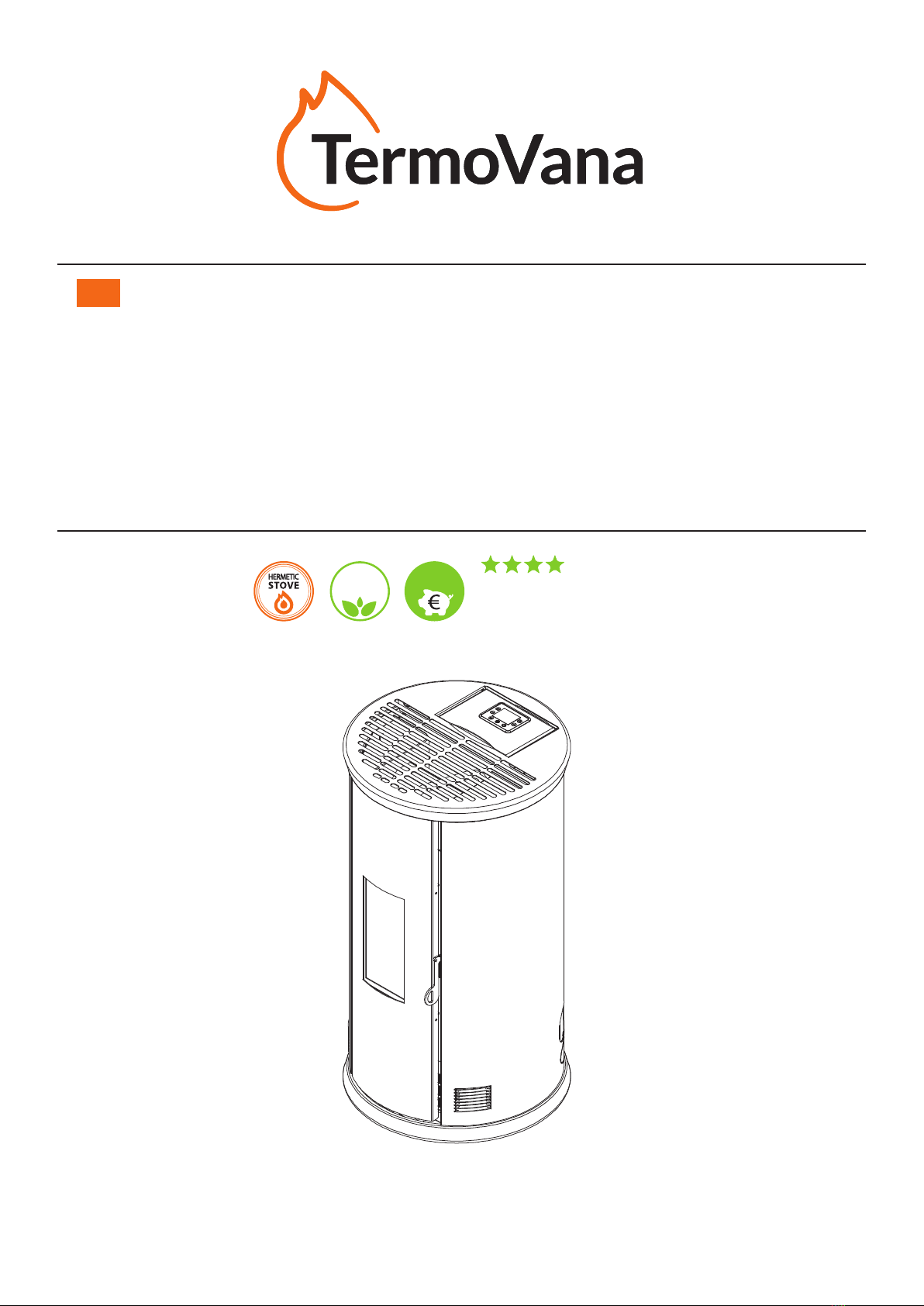

termovana FANCY 12 Configuration guide

This manual is an integral part of the product.

It is recommended to carefully read the instructions before installation, maintenance or use of the product.

Product images are purely indicative.

AIR PELLET STOVES

EN

GENERAL INFORMATION - WARNINGS - INSTALLATION - MAINTENANCE

This product complies with the 4-star class

as per the emission and performance standards

of Italian Legislative Decree no. 186, 7th November 2017

FANCY 12

ECO

DESIGN

2022

CONTO

TERMICO

Alexa,

turn on

the stove

The stoves are supplied ready for the

optional Wi-Fi module allowing the automatic

management of functions through the

Termovana App available on Apple Store and

Google Play.

Or else through Amazon Alexa voice

commands, and coming soon,

Google Home.

Download the Termovana App

and automatically manage

your stove by remote

The stoves are supplied ready for the

optional Wi-Fi module allowing the automatic

management of functions through the

Termovana App available on Apple Store and

Google Play.

Or else through Amazon Alexa voice

commands, and coming soon,

Google Home.

Download the Termovana App

and automatically manage

your stove by remote

Dear Customer,

We’d like to thank you for having purchased one of our products and congratulate you on your choice.

To make sure you get the most out of your new stove, please carefully follow the instructions provided

in this manual.

EN

ITALIANO

ENGLISH

3

08/2020 - EN

INDEX

1 GENERAL INTRODUCTION > 4-6

1.1 SYMBOLS

1.2 DESTINATION OF USE

1.3 SCOPE AND CONTENTS OF MANUAL

1.4 STORAGE OF MANUAL

1.5 UPDATE OF THIS MANUAL

1.6 GENERAL INFORMATION

1.7 MAIN STANDARDS APPLIED AND TO BE APPLIED

1.8 LEGAL WARRANTY

1.9 MANUFACTURER'S LIABILITY

1.10 CHARACTERISTICS OF THE USER

1.11 TECHNICAL ASSISTANCE

1.12 SPARE PARTS

1.13 IDENTIFICATION PLATE

1.14 STOVE DELIVERY

2 SAFETY WARNINGS > 7-8

2.1 WARNINGS FOR THE INSTALLER

2.2 WARNINGS FOR THE MAINTENANCE TECHNICIAN

2.3 WARNINGS FOR THE USER

3 CHARACTERISTICS OF FUEL > 9

3.1 CHARACTERISTICS OF FUEL

3.2 STORAGE OF PELLETS

4 HANDLING AND TRANSPORT > 9

4.1 REMOVAL FROM TRANSPORT PALLET

5 INSTALLATION > 10-14

5.1 GENERAL CONSIDERATIONS

5.2 SAFETY PRECAUTIONS

5.3 PLACE OF INSTALLATION OF STOVE

5.4 COMBUSTION AIR

5.5 FLUE GAS EXHAUST PIPE

5.6 STOVE LEVELLING

5.7 CONNECTION TO UTILITIES

5.8 OPTIMISATION OF COMBUSTION

5.9 VENTILATION

6 MAINTENANCE > 15

6.1 MAINTENANCE

7 DEMOLITION AND DISPOSAL > 16

8 USE > 17-18

8.1 INTRODUCTION

8.2 FIRST START-UP

8.3 CONTROL PANEL

8.4 MAIN MENU

8.5 SETTING THE TEMPERATURE

8.6 SETTING THE OPERATING PROGRAM

8.7 TURNING ON THE STOVE

8.8 TURNING OFF THE STOVE

8.9 RESETTING SYSTEM ERRORS

8.10 HEATING MODE

8.11 PELLET SAVING MODE

8.12 AUTOMATIC OR MANUAL MODE

8.13 MANUAL

8.14 AUTO

9 USER PROGRAMMING > 19

9.1 DATE AND TIME SETTINGS

9.2 WEEKLY PROGRAMMER

9.3 PROGRAM NUMBER

9.4 DAY OF THE WEEK

9.5 HOURS

9.6 MINUTES

9.7 REQUIRED TEMPERATURE

9.8 REQUIRED PROGRAM

9.9 PROGRAM TYPE

9.10 ENABLING THE PROGRAM

1.1 EXAMPLE OF PROGRAMMING

1 STOVE PARAMETERS > 20

1.1 LOADING PELLETS

1.2 FUME EXTRACTION

1.3 ROOM FAN

2 LANGUAGE SELECTION

3 LAST ERROR LOG

4 DUCTED > 20

4.1 DUCTED LEFT

4.2 DUCTED RIGHT

5 DIAGNOSTIC ERRORS > 21

5.1 ERROR 1 NOT ACTIVE

5.2 ERROR 2 PRESSURE SWITCH ALARM

5.3 ERROR 3 NO PELLETS

5.4 ERROR 4 NOT ACTIVE

5.5 ERROR 5 HIGH EXHAUST TEMPERATURE ALARM

5.6 ERROR 6 SAFETY THERMOSTAT

5.7 ERROR 7 SMOKE EXTRACTION MOTOR ALARM

5.8 ERROR 8 NOT ACTIVE

5.9 ERROR 9 NOT ACTIVE

5.10 ERROR 10 NOT ACTIVE

5.11 ERROR 11 NOT ACTIVE

5.12 ERROR 12 POWER FAILURE

5.13 ERROR 13 NOT ACTIVE

5.14 ERROR 14 NOT ACTIVE

5.15 ERROR 15 IGNITION FAILURE

5.16 ERROR 16 INTAKE SENSOR FAULT (ONLY IF INTAKE SENSOR

ENABLED)

5.17 ERROR 17 NOT ACTIVE

5.18 ERROR 18 FUME EXTRACTION CIRCUIT FAULT

5.19 ERROR 19 REMOTE CONTROL OVERTEMPERATURE

ALARM (OPTIONAL)

6 PRELIMINARY OPERATIONS > 22-23

6.1 LOADING PELLETS

6.2 ELECTRICAL POWER SUPPLY

6.3 POWER ON

6.4 POWER OFF

6.5 OPERATION WITH AMBIENT PROBE ON STOVE

TROUBLESHOOTING > 24-25

7 CLEANING > 26-27

8 HOT AIR DUCTING > 28

9 3RD TANGENTIAL FAN > 29

ID PLATE KEY > 30

WIRING DIAGRAM > 31

DESCRIPTION > 32

TECHNICAL SPECIFICATIONS > 33

REMOVAL FROM PALLET > 34

MINIMUM DISTANCE FROM COMBUSTIBLE MATERIALS > 34

DIMENSIONS > 35

408/2020 - EN

1.3 PURPOSE AND CONTENTS OF THE

MANUAL

The purpose of the manual is to provide the basic

rules and the basis for correct product installation,

maintenance and use. Scrupulous compliance with

the instructions provided therein ensures a high

degree of safety and productivity of the stove.

1.4 PRESERVATION OF THE MANUAL

This manual must be carefully stored and must

be available at all times for consultation, both

on the part of the user that the installation and

maintenance personnel.

The installation manual is an integral part of the

stove.

If necessary, request a further copy from DELKA.

In the event of transferring the stove the user is

obliged to deliver even this manual to the new

owner.

1.5 UPDATE OF THIS MANUAL

Thismanualreectsthestateoftheartatthetime

of placing the stove on the market.

1.6 GENERAL INFORMATION

In case of exchange of information with the

Manufacturer of the stove, refer to the serial number

andidenticationdataindicatedontheproduct’s

serial number plate.

Extraordinary maintenance operations must be

performed by qualied personnel authorised to

intervene on the model of stove to which this

manual refers.

DELKA cannot be held responsible for stove

installation works, which are and remain the

responsibility of the installer, who is also in charge

ofperformingthenecessaryinspectionsontheue

and air intake, as well as ensuring the correctness

of the proposed installation solutions. Furthermore,

allthesafetyregulationsprovidedforbythespecic

legislation in force in the state where the same is

installed must be observed.

Use of the stove is also subject, in addition to the

provisions contained in this manual, to compliance

withallthesafetystandardsrequiredbythespecic

legislation in force in the state where it is installed.

1 GENERAL INTRODUCTION

The product, subject of this manual, was

manufactured and tested according to the safety

requirements stated in the reference European

directives.

This manual is intended for stove owners,

installers, users and maintenance personnel of

the stove and is an integral part of the product.

In case of uncertainty about the content and for

anyclarication,contact themanufactureror the

authorised technical assistance service, stating the

number of the paragraph of the topic in question.

Even partial printing, translation and reproduction

of this manual are bound by the authorisation

of DELKA. Technical information, graphical

representationsandspecicationsinthismanual

may not be disclosed to third parties.

Do not operate unless all information reported in

this manual has been perfectly understood; if in

doubt, always request the advice or intervention

of DELKA specialised personnel.

DELKA reserves the right to change specications

and technical and/or functional characteristics of the

stove at any time without prior warning.

1.1 SYMBOLS

In this manual the points of major importance are

highlighted by the following symbols:

INDICATION: Indications concerning the correct

use of the stove and the responsibilities of the

persons responsible.

ATTENTION: The point in which a note of particular

importance is expressed.

DANGER: Expresses an important note of

behaviour for the prevention of injuries or damage

to properties.

1.2 DESTINATION OF USE

The product covered by this manual is a stove for

indoor domestic heating, fed exclusively by wood

pellets with automatic operation.

The stove only works with the fire box door

closed.

The door must never be opened during stove

operation.

The appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capacity, or without experience and

knowledge, unless they have received instructions

relating to the safe use of the appliance and they

are under the surveillance of a person responsible

for their safety.

The intended use specified above and the

congurationsprovidedforthestovearetheonly

ones permitted by the manufacturer: only use the

stove following the instructions provided.

ITALIANO

ENGLISH

5

08/2020 - EN

1.7 MAIN STANDARDS OBSERVED AND

TO BE OBSERVED

A) Directive 2014/35/EU: "Electrical equipment

designed for use within certain voltage limits'.

B) Directive 2014/30/EU: "The approximation

of the laws of the Member States relating to

electromagnetic compatibility".

C) Directive 89/391/EEC: "Implementation of

measures to encourage improvements in the

safety and health of workers at work".

D) Regulation EU 305/2011: “Establishes

harmonised conditions for the marketing of

construction products and repeals Directive

89/106/EEC”.

E) Directive 1999/34/EC: "Concerning the

rapprochement of the laws, regulations and

administrative provisions of the member states

with regard to liability for damage caused by

defective products".

F) Standard EN 14785/2006: Concerning

"Domestic heating appliances supplied with

wood pellets - Requirements and test methods".

1.8 LEGAL WARRANTY

The user, in order to be able to take advantage of

the legal warranty, referred to in Directive 1999/44/

EC, must strictly observe the provisions contained

in this manual and in particular must:

• always operate within the stove's limits of use;

• always carry out constant and diligent maintenance;

• authorise use of the stove by persons of proven

capacity, aptitude and who are adequately trained

for the purpose;

• useoriginalsparepartsspecicforthestovemodel.

1.8.1 THE FOLLOWING CIRCUMSTANCES ARE

EXCLUDED FROM THE WARRANTY:

• Improper overheating of the appliance, or use

of fuels not compliant with the type and quantity

indicated in the supplied instructions;

• Any parts found to be defective due to negligence or

careless use, incorrect maintenance or installation

that does not comply with the manufacturer’s

instructions (always refer to the installation and use

manual supplied with the appliance);

• Further damage caused by makeshift user

interventions in an attempt to solve the initial failure;

• Aggravation of damages caused by continued use

of the appliance by the user once the defect has

already been manifested;

• Damage caused by transport and/or handling;

• Inefficiency of chimneys, flues, or parts of the

system on which the appliance depends.

• Damage caused due to tampering with the device,

atmospheric agents, natural disasters, acts of

vandalism, electrical discharges, defects in the

electrical and/or water system.

• Failure to arrange for the annual cleaning of the

stove by an authorised technician or qualified

personnel, shall invalidate the warranty.

• Parts subject to normal wear such as gaskets, glass,

cast iron cladding and grilles, painted, chrome-

plated or gilded details, handles and electrical

cables, lamps, luminous indicators, knobs, all parts

thatcanberemovedfromtherebox;

• Colour variations of painted and or ceramic/coil

parts, as well as aws in the ceramic insofar as

these are natural characteristics of the material and

use of the product;

• Masonry works;

• Parts of the system (if included) not supplied by the

manufacturer.

1.8.2 WARRANTY TERMS:

The company guarantees the product, except

for elements subject to normal wear reported

below, for a period of 2 (two) years from the date

of purchase, which must be proven by:

• valid documentation (invoice and/or tax receipt)

showing the name of the vendor and date on which

the sale was made;

• theforwardingofthecompletedwarrantycerticate

within 8 days of the purchase;

• The term warranty implies the free replacement or

repair of parts recognised as defective at the origin

due to manufacturing defects;

• In order to claim under warranty, in the event of a

defectthebuyermustkeepthewarrantycerticate

and submit it together with the document issued at

the time of purchase, to the Technical Assistance

Centre;

Moreover, it is necessary to provide:

• a tax receipt with the date of purchase;

• acerticateofconformityoftheinstallationissued

by the installer;

Failure to comply with the requirements

contained in this manual will imply the immediate

cancellation of the warranty.

1.8.3 This warranty does not cover any

malfunctions and/or damage to the appliance

due to the following causes:

• Any technical interventions on the product to eliminate

the aforementioned defects and resulting damage;

these must be agreed upon with the Technical

Assistance Centre, which reserves the right to accept

or reject the relative claim, which in any case will

not be carried out under warranty, but rather in the

form of technical assistance provided in accordance

withanyconditions,specicallyagreedupon,andin

accordance with the rates in force for the works to be

carried out;

• The user will also be responsible for any expenses

incurred to rectify their own makeshift technical

interventions, tampering, or in any case factors that

are damaging to the appliance and not attributable to

manufacturing defects;

• Without prejudice to the limits imposed by laws or

608/2020 - EN

regulations, any guarantee of containment of airborne

and noise pollution is also excluded;

The company declines all liability for any

damage that may, either directly or indirectly,

as a consequence of the failure to comply with

any of the provisions contained in this manual,

in particular in regards to warnings for the

installation, use and maintenance of the appliance.

1.9 MANUFACTURER'S LIABILITY

With the delivery of this manual, DELKA declines

all responsibility, both civil and criminal, direct or

indirect, due to:

• installation not complying with the existing

regulations in the country and with the safety

directives;

• partial or total non-compliance with the

instructions in this manual, in particular those

concerning the necessary routine cleaning;

• installation by unqualified and untrained

personnel;

• use not in compliance with the safety directives;

• modicationsandrepairsnotauthorisedbythe

manufacturer on the stove;

• the use of spare parts that are not original or

whicharenotspecictothestovemodel;

• insucientmaintenance;

• exceptional events.

1.10 CHARACTERISTICS OF THE USER

The user of the stove must be an adult and

responsible person having the knowledge needed

for routine maintenance of the stove components.

Make sure that children do not come close to the

stove, while it is running with the intent to play.

1.11 TECHNICAL ASSISTANCE

DELKA provides a dense network of specialist

technical assistance centres, trained and prepared

directly at the company.

Theheadoceandoursalesnetworkisatyour

disposal to direct you to the nearest authorised

service centre.

1.12 SPARE PARTS

Use only genuine spare parts.

Do not wait until the components are worn by use

before proceeding to their replacement.

Replacing a worn component before it breaks helps

prevent injuries resulting from accidents caused by

the sudden breakage of the components, which

may cause serious damage to people and property.

Perform periodic maintenance checks as indicated

in the "Maintenance" chapter.

1.13 IDENTIFICATION PLATE

The serial number plate on the stove shows all the

characteristic data relating to the product, including

the manufacturer's data, the serial number and the

marking .

1.14 STOVE DELIVERY

The stove is delivered perfectly packed with

cardboard or heat-shrinkable sheet and secured to

a wooden platform that allows it to be moved using

forklift trucks and/or other means.

Inside of the stove there is the following material:

• instruction manuals.

ITALIANO

ENGLISH

7

08/2020 - EN

2 SAFETY WARNING

2.1 WARNING FOR THE INSTALLER

Observe the prescriptions contained in this manual.

• The stove removal and installation instructions are

reserved to specialist technicians only.

• It is always recommended that users contact our

technical assistance service to request qualied

technicians. In the case other technicians are

involved, it is recommended to verify their actual

abilities.

• Responsibility for the works carried out in the

location of the machine is, and remains, attributable

to the user; the latter is also required to perform

checks on the proposed installation solutions.

• The user must comply with all local, national and

European safety regulations.

• Theappliancemustbeinstalledonoorswithan

adequate load bearing capacity.

Checkthattheueandairintakepredispositions

conform to the type of installation.

• Donotcarryoutyingelectricalconnectionswith

provisional or non-insulated cables.

• Check that the earthing of the electrical system is

ecient.

• It is prohibited to install the stove in bedrooms,

bathrooms and shower rooms, in rooms where

combustible materials are stored and in studio

apartments.

Installation is allowed in studio apartments only

with outside air intakes and if properly installed in

accordance with regulations;

• Under no circumstances can the stove be installed

in rooms where it is exposed to contact with water

or splashes of water, as this may cause the risk of

burns and short circuits.

• Inaccordancewithresafetylaws,theclearances

fromammableorheat-sensitiveobjectsmustbe

respected (sofas, furniture, wood cladding, etc.).

• Inthecaseofhighlyammableobjects(curtains,

carpet, etc.), all these clearances must be increased

by 1 metre.

2.1.1 WARNINGS FOR THE INSTALLER

The person in charge of the installation, before

starting assembling or disassembling of the stove,

must comply with the safety precautions required

by law and in particular:

A) do not operate in adverse conditions;

B) must operate in perfect psychophysical

conditions and must check that the personal

protective equipment, are intact and functioning

perfectly;

C) must wear safety gloves;

D) must wear safety shoes;

E) must use electrical insulated tools;

F) must ensure that the area affected by the

phases of assembly and disassembly is free

from obstacles.

2.2 WARNING FOR THE MAINTENANCE

TECHNICIAN

Observe the prescriptions contained in this manual.

• Always use individual safety devices and other

means of protection.

• If the oor is made of combustible material, it

is recommended to use protection in a non-

combustible material (steel, glass) that also protects

the front part in the event of any fuel spills during

cleaning operations.

• Before starting any maintenance operation, make

sure that the stove has cooled down if it has been

used.

• If even one of the safety devices is found to be out-

of-adjustment or not functioning, the stove should

be considered as not functioning.

• Non-specialised users must be prevented from

accessing any parts that may expose them to

dangers. This person must therefore not be allowed

to intervene on internal parts at risk (electrical

or mechanical), even if the disconnection of the

electrical supply is required

• Disconnect the power supply before working on

electrical and electronic parts and connectors.

2.3 WARNING FOR THE USER

Do not touch and do not approach the door glass

as it could cause burns;

• Donotlookattheameforalongtime;

• Donottouchtheuegasexhaustpipe;

• Do not dispose of hot ash (ensure it is completely

extinguished and cooled before vacuuming or

removing it);

• Do not open the glass door;

• do not open the ash drawer (where provided);

• Do not touch and do not approach the glass of the

door, it could cause burns;

• Donotlookattheameforalongtime;

• Donottouchtheuegasexhaustpipe;

• do not perform any type of cleaning;

• Do not dispose of hot ash (ensure it is completely

extinguished and cooled before vacuuming or

removing it);

• Do not open the glass door;

• do not open the ash drawer (where provided);

• Do not use the appliance as a waste incinerator.

• It is prohibited to operate the product with the door

open or the glass broken.

• It is prohibited to make unauthorised changes to

the appliance.

• Do not use flammable liquids during ignition

(alcohol, benzene, oil, etc.).

• After a failed ignition attempt, the accumulated

pellets must be emptied from the burn pot before

igniting the stove again.

• The pellet tank must always be closed with the lid

on.

808/2020 - EN

• Before performing any type of operation, wait for

theameinthecombustionchambertofullydrop

until it is completely extinguished and cooled, and

always detach the plug from the power socket.

• Before performing any type of operation, the user

or whoever is operating the product must have read

and fully understood the contents of this installation

and use manual. Errors or bad settings may cause

hazardous conditions and/or irregular operation.

• The only type of fuel that can be used is pellets.

• Do not place laundry on the product to dry. Any

clotheslines or similar must be kept at a suitable

distance from the product. Fire hazard.

• The electrical cord must never come into contact

withtheuegasexhaustpipeoranyotherpartof

the stove.

• Packaging materials are NOT toys, they may

cause asphyxiation or choking risks and other

health hazards! Persons (including children) with

reduced physical or motor skills, or who are lacking

the necessary experience and knowledge, must be

kept away from the packaging. The stove is NOT a

toy.

• Children must be constantly supervised to ensure

they do not play with the appliance.

• Cleaning and maintenance must be performed

by the user and cannot be carried out by children

without supervision.

• During operation, the stove reaches high

temperatures: keep out of reach of children and

animals and use ame-proof personal protective

equipment suitable to protect against the heat.

• If the oor is made of combustible material, it

is recommended to use protection in a non-

combustible material (steel, glass) that also protects

the front part in the event of any fuel spills during

cleaning operations.

2.3.1 WARNINGS AND RECOMMENDATIONS FOR

THE USER

• Observe the prescriptions contained in this manual.

• Respect the instructions and warnings highlighted

by the plates displayed on the stove.

• The plates are safety devices, therefore they must

always be perfectly legible. If these are damaged

and unreadable, it is mandatory to replace them,

requesting the original spare parts from the

Manufacturer.

• Use only the fuel complying with the indications given

in the chapter relating to the fuel characteristics.

• Follow the routine and extraordinary maintenance

schedule carefully.

• Do not use the stove without first performing

the daily inspection as prescribed in the section

“Maintenance” of this manual.

• Do not use the stove in case of abnormal operation,

suspicion of breakage or unusual noises.

• Do not throw water on the stove in operation or with

theintentionofextinguishingthereintheburnpot.

• Donot switcho thestove bydisconnecting the

mains electrical connection.

• Do not lean on the open door, it could compromise

its stability.

• Do not use the stove as a support or anchor of any

kind.

• Do not clean the stove until the structure and the

ashes are completely cooled down.

• Only touch the door when the stove is cool.

• Perform all operations in maximum safety and when

calm.

Incaseofare,contacttherebrigade.

In the event of stove malfunction due to non-optimal

flue draught, clean it following the procedure

described.

Theuemustbecleanedasdescribedinparagraph

6.

Do not touch the painted parts during operation to

avoid damage to the paintwork.

ITALIANO

ENGLISH

9

08/2020 - EN

3 CHARACTERISTICS OF FUEL

3.1 FUEL CHARACTERISTICS

Thepellet(g.3.1)iscomposedofvarioustypes

of wood, compressed using mechanical processes

in accordance with environmental protection laws

and is the only type of fuel intended for this type of

stove.

Theeciency andthermal potentialof thestove

may vary depending on the type and quality of the

pellets used.

We recommend the use of class A1 pellets

(ISO 17225-2, ENplus A1, DIN Plus or NC 444

category "High Performance NF Pellets Biofuels

Quality").

The stove is equipped with a pellet holding tank

having the capacity indicated in the technical

specicationstableinsection14.

The loading compartment is positioned in the upper

part. It must always be openable in order to load

the pellets and must remain closed during stove

operation.

For reasons of operating temperature control,

traditional wood operation is not possible.

It is forbidden to use the stove as a waste

incinerator.

3.2 STORAGE OF PELLETS

The pellets must be stored in a dry environment

where the temperature is not too cold.

It is recommended to keep a few bags of pellets in

the room where the stove is used, or in a nearby

place provided the temperature and humidity are

acceptable.

Wet and/or cold pellets (5°C) reduce the thermal

potential of the fuel resulting in the need for more

cleaning maintenance of the burn pot (unburned

material)andoftherebox.

Pay particular attention to the storage and handling

of pellet bags. Their crushing and the formation of

sawdust must be avoided.

If sawdust is introduced into the stove's tank, this

could cause the pellet loading system to become

blocked.

Keep the fuel at a safe distance from the stove.

The use of poor quality pellets can compromise the

normal operation of the pellet stove and result in

forfeiture of the warranty.

4 HANDLING AND TRANSPORT

The stove is delivered complete with all the parts

provided.

Pay attention to the tendency to unbalance the

stove.

The centre of gravity of the stove is moved towards

the front.

Bear in mind the above also when moving the stove

on the transportation support.

During lifting, avoid jerking or abrupt movements.

Make sure the forklift truck has a capacity greater

than the weight of the stove to be lifted.

The full responsibility of the lifting of loads lies on

the person handling the lifting equipment.

Make sure that children do not play with the

components of the packaging (e.g. films and

polystyrene).Dangerofsuocation!

4.1 REMOVAL FROM THE SHIPPING

PALLET

To remove the stove from the transport pallet, follow

the instructions on page 34.

Fig. 3.1

10 08/2020 - EN

Pi

Pp

Pi

X

80 cm

5 INSTALLATION

5.1 GENERAL CONSIDERATIONS

In the following paragraphs there are some

guidelines to follow in order to obtain the maximum

performance of the product purchased.

The following instructions are nevertheless subject

to compliance with any laws and national, regional

and municipal regulations in force in the country

where the product is installed.

Installation must be performed by qualified

personnel in compliance with the UNI 10683

standard.

5.2 SAFETY PRECAUTIONS

The responsibility of the works carried out in the

area where the stove will be installed falls, and

remains, on the user; the latter is also entrusted

with the execution of the inspections related to the

installation solutions proposed.

The user must comply with all local, national and

European safety regulations.

The appliance must be installed on oors with

adequate load bearing capacity.

The stove removal and installation instructions

must only be performed by specialist technicians.

It is always recommended that users contact our

after-saleservicetorequestqualiedtechnicians.

In the case other technicians are involved, it is

recommended to verify their actual abilities. Before

starting assembling or disassembling of the stove,

the installer must comply with the safety precautions

required by law and in

particular with:

A) do not operate in adverse conditions;

B) must operate in perfect psychophysical

conditions and must check that the personal

protective equipment, are intact and functioning

perfectly;

C) must wear safety gloves;

D) must wear safety shoes;

E) must use electrical insulated tools;

F) must ensure that the area affected by the

phases of assembly and disassembly is free

from obstacles.

5.3 STOVE INSTALLATION SITE

On page 34 of this manual, the minimum clearances

are shown, expressed in cm, which must be

respected when positioning the stove with respect

to combustible materials and objects.

Protect all structures which could ignite if exposed

to excessive heat.

Floors consisting of ammable material such as

for example: wood, parquet, linoleum, laminate or

coveredwithcarpets,mustbeprotectedbyaame

retardantbaseunderthestove,ofasucientsize.

This base can be, for example, in steel, pressed

slate,glassorstoneandmustcovertheoorinthe

areabelowthestoveandtheueconnectingpipe

and must protrude at least 50 cm in front.

The manufacturer declines all responsibility for

any variations in the characteristics of the material

constitutingtheoorundertheprotection.

Any wooden elements (e.g. beams) or combustible

materials located near the stove must be protected

withreproofmaterial.

Flammable walls or elements must be kept at a

distance of at least 150 cm from the stove.

Provide a technical space accessible for possible

maintenance.

Remember to respect the minimum clearance from

ammablematerials(x)shownontheIDplateof

thepipesusedforthechimney(g.5.2).

Pi = Flammable wall

Pp = Floor protection

It is prohibited to install the stove in bedrooms,

small rooms and environments having potentially

explosive dusts in the atmosphere.

Product images are purely indicative

Fig. 5.2

ITALIANO

ENGLISH

11

08/2020 - EN

C

G

S

Fig. 5.4

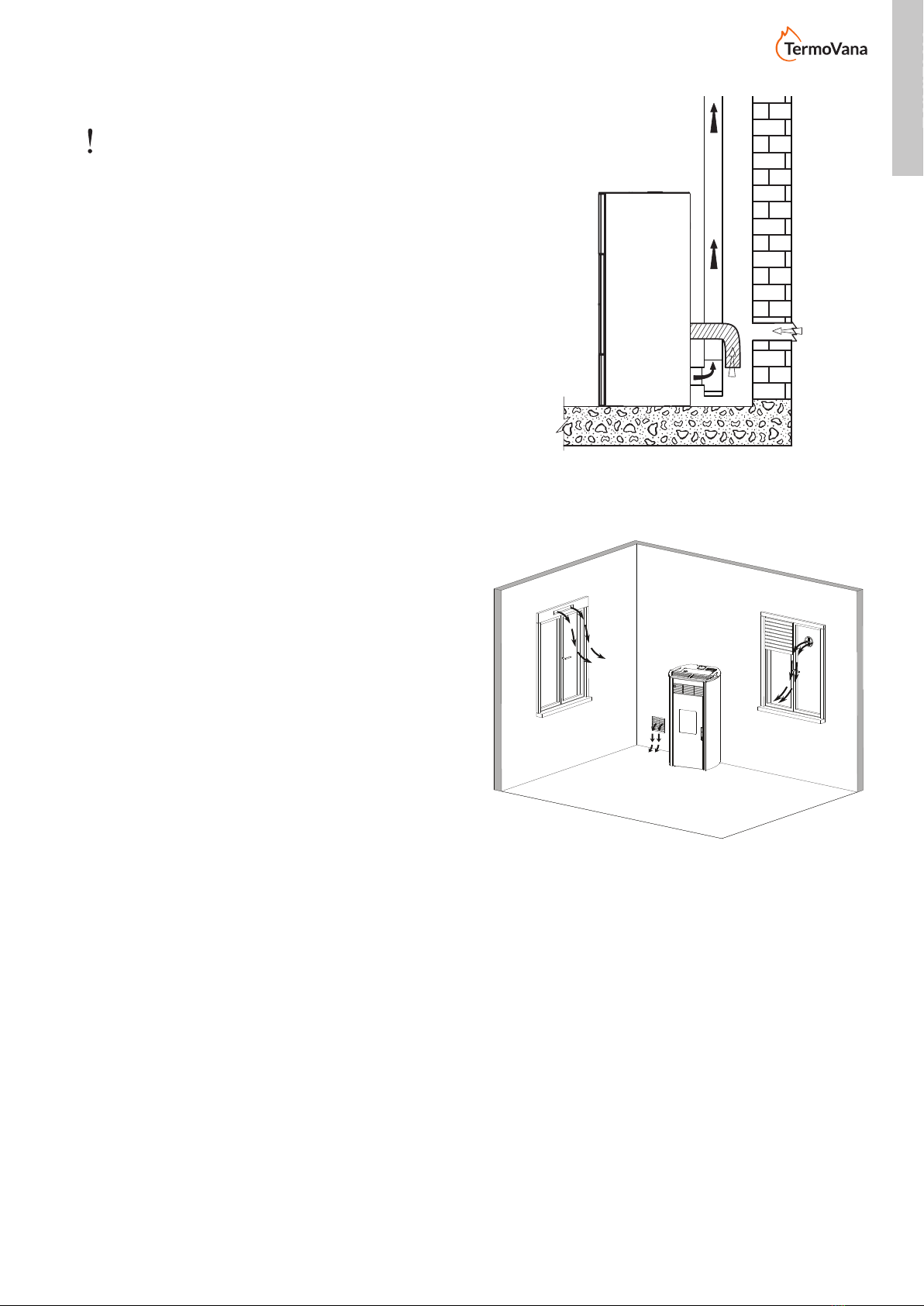

5.4 COMBUSTION AIR

During use, the stove withdraws a certain quantity

of air from the environment where it is located

(except for products in the hermetic series, which

can withdraw air directly from the outside); this air

must be reintegrated through an external air intake

(g.5.3-PA=AirIntake).

If the rear wall of the stove is an external wall,

create a hole for suction of the combustion air at a

height of approximately 20-30 cm from the ground,

respecting the dimensional indications provided

in the product technical sheet at the end of the

manual.

A non-closable permanent aeration grid must be

placed external; in areas that are particularly windy

and exposed to weathering, provide rain and wind

protection.

Make sure the air intake is positioned so that it is

not accidentally obstructed.

If it is impossible to create the external air intake

in the rear wall of the stove (non-perimeter wall) a

hole must be created in an external wall of the room

where the stove is positioned.

If it is not possible to create the external air intake

in the room, an external hole can be created

in an adjacent room provided it communicates

permanentlywithatransitgrille.(g.5.4-C=Box,

G = Grille, S = Shutter)

The UNI 10683 standard prohibits the taking of

combustion air from garages, combustible material

warehousesoractivitieswiththeriskofre.

If there are other heating appliances in the room,

the combustion air intakes must guarantee the

necessary volume of air for correct operation of all

the devices.

In the event that one or more extraction fans

(suction hoods) are present and functioning in

the room where the stove is located, combustion

malfunctions due to the lack of combustion air could

occur.

Product images are purely indicative

Fig. 5.3

PA

12 08/2020 - EN

Fig. 5.7

B

B

B

MAX 2 - 3 m

C > 3 - 5%

min 1.5 m

Fig. 5.7a

g.5.4

Fig. 5.5 Fig. 5.6

If a pellet stove in the “Hermetic” series is installed,

alternatively it is possible to:

- channel the combustion air using a coaxial exhaust

pipe for the expulsion of the ue gases and air

withdrawal; therefore it is not necessary to create

aclassicairintakeintheroom(g.5.5A,B=Air

inlet C,D = Flue gas outlet);

- connect the stove’s combustible air inlet to the air

intakewithasuitableduct(g.5.6).

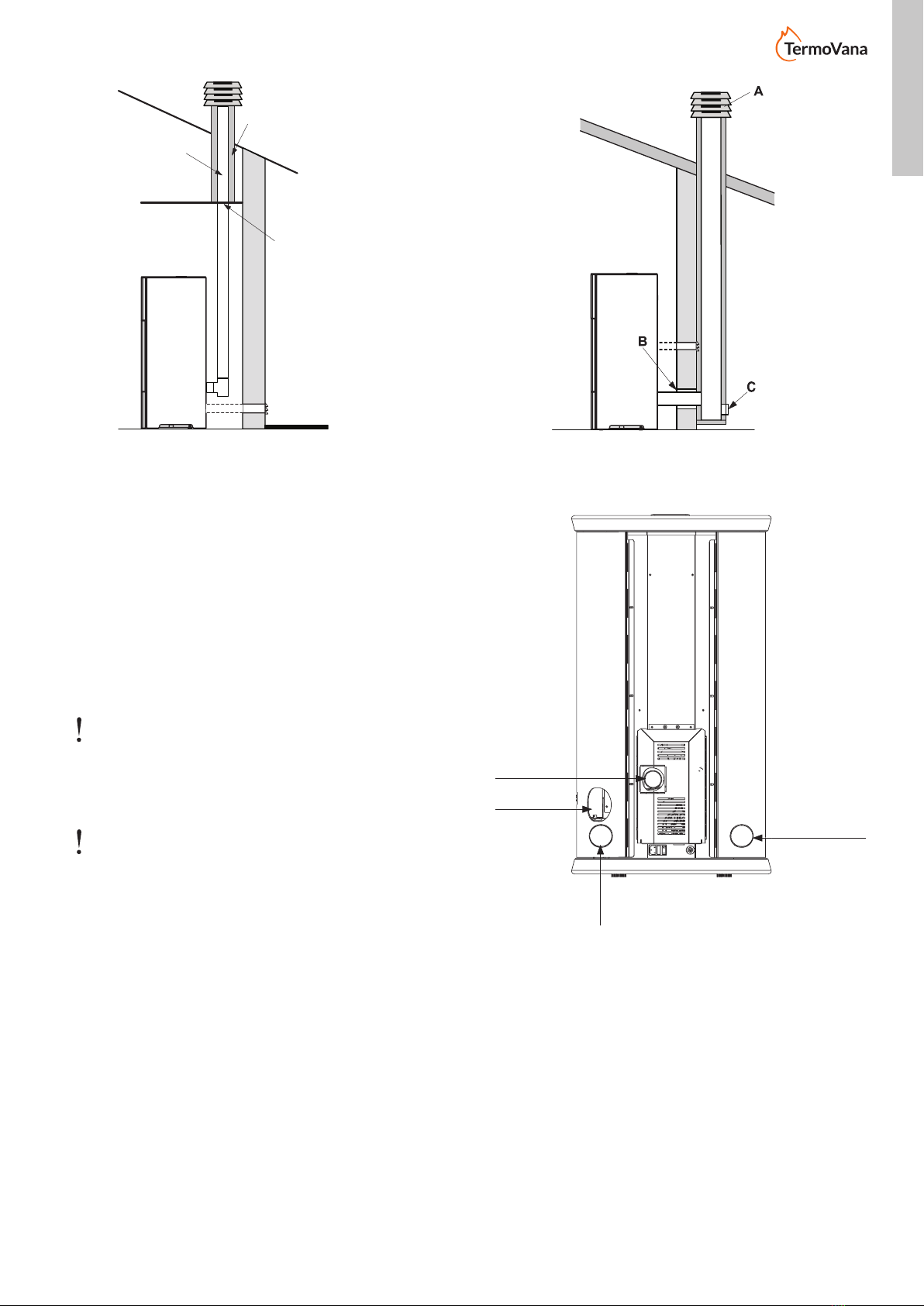

5.5 FLUE GAS EXHAUST PIPE

The stove operates with the negative pressure in the

combustion chamber and so, it is essential to ensure

that the fume outlet is leak-proof.

The stove must be connected to its own exclusive fume

discharge system which can adequately disperse the

combustion products into the atmosphere.

The components that make up the smoke evacuation

system must be declared suitable for the specic

operating conditions and provided with CE marking.

It is mandatory to create a rst vertical section of a

minimum 1.5 meters to guarantee correct expulsion

of the fumes.

It is advisable to make a maximum of 3 changes of

direction, in addition to that resulting from the rear

connection of the stove to the chimney, using 45-90°

bendsorT-ttings(g.5.7).

AlwaysuseaT-ttingwithaninspectioncapateach

horizontalandverticalvariationoftheuegasexhaust

pipe.

OntherstT,attheexitoftheuegasoutletofthe

stove, it is necessary to connect a pipe at the bottom

in order to evacuate any condensate that may form in

the chimney (Fig. 5.7a).

The horizontal sections must have a maximum length

of2-3mwithanupwardslopeof3-5%(g.5.7).

Anchor the pipes with suitable collars to the wall.

The fume exhaust connection MUST NOT be

connected:

- to a replace used by other generators (boilers,

stoves,replaces,etc.);

- to air extraction systems (hoods, vents, etc.) even

if "intubated".

Itisforbiddentoinstallshut-oanddraughtvalves.

The exhaust of the combustion products must be

provided on the roof.

If a pellet stove in the “Hermetic” series is installed, it

ispossibletouseaspeciccoaxialpipethatallows

boththeexpulsionofuegasesandtheductingofthe

combustionairfromtheoutside(g.5.5A,B=Airinlet

C,D=Flue gas outlet).

5.5.1

The ue for ue gas discharge must be carried out

Product images are purely indicative

ITALIANO

ENGLISH

13

08/2020 - EN

in compliance with the UNI 10683- EN 1856-1-2-

EN 1857- EN 1443- EN 13384-1-3- EN 12391-1

standards both regarding the dimensions and the

materials used in its construction.

RAMSHACKLEues,madeofunsuitablematerial

(bre cement, galvanised steel, etc. with rough,

porous inner surfaces) are illegal and prevent the

stove from working correctly.

The discharge of fumes through a traditional

replace(Fig.5.8)canbedoneprovidedthatthe

chimney is maintained;

If the chimney has a bigger section, it must be

“intubated” with a suitably insulated steel pipe (with

diameter in line with the route) (Fig. 5.9).

Make sure that the connection to the brickwork

chimney is properly sealed.

If the pipes pass through roofs or wooden walls,

you should use special certied transition kits,

commercially available.

.

5.6 LEVELLING THE STOVE

The stove must be levelled, with the help of a spirit

level, by regulating the adjustable feet (if included)

g.5.10).

A B = Spirit Level

Product images are purely indicative

Fig. 5.9 Fig. 5.8

1) Vermiculite and/or mineral wool.

2) Steel piping.

3) Closing panel.

A) Windproof cowl

B) Seal

C) Inspect

Ducted

outlet

Fig. 5.5.2

Primary air

extraction

Flue gas outlet

Ducted

outlet

1

2

3

Flue gas outlet

Flue gas outlet

Flue gas outlet

14 08/2020 - EN

5.7 CONNECTION TO SYSTEMS

5.7.1 Electrical connection

Just connect the stove to the electrical system using

the plug provided.

The electrical connection (plug) must be easily

accessible even after installing the stove.

If the power cord is damaged, it must be replaced

bythetechnicalassistanceserviceorbyaqualied

technician in order to prevent any risk.

5.7.1.1 Earthing

The system must be earthed and equipped with a

dierentialswitchinaccordancewithlegislationinforce

(g.5.11).

Make sure the power cord does not come into contact

with hot parts.

The ue gas exhaust pipe must have its own earth

connection.

5.8 OPTIMISATION OF COMBUSTION

Excellent fuel depends on dierent factors (type of

installation, operating and maintenance conditions,

type of pellets, etc.)

Whenrstswitchedon,thestovecombustioncanbe

optimised.

Generally speaking, if at the end of combustion,

there is a lot of residue in the burn pot, you should

changethe combustionconguration (byincreasing

thevalue)untilyoundthebestsolution.

See sections 9.17- 9.18 - 9.19.

5.9 VENTILATION

The stove is equipped with ventilation.

The air pushed by the fans keeps the appliance at

a low enough temperature, thus avoiding excessive

stress on the materials of which it is composed.

Do not close the hot air outlet vents with any objects

or the stove will overheat!

The stove is not suitable for cooking food.

ATTENTION: Do not cover the air vents.

Fig. 5.10

Product images are purely indicative

ITALIANO

ENGLISH

15

08/2020 - EN

6 MAINTENANCE

(Tobeperformedbyaqualiedtechnicalsupportcentre)

6.1 MAINTENANCE

Maintenance operations must be performed by an authorised

technical assistance centre.

Before performing any maintenance operation, take the

following precautions:

- Make sure that all the parts of the stove are cold.

- Make sure that the ashes are completely extinguished.

-Use personal protective equipment provided for by Directive

89/391/EEC.

-Makesurethatthegenerallineswitchisturnedo.

-Make sure that the power supply cannot be accidentally

reactivated. Remove the plug from the wall socket.

- Always use appropriate equipment for maintenance.

-Once the maintenance or the repair operations are

completed, before re-commissioning the stove, install again

all the protections and restart all the safety devices.

6.1.1 FLUE SYSTEM MAINTENANCE

To be performed at least once a year, or every 40 tons of burned

pellets.

If there are horizontal sections, it is necessary to check and

remove any ash and soot deposits before they block the

passage of the fumes.

In the event of failure or inadequate cleaning, the stove may

have functional problems such as:

- bad combustion

- glass blackening

-blockage of the burn pot with accumulation of ash and pellets

-riskofuecatchingre.

6.1.2 STOVE MAINTENANCE

It must be carried out at least once a year, or each time the

stove indicates that maintenance is required.

During the maintenance operation, the technician must:

- clean the fume transit area thoroughly and completely;

- check the condition and tightness of all the seals;

-check the condition of all internal components and make

sure they are clean;

-make sure the smoke outlet connection is sealed and clean;

- remove any deposits of pellet residues in the tank;

- make sure that the stove is working properly;

- reset any warnings or alarms

-for easy access to the fan (A), simply remove the lid (B) by

adjusting the two screws (C) (Fig. 6.1.2).

6.1.3 GASKET REPLACEMENT

Ifthegasketsoftheredoor,tankoruegaschamberbecome

worn, they must be replaced by an authorised technician in

order to guarantee the proper operation of the stove.

ATTENTION: Use only original spare parts.

Product images are purely indicative

Fig. 5.11

Fig. 6.1.2

A

B

C

16 08/2020 - EN

EACH

IGNITION

EACH

WEEK

1

MONTH

1

YEAR (y)

BURN POT X

ASH DRAWER X

GLASS X

ROOM FAN EXTRACTION GRILLE X

BOILER X

HEATING ELEMENT SLEEVE X

EXHAUST MANIFOLD X

DOOR AND BURN POT GASKETS* X

FLUE DUCT* X

FANS* X

(*)Tobeperformedbyaqualiedtechnicalsupportcentre.

(a) At least once a year or every 4 tonnes of burnt pellets.

7 DEMOLITION AND DISPOSAL

The responsibility for the demolition and disposal of the stove is the exclusive responsibility of the owner who

must act in compliance with the laws on safety, respect and protection of the environment, in force in the country

wherethereplaceisinstalled.

Decommissioning and disposal can be entrusted to a third party, provided to always use companies authorised

for recovery and elimination of the materials in question.

INDICATION:followalwaysandinanycasetheregulationsinforceinthecountrywherethereplaceisinstalled

for the disposal of materials and possibly for the disposal report.

ATTENTION: All disassembly operations for the demolition must take place when the replace is off and the

power supply disconnected.

• remove the entire electric system;

• separate the accumulators in the electronic cards;

• the demolition of the stove’s structure should be carried out by authorised companies;

ATTENTION: Dumping the stove in accessible areas poses a serious risk for people and animals.

Any liability for damage to people and animals always falls on the owner.

Atthetimeofdemolition,theCEmarking,thismanualandanyotherdocumentsrelatingtothisreplaceshould

be destroyed.

The crossed-out wheelie bin symbol that appears on the label of the appliance indicates that the product at the

end of its useful life must be disposed of separately from other waste.

Within the meaning of art.13 of Legislative Decree no. 151 of 25 July 2005 implementing

the Directive 2002/96/EC of 23 February 2003 on Waste Electrical and Electronic

Equipment relating to the measures and procedures designed to prevent the production

of waste electrical and electronic equipment, called WEEE, promoting the reuse,

recycling and other forms of recovery so as to reduce the quantity to be disposed of

and improving the intervention of the parties involved in the life cycle of such products.

CONTROL AND MAINTENANCE

PROGRAMME

ITALIANO

ENGLISH

17

08/2020 - EN

8 USE

8.1 INTRODUCTION

The board automatically controls the various operating parameters of the stove. The user can control the stove

manually,toswitchitonorswitchito,orusetheadvancedfunctionssuchastheweeklyprogrammerorthe

timer.

8.2 FIRST START-UP

Once the board is powered, the LCD display will show the software version and then the stove status which, in

thecaseofrstignition,willbeo.

For the best performance with the lowest consumption, follow these instructions.

• Thepelletswilligniteveryeasilyifithasbeeninstalledcorrectlyandtheueisecient.

• SwitchonthestovetoPower1,foratleast2hours,toallowthematerialsfromwhichtheboilerandtherebox

are made to settle the internal elastic stresses.

• When the stove is used, the paint inside the combustion chamber may undergo alterations. This phenomenon can

be attributable to various reasons: overheating of the stove, chemicals found in low quality pellets, bad chimney

draught, etc. Therefore, the preservation of the paint in the combustion chamber cannot be guaranteed.

• Duringthersthoursofoperation,greasyprocessingresiduesandpaintsmayproduceodoursandsmoke:itis

recommended to ventilate the room because they can be harmful to people and animals.

• Theprogrammingvaluesfrom1to5arepresetbythecompanyandcanbemodiedbyanauthorisedtechnician

only.

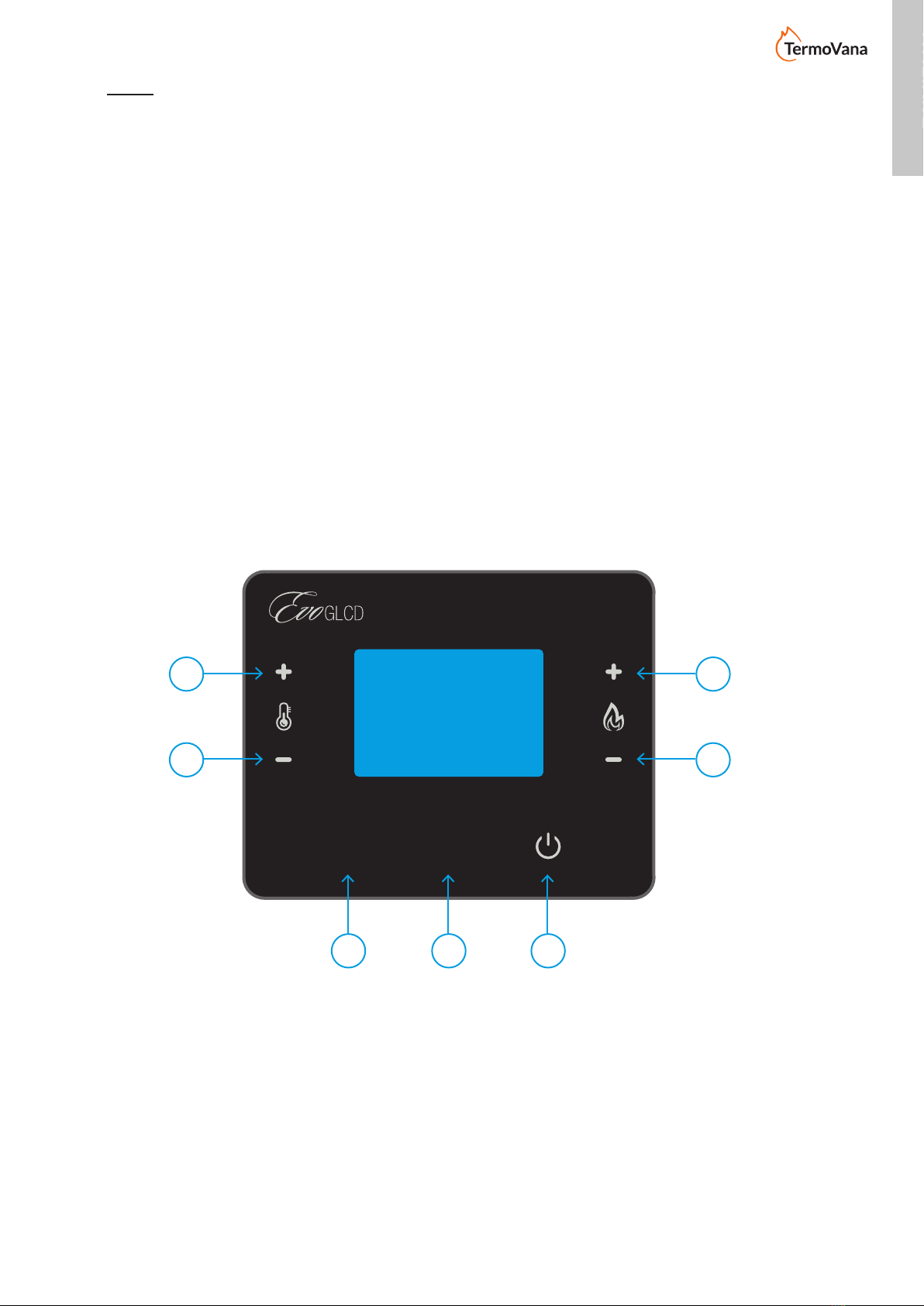

8.3 THE STOVE PANEL

1 2 3

AUTO

MAN

SET

4 6

5 7

1)SET: Usedtoenterthemenuandconrmdatachangesduringthesettingphase.

2)AUTO: Allows you to switch stove operation from Automatic to Manual.

3)ON/OFF: ToswitchthestoveOnandO.Ifthereisanerror,pressitforafewsecondstoresetthealarm.

Also used to exit the menu without changing data.

4)TEMP+: Key to increase the desired temperature. Also used to scroll through the menus and data.

5)TEMP-: Key to decrease the desired temperature. Also used to scroll through the menus and data.

6)PROG+: Key to increase the desired operating power or program. Also used to scroll through the menus and data.

7)PROG-: Key to decrease the desired operating power or program. Also used to scroll through the menus and data.

18 08/2020 - EN

8.4 MAIN MENU

8.5 Setting the Temperature

The desired room temperature is set using the

Temp+ and Temp- keys on the panel. The settable

values are from 15 to 30°C. If in IDRO PLUS mode,

themaximumsettablevalueisdenedinpar.68

8.6 Setting the Operating Program

The operating program represents the stove

heating power. The program can be set using the

PROG+ and PROG- keys and it ranges from 1,

minimum power, to 5, maximum power.

8.7 Turning on the stove

To turn on the stove, it is necessary to press the

ON/OFF button for a few seconds. The stove will

automatically proceed with the ignition and heating

phase. If it is the rst ignition, and therefore the

rstloadofpellets,itwillbenecessarytoperform

several ignition cycles so that the pellets enter the

supply circuit. Even in the case of re-ignition, after

anautomaticswitch-odueto the lackofpallets

(Error Code 5), there may be an ignition error due

to the fact that the pellet supply circuit is empty.

If the stove has not performed a correct ignition,

the next ignition will be with a reduced amount of

pellets based on the auger power setting during

ignition, settable from 1 to 5 (parameter code 25).

If the stove is started while it is still in the cooling

phase, the stove will switch to waiting mode until

the fume temperature has dropped below the

stoveotemperature(parametercode36).

8.8

To turn o the stove, simply press the ON/OFF

button, with the LCD display lit up. By means of

controlled cooling, the system will bring the stove

totheostatus.

8.9 Resetting System Errors

The stove reports any detected fault by means of

an error code and a comment. Before turning the

stove on again, it is necessary to reset all errors by

pressing the STOP key for about 3 seconds and

in any case until the error message on the LCD

display disappears. The last 10 errors are saved

in a non-volatile memory and can be viewed by

entering the ERROR LOG menu.

8.10 Heating Mode

It is possible to change the heating mode at any

time by controlling both the program and the set

temperature using the keys present and following

the instructions on the display and on the panel

itself. The stove will automatically adjust the power

delivered according to the program and the room

temperature measured by the special probe.

8.11 Pellet Saving Mode

If, during the heating phase, the room temperature

exceeds the delta T value set in system parameter

64, the stove will enter pellet saving mode and

start cooling. The stove will restart automatically

if the room temperature drops below the set

temperature for at least 1 minute. By default, if

parameter 100 is set to 0 the function is disabled.

The settable temperature value ranges from 1 to

15°C.

8.12 Automatic or Manual Mode

The stove can be operated manually, being

switchedonandobytheoperator,orautomatically

by means of the built-in weekly programmer or

timewhichturnthestoveonandoautomatically

at set times as required. To change the mode,

press the SET key on the panel. The selected

mode will always be indicated on the display.

8.13 Manual

The stove is controlled manually only and therefore

itmustbeturnedonandobyusingtheON/OFF

button.

8.14 Auto

In addition to being manually turned on and o,

the stove also controls the settings in the timer

andtheweeklyprogrammer,byturningonano

at the set times and days.

ITALIANO

ENGLISH

19

08/2020 - EN

9 USER PROGRAMMING

User programming is possible through the menu,

which can be opened by pressing the SET key on

the illuminated display panel. To exit the menu at

any time without making any changes, press the

STOP key. In any case, if the keys are not pressed

for about 1 minute, the system will automatically

exit the menu to show the stove status. To scroll

the various menus use the TEMP+ and TEMP-

keys, to open the displayed menu, press SET.

9.1 Date and Time Settings

Press SET to open the incorporated calender

setting menu. The day of the week can be

changed from Monday to Sunday, as well as the

time and date. To switch between the variables,

use the PROG+ and PROG- keys, and to change

the values, use the TEMP+ and TEMP- keys. To

conrmthechangesandexit,presstheSETkey.

9.2 Weekly Programmer

The programmer is only active in the automatic

operating mode (AUTO on the display). There

are 30 settable programming levels for on

and o times, the temperature and operating

programme. Each programme can be disabled

without needing to be cancelled, by following a

very simple procedure. Press SET to open and

scroll the various programmes, or the TEMP+ and

TEMP- keys to scroll the variables to be changed.

Then use the PROG+ and PROG- keys to set the

required values.

9.3 Program Number

Indicates the selected programme, from 1 to 30.

9.4 Day of the week

Indicates the day of the week of the displayed

programme. A setting can be made for each day,

from Monday to Sunday (Mo,Tu,We,Th,Fr,Sa,Su)

or else for all work days from Monday to Friday

(MF), or else for weekends from Saturday to

Sunday (SS). This system allows the setting of a

singleprogrammetoturnthestoveonoroevery

day, from Monday to Friday, at the same time.

9.5 Hours

Stoveonorohour

9.6 Minutes

Stoveonorominutes

9.7 Required Temperature

In the case of ignition program, it is necessary to

set the required room temperature between 5 and

30°C.

9.8 Required Program

For ignition programmes, the requested heating

programme must be set between 1 and 5.

9.9 Program Type

Seteitheranignitionprogramme,ON,orpowero

programme, OFF.

9.10 Enabling the Program

This function is essential, because if in the disabled

position (No A.) the system will not control the

programme and the programme function may not

be executed.

9.11 Example of Programming

To programme the stove so that it turns on every

day from Monday to Friday at 8am at level 5, with

a temperature of 20°C, proceed as follows after

opening the ignition programme setting.

• With TEMP+ select MF as the ignition days from

Monday to Friday.

• Select the Hour using the PROG+ key and set 08

with the TEMP+ and TEMP- keys.

• Select the minutes using the PROG+ key and set

30 with the TEMP+ and TEMP- keys.

• Select the temperature using the PROG+ key and

set 20° with the TEMP+ and TEMP- keys.

• Select the heating power using the PROG+ key and

set 5 with the TEMP+ and TEMP- keys.

• Select the mode using the PROG+ key and set ON

with the TEMP+ and TEMP- keys.

• Select the programme type using the PROG+ key

and set Enab. with the TEMP+ and TEMP- keys.

• Press SET to save the data and insert a new ignition

programme. If programming is complete, press

STOP to exit.

• Remember to set the operating mode to Automatic

to enable control of the weekly programmer.

20 08/2020 - EN

REMOTECONTROL(OPTIONAL)

The system is designed for use with

the optional IR remote control, which

can be installed at any time. The

remote control allows the stove to be

turned on and off by remote. Before

use, the remote control code must be

memorised. This operation is carried

out directly from the stove panel

without the need for any other tools.

CODE MEMORISATION

Press the PROG+ and TEMP+ keys for about

5 seconds, until the message “IR REMOTE

CONTROL” is displayed. Now point the remote

control toward the panel and press any of the keys

present. An acoustic signal will inform the user that

the operation was successful. Exit the menu using

the STOP key and try to control the stove.

10 STOVE PARAMETERS

Press SET to open and modify the main stove

parameterssuchaspelletload,uegasextraction

speed, ambient air fan and ambient temperature

correction. Using the TEMP+ and TEMP- keys it is

possible to change the stove setting percentages

to correct its operation based on the pellets used.

ThenpressSETtoconrmthemodiedparameter

and save it in the memory. Use the PROG+ and

PROG- keys to scroll the parameters. Press the

STOP key to exit the menu.

10.1 Loading Pellets

Allows all loading parameters to be increased or

decreased in percentage from 50 to +50%.

10.2 Fume Extraction

Allows all ue gas extraction parameters to be

increased or decreased in percentage from -50 to

+50%.

10.3 Room Fan

Allows all air ventilation parameters to be increased

or decreased in percentage from -50 to +50%. 16.4

Stand-By Function

Set parameter 100 to 1 to have the stand-by

function directly in the user menu. The stove will

therefore automatically go to stand-by mode if

the measured room temperature exceeds the

programmed temperature. The stove will restart

when the measured room temperature drops below

the programmed temperature.

11 LANGUAGE SELECTION

It is possible to select a language for the messages

on the display from Italian, English, French,

German, Spanish, Dutch. Other languages are

available on request. The selection is made by

using the PROG+ and PROG- keys.

12 LAST ERROR LOG

The menu allows you to view the last errors

recorded by the board accompanied by the date

and time of the event, as well as a brief description

of the event itself.

13 DUCTED

In this menu, if provided by the Hardware, it is

possible to manually change the external or

ductedfan from 0,o, to 5,maximum speed. In

any case, it will work if the fumes, and therefore

the stove, are at the temperature set by the fan

parameters.

13.1 Ducted left

In this menu, you can set the left motor ducting or

ventilation speed from 1 to 5, which allows you to

choose the heat propagation speed. If the value is

set to AUTO, the ventilation follows the set power

of the stove. If the AUTO function is not set, the

fan will be freed from the stove power, except

forwhentheameswitchestomodulationmode

(when the stove reduces or increases its power

level).

13.2 Ducted right

In this menu, you can set the right motor ducting or

ventilation speed from 1 to 5, which allows you to

choose the heat propagation speed. If the value is

set to AUTO, the ventilation follows the set power

of the stove. If the AUTO function is not set, the

fan will be freed from the stove power, except

forwhentheameswitchestomodulationmode

(when the stove reduces or increases its power

level).

Table of contents

Other termovana Stove manuals

Popular Stove manuals by other brands

Bio Bronpi

Bio Bronpi ELSA Y PAULA Installation, operating and servicing instructions

Cleveland

Cleveland PS20W Operating instructions and owner's manual

Charnwood

Charnwood Country 8WB MkII Operating and installation instructions

Coleman

Coleman 442 Instructions for use

Bimar

Bimar HR313 Instruction booklet

Stanley

Stanley Erin Installation and operating instructions