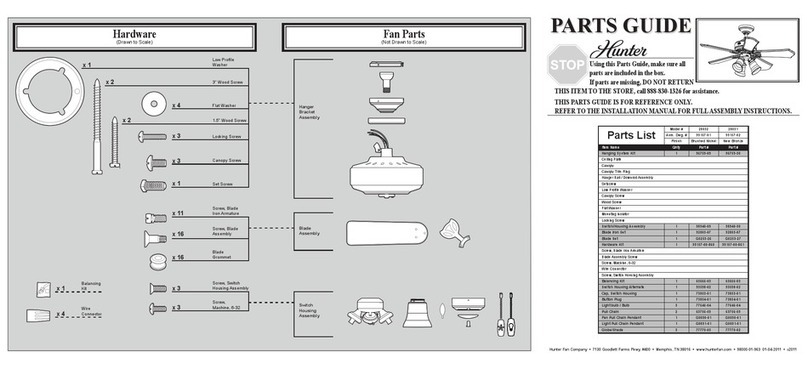

2.2 Specifications and accessories of the fan ··············································································· 2-2

3. Placement and installation ············································································································· 3-1

3.1 Before using the fan ················································································································ 3-1

3.2 Precautions during transportation and storage ······································································· 3-1

3.2.1. Precautions for transportation ·························································································· 3-1

3.2.2. Precautions for storage···································································································· 3-2

3.3 Precautions for the location of installation··············································································· 3-2

3.4 Foundation ······························································································································ 3-3

3.5 Installation······························································································································· 3-3

3.5.1. Floor-mount type·············································································································· 3-3

3.6 Alignment ································································································································ 3-5

3.6.1. Alignment of belt drive type······························································································ 3-5

3.6.2. Alignment of direct type shaft coupling ············································································ 3-6

3.7 Precautions for connecting the ducts ······················································································ 3-6

3.8 Precautions for wiring work ·····································································································3-8

4. Preparation for operation················································································································ 4-1

4.1 Points to be checked before test running ················································································ 4-1

4.1.1. Checking the electrical system························································································· 4-1

4.1.2. Checking the fan system·································································································· 4-1

5. Operation ······································································································································· 5-1

5.1 Precautions in test run ············································································································ 5-1

5.2 Precautions in normal operation······························································································ 5-2

5.3 Precautions when stopping the operation ··············································································· 5-2

5.4 Precautions when stopping the use ························································································ 5-2

6. Maintenance and inspection··········································································································· 6-1

6.1 Daily inspection······················································································································· 6-1

6.2 Periodic inspection ·················································································································· 6-2

6.3 Refill and change of grease (oil)······························································································6-3

6.3.1. Rolling bearing ·················································································································6-3

6.3.2. Oil bath type bearing········································································································ 6-4

6.3.3. Refill of grease in spring coupling ···················································································· 6-4

6.3.4. Consumables ··················································································································· 6-4

7. Troubleshooting ····························································································································· 7-1

7.1 Troubleshooting ······················································································································ 7-1

8. Special accessories························································································································ 8-1