terneo k2 User manual

If necessary the sensor connecting wires may be shortened

and extended (for not more than 20 m).

The cross section of copper wiring to which the temperature

controller is connected should be at least 2 × 1 0 mm, 2.

section not more than 2,5 . To reduce the mechanical

loads on the terminals it is desirable to use a soft wire.

The ends of the wires must be cleaned and crimped with

ferrules with insulation. The wires are tightened in the

terminals using

. The screwdriver with a blade width more

than 3 mm can cause mechanical damage to the terminals.

This may result in the loss of right for warranty.

mm2

a screwdriver with a blade width no

more than 3 mm

It is necessary for the temperature controller to switch

the current to no more than 2/3 of the maximum current

specified in the specification. If the current exceeds this

value, the load must be connected through a contactor

(magnetic actuator, power relay), which is optimized for this

current (Wiring ).3

The temperature is controlled at the location of the

temperature sensor. If both terneo k2 temperature

sensors are located in the same place, one for heating

control and the other one for cooling control, then a

comfortable temperature in the room can be maintained

all year round.

The control of a water heated floor is carried out using

an electrothermal servo drive 230 V. The servo drive can

be normally closed or open. Use wiring 2 to connect a

normally open servo.

Terneo k2

–20 ... +100 °

using heating or cooling equipment.

С

thermostat comprises two independent

thermostats in one housing. Each of them is designed to

maintain a constant temperature from

k2

21 3

Maximum load current

(for category AC-1)

2 6 × 1 А

Rated load capacity (for category AC-1)

–20...+100 °С

2 3× 000 АV

52 × × 67 90 mm

230 10 %V ±

50 000 cycles

20 000 000 cycles

IP20

–30...+ °С130

0,1...10 , step °С 0,1

4 m

0, ±10 %37 kg

The limits of regulation

Input voltage

Weight in the complete set

Overall dimensions ( × × )w h d

The length of the sensor

connected cable

Temperature hysteresis

Degree of protection GOST14254

Measured temperature range

Temperature sensor

TECHNICAL DATA INSTALLATION

WIRING

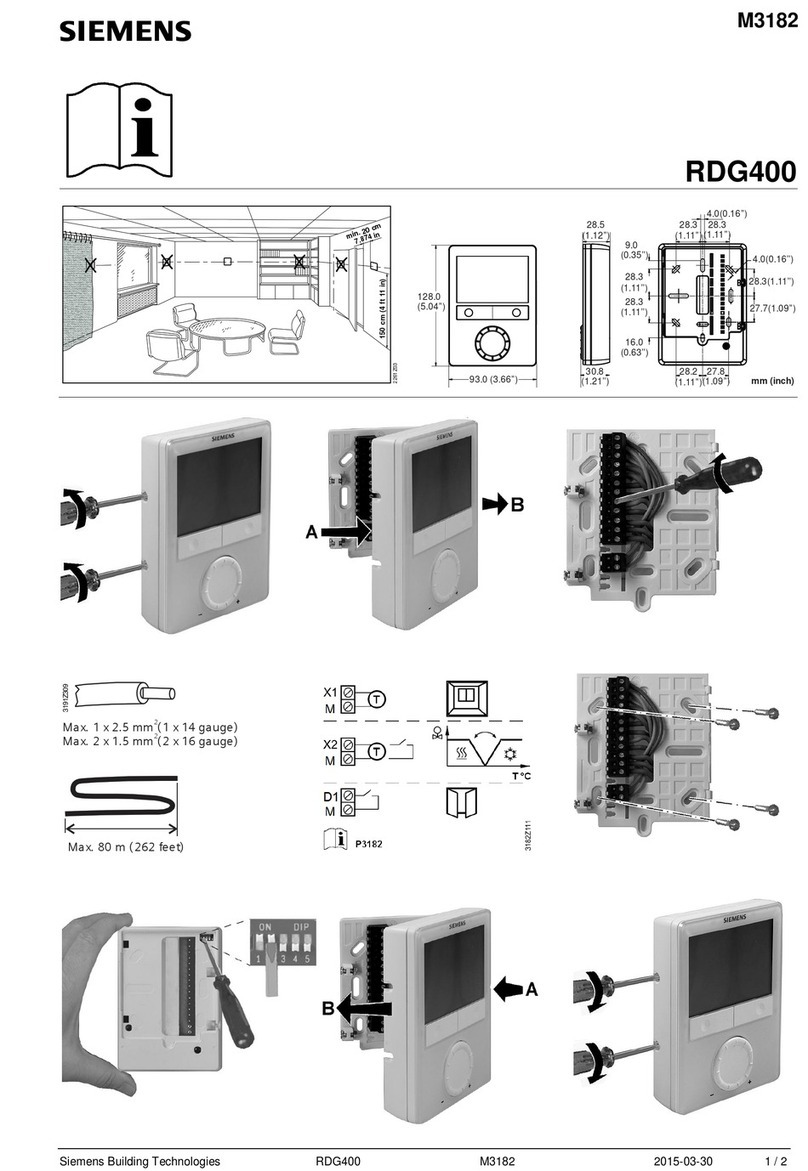

The thermostat is mounted and connected after the

installation and load testing.

In order to protect from short circuits and excess power

events appearance in the load circuit, it is necessary

to install an automatic circuit breaker (CB), which should

be installed in the live wire break, as shown on Wiring .

1

The thermostat terminals are designed for a wire with

The ambient temperature during installation must be

between –5 ... + 45 °C.

The thermo stat is designed for indoor installation. The

ingress risk of moisture or liquid into the place of

installation must be minimized. When installed in a

bathroom, toilet, kitchen, swimming pool the stat

should be installed at the place out of reach of casual

spraying.

thermo

The temperature controller should be mounted in a special

cabinet, which allows accessible installation and

operation. The cabinet must be equipped with a standard

35 mm mounting rail (DIN-rail). The temperature controller

has width of three standard 18 mm modules. The

installation height of the stat should be in the range

0,5 1,7 m above the floor level.

thermo

...

IT IS FORBIDDEN TO POWER THE DEVICE FROM

SOURCES WITH A MODIFIED SINUSOID, as well as

uninterruptible power supplies, the output voltage of

which is not a sinusoid. Long-term operation, more

than 5 minutes, from such voltage sources may

damage the device and lead to out-of-warranty

repairs.

CONNECT APPROPRIATE PHASES TO THE

CONTROL RELAY k2 for switching, since the relay

contacts do not have a galvanic connection with the

power supply circuits, that is, the relays used in the

thermostat have a dry normally open contact (see « »

wiring1).

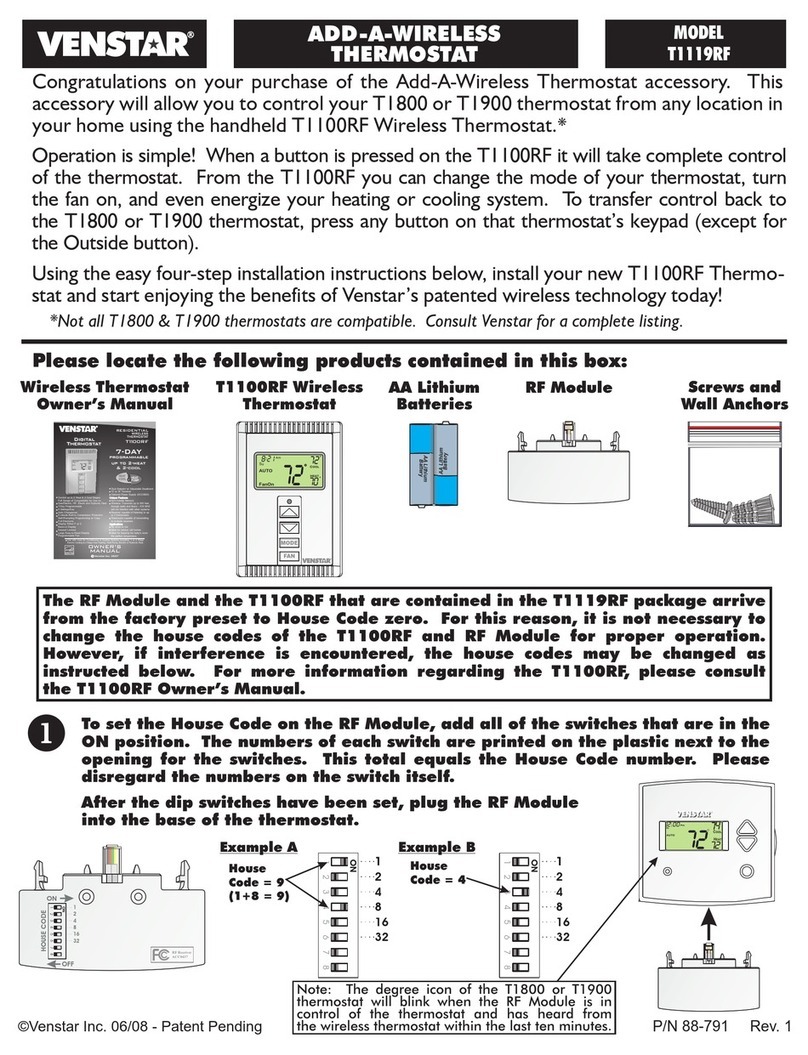

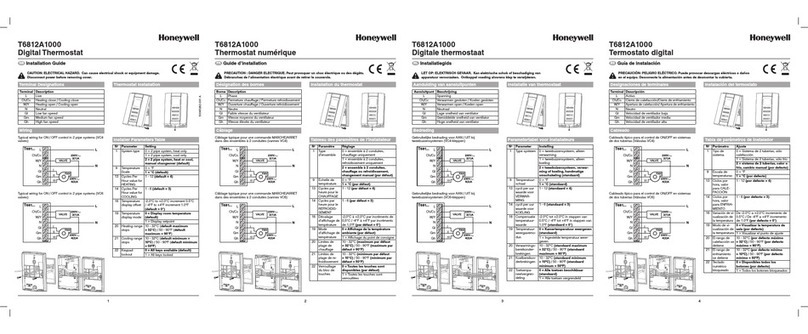

Wiring 1. Connecting each channel to a separate load

Wiring Connecting a normally open servo drive

on the example of channel 1

2.

Wiring 3. Using a contactor to increase the switching

power of the channel

The supply voltage (230 V ±10 %, 50 Hz) is supplied to

terminals 6 zero and 12 phase( , N) ( , L).

Digital sensor of channel 1 Ch1 is connected with white

wire to terminal 1 and yellow / red wire is connected to

terminal 2. White wire of channel 2 Ch2 is connected to

terminal 7, and yellow / red wire is connected to terminal 8.

In the thermostat function menu, select the type of sensor:

d18 (see Table 1 menu item Sensor type ).

« »

« »

« »

Terminals 3, 4, 5 are used to control channel №1 Ch1

and terminals 9, 10, 11 are used to control channel 2

« »

№

« »Ch2 .

Thermostat supports two types of sensors: analog sensor

R10

( , ) (D ).default or digital sensor 18

The analog sensor of channel 1 Ch1 is connected to

terminals 1 and 2, and the analog sensor of channel 2

Ch2 is connected to terminals 7 and 8. The colors of the

wires do not matter when connecting.

« »

« »

sensor normally open servo drive

t

°С

~230 V

N

Nzero terminal block

zero

terminal

block

zero terminal

block

zero

phasa

L

N

L

zero

phasa

2А2

А1 1

CВ CВ

t

°С

N

sensor

2А2

А1 1

t

°С

sensor

Ch1

Ch2

Тhermostat

L

CВ CВ

sensor

t

°С

t

°С

16 А 16 А

16 А

load

load

16 А ~230 V

N

N

Ch1

Ch1

Ch2

Ch2

sensor

zero

phasa

Тhermostat

L

L

SERVICE CENTER CONTACT:

+38 (091) 481-91-81

WhatsApp Viber Telegram

support@dse.com.ua

WARRANTY CARD

If your device is not working properly, we recommend

that you first read the section «Possible problems». If

you cannot find an answer, contact Service Center. In

most cases, these actions resolve all issues.

The warranty for devices is valid for

from the date of sale, provided that the instructions are

followed. The warranty period for products without a

warranty certificate is counted from the date of

production.

terneo 36 months

If you continue to have issues with the device, please

send it to a Service Center or to the store where you

purchased the device. If your device is defective due to

our fault, we will repair or replace it under warranty

within 14 business days.

Please see the full text of the warranty and the data you

need to send to your Service Center on the website

https://www.ds-electronics.com.ua/en/. If you have a

warranty case, please, contact the General distributor in

your area.

WARRANTY TERMS

serial №:

a seller, a seal:

place of a seal

date of sale:

an owner contact

for a service center:

smart control of heating

terneo

Technical data sheet

installation and operation manual

and

Thermostat

Temperature sensor

with connected sensor

Technical data sheet and

installation and operation manual

and warranty card

The packing box

1 piece

1 piece

2 piece

1 piece

IN THE BOX

IMPORTANT. Before the installation and operation

d

of the device, please read by the end of this

ocument. This will help to avoid possible danger,

mistakes and misunderstandings.

RELIABILITY OF THE POWER RELAY provides

protection against frequent switching in the

thermostat. If there was less than 1 minute between

relay switching, the relay activation will be delayed,

marking the countdown with a flashing dot.

NON-VOLATILE THERMOSTAT STORAGE

saves all settings in the event of a power outage.

MOUNTING OF THE SENSOR MUST BE

PERFORMED SO THAT IT WAS POSSIBLE TO

EASILY REPLACE IT.

Number of combinations without

heating, no less than

Number combinations

under heat, at least

NTC thermo-resistor

10 kOhm 25 °C (R10)

If necessary the sensor connecting wires may be shortened

and extended (for not more than 20 m).

The cross section of copper wiring to which the temperature

controller is connected should be at least 2 × 1 0 mm, 2.

section not more than 2,5 . To reduce the mechanical

loads on the terminals it is desirable to use a soft wire.

The ends of the wires must be cleaned and crimped with

ferrules with insulation. The wires are tightened in the

terminals using

. The screwdriver with a blade width more

than 3 mm can cause mechanical damage to the terminals.

This may result in the loss of right for warranty.

mm2

a screwdriver with a blade width no

more than 3 mm

It is necessary for the temperature controller to switch

the current to no more than 2/3 of the maximum current

specified in the specification. If the current exceeds this

value, the load must be connected through a contactor

(magnetic actuator, power relay), which is optimized for this

current (Wiring ).3

The temperature is controlled at the location of the

temperature sensor. If both terneo k2 temperature

sensors are located in the same place, one for heating

control and the other one for cooling control, then a

comfortable temperature in the room can be maintained

all year round.

The control of a water heated floor is carried out using

an electrothermal servo drive 230 V. The servo drive can

be normally closed or open. Use wiring 2 to connect a

normally open servo.

Terneo k2

–20 ... +100 °

using heating or cooling equipment.

С

thermostat comprises two independent

thermostats in one housing. Each of them is designed to

maintain a constant temperature from

k2

21 3

Maximum load current

(for category AC-1)

2 6 × 1 А

Rated load capacity (for category AC-1)

–20...+100 °С

2 3× 000 АV

52 × × 67 90 mm

230 10 %V ±

50 000 cycles

20 000 000 cycles

IP20

–30...+ °С130

0,1...10 , step °С 0,1

4 m

0, ±10 %37 kg

The limits of regulation

Input voltage

Weight in the complete set

Overall dimensions ( × × )w h d

The length of the sensor

connected cable

Temperature hysteresis

Degree of protection GOST14254

Measured temperature range

Temperature sensor

TECHNICAL DATA INSTALLATION

WIRING

The thermostat is mounted and connected after the

installation and load testing.

In order to protect from short circuits and excess power

events appearance in the load circuit, it is necessary

to install an automatic circuit breaker (CB), which should

be installed in the live wire break, as shown on Wiring .

1

The thermostat terminals are designed for a wire with

The ambient temperature during installation must be

between –5 ... + 45 °C.

The thermo stat is designed for indoor installation. The

ingress risk of moisture or liquid into the place of

installation must be minimized. When installed in a

bathroom, toilet, kitchen, swimming pool the stat

should be installed at the place out of reach of casual

spraying.

thermo

The temperature controller should be mounted in a special

cabinet, which allows accessible installation and

operation. The cabinet must be equipped with a standard

35 mm mounting rail (DIN-rail). The temperature controller

has width of three standard 18 mm modules. The

installation height of the stat should be in the range

0,5 1,7 m above the floor level.

thermo

...

IT IS FORBIDDEN TO POWER THE DEVICE FROM

SOURCES WITH A MODIFIED SINUSOID, as well as

uninterruptible power supplies, the output voltage of

which is not a sinusoid. Long-term operation, more

than 5 minutes, from such voltage sources may

damage the device and lead to out-of-warranty

repairs.

CONNECT APPROPRIATE PHASES TO THE

CONTROL RELAY k2 for switching, since the relay

contacts do not have a galvanic connection with the

power supply circuits, that is, the relays used in the

thermostat have a dry normally open contact (see « »

wiring1).

Wiring 1. Connecting each channel to a separate load

Wiring Connecting a normally open servo drive

on the example of channel 1

2.

Wiring 3. Using a contactor to increase the switching

power of the channel

The supply voltage (230 V ±10 %, 50 Hz) is supplied to

terminals 6 zero and 12 phase( , N) ( , L).

Digital sensor of channel 1 Ch1 is connected with white

wire to terminal 1 and yellow / red wire is connected to

terminal 2. White wire of channel 2 Ch2 is connected to

terminal 7, and yellow / red wire is connected to terminal 8.

In the thermostat function menu, select the type of sensor:

d18 (see Table 1 menu item Sensor type ).

« »

« »

« »

Terminals 3, 4, 5 are used to control channel №1 Ch1

and terminals 9, 10, 11 are used to control channel 2

« »

№

« »Ch2 .

Thermostat supports two types of sensors: analog sensor

R10

( , ) (D ).default or digital sensor 18

The analog sensor of channel 1 Ch1 is connected to

terminals 1 and 2, and the analog sensor of channel 2

Ch2 is connected to terminals 7 and 8. The colors of the

wires do not matter when connecting.

« »

« »

sensor normally open servo drive

t

°С

~230 V

N

Nzero terminal block

zero

terminal

block

zero terminal

block

zero

phasa

L

N

L

zero

phasa

2А2

А1 1

CВ CВ

t

°С

N

sensor

2А2

А1 1

t

°С

sensor

Ch1

Ch2

Тhermostat

L

CВ CВ

sensor

t

°С

t

°С

16 А 16 А

16 А

load

load

16 А ~230 V

N

N

Ch1

Ch1

Ch2

Ch2

sensor

zero

phasa

Тhermostat

L

L

SERVICE CENTER CONTACT:

+38 (091) 481-91-81

WhatsApp Viber Telegram

support@dse.com.ua

WARRANTY CARD

If your device is not working properly, we recommend

that you first read the section «Possible problems». If

you cannot find an answer, contact Service Center. In

most cases, these actions resolve all issues.

The warranty for devices is valid for

from the date of sale, provided that the instructions are

followed. The warranty period for products without a

warranty certificate is counted from the date of

production.

terneo 36 months

If you continue to have issues with the device, please

send it to a Service Center or to the store where you

purchased the device. If your device is defective due to

our fault, we will repair or replace it under warranty

within 14 business days.

Please see the full text of the warranty and the data you

need to send to your Service Center on the website

https://www.ds-electronics.com.ua/en/. If you have a

warranty case, please, contact the General distributor in

your area.

WARRANTY TERMS

serial №:

a seller, a seal:

place of a seal

date of sale:

an owner contact

for a service center:

smart control of heating

terneo

Technical data sheet

installation and operation manual

and

Thermostat

Temperature sensor

with connected sensor

Technical data sheet and

installation and operation manual

and warranty card

The packing box

1 piece

1 piece

2 piece

1 piece

IN THE BOX

IMPORTANT. Before the installation and operation

d

of the device, please read by the end of this

ocument. This will help to avoid possible danger,

mistakes and misunderstandings.

RELIABILITY OF THE POWER RELAY provides

protection against frequent switching in the

thermostat. If there was less than 1 minute between

relay switching, the relay activation will be delayed,

marking the countdown with a flashing dot.

NON-VOLATILE THERMOSTAT STORAGE

saves all settings in the event of a power outage.

MOUNTING OF THE SENSOR MUST BE

PERFORMED SO THAT IT WAS POSSIBLE TO

EASILY REPLACE IT.

Number of combinations without

heating, no less than

Number combinations

under heat, at least

NTC thermo-resistor

10 kOhm 25 °C (R10)

If necessary the sensor connecting wires may be shortened

and extended (for not more than 20 m).

The cross section of copper wiring to which the temperature

controller is connected should be at least 2 × 1 0 mm, 2.

section not more than 2,5 . To reduce the mechanical

loads on the terminals it is desirable to use a soft wire.

The ends of the wires must be cleaned and crimped with

ferrules with insulation. The wires are tightened in the

terminals using

. The screwdriver with a blade width more

than 3 mm can cause mechanical damage to the terminals.

This may result in the loss of right for warranty.

mm2

a screwdriver with a blade width no

more than 3 mm

It is necessary for the temperature controller to switch

the current to no more than 2/3 of the maximum current

specified in the specification. If the current exceeds this

value, the load must be connected through a contactor

(magnetic actuator, power relay), which is optimized for this

current (Wiring ).3

The temperature is controlled at the location of the

temperature sensor. If both terneo k2 temperature

sensors are located in the same place, one for heating

control and the other one for cooling control, then a

comfortable temperature in the room can be maintained

all year round.

The control of a water heated floor is carried out using

an electrothermal servo drive 230 V. The servo drive can

be normally closed or open. Use wiring 2 to connect a

normally open servo.

Terneo k2

–20 ... +100 °

using heating or cooling equipment.

С

thermostat comprises two independent

thermostats in one housing. Each of them is designed to

maintain a constant temperature from

k2

21 3

Maximum load current

(for category AC-1)

2 6 × 1 А

Rated load capacity (for category AC-1)

–20...+100 °С

2 3× 000 АV

52 × × 67 90 mm

230 10 %V ±

50 000 cycles

20 000 000 cycles

IP20

–30...+ °С130

0,1...10 , step °С 0,1

4 m

0, ±10 %37 kg

The limits of regulation

Input voltage

Weight in the complete set

Overall dimensions ( × × )w h d

The length of the sensor

connected cable

Temperature hysteresis

Degree of protection GOST14254

Measured temperature range

Temperature sensor

TECHNICAL DATA INSTALLATION

WIRING

The thermostat is mounted and connected after the

installation and load testing.

In order to protect from short circuits and excess power

events appearance in the load circuit, it is necessary

to install an automatic circuit breaker (CB), which should

be installed in the live wire break, as shown on Wiring .

1

The thermostat terminals are designed for a wire with

The ambient temperature during installation must be

between –5 ... + 45 °C.

The thermo stat is designed for indoor installation. The

ingress risk of moisture or liquid into the place of

installation must be minimized. When installed in a

bathroom, toilet, kitchen, swimming pool the stat

should be installed at the place out of reach of casual

spraying.

thermo

The temperature controller should be mounted in a special

cabinet, which allows accessible installation and

operation. The cabinet must be equipped with a standard

35 mm mounting rail (DIN-rail). The temperature controller

has width of three standard 18 mm modules. The

installation height of the stat should be in the range

0,5 1,7 m above the floor level.

thermo

...

IT IS FORBIDDEN TO POWER THE DEVICE FROM

SOURCES WITH A MODIFIED SINUSOID, as well as

uninterruptible power supplies, the output voltage of

which is not a sinusoid. Long-term operation, more

than 5 minutes, from such voltage sources may

damage the device and lead to out-of-warranty

repairs.

CONNECT APPROPRIATE PHASES TO THE

CONTROL RELAY k2 for switching, since the relay

contacts do not have a galvanic connection with the

power supply circuits, that is, the relays used in the

thermostat have a dry normally open contact (see « »

wiring1).

Wiring 1. Connecting each channel to a separate load

Wiring Connecting a normally open servo drive

on the example of channel 1

2.

Wiring 3. Using a contactor to increase the switching

power of the channel

The supply voltage (230 V ±10 %, 50 Hz) is supplied to

terminals 6 zero and 12 phase( , N) ( , L).

Digital sensor of channel 1 Ch1 is connected with white

wire to terminal 1 and yellow / red wire is connected to

terminal 2. White wire of channel 2 Ch2 is connected to

terminal 7, and yellow / red wire is connected to terminal 8.

In the thermostat function menu, select the type of sensor:

d18 (see Table 1 menu item Sensor type ).

« »

« »

« »

Terminals 3, 4, 5 are used to control channel №1 Ch1

and terminals 9, 10, 11 are used to control channel 2

« »

№

« »Ch2 .

Thermostat supports two types of sensors: analog sensor

R10

( , ) (D ).default or digital sensor 18

The analog sensor of channel 1 Ch1 is connected to

terminals 1 and 2, and the analog sensor of channel 2

Ch2 is connected to terminals 7 and 8. The colors of the

wires do not matter when connecting.

« »

« »

sensor normally open servo drive

t

°С

~230 V

N

Nzero terminal block

zero

terminal

block

zero terminal

block

zero

phasa

L

N

L

zero

phasa

2А2

А1 1

CВ CВ

t

°С

N

sensor

2А2

А1 1

t

°С

sensor

Ch1

Ch2

Тhermostat

L

CВ CВ

sensor

t

°С

t

°С

16 А 16 А

16 А

load

load

16 А ~230 V

N

N

Ch1

Ch1

Ch2

Ch2

sensor

zero

phasa

Тhermostat

L

L

SERVICE CENTER CONTACT:

+38 (091) 481-91-81

WhatsApp Viber Telegram

support@dse.com.ua

WARRANTY CARD

If your device is not working properly, we recommend

that you first read the section «Possible problems». If

you cannot find an answer, contact Service Center. In

most cases, these actions resolve all issues.

The warranty for devices is valid for

from the date of sale, provided that the instructions are

followed. The warranty period for products without a

warranty certificate is counted from the date of

production.

terneo 36 months

If you continue to have issues with the device, please

send it to a Service Center or to the store where you

purchased the device. If your device is defective due to

our fault, we will repair or replace it under warranty

within 14 business days.

Please see the full text of the warranty and the data you

need to send to your Service Center on the website

https://www.ds-electronics.com.ua/en/. If you have a

warranty case, please, contact the General distributor in

your area.

WARRANTY TERMS

serial №:

a seller, a seal:

place of a seal

date of sale:

an owner contact

for a service center:

smart control of heating

terneo

Technical data sheet

installation and operation manual

and

Thermostat

Temperature sensor

with connected sensor

Technical data sheet and

installation and operation manual

and warranty card

The packing box

1 piece

1 piece

2 piece

1 piece

IN THE BOX

IMPORTANT. Before the installation and operation

d

of the device, please read by the end of this

ocument. This will help to avoid possible danger,

mistakes and misunderstandings.

RELIABILITY OF THE POWER RELAY provides

protection against frequent switching in the

thermostat. If there was less than 1 minute between

relay switching, the relay activation will be delayed,

marking the countdown with a flashing dot.

NON-VOLATILE THERMOSTAT STORAGE

saves all settings in the event of a power outage.

MOUNTING OF THE SENSOR MUST BE

PERFORMED SO THAT IT WAS POSSIBLE TO

EASILY REPLACE IT.

Number of combinations without

heating, no less than

Number combinations

under heat, at least

NTC thermo-resistor

10 kOhm 25 °C (R10)

If necessary the sensor connecting wires may be shortened

and extended (for not more than 20 m).

The cross section of copper wiring to which the temperature

controller is connected should be at least 2 × 1 0 mm, 2.

section not more than 2,5 . To reduce the mechanical

loads on the terminals it is desirable to use a soft wire.

The ends of the wires must be cleaned and crimped with

ferrules with insulation. The wires are tightened in the

terminals using

. The screwdriver with a blade width more

than 3 mm can cause mechanical damage to the terminals.

This may result in the loss of right for warranty.

mm2

a screwdriver with a blade width no

more than 3 mm

It is necessary for the temperature controller to switch

the current to no more than 2/3 of the maximum current

specified in the specification. If the current exceeds this

value, the load must be connected through a contactor

(magnetic actuator, power relay), which is optimized for this

current (Wiring ).3

The temperature is controlled at the location of the

temperature sensor. If both terneo k2 temperature

sensors are located in the same place, one for heating

control and the other one for cooling control, then a

comfortable temperature in the room can be maintained

all year round.

The control of a water heated floor is carried out using

an electrothermal servo drive 230 V. The servo drive can

be normally closed or open. Use wiring 2 to connect a

normally open servo.

Terneo k2

–20 ... +100 °

using heating or cooling equipment.

С

thermostat comprises two independent

thermostats in one housing. Each of them is designed to

maintain a constant temperature from

k2

21 3

Maximum load current

(for category AC-1)

2 6 × 1 А

Rated load capacity (for category AC-1)

–20...+100 °С

2 3× 000 АV

52 × × 67 90 mm

230 10 %V ±

50 000 cycles

20 000 000 cycles

IP20

–30...+ °С130

0,1...10 , step °С 0,1

4 m

0, ±10 %37 kg

The limits of regulation

Input voltage

Weight in the complete set

Overall dimensions ( × × )w h d

The length of the sensor

connected cable

Temperature hysteresis

Degree of protection GOST14254

Measured temperature range

Temperature sensor

TECHNICAL DATA INSTALLATION

WIRING

The thermostat is mounted and connected after the

installation and load testing.

In order to protect from short circuits and excess power

events appearance in the load circuit, it is necessary

to install an automatic circuit breaker (CB), which should

be installed in the live wire break, as shown on Wiring .

1

The thermostat terminals are designed for a wire with

The ambient temperature during installation must be

between –5 ... + 45 °C.

The thermo stat is designed for indoor installation. The

ingress risk of moisture or liquid into the place of

installation must be minimized. When installed in a

bathroom, toilet, kitchen, swimming pool the stat

should be installed at the place out of reach of casual

spraying.

thermo

The temperature controller should be mounted in a special

cabinet, which allows accessible installation and

operation. The cabinet must be equipped with a standard

35 mm mounting rail (DIN-rail). The temperature controller

has width of three standard 18 mm modules. The

installation height of the stat should be in the range

0,5 1,7 m above the floor level.

thermo

...

IT IS FORBIDDEN TO POWER THE DEVICE FROM

SOURCES WITH A MODIFIED SINUSOID, as well as

uninterruptible power supplies, the output voltage of

which is not a sinusoid. Long-term operation, more

than 5 minutes, from such voltage sources may

damage the device and lead to out-of-warranty

repairs.

CONNECT APPROPRIATE PHASES TO THE

CONTROL RELAY k2 for switching, since the relay

contacts do not have a galvanic connection with the

power supply circuits, that is, the relays used in the

thermostat have a dry normally open contact (see « »

wiring1).

Wiring 1. Connecting each channel to a separate load

Wiring Connecting a normally open servo drive

on the example of channel 1

2.

Wiring 3. Using a contactor to increase the switching

power of the channel

The supply voltage (230 V ±10 %, 50 Hz) is supplied to

terminals 6 zero and 12 phase( , N) ( , L).

Digital sensor of channel 1 Ch1 is connected with white

wire to terminal 1 and yellow / red wire is connected to

terminal 2. White wire of channel 2 Ch2 is connected to

terminal 7, and yellow / red wire is connected to terminal 8.

In the thermostat function menu, select the type of sensor:

d18 (see Table 1 menu item Sensor type ).

« »

« »

« »

Terminals 3, 4, 5 are used to control channel №1 Ch1

and terminals 9, 10, 11 are used to control channel 2

« »

№

« »Ch2 .

Thermostat supports two types of sensors: analog sensor

R10

( , ) (D ).default or digital sensor 18

The analog sensor of channel 1 Ch1 is connected to

terminals 1 and 2, and the analog sensor of channel 2

Ch2 is connected to terminals 7 and 8. The colors of the

wires do not matter when connecting.

« »

« »

sensor normally open servo drive

t

°С

~230 V

N

Nzero terminal block

zero

terminal

block

zero terminal

block

zero

phasa

L

N

L

zero

phasa

2А2

А1 1

CВ CВ

t

°С

N

sensor

2А2

А1 1

t

°С

sensor

Ch1

Ch2

Тhermostat

L

CВ CВ

sensor

t

°С

t

°С

16 А 16 А

16 А

load

load

16 А ~230 V

N

N

Ch1

Ch1

Ch2

Ch2

sensor

zero

phasa

Тhermostat

L

L

SERVICE CENTER CONTACT:

+38 (091) 481-91-81

WhatsApp Viber Telegram

WARRANTY CARD

If your device is not working properly, we recommend

that you first read the section «Possible problems». If

you cannot find an answer, contact Service Center. In

most cases, these actions resolve all issues.

The warranty for devices is valid for

from the date of sale, provided that the instructions are

followed. The warranty period for products without a

warranty certificate is counted from the date of

production.

terneo 36 months

If you continue to have issues with the device, please

send it to a Service Center or to the store where you

purchased the device. If your device is defective due to

our fault, we will repair or replace it under warranty

within 14 business days.

Please see the full text of the warranty and the data you

need to send to your Service Center on the website

https://www.ds-electronics.com.ua/en/. If you have a

warranty case, please, contact the General distributor in

your area.

WARRANTY TERMS

serial №:

a seller, a seal:

place of a seal

date of sale:

an owner contact

for a service center:

smart control of heating

terneo

Technical data sheet

installation and operation manual

and

Thermostat

Temperature sensor

with connected sensor

Technical data sheet and

installation and operation manual

and warranty card

The packing box

1 piece

1 piece

2 piece

1 piece

IN THE BOX

IMPORTANT. Before the installation and operation

d

of the device, please read by the end of this

ocument. This will help to avoid possible danger,

mistakes and misunderstandings.

RELIABILITY OF THE POWER RELAY provides

protection against frequent switching in the

thermostat. If there was less than 1 minute between

relay switching, the relay activation will be delayed,

marking the countdown with a flashing dot.

NON-VOLATILE THERMOSTAT STORAGE

saves all settings in the event of a power outage.

MOUNTING OF THE SENSOR MUST BE

PERFORMED SO THAT IT WAS POSSIBLE TO

EASILY REPLACE IT.

Number of combinations without

heating, no less than

Number combinations

under heat, at least

NTC thermo-resistor

10 kOhm 25 °C (R10)

7

5 6

v2G328_2 09052

Menu section

« »≡

Press NotesScreen

If necessary, use the temperature correction on the thermostat

screen.

Correction of screen reading

( actory setting « », ±9,9 °С)f 0.0 range

Temporary temperature

maintenance timer

f .0( actory setting «1 »,

0,5...99,5 , 0,5 )range h step h

L toad work ime

counter ( )view

Temperature in timer mode

( actory setting «5.0», –20...+100 °С)f range

This is the temperature that the thermostat will maintain

in timer mode.

1 time

3 times

4 times

5 times

2 times

6 times

It allows you to calculate energy consumption trough

multiplying the operating time by the load power and t

he tariff. Displays the time (hours, minutes) using a running

line. To reset the counter while watching, press «–».

Hysteresis

step

( factory setting 1,0 °С,

0,1...10 , 0,1range °С )

This is the difference between the temperature of the load turn

on and off. The lower value of hysteresis allows you to

maintain the temperature more accurately, upper to save on

energy consumption and increase the service life of the relay

—

.by reducing the number of load switches

Heating / cooling modes

actory setting Hot( — )f

— heat,«Hot»

«CoL» — cooling.

Sensor type

( actory setting «1 »)f 0r

7 times Select the type of sensor you want to use:

: 2 3, 4 7, 6 8, 10 , 12 , 15 , 33 , 47 ,

— ,

: 18

analog r r r r r r r r where r

is kOhm at 25 °C

digital d .

Control of protection from frequent

switching of power relay

actory setting( « »)f don

If you want to disable protection, select «doF».8 times

EXPLOITATION

If the temperature is higher than the sensor

temperature, the load will turn on and the red indicator of

the corresponding channel will turn on.

preset

View firmware version

Hold down the button for 6 seconds. « »

≡ The manu-

facturer reserves the right to modify the firmware to

enhance the device technical characteristics.

5 seconds after the last pressing, the stat will

automatically return to the air temperature display.

thermo

Select the channel to be adjusted (« » « »Ch1 / Ch2 ): short

press and use the and buttons to select. «≡» «+» «–»

Use the middle button to navigate through the menu«≡»

(Table 1). Use the and buttons to change the

parameters. After pressing the button for the first time

the parameter will flash, after pressing it for the second

time the parameter will change.

«+» «–»

Preset temperature factory setting( 30 °С)

Use the «+»

«–»

«+» «–»

button to select the upper channel, and the

button for the lower channel. Changing the channel

temperature using the and buttons.

short circut — short circuit of the sensor circuit

open circut — sensor circuit break

Possible cause: damage to the sensor and its circuit,

incorrectly selected sensor type in the thermostat settings,

the temperature measured by the analogue sensor exceeds

range of –30...+ °С.130

It is necessary: to check the integrity of the sensor and the

absence of mechanical damage to its circuit, the absence of

power wires that are laid close. Check if the colours are

correct when connecting the digital sensor. Make sure that

the appropriate type is selected in the sensor settings.

Features of the protection against internal overheating:

when the temperature inside the housing drops below

60 °C, the thermostat will resume operation. When

the protection is triggered more than 5 times in a row,

the thermostat will be blocked until the temperature inside

the housing drops below 60 °C and one of the buttons is

pressed.

The temperature controller has switched to the

Emergency Timer Mode. The symbol and

the remaining time until the next load on / off

flash on the screen

« »t

.

While the load is running, the symbol « »

t flashes

on the screen

Timer-based emergency operation mode (factory setting

15 min.)

« » «–»+

« » « »on oFF

This mode ensures the operation of the thermostat

in case of damage to the sensor: in a 30-minute cyclic

interval it turns on the load for the set time, the rest of the

time the load is turned off. The load operating time is

adjustable from 1 to 29 minutes using the or

buttons. To ensure continuous operation of the load, select

and to turn the load completely off, select .

Heating temperature control is not available.

The load of both channels does not work, the screen

flashes «oht»

The temperature inside the housing exceeded 80 °C, the

protection against internal overheating worked.

Possible cause: internal overheating of the thermostat,

which can be caused by: poor contact in the terminals of the

thermostat, high ambient temperature, exceeding the power

of the switching load, or the cross section of the wires for

connection is incorrectly selected.

It is necessary: to check the tightening of power wires in the

terminals of the thermostat, make sure that the switching

load power does not exceed the permissible one, the cross

section of the wires for connection are selected correctly.

Every 5 seconds the screen displays Ert« »

Possible cause: is a break or short circuit of the

internal overheating sensor. Internal

overheating is not monitored.

It is necessary: to send the thermostat to the service center.

Otherwise, overheating control will not be carried out.

To reset the factory settings, hold the three

buttons at the same time for more than 6 s

until message appears on the screen.

ec

«dEF»

After release it will reset to the factory settings

and reboot.

In order to enable (disable) button blocking

press the and buttons at the same

time for 6 seconds till the ( ) sign

appears on the screen.

«+» «–»

«Loc» «oFF»

(child and public protection)

Reset to the factory settings

Button blocking

It is necessary: make sure that the supply voltage is

available. If power supply is available, contact the Service

Center.

Load is off, screen and indicator are off

Possible cause: No power supply.

Table 1. FUNCTION MENU of the selected channel

1. XXh, where XX is the time in hours if the time is > 10 h.

Hold down button for on / off timer of the first channel and «+»

«–» button for on / off timer of the second channel for 4 seconds.

The screen displays zit dashes, then .« » « »ton toF /

This is the time during which the temperature different from set

main temperature will be maintained.

During operation, the screen alternately displays the time until

the end of the timer and the current temperature. The time is

displayed in the following format:

2. X.YY, where X is hours, YY is minutes if the time is < 10 h.

When the power is switched, the Timer is reset.

Avoid hitting of water or moisture to the device.

Carefully read and become aware of yourself these

instructions.

Connection of the device must be done by a qualified

electrician.

Do not switch the non assembled device to the network.

Do not immerse the sensor with a connecting wire in the

liquid medium.

Turning on and off or and configure the device should be

with dry hands.

Do not connect the device to the network disassembled.

Do not expose the device to extreme temperatures (higher

than 40 ºС or below 5 °C) and high humidity.

–

Do not connect 230 V mains voltage instead of the sensor

(it leads to failure of the thermostat).

Never clean the device with the use of chemicals such as

benzene, solvents.

Do not store the device and do not use it in areas with the

dust.

Do not attempt to disassemble and repair the device.

Do not exceed the landmarks value adaptor and power.

To protect against overvoltage caused by lightning

discharges, use a lightning protector.

Before the installation (dismantling) and connection

(disconnection) of the device, turn off voltage supply and

also act according to the «Rules of an arrangement of

electric installations».

Protect the children from games with the working device, it

is dangerous.

SAFETY INSTRUCTIONS

Low Voltage Directive 2014/35/E U

1 30 UEMC Directive 20 4/ /E

Manufacturer and vendor: DS ELECTRONICS, LTD

04136,

+38 (091) 1-91-8 , : +38 (091) 1-91-8

support@dse.com.ua www.ds-electronics.com.ua/en/

Ukraine, Kyiv region, Kyiv, 1–3 Pivnichno-Syretska str.

48 1 48 1Service Center

Transportation of goods carried in the package, ensuring

the safety of the product.

Do not fire and do not throw away the device with the

household waste.

After the end of its service life, the product must be

disposed of in accordance with applicable law.

The devi e is transported by any kind of transport (rail,

sea, motor, air transportation).

c

Date of manufacture is on the back side of device.

Application time is unlimited.

The device does not contain harmful substances.

If you have any questions or you something will not clear,

call the Service centre the telephone number listed below.

ADDITIONAL INFORMATION

POSSIBLE PROBLEMS, CAUSES

AND WAYS TO OVERCOME THEM

7

5 6

v2G328_2 09052

Menu section

« »≡

Press NotesScreen

If necessary, use the temperature correction on the thermostat

screen.

Correction of screen reading

( actory setting « », ±9,9 °С)f 0.0 range

Temporary temperature

maintenance timer

f .0( actory setting «1 »,

0,5...99,5 , 0,5 )range h step h

L toad work ime

counter ( )view

Temperature in timer mode

( actory setting «5.0», –20...+100 °С)f range

This is the temperature that the thermostat will maintain

in timer mode.

1 time

3 times

4 times

5 times

2 times

6 times

It allows you to calculate energy consumption trough

multiplying the operating time by the load power and t

he tariff. Displays the time (hours, minutes) using a running

line. To reset the counter while watching, press «–».

Hysteresis

step

( factory setting 1,0 °С,

0,1...10 , 0,1range °С )

This is the difference between the temperature of the load turn

on and off. The lower value of hysteresis allows you to

maintain the temperature more accurately, upper to save on

energy consumption and increase the service life of the relay

—

.by reducing the number of load switches

Heating / cooling modes

actory setting Hot( — )f

— heat,«Hot»

«CoL» — cooling.

Sensor type

( actory setting «1 »)f 0r

7 times Select the type of sensor you want to use:

: 2 3, 4 7, 6 8, 10 , 12 , 15 , 33 , 47 ,

— ,

: 18

analog r r r r r r r r where r

is kOhm at 25 °C

digital d .

Control of protection from frequent

switching of power relay

actory setting( « »)f don

If you want to disable protection, select «doF».8 times

EXPLOITATION

If the temperature is higher than the sensor

temperature, the load will turn on and the red indicator of

the corresponding channel will turn on.

preset

View firmware version

Hold down the button for 6 seconds. « »

≡ The manu-

facturer reserves the right to modify the firmware to

enhance the device technical characteristics.

5 seconds after the last pressing, the stat will

automatically return to the air temperature display.

thermo

Select the channel to be adjusted (« » « »Ch1 / Ch2 ): short

press and use the and buttons to select. «≡» «+» «–»

Use the middle button to navigate through the menu«≡»

(Table 1). Use the and buttons to change the

parameters. After pressing the button for the first time

the parameter will flash, after pressing it for the second

time the parameter will change.

«+» «–»

Preset temperature factory setting( 30 °С)

Use the «+»

«–»

«+» «–»

button to select the upper channel, and the

button for the lower channel. Changing the channel

temperature using the and buttons.

short circut — short circuit of the sensor circuit

open circut — sensor circuit break

Possible cause: damage to the sensor and its circuit,

incorrectly selected sensor type in the thermostat settings,

the temperature measured by the analogue sensor exceeds

range of –30...+ °С.130

It is necessary: to check the integrity of the sensor and the

absence of mechanical damage to its circuit, the absence of

power wires that are laid close. Check if the colours are

correct when connecting the digital sensor. Make sure that

the appropriate type is selected in the sensor settings.

Features of the protection against internal overheating:

when the temperature inside the housing drops below

60 °C, the thermostat will resume operation. When

the protection is triggered more than 5 times in a row,

the thermostat will be blocked until the temperature inside

the housing drops below 60 °C and one of the buttons is

pressed.

The temperature controller has switched to the

Emergency Timer Mode. The symbol and

the remaining time until the next load on / off

flash on the screen

« »t

.

While the load is running, the symbol « »

t flashes

on the screen

Timer-based emergency operation mode (factory setting

15 min.)

« » «–»+

« » « »on oFF

This mode ensures the operation of the thermostat

in case of damage to the sensor: in a 30-minute cyclic

interval it turns on the load for the set time, the rest of the

time the load is turned off. The load operating time is

adjustable from 1 to 29 minutes using the or

buttons. To ensure continuous operation of the load, select

and to turn the load completely off, select .

Heating temperature control is not available.

The load of both channels does not work, the screen

flashes «oht»

The temperature inside the housing exceeded 80 °C, the

protection against internal overheating worked.

Possible cause: internal overheating of the thermostat,

which can be caused by: poor contact in the terminals of the

thermostat, high ambient temperature, exceeding the power

of the switching load, or the cross section of the wires for

connection is incorrectly selected.

It is necessary: to check the tightening of power wires in the

terminals of the thermostat, make sure that the switching

load power does not exceed the permissible one, the cross

section of the wires for connection are selected correctly.

Every 5 seconds the screen displays Ert« »

Possible cause: is a break or short circuit of the

internal overheating sensor. Internal

overheating is not monitored.

It is necessary: to send the thermostat to the service center.

Otherwise, overheating control will not be carried out.

To reset the factory settings, hold the three

buttons at the same time for more than 6 s

until message appears on the screen.

ec

«dEF»

After release it will reset to the factory settings

and reboot.

In order to enable (disable) button blocking

press the and buttons at the same

time for 6 seconds till the ( ) sign

appears on the screen.

«+» «–»

«Loc» «oFF»

(child and public protection)

Reset to the factory settings

Button blocking

It is necessary: make sure that the supply voltage is

available. If power supply is available, contact the Service

Center.

Load is off, screen and indicator are off

Possible cause: No power supply.

Table 1. FUNCTION MENU of the selected channel

1. XXh, where XX is the time in hours if the time is > 10 h.

Hold down button for on / off timer of the first channel and «+»

«–» button for on / off timer of the second channel for 4 seconds.

The screen displays zit dashes, then .« » « »ton toF /

This is the time during which the temperature different from set

main temperature will be maintained.

During operation, the screen alternately displays the time until

the end of the timer and the current temperature. The time is

displayed in the following format:

2. X.YY, where X is hours, YY is minutes if the time is < 10 h.

When the power is switched, the Timer is reset.

Avoid hitting of water or moisture to the device.

Carefully read and become aware of yourself these

instructions.

Connection of the device must be done by a qualified

electrician.

Do not switch the non assembled device to the network.

Do not immerse the sensor with a connecting wire in the

liquid medium.

Turning on and off or and configure the device should be

with dry hands.

Do not connect the device to the network disassembled.

Do not expose the device to extreme temperatures (higher

than 40 ºС or below 5 °C) and high humidity.

–

Do not connect 230 V mains voltage instead of the sensor

(it leads to failure of the thermostat).

Never clean the device with the use of chemicals such as

benzene, solvents.

Do not store the device and do not use it in areas with the

dust.

Do not attempt to disassemble and repair the device.

Do not exceed the landmarks value adaptor and power.

To protect against overvoltage caused by lightning

discharges, use a lightning protector.

Before the installation (dismantling) and connection

(disconnection) of the device, turn off voltage supply and

also act according to the «Rules of an arrangement of

electric installations».

Protect the children from games with the working device, it

is dangerous.

SAFETY INSTRUCTIONS

Low Voltage Directive 2014/35/E U

1 30 UEMC Directive 20 4/ /E

Manufacturer and vendor: DS ELECTRONICS, LTD

04136,

+38 (091) 1-91-8 , : +38 (091) 1-91-8

support@dse.com.ua www.ds-electronics.com.ua/en/

Ukraine, Kyiv region, Kyiv, 1–3 Pivnichno-Syretska str.

48 1 48 1Service Center

Transportation of goods carried in the package, ensuring

the safety of the product.

Do not fire and do not throw away the device with the

household waste.

After the end of its service life, the product must be

disposed of in accordance with applicable law.

The devi e is transported by any kind of transport (rail,

sea, motor, air transportation).

c

Date of manufacture is on the back side of device.

Application time is unlimited.

The device does not contain harmful substances.

If you have any questions or you something will not clear,

call the Service centre the telephone number listed below.

ADDITIONAL INFORMATION

POSSIBLE PROBLEMS, CAUSES

AND WAYS TO OVERCOME THEM

7

5 6

v2G328_2 09052

Menu section

« »≡

Press NotesScreen

If necessary, use the temperature correction on the thermostat

screen.

Correction of screen reading

( actory setting « », ±9,9 °С)f 0.0 range

Temporary temperature

maintenance timer

f .0( actory setting «1 »,

0,5...99,5 , 0,5 )range h step h

L toad work ime

counter ( )view

Temperature in timer mode

( actory setting «5.0», –20...+100 °С)f range

This is the temperature that the thermostat will maintain

in timer mode.

1 time

3 times

4 times

5 times

2 times

6 times

It allows you to calculate energy consumption trough

multiplying the operating time by the load power and t

he tariff. Displays the time (hours, minutes) using a running

line. To reset the counter while watching, press «–».

Hysteresis

step

( factory setting 1,0 °С,

0,1...10 , 0,1range °С )

This is the difference between the temperature of the load turn

on and off. The lower value of hysteresis allows you to

maintain the temperature more accurately, upper to save on

energy consumption and increase the service life of the relay

—

.by reducing the number of load switches

Heating / cooling modes

actory setting Hot( — )f

— heat,«Hot»

«CoL» — cooling.

Sensor type

( actory setting «1 »)f 0r

7 times Select the type of sensor you want to use:

: 2 3, 4 7, 6 8, 10 , 12 , 15 , 33 , 47 ,

— ,

: 18

analog r r r r r r r r where r

is kOhm at 25 °C

digital d .

Control of protection from frequent

switching of power relay

actory setting( « »)f don

If you want to disable protection, select «doF».8 times

EXPLOITATION

If the temperature is higher than the sensor

temperature, the load will turn on and the red indicator of

the corresponding channel will turn on.

preset

View firmware version

Hold down the button for 6 seconds. « »

≡ The manu-

facturer reserves the right to modify the firmware to

enhance the device technical characteristics.

5 seconds after the last pressing, the stat will

automatically return to the air temperature display.

thermo

Select the channel to be adjusted (« » « »Ch1 / Ch2 ): short

press and use the and buttons to select. «≡» «+» «–»

Use the middle button to navigate through the menu«≡»

(Table 1). Use the and buttons to change the

parameters. After pressing the button for the first time

the parameter will flash, after pressing it for the second

time the parameter will change.

«+» «–»

Preset temperature factory setting( 30 °С)

Use the «+»

«–»

«+» «–»

button to select the upper channel, and the

button for the lower channel. Changing the channel

temperature using the and buttons.

short circut — short circuit of the sensor circuit

open circut — sensor circuit break

Possible cause: damage to the sensor and its circuit,

incorrectly selected sensor type in the thermostat settings,

the temperature measured by the analogue sensor exceeds

range of –30...+ °С.130

It is necessary: to check the integrity of the sensor and the

absence of mechanical damage to its circuit, the absence of

power wires that are laid close. Check if the colours are

correct when connecting the digital sensor. Make sure that

the appropriate type is selected in the sensor settings.

Features of the protection against internal overheating:

when the temperature inside the housing drops below

60 °C, the thermostat will resume operation. When

the protection is triggered more than 5 times in a row,

the thermostat will be blocked until the temperature inside

the housing drops below 60 °C and one of the buttons is

pressed.

The temperature controller has switched to the

Emergency Timer Mode. The symbol and

the remaining time until the next load on / off

flash on the screen

« »t

.

While the load is running, the symbol « »

t flashes

on the screen

Timer-based emergency operation mode (factory setting

15 min.)

« » «–»+

« » « »on oFF

This mode ensures the operation of the thermostat

in case of damage to the sensor: in a 30-minute cyclic

interval it turns on the load for the set time, the rest of the

time the load is turned off. The load operating time is

adjustable from 1 to 29 minutes using the or

buttons. To ensure continuous operation of the load, select

and to turn the load completely off, select .

Heating temperature control is not available.

The load of both channels does not work, the screen

flashes «oht»

The temperature inside the housing exceeded 80 °C, the

protection against internal overheating worked.

Possible cause: internal overheating of the thermostat,

which can be caused by: poor contact in the terminals of the

thermostat, high ambient temperature, exceeding the power

of the switching load, or the cross section of the wires for

connection is incorrectly selected.

It is necessary: to check the tightening of power wires in the

terminals of the thermostat, make sure that the switching

load power does not exceed the permissible one, the cross

section of the wires for connection are selected correctly.

Every 5 seconds the screen displays Ert« »

Possible cause: is a break or short circuit of the

internal overheating sensor. Internal

overheating is not monitored.

It is necessary: to send the thermostat to the service center.

Otherwise, overheating control will not be carried out.

To reset the factory settings, hold the three

buttons at the same time for more than 6 s

until message appears on the screen.

ec

«dEF»

After release it will reset to the factory settings

and reboot.

In order to enable (disable) button blocking

press the and buttons at the same

time for 6 seconds till the ( ) sign

appears on the screen.

«+» «–»

«Loc» «oFF»

(child and public protection)

Reset to the factory settings

Button blocking

It is necessary: make sure that the supply voltage is

available. If power supply is available, contact the Service

Center.

Load is off, screen and indicator are off

Possible cause: No power supply.

Table 1. FUNCTION MENU of the selected channel

1. XXh, where XX is the time in hours if the time is > 10 h.

Hold down button for on / off timer of the first channel and «+»

«–» button for on / off timer of the second channel for 4 seconds.

The screen displays zit dashes, then .« » « »ton toF /

This is the time during which the temperature different from set

main temperature will be maintained.

During operation, the screen alternately displays the time until

the end of the timer and the current temperature. The time is

displayed in the following format:

2. X.YY, where X is hours, YY is minutes if the time is < 10 h.

When the power is switched, the Timer is reset.

Avoid hitting of water or moisture to the device.

Carefully read and become aware of yourself these

instructions.

Connection of the device must be done by a qualified

electrician.

Do not switch the non assembled device to the network.

Do not immerse the sensor with a connecting wire in the

liquid medium.

Turning on and off or and configure the device should be

with dry hands.

Do not connect the device to the network disassembled.

Do not expose the device to extreme temperatures (higher

than 40 ºС or below 5 °C) and high humidity.

–

Do not connect 230 V mains voltage instead of the sensor

(it leads to failure of the thermostat).

Never clean the device with the use of chemicals such as

benzene, solvents.

Do not store the device and do not use it in areas with the

dust.

Do not attempt to disassemble and repair the device.

Do not exceed the landmarks value adaptor and power.

To protect against overvoltage caused by lightning

discharges, use a lightning protector.

Before the installation (dismantling) and connection

(disconnection) of the device, turn off voltage supply and

also act according to the «Rules of an arrangement of

electric installations».

Protect the children from games with the working device, it

is dangerous.

SAFETY INSTRUCTIONS

Low Voltage Directive 2014/35/E U

1 30 UEMC Directive 20 4/ /E

Manufacturer and vendor: DS ELECTRONICS, LTD

04136,

+38 (091) 1-91-8 , : +38 (091) 1-91-8

support@dse.com.ua www.ds-electronics.com.ua/en/

Ukraine, Kyiv region, Kyiv, 1–3 Pivnichno-Syretska str.

48 1 48 1Service Center

Transportation of goods carried in the package, ensuring

the safety of the product.

Do not fire and do not throw away the device with the

household waste.

After the end of its service life, the product must be

disposed of in accordance with applicable law.

The devi e is transported by any kind of transport (rail,

sea, motor, air transportation).

c

Date of manufacture is on the back side of device.

Application time is unlimited.

The device does not contain harmful substances.

If you have any questions or you something will not clear,

call the Service centre the telephone number listed below.

ADDITIONAL INFORMATION

POSSIBLE PROBLEMS, CAUSES

AND WAYS TO OVERCOME THEM

7

5 6

v2G328_2 09052

Menu section

« »≡

Press NotesScreen

If necessary, use the temperature correction on the thermostat

screen.

Correction of screen reading

( actory setting « », ±9,9 °С)f 0.0 range

Temporary temperature

maintenance timer

f .0( actory setting «1 »,

0,5...99,5 , 0,5 )range h step h

L toad work ime

counter ( )view

Temperature in timer mode

( actory setting «5.0», –20...+100 °С)f range

This is the temperature that the thermostat will maintain

in timer mode.

1 time

3 times

4 times

5 times

2 times

6 times

It allows you to calculate energy consumption trough

multiplying the operating time by the load power and t

he tariff. Displays the time (hours, minutes) using a running

line. To reset the counter while watching, press «–».

Hysteresis

step

( factory setting 1,0 °С,

0,1...10 , 0,1range °С )

This is the difference between the temperature of the load turn

on and off. The lower value of hysteresis allows you to

maintain the temperature more accurately, upper to save on

energy consumption and increase the service life of the relay

—

.by reducing the number of load switches

Heating / cooling modes

actory setting Hot( — )f

— heat,«Hot»

«CoL» — cooling.

Sensor type

( actory setting «1 »)f 0r

7 times Select the type of sensor you want to use:

: 2 3, 4 7, 6 8, 10 , 12 , 15 , 33 , 47 ,

— ,

: 18

analog r r r r r r r r where r

is kOhm at 25 °C

digital d .

Control of protection from frequent

switching of power relay

actory setting( « »)f don

If you want to disable protection, select «doF».8 times

EXPLOITATION

If the temperature is higher than the sensor

temperature, the load will turn on and the red indicator of

the corresponding channel will turn on.

preset

View firmware version

Hold down the button for 6 seconds. « »

≡ The manu-

facturer reserves the right to modify the firmware to

enhance the device technical characteristics.

5 seconds after the last pressing, the stat will

automatically return to the air temperature display.

thermo

Select the channel to be adjusted (« » « »Ch1 / Ch2 ): short

press and use the and buttons to select. «≡» «+» «–»

Use the middle button to navigate through the menu«≡»

(Table 1). Use the and buttons to change the

parameters. After pressing the button for the first time

the parameter will flash, after pressing it for the second

time the parameter will change.

«+» «–»

Preset temperature factory setting( 30 °С)

Use the «+»

«–»

«+» «–»

button to select the upper channel, and the

button for the lower channel. Changing the channel

temperature using the and buttons.

short circut — short circuit of the sensor circuit

open circut — sensor circuit break

Possible cause: damage to the sensor and its circuit,

incorrectly selected sensor type in the thermostat settings,

the temperature measured by the analogue sensor exceeds

range of –30...+ °С.130

It is necessary: to check the integrity of the sensor and the

absence of mechanical damage to its circuit, the absence of

power wires that are laid close. Check if the colours are

correct when connecting the digital sensor. Make sure that

the appropriate type is selected in the sensor settings.

Features of the protection against internal overheating:

when the temperature inside the housing drops below

60 °C, the thermostat will resume operation. When

the protection is triggered more than 5 times in a row,

the thermostat will be blocked until the temperature inside

the housing drops below 60 °C and one of the buttons is

pressed.

The temperature controller has switched to the

Emergency Timer Mode. The symbol and

the remaining time until the next load on / off

flash on the screen

« »t

.

While the load is running, the symbol « »

t flashes

on the screen

Timer-based emergency operation mode (factory setting

15 min.)

« » «–»+

« » « »on oFF

This mode ensures the operation of the thermostat

in case of damage to the sensor: in a 30-minute cyclic

interval it turns on the load for the set time, the rest of the

time the load is turned off. The load operating time is

adjustable from 1 to 29 minutes using the or

buttons. To ensure continuous operation of the load, select

and to turn the load completely off, select .

Heating temperature control is not available.

The load of both channels does not work, the screen

flashes «oht»

The temperature inside the housing exceeded 80 °C, the

protection against internal overheating worked.

Possible cause: internal overheating of the thermostat,

which can be caused by: poor contact in the terminals of the

thermostat, high ambient temperature, exceeding the power

of the switching load, or the cross section of the wires for

connection is incorrectly selected.

It is necessary: to check the tightening of power wires in the

terminals of the thermostat, make sure that the switching

load power does not exceed the permissible one, the cross

section of the wires for connection are selected correctly.

Every 5 seconds the screen displays Ert« »

Possible cause: is a break or short circuit of the

internal overheating sensor. Internal

overheating is not monitored.

It is necessary: to send the thermostat to the service center.

Otherwise, overheating control will not be carried out.

To reset the factory settings, hold the three

buttons at the same time for more than 6 s

until message appears on the screen.

ec

«dEF»

After release it will reset to the factory settings

and reboot.

In order to enable (disable) button blocking

press the and buttons at the same

time for 6 seconds till the ( ) sign

appears on the screen.

«+» «–»

«Loc» «oFF»

(child and public protection)

Reset to the factory settings

Button blocking

It is necessary: make sure that the supply voltage is

available. If power supply is available, contact the Service

Center.

Load is off, screen and indicator are off

Possible cause: No power supply.

Table 1. FUNCTION MENU of the selected channel

1. XXh, where XX is the time in hours if the time is > 10 h.

Hold down button for on / off timer of the first channel and «+»

«–» button for on / off timer of the second channel for 4 seconds.

The screen displays zit dashes, then .« » « »ton toF /

This is the time during which the temperature different from set

main temperature will be maintained.

During operation, the screen alternately displays the time until

the end of the timer and the current temperature. The time is

displayed in the following format:

2. X.YY, where X is hours, YY is minutes if the time is < 10 h.

When the power is switched, the Timer is reset.

Avoid hitting of water or moisture to the device.

Carefully read and become aware of yourself these

instructions.

Connection of the device must be done by a qualified

electrician.

Do not switch the non assembled device to the network.

Do not immerse the sensor with a connecting wire in the

liquid medium.

Turning on and off or and configure the device should be

with dry hands.

Do not connect the device to the network disassembled.

Do not expose the device to extreme temperatures (higher

than 40 ºС or below 5 °C) and high humidity.

–

Do not connect 230 V mains voltage instead of the sensor

(it leads to failure of the thermostat).

Never clean the device with the use of chemicals such as

benzene, solvents.

Do not store the device and do not use it in areas with the

dust.

Do not attempt to disassemble and repair the device.

Do not exceed the landmarks value adaptor and power.

To protect against overvoltage caused by lightning

discharges, use a lightning protector.

Before the installation (dismantling) and connection

(disconnection) of the device, turn off voltage supply and

also act according to the «Rules of an arrangement of

electric installations».

Protect the children from games with the working device, it

is dangerous.

SAFETY INSTRUCTIONS

Low Voltage Directive 2014/35/E U

1 30 UEMC Directive 20 4/ /E

Manufacturer and vendor: DS ELECTRONICS, LTD

04136,

+38 (091) 1-91-8 , : +38 (091) 1-91-8

support@dse.com.ua www.ds-electronics.com.ua/en/

Ukraine, Kyiv region, Kyiv, 1–3 Pivnichno-Syretska str.

48 1 48 1Service Center

Transportation of goods carried in the package, ensuring

the safety of the product.

Do not fire and do not throw away the device with the

household waste.

After the end of its service life, the product must be

disposed of in accordance with applicable law.

The devi e is transported by any kind of transport (rail,

sea, motor, air transportation).

c

Date of manufacture is on the back side of device.

Application time is unlimited.

The device does not contain harmful substances.

If you have any questions or you something will not clear,

call the Service centre the telephone number listed below.

ADDITIONAL INFORMATION

POSSIBLE PROBLEMS, CAUSES

AND WAYS TO OVERCOME THEM

7

5 6

v2G328_2 09052

Menu section

« »≡

Press NotesScreen

If necessary, use the temperature correction on the thermostat

screen.

Correction of screen reading

( actory setting « », ±9,9 °С)f 0.0 range

Temporary temperature

maintenance timer

f .0( actory setting «1 »,

0,5...99,5 , 0,5 )range h step h

L toad work ime

counter ( )view

Temperature in timer mode

( actory setting «5.0», –20...+100 °С)f range

This is the temperature that the thermostat will maintain

in timer mode.

1 time

3 times

4 times

5 times

2 times

6 times

It allows you to calculate energy consumption trough

multiplying the operating time by the load power and t

he tariff. Displays the time (hours, minutes) using a running

line. To reset the counter while watching, press «–».

Hysteresis

step

( factory setting 1,0 °С,

0,1...10 , 0,1range °С )

This is the difference between the temperature of the load turn

on and off. The lower value of hysteresis allows you to

maintain the temperature more accurately, upper to save on

energy consumption and increase the service life of the relay

—

.by reducing the number of load switches

Heating / cooling modes

actory setting Hot( — )f

— heat,«Hot»

«CoL» — cooling.

Sensor type

( actory setting «1 »)f 0r

7 times Select the type of sensor you want to use:

: 2 3, 4 7, 6 8, 10 , 12 , 15 , 33 , 47 ,

— ,

: 18

analog r r r r r r r r where r

is kOhm at 25 °C

digital d .

Control of protection from frequent

switching of power relay

actory setting( « »)f don

If you want to disable protection, select «doF».8 times

EXPLOITATION

If the temperature is higher than the sensor

temperature, the load will turn on and the red indicator of

the corresponding channel will turn on.

preset

View firmware version

Hold down the button for 6 seconds. « »

≡ The manu-

facturer reserves the right to modify the firmware to

enhance the device technical characteristics.

5 seconds after the last pressing, the stat will

automatically return to the air temperature display.

thermo

Select the channel to be adjusted (« » « »Ch1 / Ch2 ): short

press and use the and buttons to select. «≡» «+» «–»

Use the middle button to navigate through the menu«≡»

(Table 1). Use the and buttons to change the

parameters. After pressing the button for the first time

the parameter will flash, after pressing it for the second

time the parameter will change.

«+» «–»

Preset temperature factory setting( 30 °С)

Use the «+»

«–»

«+» «–»

button to select the upper channel, and the

button for the lower channel. Changing the channel

temperature using the and buttons.

short circut — short circuit of the sensor circuit

open circut — sensor circuit break

Possible cause: damage to the sensor and its circuit,