Operator's Manual Fourth Edition • Second Printing

Introduction

2 TZ-50 Part No. 1272897GT

Contacting the Manufacturer

At times it may be necessary to contact Genie.

When you do, be ready to supply the model

number and serial number of your machine, along

with your name and contact information. At

minimum, Genie should be contacted for:

Accident reporting

Questions regarding product applications and

safety

Standards and regulatory compliance information

Current owner updates, such as changes in

machine ownership or changes in your contact

information. See Transfer of Ownership, below.

Transfer of Machine Ownership

Taking a few minutes to update owner information

will ensure that you receive important safety,

maintenance and operating information that

applies to your machine.

Please register your machine by visiting us on the

web at www.genielift.com or by calling us toll free

at 1-800-536-1800.

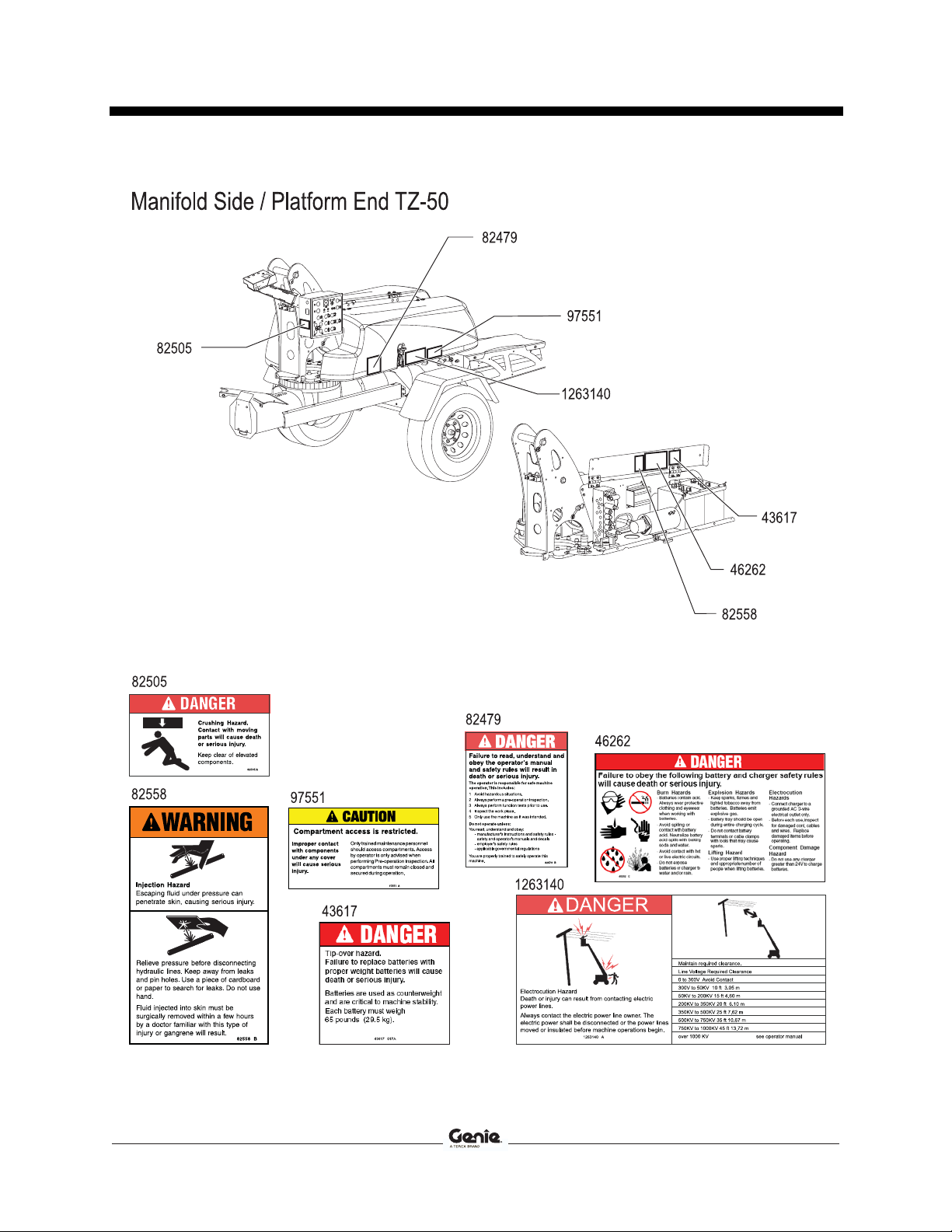

Danger

Failure to obey the instructions and

safety rules in this manual will result

in death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

Know and understand the safety rules

before going on to the next section.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

You read, understand and obey the

manufacturer’s instructions and safety

rules–safety and operator’s manuals and

machine decals.

You read, understand and obey employer’s

safety rules and worksite regulations.

You read, understand and obey all applicable

governmental regulations.

You are properly trained to safely operate the

machine.