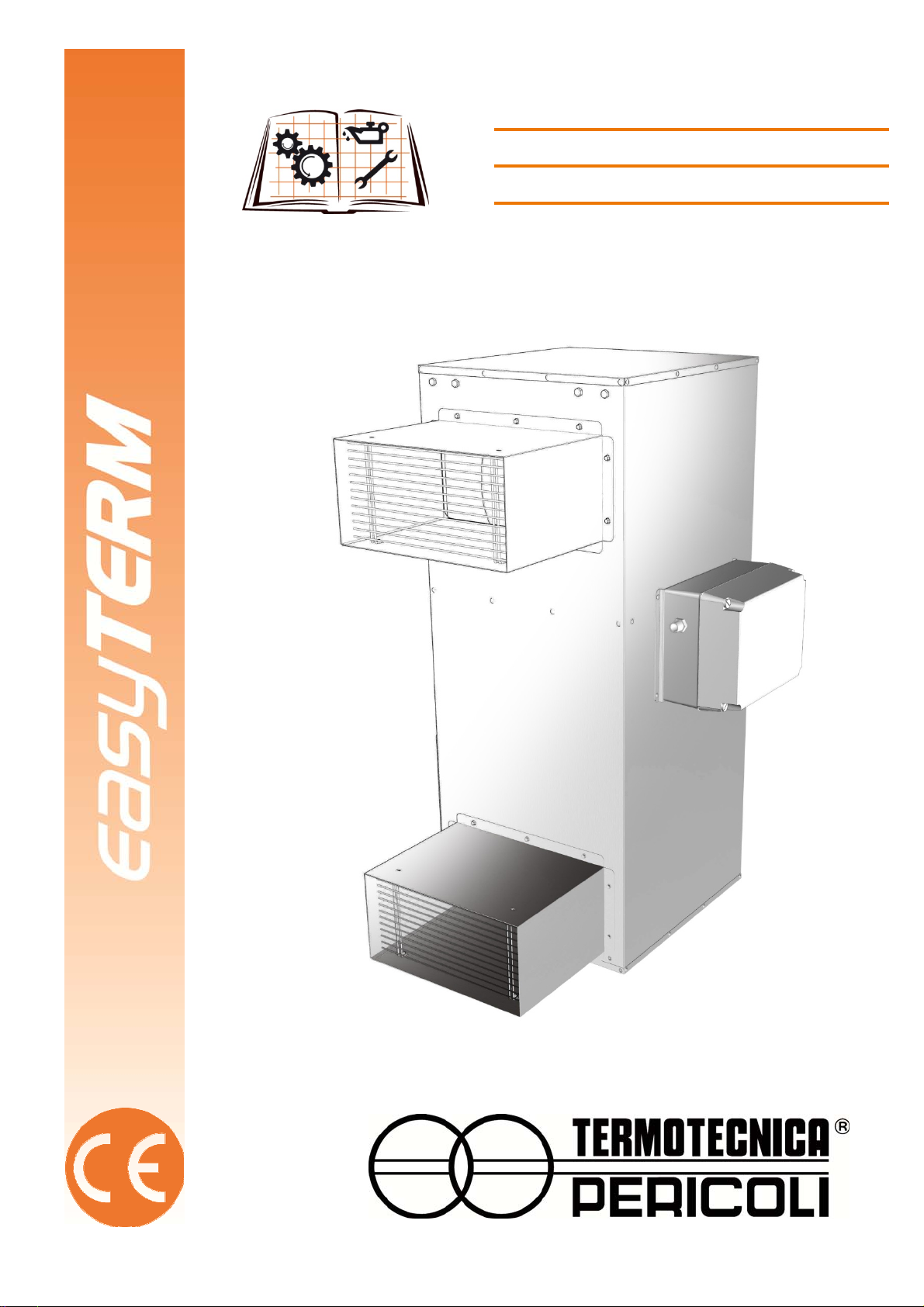

TERMOTECNICA PERICOLI easyTERM Series User manual

--- IIZl:Il __

==

IIIIIIIIIIli milm~~i£~l

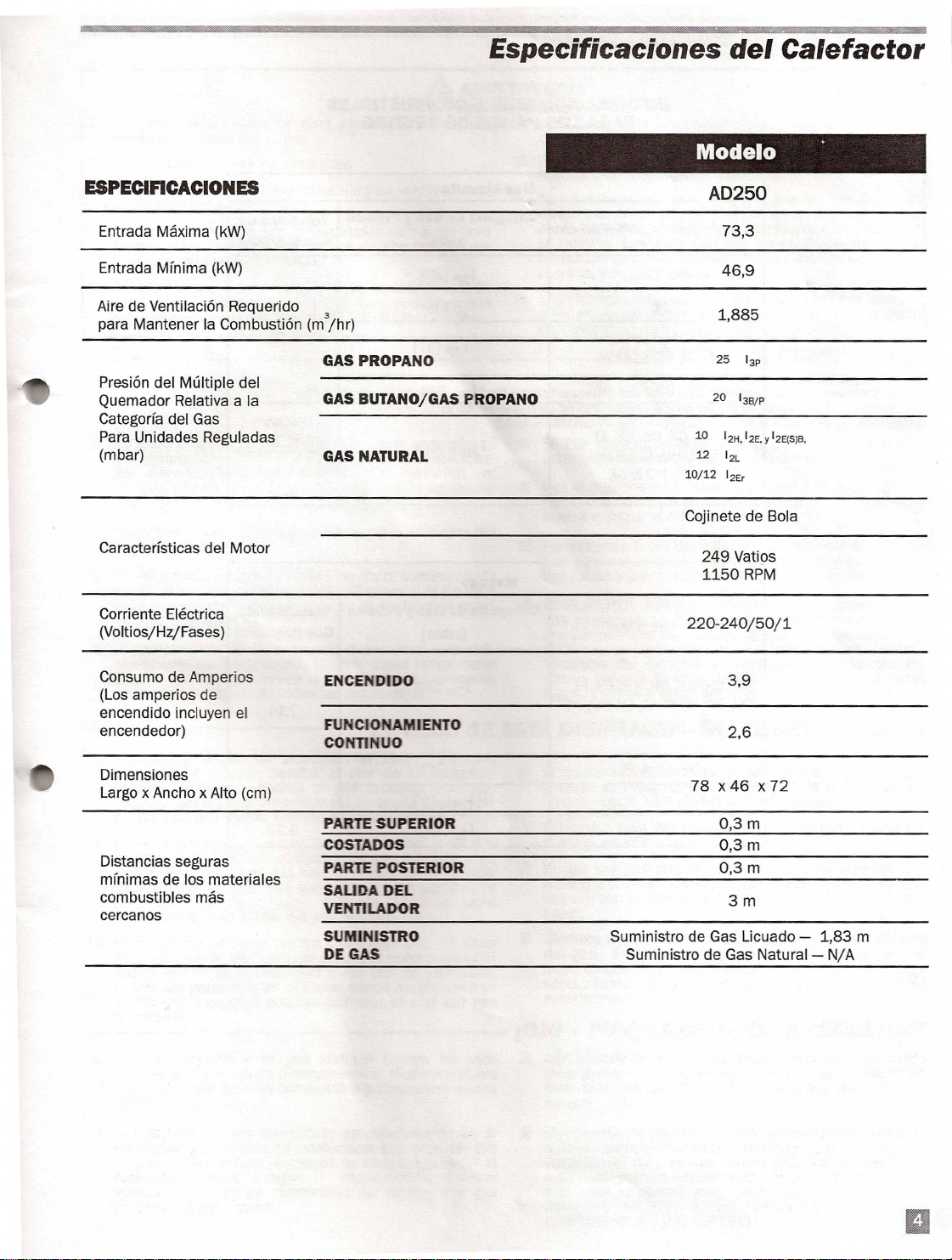

Especificaciones del alefactor

Modelo

Aire de Ventilaci6nRequerido

para Mantener la Combusti6n (m

3

jhr)

Presi6n del Multiple del

QuemadorRelativa a la

Categorfa del Gas

Para Unidades Reguladas

(mbar)

10

12H,12E•

y

12E(S)B,

12

1

2L

10 12

1

2Er

249 Vati9s

5a

RPM

Corriente Electrica

(VoltiosjHzjFases)

ConsumodeAmperios

(Los amperios de

encendido incluyen el

encendedor) F\JNCIONAMIENTO

CONTlNUO

Dimensiones

Largo x Ancho xAlto (cm)

Distancias seguras

mfnimas de los materiales

combustibles mas

cercanos

PARTE SUPERIOR

costADOS

PARTEPOSTERIOR

SAUDADEL

VENTlLADOR

SUMINlSTRO

DE GAS

a3m

a3m

a3m

Suministro de Gas Licuado - 1,83 m

Suministro deGas Natural- NjA

INFORMACION SQBRE COMBUSTIBLES

PARA LOS PAISES DE DESTINO

Gas Licuado

Paesis de Destino Categoria de Gas

y

Presion Velocidad del

(mbar) Gas (kgfhora)

HU NL

1

3P(30)

PL

1

3P(36)

BE, CH, CZ, E5,

1

3P(37) 5.25

GB, IE, PT,51 SK

BE, CH, DE, ES NL

1

3P(50)

CY,CZ, OK, EE, FI, (Butano)

1

38/P(30) 5.36

GR, HU, IT, LT,LV,

MT, NO SE (Gas Licuado)

5.25

Metano

Paesis de Destino Categoria de Gas

y

Presion Velocidad del

(mbar) Gas (m

3

jhora)

AT,CH, CZ, OK, EE, ES, FI,

1

2H(20)

GB, GR, IE, IT, LT,LV,NO, PT

7.14

SE, SI, SK TR

DE, LU PL

1

2E(20)

BE

1

2E(S)B(20)

NL

1

2L(25) 8.28

Calentadores de aire para colgar

GA

Los calentadores de aire para coplgar GA han sido diseñados para suministrar

calor a un bajo coste y en una amplia variedad de aplicaciones: invernaderos,

granjas, naves industriales...

Tecnología

Todos los modelos se basan en el principio de calentamiento de gas directo, en

el cual se usa un potente ventilador que hace que el aire pase por una cámara

de combustión en la que estáel quemador. A medida que pasa el aire por el

quemador, todo el calor que produce el proceso de combustión pasa a la

corriente de aire. Esto hace que el calentador tenga una eficacia térmica del

100%. El grado de calor del calentador se puede ajustar manualmente con

una válvula reguladora.

Diseño

Los calentadores GA funcionan con Gas Licuado de Propano (GLP), que es

un combustible muy limpio. Los productos de la combustión son principal-

mente vapor de agua y dióxido de carbono (CO2).

Para garantizar un funcionamiento prolongado en ambientes húmedos, los

calentadores GA se fabrican en acero inoxidable y todos sus componentes

eléctricos van en el interior de una caja de protección IP55.

Por razones de seguridad, los calentadores vienen equipados con una válvu-

la solenoide doble para abrir y cerrar el paso del gas. Además, los calentadores

tienen también un sensor de presión de seguridad que corta el paso del gas en

cuanto detecta una obstrucción en el paso del aire.

Todos los modelos vienen equipados también con un cable eléctrico y un

conducto de conexión del gas con regulador de presión listos para utilizar. El

calentador también estádisponible con termostato mecánico o electrónico

opcionales. Los termostatos vienen con un cable de 10 m. capaz de medir la

temperatura si asíse desea.

EQUIPAMIENTOS

GA

• Eficacia térmica del 100%

• Ajuste manual del grado de calor

• Fácil de instalar

• Fácil de manejar

• Funciona con GLP

• Válvula solenoide doble para cortar el

paso del gas

• Interruptor de seguridad para evitar el

sobrecalentamiento

• Sensor de presión para detectar blo-

queos en el paso del aire

• Protección exterior de acero inoxi-

dable y cámara de combustión

• Equipo eléctrico alojado en caja de

protección IP55

La foto muestra el equipo completo del GA55.

Sistema CELdek®– vista general

Información sobre pedidos

GA-XXX-X p. ej., GA95-c

Código para especificar medidas

55

95

95t

Código para especificar termostato

a Sin termostato

b Termostato mecánico

c Termostato digital

GA es un producto de Munters euroemme S.p.A., Italia.

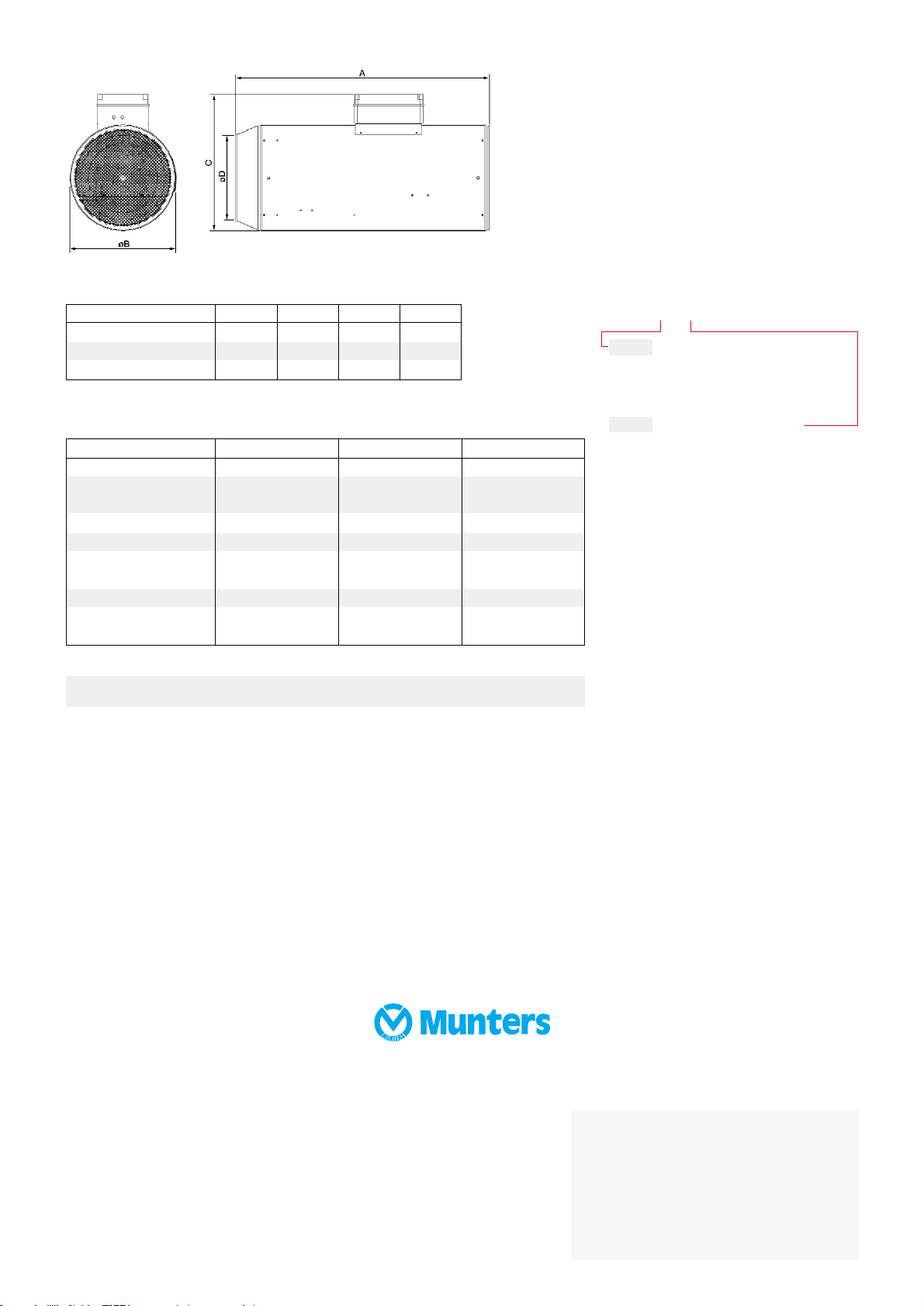

Especificaciones técnicas

GA55 GA95 GA95t

Peso [kg] 25 28 32

Potencia calorífica en [kW] de 27,4 a 52 de 51,7 a 97 de 46 a 97

[kCal/h] de 23.600 a 44.800 de 44.500 a 83.400 de 39.600 a 83.400

Consumo de gas [kg/h] de 2,16 a 3,7 de 4,08 a 6,6 de 3.6 a 6,6

Presión de gas [bar] 2 2 2

Potencia [W] 200 300 600

eléctrica nominal

Voltaje [V] 230 230 230

Flujo de aire [m3/h] 1.500 3.300 6.000

[cfm] 2.550 5.610 10.140

HC/MMA/EqES-0522-07/05 2000 SOS ReklamStudio

Medidas [mm]

Tamaño del calentador A B C D

GA55 700 416 523 351

GA95 990 416 523 351

GA95t 1.140 473 608 378

Munters Europe AB, HumiCool Division, Kung Hans Väg 8, P O Box 434, SE-191 24 Sollentuna, Suecia. Teléfono +46/(0)8/626 63 00, Fax +46/(0)8/754 56 66.

Munters euroemme S.p.A., Strada Piani 2, IT-18027 Chiusavecchia, Italia. Teléfono +39/0183/52 11, Fax +39/0183/521 333.

www.munters.com

Alemania Munters Euroform GmbH, Tel +49 (0)241-89 000, Fax +49 (0)241-89 00 199, Arabia Saudí y el Oriente Medio Hawa Munters, c/o Hawa United Cooling

Syst. Co. Ltd., Tel +966 (0)1-477 15 14, Fax +966 (0)1-476 09 36, Austria a través de la oficina comercial de Alemania, Munters Euroform GmbH,

Tel +49 (0)241-89 000, Fax +49 (0)241-89 00 199, Dinamarca a través de la oficina comercial de Suecia, Munters Europe AB, Tel +46 (0)8-626 63 00,

Fax +46 (0)8-754 56 66, EspañaMunters Spain S.A., Tel +34/(0)91/640 09 02, Fax +34/(0)91/640 11 32, Finlandia Munters Oy, Tel +358 (0)9-83 86 030,

Fax +358 (0)9-83 86 0336, Francia Munters France S.A., Tel +33 (0)1-34 11 57 50, Fax +33 (0)1-34 11 57 51, Inglaterra Munters Ltd, Tel +44 (0)845-644 3980,

Fax +44 (0)845-644 3981, Italia Munters euroemme S.p.A., Tel +39 0183-52 11, Fax +39 0183-521 333, Noruega a través de la oficina comercial de Suecia, Munters

Europe AB, Tel +46 (0)8-626 63 00, Fax +46 (0)8-754 56 66, Sudáfrica y Sub-Sahara Countries Munters (Pty) Ltd, Tel +27 (0)11-971 9700, Fax +27 (0)11-971

9701, Suecia Munters Europe AB, Tel +46 (0)8-626 63 00, Fax +46 (0)8-754 56 66, Suiza a través de la oficina comercial de Alemania, Munters Euroform GmbH,

Tel +49 (0)241-89 000, Fax +49 (0)241-89 00 199, Exportación y otros países Munters Europe AB Tel +46 (0)8-626 63 00, Fax +46 (0)8-754 56 66, Region de

América Munters Corporation, Tel +1 (0)978-241 1100, Fax +1 (0)978-241 1219, Region de Asia Munters K.K., Tel +81 (0)3-5970 0021, Fax +81 (0)3-5970 3197.

Munters se reserva el derecho de efectuar modificaciones en las especificaciones, cantidades, etc., después de la publicación por razones de producción u otras.

© Munters Europe AB, 2005

Su distribuidor más próximo

MANUALE D’USO

INSTRUCTION BOOKLET

BEDIENUNGSANLEITUNG

MANUEL INSTRUCTION

2

INDEX

INDEX ...................................................................................................................................... 2

1 - INTRODUCTION.................................................................................................................3

1.1 General warnings..........................................................................................................3

1.2 Instructions for proper disposal of the product..............................................................3

1.3 Covenants used throughout this manual.......................................................................4

1.4 Conservation of the instruction manual.........................................................................4

1.5 Recipients.....................................................................................................................5

1.6 Glossary and pictographs.............................................................................................5

1.7 Applications ..................................................................................................................9

1.8 Versions........................................................................................................................9

1.9 Identification and data label of the unit .........................................................................9

1.10 Parts description.........................................................................................................10

1.11 Transport and handling............................................................................................... 11

1.12 Warranty..............................................................Errore. Il segnalibro non è definito.

1.13 Statements...........................................................Errore. Il segnalibro non è definito.

1.14 Declaration of conformity............................................................................................12

2 - INSTALLATION................................................................................................................ 13

2.1 Before installing..........................................................................................................13

2.2 Positioning..................................................................................................................13

2.3 Electrical connection...................................................................................................15

2.4 Gas supply connection................................................................................................16

3 - OPERATION..................................................................................................................... 17

3.1 Getting started............................................................................................................17

3.2 First start.....................................................................................................................17

3.3 Start and stop .............................................................................................................17

4 - MAINTENANCE................................................................................................................ 18

4.1 Cleaning...................................................................................................................... 18

4.2 Replacement or cleaning of the nozzle.......................................................................18

4.3 Accessories ................................................................................................................18

5 - TECHNICAL SPECIFICATIONS ...................................................................................... 19

5.1 Technical data ............................................................................................................19

5.2 Spare parts.................................................................................................................19

5.3 Wiring..........................................................................................................................22

6 - PROBLEMS AND SOLUTIONS .......................................................................................23

3

1 - INTRODUCTION

1.1 General warnings

This device must be used only for the functions for which it was intended "Hot air generator”. Any other use is to

be considered improper and dangerous. TERMOTECNICA PERICOLI s.r.l. cannot be held liable for any

damages caused by improper, incorrect or unreasonable use, or if the device is used in systems that do not

comply with safety regulations.

- Check the integrity of the device at the opening of the package, paying particular attention to the presence of

damages or deformations that can lead to breakage and / or malfunction during use. In such cases do not

connect the machine to the mains. Carry out these checks before each use.

- Before connecting the unit, make sure that the data shown on the device’s plate matches that of your electricity

distribution network. The data label is located on the side of the device (par.1.9).

- Respect the safety standards set for the electrical equipment and in particular:

oFollow the installation and operation instructions concerning the use of the equipment.

oDo not place objects on the generator.

oAvoid children from using the device, and / or unable subjects without proper supervision.

oDo not touch the generator during operation or until it is completely cooled down.

oNever place water or any other liquids into the device. In the scenario of the device becoming wet,

immediately turn off the electricity by lowering the switch on the electrical panel of your system and

disconnect the power before touching the device.

oDo not insert objects inside the tank as the device may be damaged irreparably.

oDo not use accessories, spare parts and / or components that are not provided or supplied by the

manufacturer.

oAvoid touching the appliance with wet and / or humid hands.

oDo not pull the power cord nor expose it to risk of severing.

oDo not expose the unit to weather (rain, sun, etc...).

oIn case of failure or malfunction, switch off immediately and disconnect the power.

oDo not try to open or tamper the device: contact the technical service offered by

Termotecnica Pericoli Srl.

1.2 Instructions for proper disposal of the product

Under the European Directive 2002/96/EC.

At the end of its useful life the product must not be disposed of as waste.

The device can be taken to special recycling centers provided by local authorities, or at retailers that provide this

service. Disposing the product in separate parts avoids possible negative consequence to the environment and

to human health, which would both be the result of an inappropriate disposal, and allows the retrieval of

materials so that significant savings in energy and resources would be reached. As a reminder of the obligation

to dispose electrical equipment separately, the product is marked with the crossed mobile waste container.

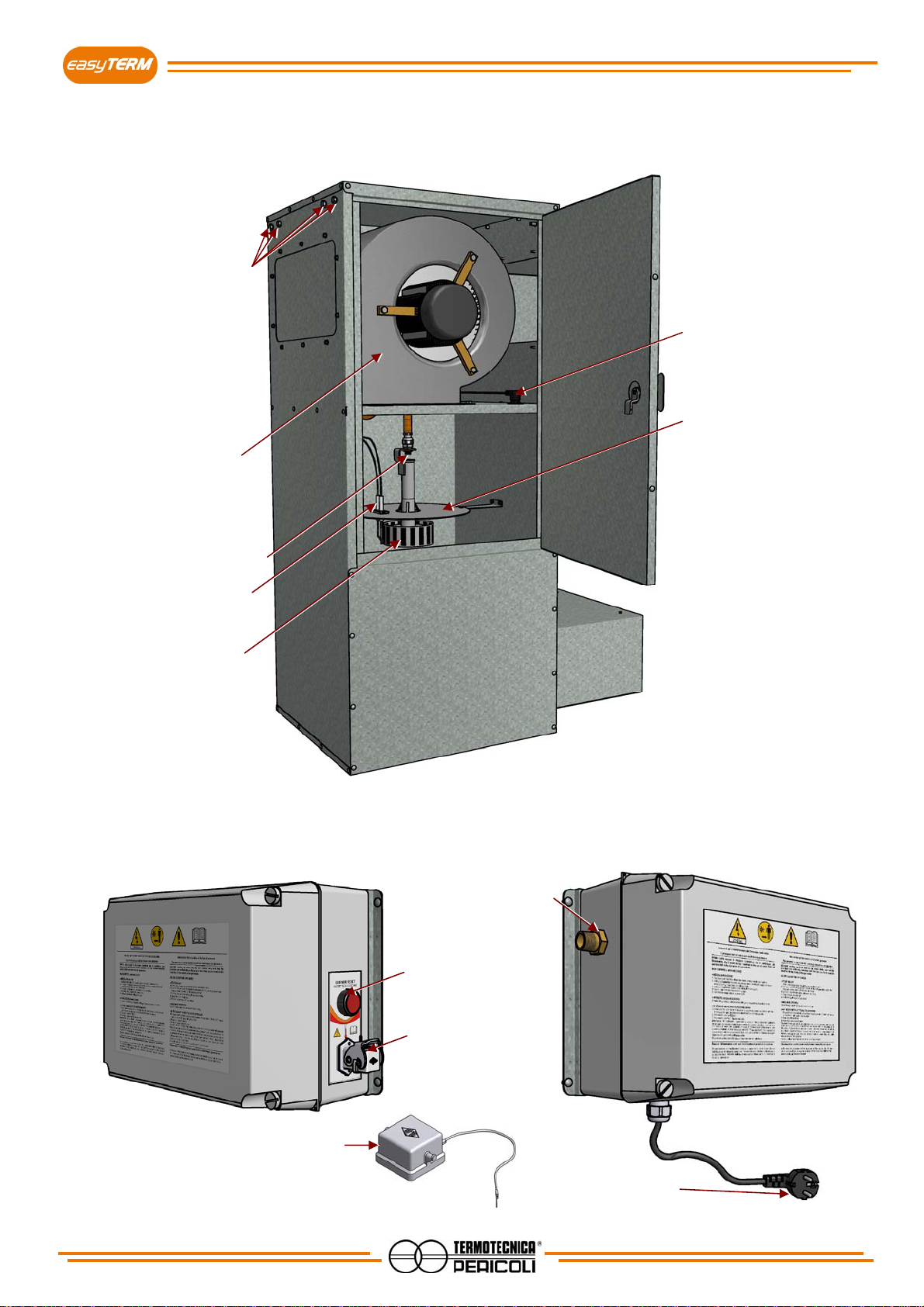

Fig. 1.1

4

1.3 Covenants used throughout this manual

The Manual is divided into autonomous chapters, each of which is addressed to a specific operator’s figure

(installer, operator and maintainer), for which the skills needed to operate the machine safely have been defined.

The sequence of chapters follows the temporal logic life of the machine.

To facilitate the immediate comprehension of the text, throughout the manual are used terms, abbreviations and

pictograms, whose meaning is shown below.

The Instruction Manual consists of a cover, an index and a series of chapters (sections).

The home page lists the identification data of the machine and model, the revision of the manual instructions,

and finally, a picture of the machine described, drawn in order to facilitate the reader in identifying the machine

and its use.

ABBREVIATIONS

Ch. = Chapter

Par. = Paragraph

P. = Page

Fig. = Figure

Tab. = Table

UNITS OF MEASURE

The units of measure used in this manual are those provided by the International System (SI).

1.4 Conservation of the instruction manual

The instruction manual must be carefully stored and must follow and match the device in all the cases of change

of ownership incurred during the life span of the machine itself.

The conservation must be done by handling the manual with care, with clean hands and on clean surfaces. Parts

must not be removed, torn or arbitrarily modified.

The manual must be stored in a secure environment, protected from moisture and heat, and near the referring

device. The manufacturer, if requested by the User, may provide additional copies of the instruction manual of

the machine.

METHODOLOGY FOR UPDATING THE MANUAL

The Manufacturer reserves the right to modify the design or specifications of the machine as part of its policy of

improving and enabling them to comply with the statutory or other requirements or standards applicable in any

territory in which goods are sold, without notifying the Customer and without updating the manuals given to the

user. Moreover, in case of changes (previously agreed between the Customer and the manufacturer) to the

machine installed, which signifies the modification of one or more chapters of the Handbook of Instructions, the

manufacturer will be responsible for sending the modified chapters affected by the structural change (including

the new model of revision) to the User.

The User is responsible, following the directions accompanying the updated documentation, for replacing all the

copies owned, the old chapters with the new chapters, the home page, and the index with the copy updated to

the new revision level.

The manufacturer shall be responsible for the descriptions included in this manual; in case of an inconsistency

being detected in a translated version of the manual (English version), the reader must refer back to the original

Italian version of the handbook and, eventually, contact the sales department, who will make necessary

changes.

5

1.5 Recipients

The manual is addressed to: the installer, the operator, and the qualified personnel entitled to the maintenance

of the device.

EXPOSED PERSON: refers to any person exposed, wholly or partially, to a danger zone;

OPERATOR: refers to those persons responsible for installing, operating, regulating,

clearing, repairing and moving the machine, and also performing the

maintenance of the device;

QUALIFIED PERSONNEL

QUALIFIED OPERATOR:

refers to the persons who have completed courses of specialization and

training, and that have acquired experience in: installing, starting,

operating, maintaining, repairing and transporting the device, or similar

ones.

The machine is intended for industrial use (professional and not widespread) for which qualified operators are

needed, in particular, workers that:

Have reached the age of majority;

Are physically and mentally appropriate to perform works that include technical difficulties;

Have been properly educated on the use and maintenance of the machinery;

Have been considered suitable to undertake the assigned job by their employer;

Can understand and interpret the operator’s manual and the safety requirements;

Know the emergency procedures and their implementation;

Posses the ability to operate the specific type of equipment;

Are familiar with the specific applicable rules;

Have understood the operating procedures defined by the manufacturer of the machine.

1.6 Glossary and pictographs

In this section we list the non common terms included in the manual. The following also explains the

abbreviations used and the meaning of the pictograms in relation to the qualification of the operator and the state

of the machine; their use can provide quick and unique information, necessary for the proper use of the machine

under safety conditions.

GLOSSARY (Att. I p. 1.1.1 Dir. 2006/42/CE)

HAZARD A potential source of injury or damage to personal health;

DANGER ZONE All areas within and/or around the machinery in which the

presence of a person constitutes a risk to the health and safety of

himself/herself;

EXPOSED PERSON Any person that finds himself/herself entirely or partially in a

hazardous area;

OPERATOR The person responsible for installing, operating, regulating,

clearing, repairing and moving the machine, and also performing

the maintenance of the machinery;

RISK The combination of probability and severity of an injury or harm to

health that can arise in a hazardous situation;

GUARD The part of the machinery used specifically to provide protection by

means of a physical barrier;

PROTECTION DEVICE The device (other than a shelter) that reduces (alone or in

conjunction with a shelter) the risk of an operation;

INTENDED USE Use of the machinery according to the information provided in the

instruction manual;

REASONABLY FORESEEABLE

MISURE

Use of the machinery in an indifferent manner from that stated in

the instruction manual, which may result from a foreseeable

human behavior.

6

OTHER DEFINITIONS:

HUMAN-MACHINE INTERACTION: Any situation in which an operator interacts with the machine in any of

the operational phases at any time of the life of the machine itself;

OPERATOR’S QUALIFICATION: Minimum level of competence that an operator must have in order to

perform the described operation;

NUMBER OF OPERATORS: The appropriate number of operators needed to optimally perform the

described operation, it is derived from an accurate analysis made by the

manufacture, and for which the use of a different number of operators

may prevent the occurrence of the expected result or endanger the

safety of the personnel involved;

STATE OF THE MACHINE: The state of the machine includes the operating mode, for example:

running in automatic mode, maintained action control (jog), shutdown,

etc… the safety conditions on the machine such as included protectors,

excluded protectors, emergency shutdown, isolation from energy

sources, etc…

RESIDUAL RISK: Risks that remain, despite of the protective measures incorporated in the

design of the machine, the complementary protections, and the

additional protective measures.

SAFETY COMPONENT: Component:

- designed to fulfill a safety function;

- the failure and/or malfunctioning of which endangers the safety of

persons (such as a lifter; a fixed, moving or adjustable protector; an

electrical, electronic, optical, pneumatic or hydraulic device that interlock

a protector; etc…).

7

PICTOGRAPHS CONCERNING THE OPERATOR’S QUALIFICATION

Symbol Description

Generic laborer: operator lacking of specific competences, capable of performing only simple tasks

under the control of qualified technicians.

Lifting and handling vehicles driver: operator qualified for the use of vehicles used in lifting and

handling materials and machines (carefully following the manufacturer’s instructions), in accordance

with the user’s country’s laws.

Mechanic maintainer: qualified technician, able to operate the machine under normal conditions, to

run it with the maintained action control (JOG) with disabled protections, and to intervene on the

mechanical parts in order to make the necessary adjustments, maintenances and repairs. Typically

this operator is not qualified to work on electrical systems while the device is connected to the

mains.

Electrical maintainer: qualified technician, able to operate the machine under normal conditions, to

run it with the maintained action control (JOG) with disabled protections, and enabled to any kind of

operation of electrical adjustment, maintenance and repair. This operator is qualified to work on

electrical systems while the device is connected to the mains.

Manufacturer’s technician: qualified technician offered by the manufacturer to carry out complex or

particular operations or, in any other case agreed with the user. The skills are, as contingently

appropriated, mechanical and/or electrical and/or electronic and/or concerning software.

PICTOGRAPHS CONCERNING THE STATE OF THE DEVICE

The pictographs contained in a square/rectangle provide information.

Symbol State of the device

Device OFF: with electric and pneumatic power disconnected.

Machine in motion: with automatic function, movable protections closed and relative interlocking

devices activated, and fixed protections closed.

Device ON: in standby and ready to start by functional consent activation (eg. switchboard

consent), movable protections closed with relative safety device included, and fixed protections

closed.

8

PICTOGRAPHS CONCERNING SAFETY

The pictograms contained in a triangle indicate DANGER.

The pictograms contained in a circle impose PROHIBITION / OBLIGATION.

Pictograph Denomination

Hazardous voltage.

Entanglement.

Dragging.

General danger.

Do not remove safety devices.

Prohibition of cleaning, oiling, greasing, repairing or adjusting by hand when the device is in motion.

Duty to remove power before starting works or repairs.

Protective gloves required.

Safety footwear required.

Safety helmet required.

9

1.7 Applications

The easyTERM series hot air generators run on GPL (Liquid petroleum gas) and methane as the combustion

fuel. The easyTERM generators are of direct combustion type. The air is heated by means of the thermal energy

generated during combustion and is transferred to the environment to be heated with the combustion products,

thereby rendering the thermal energy produced 100% available. The environment must be suitably ventilated in

order to ensure sufficient air exchange.

Do not use the generator in basements or below ground level or in premises destined for domestic use.

There are a series of safety devices which come into effect in the event of faulty function. The electronic control

device intervenes in the event of irregular flame or flame which tends to go out, stopping the burner and igniting

the burner block button indicator.

EasyTERM stops if there is a fault in ventilation.

The materials used in building the machine ensure reliability and durability in time.

This device must be used only for the functions for which it was intended

- Hot air generator.

Any other use is to be considered improper and dangerous.

1.8 Versions

Hot air generators easyTERM are available in the following versions:

BE7.2C06020100000001 Hot air generator easyTERM 80 74kW 4.000m³/h 230V 50Hz 1~+N

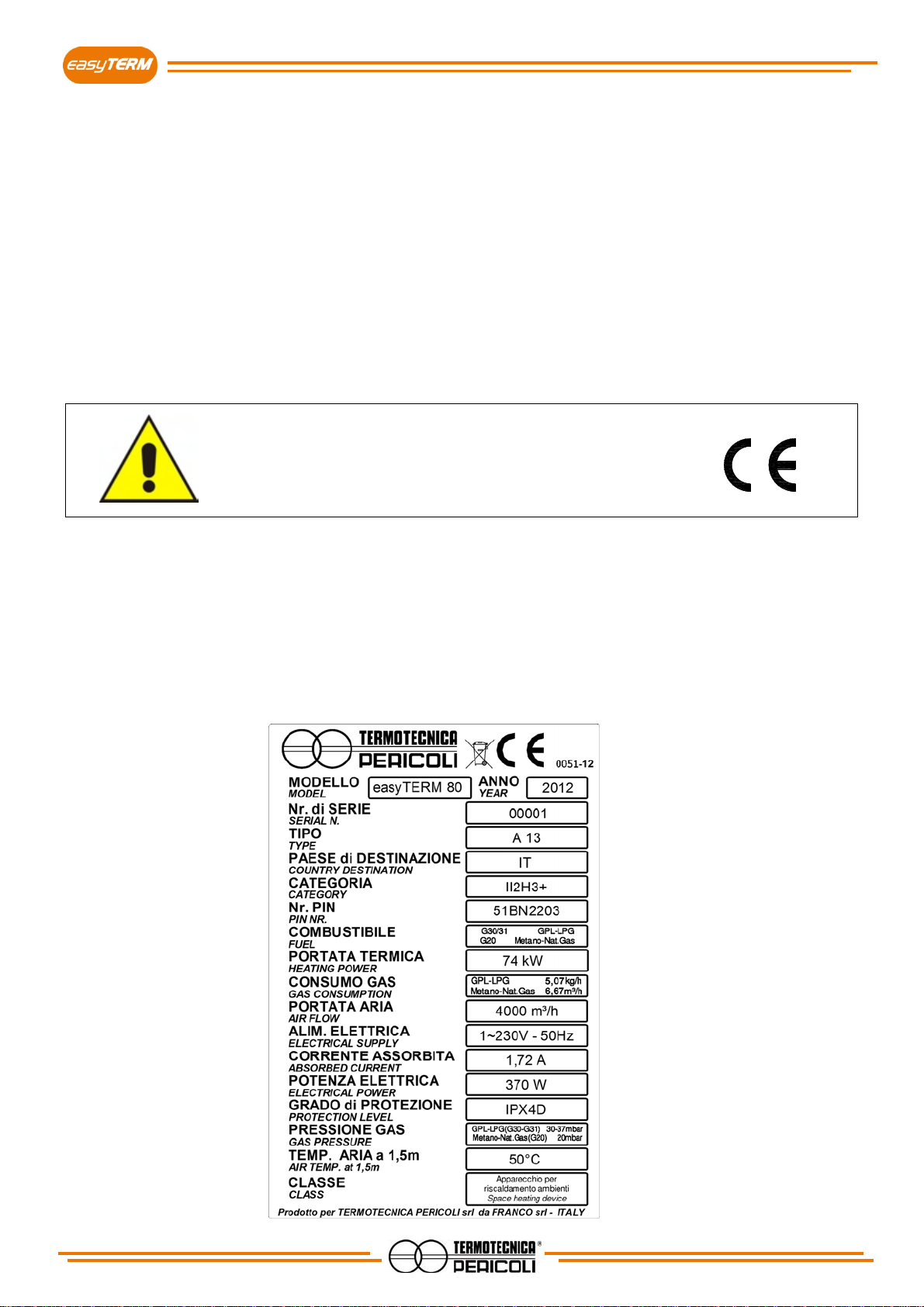

1.9 Identification and data label of the unit

Each machine is identified by the CE plate on which, indelibly set, is reference data of the device itself.

In any communication, either with the manufacturer or with the customer service, always cite these references.

Fig.1.2

10

1.10 Parts description

Constituent parts of the hot air generator.

Electrical connections box

(The gas valve and all the components for the flame control and ignition are contained inside)

Fig.1.3

Burner disk

Burne

r

Ventilato

r

Thermostat

Elettrodes

flame sensing / ignition

Gas nozzle

n.8 M8 insert nut fo

r

fixing / suspension

(n.4 on the opposite side)

Reset button

Thermostat

socket

Gas suppl

y

connection

GAS ½” M

Electrical supply plug

Schuko CEE 7/4

Connector - bypass

(insert for “manual mode” - par.2.3)

11

1.11 Transport and handling

The machine has been properly packaged before being put into strong carton boxes.

Prevent damages to the components of the device by taking care when opening the package.

Verify the integrity of the machine by controlling that there are no visible damaged parts.

Do not dispose the packaging elements in the environment; they must be placed in proper collection

points.

EasyTERM generator can be lifted and hung by using the proper brackets.

WARNING!

Before handling the device:

a. stop the machine,

b. disconnect the electricity supply,

c. interrupt the water supply.

d. Wait for the exchanger to cool down

To lift the machine, use a suitable lifting device (consult the weights table).

Lift the machine slowly, being careful not to drop it and move the straps depending on the centre of mass.

SALES TO BUSINESSES HAVING THEIR SEAT OUTSIDE ITALY

TERMOTECNICA PERICOLI S.r.l. undertakes to remedy any non-conformity (defect) of the products for which

he is liable, occurring within 12 Months from invoicing date of the products to the purchaser, provided he has

been notified timely about such defect in compliance with the terms and conditions hereinafter set out.

In addition, the present warranty is conditional on both the following conditions:

A) the compliance with the instructions guide supplied by TERMOTECNICA PERICOLI S.r.l. and

B) payment in full at due date of the sale price agreed for the products.

In such case TERMOTECNICA PERICOLI S.r.l. will, at his choice, either replace or repair the products (or parts

of the products) which result to be defective. This warranty (i.e. the obligation to replace or repair the products)

replaces any other legal guarantee or liability provided by law. It is consequently agreed that, except in case of

fraud or gross negligence of TERMOTECNICA PERICOLI S.r.l., any other TERMOTECNICA PERICOLI S.r.l. ‘s

liability (both contractual or extra-contractual) which may arise from the products supplied and/or their resale

(e.g. compensation of damages, loss of profit, etc.) is expressly excluded.

Any complaints concerning the conditions of packing, quantity or outward features of the products (apparent

defects) must be notified to the Supplier in writing within 8 days from receipt of the products; failing such

notification the purchaser’s right to claim the above defects will be forfeited. Any complaints relating to defects

which cannot be discovered on the basis of a careful inspection upon receipt (hidden defects) must be notified to

TERMOTECNICA PERICOLI S.r.l. in writing within 8 days from discovery of the defect; failing such notification

the Purchaser’s right to claim the above defects will be forfeited. The notice must indicate precisely the defect

and the products to which it refers. TERMOTECNICA PERICOLI S.r.l. does not accept return of products

lacking its express written authorization. Where TERMOTECNICA PERICOLI S.r.l. accepts such return of the

products the purchaser shall deliver the products to TERMOTECNICA PERICOLI S.r.l. at purchaser’s risks and

costs.

Notwithstanding the above the present warranty does not cover the normal wear and tear of the products and

the defects deriving from modifications made by the purchaser without TERMOTECNICA PERICOLI S.r.l.’s

consent.

With respect to possible consumer claims involving the application of domestic rules implementing the European

directive 1999/44/CE of 25 May 1999 on certain aspects of the sale of consumer goods and associated

guarantees, the purchaser accepts to bear the exclusive responsibility for any obligation arising within such

context. Consequently the parties expressly agree to exclude any right of redress by the purchaser against

TERMOTECNICA PERICOLI S.r.l. based on the above Directive and the purchaser undertakes to hold

TERMOTECNICA PERICOLI S.r.l. harmless against any such action of redress made by subsequent sellers of

the distribution chain.

1.13 Statements

The machine is built in accordance with the EC directives that are relevant and applicable at the time of the

market entry of the machine itself.

The machine is not among those mentioned in the Att. IV of the Directive 2006/42/CE.

12

1.14 Declaration of conformity (All. IIa DIR. 2006/42/CE)

TERMOTECNICA PERICOLI S.r.l.

Company

Reg. Rapalline 44 - P.O. BOX 262 17031 SV

Address Postal code Province

Campochiesa d’Albenga Italia

City Country

DECLARE THAT THE MACHINE

Hot air generators easyTERM 80

Description Model

BE7.2C06020100000001 2012

Series/Registration number Year of construction

easyTERM - hot air generator

Commercial denomination

Heating device

Intended use

Meets the following essential requirements:

DIRETTIVA MACCHINE 2006/42/CEE

DIRETTIVA GAS 2009/142/CEE (ex 90/396/CEE)

DIRETTIVA BASSA TENSIONE 2006/95/CEE

CERTIFICATO DI ESAME CE 51BN2203/ED

Complies with the EU directives

EN 437:2003 + A1:2009

EN 1596:1998

EN 1596:1998/A1:2004

AND AUTHORIZES

PERICOLI ROBERTO

Nominative

Reg. Rapalline 44 - P.O. BOX 262 17031 SV

Address Postal code Province

Campochiesa d’Albenga Italia

City Country

TO COMPILE THE TECHNICAL FILE ON HIS BEHALF

Place and date of the document

Albenga, 15th October 2012

Function Administrator

D.C.: DC N-008/000001

13

2 - INSTALLATION

2.1 Before installing

In order to start the hot air generator easyTERM, the following conditions are required:

• connection to the electric power supply with voltage and frequency suitable for the machine and with grounding

and safety devices;

• the machine is preset and is sold to work with natural gas (methane). In case of use with LPG, you must

refer to cap. 4.2 for instructions. Connection to the suitable gas supply (see technical details);

The installation must meet the safety requirements

provided by local regulation in force.

Make sure that all the connections necessary to operate the equipment have been properly prepared.

2.2 Positioning

The hot air generator easyTERM must be installed vertically, as shown in fig. 2.2.

Assemble the inlet and outlet ducts (with supplied screws), as shown in fig. 2.1.

Use the supplied special supports to hang or to anchor the appliance. Use an adequate

anchoring system to keep the machine in the working position.

Positioning of the easyTERM must be done according to the minimum recommended distances that allow a

proper machine operation and to perform maintenance when needed.

Choose, depending on the type of installation, the most suitable position within the room.

In case of long periods of unuse,

close the air inlet and the air outlet with insulating material!

fig. 2.1 - Inlet and outlet duct assembling

n.20 screws

flanged hexagonal

head 4,2x13

self-tapping

bracket

washe

r

grower

washe

r

M8 scre

w

bracket

washe

r

grower

washe

r

M8 scre

w

14

Installation of the machine must be done complying the safety distances

(law DIN EN 13857 – 4, 4.1, 4.2)

INSTALLATION EXAMPLE IN A ZOOTECHNICAL BUILDING

AIR INLET

AIR OUTLET

The installation height must be compatible

with the farm typology

OUTSIDE INSIDE

OUTSIDE INSIDE

OUTSIDE INSIDE

OUTSIDE INSIDE

Protect the machine

against

severe weather

15

2.3 Electrical connection

The installation involves the use of a humidistat or a thermostat ON/OFF controlling the power

of the machine; it is still possible to use, alternatively, a switch ON/OFF, in this case the start

and stop of the machine must be done manually.

The choice, however, does not affect the installation procedure described below.

Electrical connections must be undertaken by specialized, experienced and trained

technicians, in accordance with the current legislation.

Ensure that the electricity supply specifications correspond to those indicated in the

in this manual.

It is obligatory that the device is grounded using an efficient ground line.

The installation must foresee a device enabled to disconnect the machine from the electric supply.

16

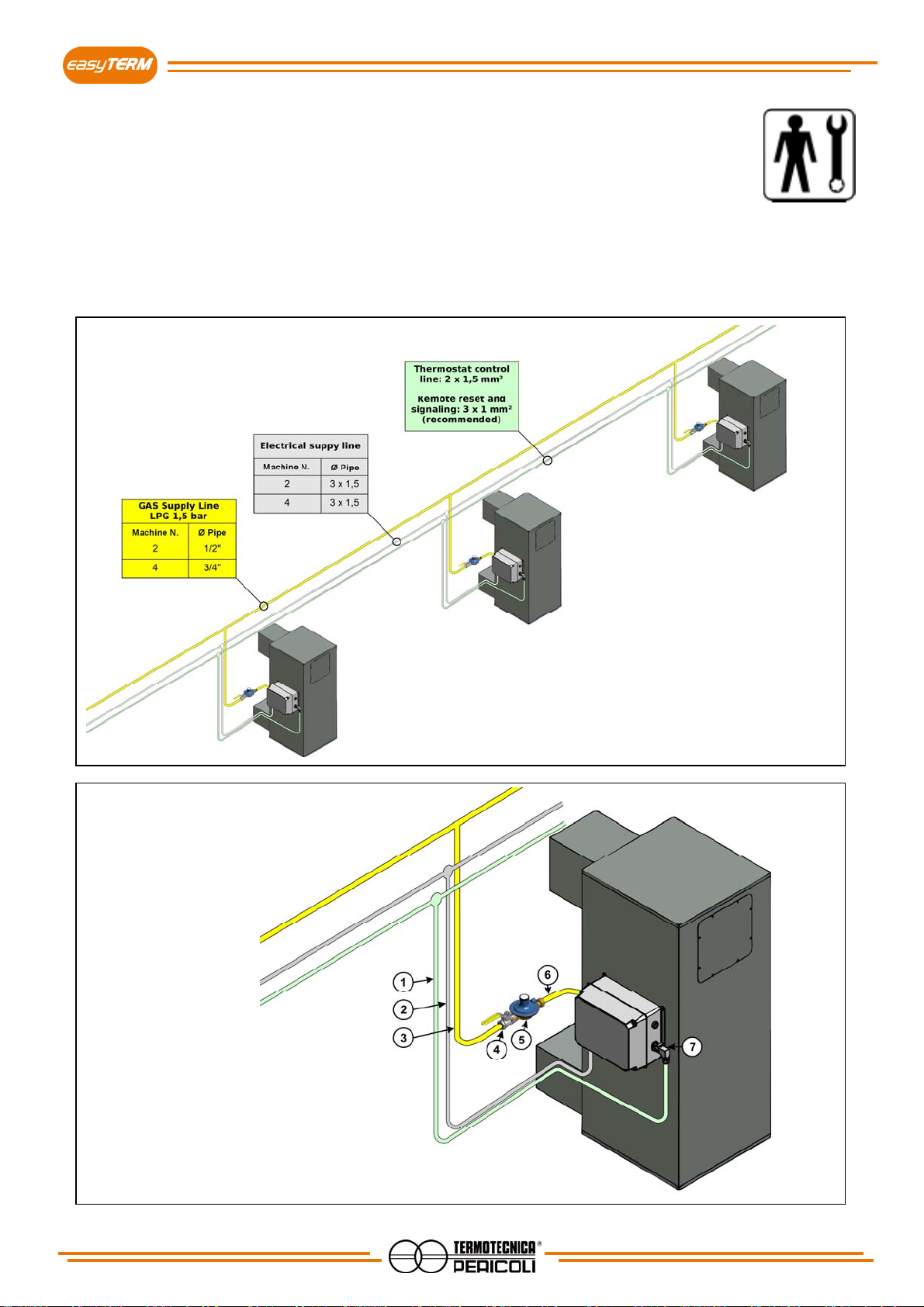

2.4 Gas supply connection

The easyTERM generator comes complete with gas valve inside the machine’s electrical box.

The plug for the line connection is 1/2”.

The gas supply line’s pressure must be in compliance with the data indicated in the

following table;

Connect the supply tube to the pressure reducer, and the latter to the cylinder of LPG or

the CNG line;

Use a flexible tube with a maximum length of 2m and make sure that there are no

bottlenecks;

The system must be adapted to the characteristics of the equipment in use and comply

with the current regulations.

1 - Thermostat control line 2x1,5

2 - Electrical supply 3x1,5

3 - Gas supply (line to valve) 1/2"

4 - Interception valve 1/2"

5 - Gas pressure regulator 30mbar

6 - Gas flexi hose 1/2"

7 - Thermostat socket

This manual suits for next models

1

Table of contents

Popular Heater manuals by other brands

Heinner

Heinner HFH-L2000SL instruction manual

MILL

MILL Invisible & Glass Series Assembly and instruction manual

Charnwood

Charnwood SLX20 Operating and installation instructions

Magnum

Magnum Ruutu L 6.0kW operating instructions

Clarke

Clarke DEVIL 371PC Operating & maintenance instructions

CLIMASTAR

CLIMASTAR SMART TOUCH 500 Installation manual and user's guide