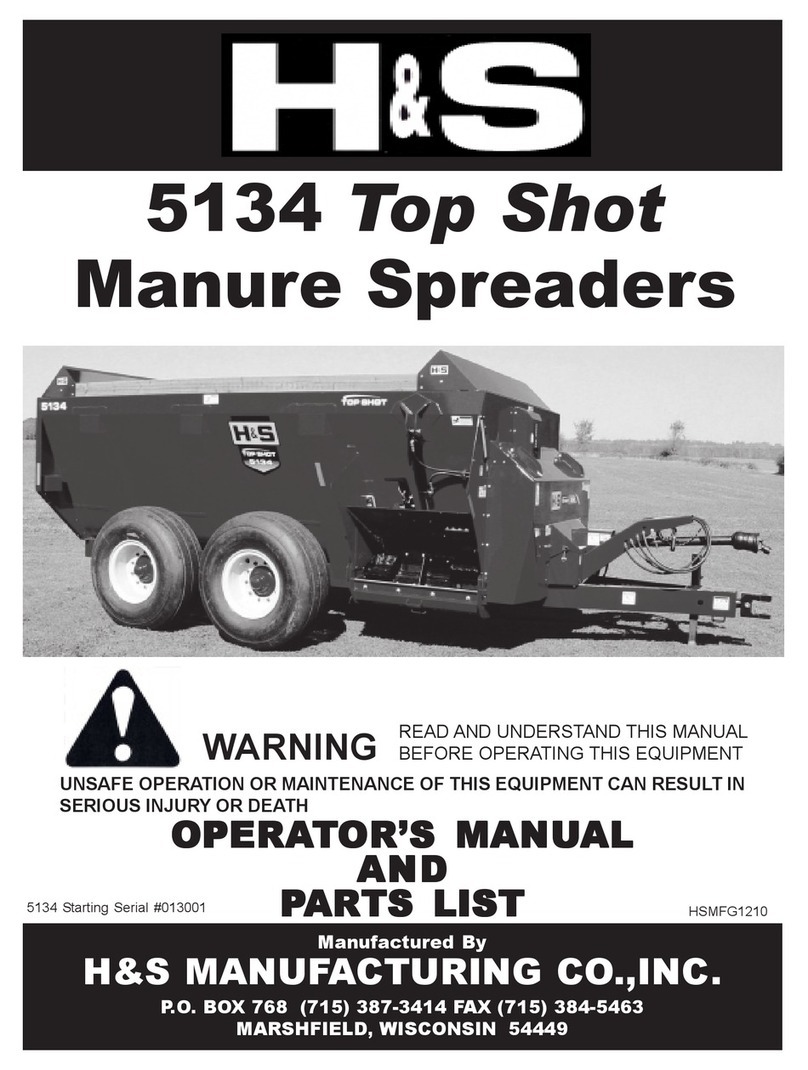

TerraKing 45-0592 User manual

OPERATOR’S MANUAL

5 cu ft Drop Spreader

45-0592 and 45-0593

04/05/22

For your safety, please read and save all

safety and operating instructions prior to

using equipment.

GREY

PMS 427

CMYK C19 M15 Y16 K0

RGB R204 G204 B204

Hex #CCCCCC

Threa Light Ash

BLUE

PMS 647

CMYK C91 M60 Y4 K0

RGB R20 G103 B172

Hex #1268AC

Thread Farm Blue

ORANGE

PMS 715

CMYK C0 M69 Y98 K0

RGB R243 G113 B33

Hex #F37121

Thread Tennessee Orange

BLACK

PMS TBD

CMYK C0 M0 Y0 K100

RGB R0 G0 B0

Hex #000000

Thread Black

GREY

PMS 428

CMYK C27 M17 Y17 K0

RGB R195 G197 B200

Hex #c3c5c8

Thread Light Gray

BLUE

PMS 287

CMYK C100 M87 Y20 K10

RGB R32 G61 B124

Hex #203d7c

Thread Dark Royal

GOLD

PMS 3965

CMYK C1 M14 Y99 K0

RGB R254 G212 B2

Hex #231f20

Thread NFL Yellow

2

Read Safety in Machine Operator’s Manual

Read the general safety operating precautions in

your machine operator’s manual for additional safety

information.

Operating Safely

• Read the machine and attachment operator’s manual

carefully. Be thoroughly familiar with the controls and

the proper use of the equipment. Know how to stop

the machine and disengage the controls quickly.

• Do not modify machine or safety devices.

Unauthorized modications to the machine of

attachment may impair its function and safety.

• Do not let children or an untrained person operate

machine.

• Make any necessary adjustments before you operate.

Never attempt to make any adjustments while

the engine is running, unless if recommended in

adjustment procedure.

• Look behind machine before you back up.

Back up carefully.

• Do not let anyone, especially children, ride on

machine or attachment. Riders are subject to injury

such as being struck by foreign objects and being

thrown o. Riders may also obstruct the operator’s

view, resulting in the machine being operated in an

unsafe manner.

• Disengage any power to the attachment when the

machine is transported or not in use.

• Never exceed 15 mph when loaded spreader is

attached to vehicle. Braking distances may be

reduced and handling characteristics may be impaired

at speeds above 15 mph.

• Never use wet materials or materials with foreign

debris in the spreader. This unit is designed to spread

dry, clean, free-owing material.

• Never leave material in hopper when not in use.

Practice Safe Maintenance

• Only qualied, trained adults should service this

machine.

• Understand service procedure before doing work.

Keep area clean and dry.

• Do not operate the engine in a conrmed space where

dangerous carbon monoxide fumes can collect.

• Never lubricate, service or adjust the machine or

attachment while it is moving. Keep safety devices in

place and in working condition. Keep hardware tight.

• Keep hands, feet, clothing, jewelry, and long hair away

from any moving parts, to prevent them from getting

caught.

• Lower any attachment completely to the ground or

to an existing attachment mechanical stop before

servicing the attachment. Disengage all power and

stop the engine. Lock park brake and remove the key.

Let machine cool.

• Disconnect battery or remove spark plug wire (for

gasoline engines) before making any repairs.

• Before servicing machine or attachment, carefully

release pressure from any components with stored

energy, such as hydraulic components and springs.

• Release hydraulic pressure by lowering attachment or

cutting units to the ground or to a mechanical stop and

move hydraulic control levers.

• Securely support any machine or attachment

elements that must be raised for service work.

Use jack stands or lock service latches to support

components when needed.

• Never run engine unless park brake is locked.

• Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken

parts. Replace all worn or damaged safety and

instruction decals.

• Check all hardware at frequent intervals to be sure the

equipment is in safe working condition.

• Do not modify machine or safety devices.

Unauthorized modications to the machine or

attachments may impair its function and safety.

Wear Appropriate Clothing

• Always wear eye protection when operating the

machine.

• Wear close tting clothing and safety equipment

appropriate for the job.

• Wear a suitable protective device such as earplug.

Loud noise can cause impairment or loss of hearing.

Safety

3

Read Chemical Container Label

• Chemicals can be dangerous. Improper selection or

use can injure persons, animals, plants, soils or other

property. Select the right chemical for the job and

handle and apply with care.

• Read the instructions, precautions, and warnings on

the container label before opening. Use the product

strictly according to label directions for specic

applications, in the amounts specied, at the times

specied and only when needed.

• Keep the container closed tightly except when

preparing the mix.

• Do not remove labels from chemical containers. Store

all chemicals in their original containers.

• Do not mix chemicals unless stated on the container

label.

• Store chemicals when not in use according to the

container label.

Handle Chemical Products Safely

• Direct exposure to hazardous chemicals can cause

serious injury. Potentially hazardous chemicals used

with equipment include pesticides, herbicides and

fungicides.

• A Material Safety Data Sheet (MSDS) provides

specic details on chemical products: Physical and

health hazards, safety procedures, and emergency

response techniques.

• The MSDS should be obtained from the chemical

dealer at the time of the chemical purchase.

• Check the MSDS before beginning any job using a

hazardous chemical. Know exactly what the risks

are and how to do the job safely. Always wear

recommended personal protection equipment.

Handling Waste Product and Chemicals

Waste products, such as, used oil, fuel, coolant, brake

uid, and batteries, can harm the environment and people:

• Do not use beverage containers for waste

uids - someone may drink from them.

• See your Recycling Center or authorized dealer to

learn how recycle or get rid of waste products.

• A Material Safety Data Sheet (MSDS) provides

specic details on chemical products: Physical and

health hazards, safety procedures, and emergency

response techniques. The seller of the chemical

products used with your machine is responsible for

providing the MSDS for that product.

Safety

4

Safety

Safety Labels

Safety Label Location

350 lbs

ST50400

TO AVOID INJURY,

DO NOT RIDE

ON PLATFORM

ST50569

Understanding The Machine Safety Labels

The machine safety labels shown in this

section are placed in important areas on

your machine to draw attention to potential

safety hazards.

On your machine safety labels, the words DANGER,

WARNING, and CAUTION are used with this safety-alert

symbol. DANGER identifies the most serious hazards.

The operator’s manual also explains any

potential safety hazards whenever necessary

in special messages that are identified with the

word, CAUTION, and the safety-alert symbol.

Replace missing or damaged safety labels. Use this

operator’s manual for correct safety label placement.

There can be more safety information contained on

parts and components sourced from suppliers that is

not reproduced in this operator’s manual.

French or Spanish Safety Labels and

Operator’s Manual

Operator’s manuals and safety labels with content in

French or Spanish are available for this machine through

authorized John Deere dealers.

Warning

Avoid Injury From Moving Parts

• Keep hands, feet and clothing away

• Disconnect power before servicing

5

Parts in Kit

Wiring Kit

The serial number label (A) is located on the lower front

right side as shown above.

Machine Requirements

2” Receiver

Maximum drop spreader weight is 540 lbs. Vehicle’s

receiver hitch must be rated accordingly to prevent

damage to vehicle and drop spreader.

3 Point Hitch

Requires category 1 three point hitch. If no front

attachment is installed on vehicle, ballast may be

required to stabilize vehicle. Refer to vehicle manual

for proper ballasting.

A

Qty Description

1 Spreader

Qty Description

1 Display

1 Battery Harness

1 Extension Harness

1 Display Harness

1 Mounting Bracket

1 P Clamp

Caution

Avoid Injury and Read Operator Manual Before Use

• Never remove spreader with material in hopper

• Maximum weight capacity 350 lb.

Caution

To Avoid injury, do not ride on platform

Safety Labels

ST50569

350 lbs

ST50400

6

Install Handle

1. Locate handle and hardware inside the parts bag

2. Attach handle to outside of Auger tray with the bolts

inserted from the inside and flange nuts on the outside as

shown in Figure 1

3. Tighten hardware using ½” wrench or socket

Install Display and Wiring

Mount display in a location that is convenient for the

operator using either the included bracket, p-clamps or

M5 screws and washers.

Starting at the battery, connect the ring terminals on

the battery harness to the battery (red positive, black

negative). Connect extension harness to the battery

harness and route the extension harness towards the

3 point hitch or 2” receiver securing the harness to the

vehicle along the way. ensure the harness does not

contact any moving or high temperature components.

Secure the connector on the free end of the extension

harness in the convenient location that is easily accessible

in order to connect/disconnect the spreader. Coil any extra

harness and secure with wire ties.

Connect the circular connector on the display harness to

the rear of the display. Hand tighten until is fully seated.

DO NOT over tighten/ DO NOT cross thread. Route the

display harness to the same location as the free end of

the extension harness. Coil any extra harness and secure

with wire ties.

Installing

Locate a 12V signal / circuit that is behind the key switch

(only powered when the key is turn to run or acc). Route

the single wire in the display harness to this location and

secure to the vehicle along the way with wire ties. Extra

harness can be removed or coiled and secured with

wire ties. Connect the single wire to the circuit using a

suitable connection. A wire splice is included in the kit for

convenience.

Mount Spreader to Vehicle

Mount the spreader to the 3 point hitch or 2” receiver.

Use the handles located on the hopper side panels to lift

into position and secure in place. It is recommended that

2 people lift the spreader into place.

Connect the 2 connectors on the harness attached to the

spreader to the free end of the extension harness and

display harness.

7

Spreader Feature

Turning On Display

The vehicle key must be in the “On” or “Run” position for

the display to turn on.

When turned on, a splash screen will appear as the

software loads. The operation page will appear when

loading is complete. The spreader is now ready to operate.

Navigation

Control the spreader using the buttons on the display.

Button functionality is described in the table below and

varies by screen.

Operation

Auger Reverse/Jam Clear

Error Message/Diagnostics

Vibratory motor for improved material ow

Variable Speed Auger

Adjustable gate for precise material application

From the operation page, an operator can power on the

spreader, enter the menu, or spinner speed.

Button # Button Functions

1ON Spinner/

Auger On

Press the “ON”

button to turn on the

auger.

2OFF Spinner/

Auger O

Press the “OFF”

button to turn o the

auger.

3OPEN/

ON

Gate Open/

Vibe ON

Press the OPEN/ON

button to turn on the

vibratory motor.

4CLOSE/

OFF

Gate

Close/Vibe

OFF

Press the CLOSE/

OFF button to turn o

the vibratory motor.

5Down

Arrow

Press to decrease

the speed of the

auger.

6Up Arrow Press to increase the

speed of the auger.

7MENU Menu

Button

Press to enter the

menu.

8

NOTE: In order to control the Gate/Vibratory Motor

the Spinner/Auger must be active, if it is not active the

Gate/Vibe label state will blink indicating the motor is

disabled.

Main Menu

Pressing the menu button will enter the main menu.

Once in the main menu, the user can select the following:

Operation

Default Motor Controls

Starting and

Stopping Spreader

Press the ON button to turn on

the spinner/auger.

Press the OFF button to turn o

the spinner/auger

Gate/Vibe Control Press the OPEN/ON button to

open the gate or to turn on the

vibe.

Press the CLOSE/OFF button to

close the gate or to turn o the

vibe.

Adjusting Motor

Speed

Press the bottom left button

(down arrow) to decrease the

speed of the motor in 11%

increments.

Press the bottom mid button (up

arrow) to increase the speed of

the motor in 11% increments.

Entering the Menu Press the bottom right button

(menu) to enter the menu.

Maintenance Menu

Reverse Auger

The reverse auger feature allows users to reverse the

auger in case of a jam.

To activate the reverse auger feature:

1. Select maintenance for the main menu.

2. Press start. The auger will pulse 3 times and the start

button changes to pulsing to indicate the auger is

turning.

3. If the auger needs to be reversed further, press start

again and wait for the reverse cycle to complete.

4. Press the exit button to return to the main menu.

5. If jam cannot be cleared, refer to cleaning auger

section

Menu Options

Diagnostics Review the warning and fault list.

Maintenance Displays maintenance menu with

options to reverse auger.

Settings Adjusts the parameters of the display.

System Display system’s voltage and

temperature.

Support Displays support information.

Controller Info Displays controller information

Display Info Displays system information.

Exit Returns to the home page.

9

Display Screen Messages

During operation a message may appear describing a

potential issue or problem.

Motor Over Current A motor is drawing too

much current. Spreader will

shut down, display an error

message, and prompt the

operator to reset the spreader.

The spinner disk may be

jammed and needs to be

cleared.

Motor Open Circuit This message is displayed

when a motor is disconnected.

Ensure that all harnesses

are installed correctly, and

connectors are fully seated.

Ensure that the status light on

the motor controller is green.

Voltage High This message is displayed

when the controller is receiving

a voltage higher than 16V.

Please check battery voltage.

Voltage low This message is displayed

when the controller is receiving

a voltage lower than 9V. Please

check battery voltage.

No Comm This message is displayed

when there is a loss of

communication with the

motor controller. Ensure that

all harnesses are installed

correctly, and connectors

are fully seated. Ensure that

the status light on the motor

controller is green.

Spreading

NOTE: Always use the hopper cover to prevent moisture

buildup. Do not let spreader sit idle with material in the

hopper for an extended period of time. This can cause

material to compact, reduce or stop the ow of material and

cause permanent hopper damage.

CAUTION: DO NOT leave unused material

in hopper. Material can freeze or solidify,

causing unit to not work properly. Empty

and clean after each use.

IMPORTANT: Never operate near pedestrians.

Never exceed 10 mph while spreading. This

spreader is for rock salt, ice melt, fertilizer or

lime only.

CAUTION: Disconnect electric and/or

hydraulic power and tag out if required

before servicing or performing maintenance.

Settings Menu

Selecting settings from the main menu will enter the

settings menu.

From the settings menu, the user can select the following:

• Display to select the brightness level.

• CAN, to enable/disable the CAN terminator resistor.

• Exit, go back to main menu.

Operation

10

To calculate application rate

• Determine the vehicle speed that will be used.

• Place the container on a scale and make note of the

weight or tare the scale.

• Measure the weight / mass of the material spread

in 30 seconds. Subtract the weight / mass of

the container.

• Divide lbs measured in 30 seconds by the intended

speed of the vehicle in mph, and multiply by 6.06 to

get lbs per 1000 ft².

Metering Gate Adjustment

To adjust the opening on the metering gate, squeeze

lever(A) downward and rotate handle(B) to desired

opening. There are 6 gate positions, each position

increments the gate by approximately 1/4”.

Preventing and Clearing blockages

Material flows best when material is free of large clumps.

If a blockage occurs or material is not spreading, proceed

with the following steps until the blockage is cleared.

1. Open the metering gate to a larger position and

attempt to spread material again.

2. Turn on the vibrator to help break apart any clumps

of material and help the material to flow into the rotor

tray. Attempt to spread again.

3. If the rotor is stalled and jammed. Disconnect the

spreader harness from the control box. Follow the

steps in the cleaning the rotor section.

4. Disconnect power from the spreader. Remove lid and

open top grate. Remove any clumped material from

the hopper

Maintenance

Before performing any maintenance, turn off the spreader

and park machine safely (see Parking Safely in the

Safety section). Unplug the spreader harness from the

control box.

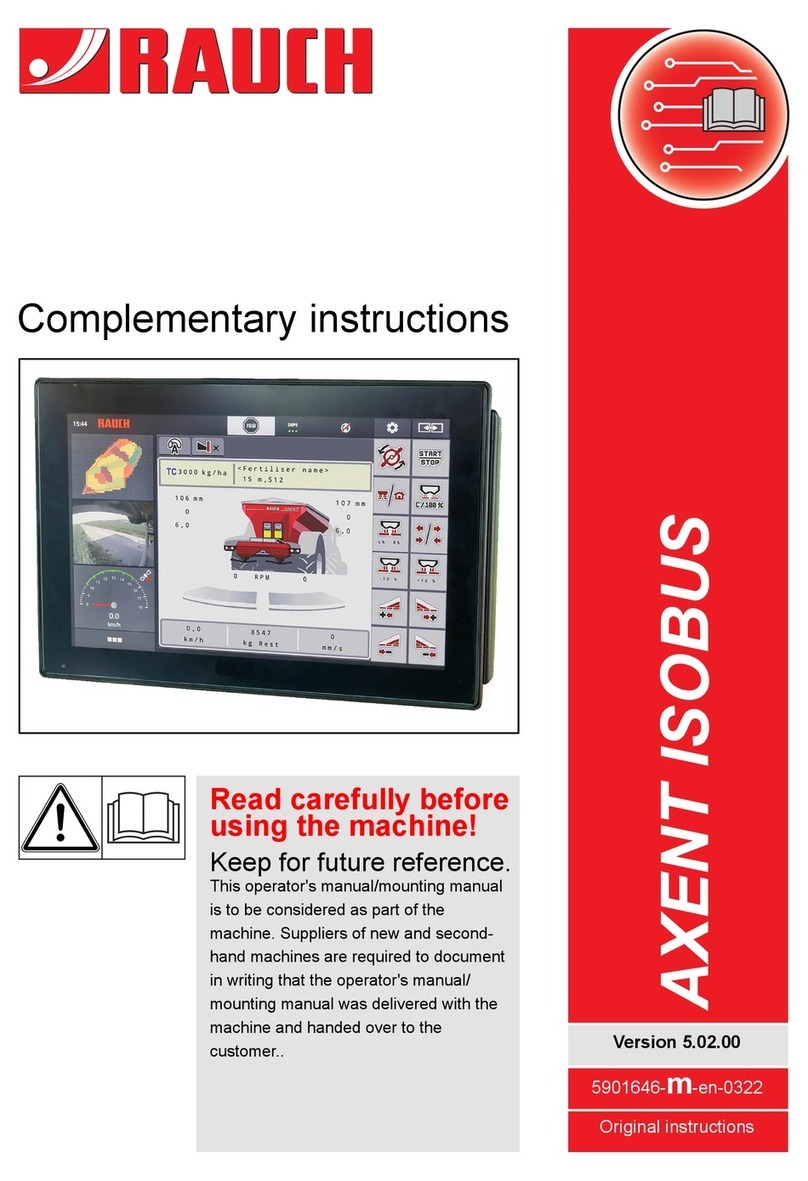

Cleaning Rotor

To clean the rotor area, do not reach down from the top of

the machine. The tray housing the rotor is removable.

1. Disconnect the power cord (A) to the drive motor.

2. Lock out the pins (B) on both sides of the machine.

When the second pin is pulled, the rear of the

tray will drop.

NOTE: It is recommended two people remove the

rotor assembly

3. Lift pivot bolts (C) off the hooks (D) and the rotor can

be removed for cleaning. (Left side shown above)

Operation

A

B

lbs per 30 seconds

intended vehicle speed in mph

lbs

1000ft2

x 6.06 =

kg per 30 seconds

intended vehicle speed in kmph

kg

1000m2

x 3.5 =

A

B

C

D

11

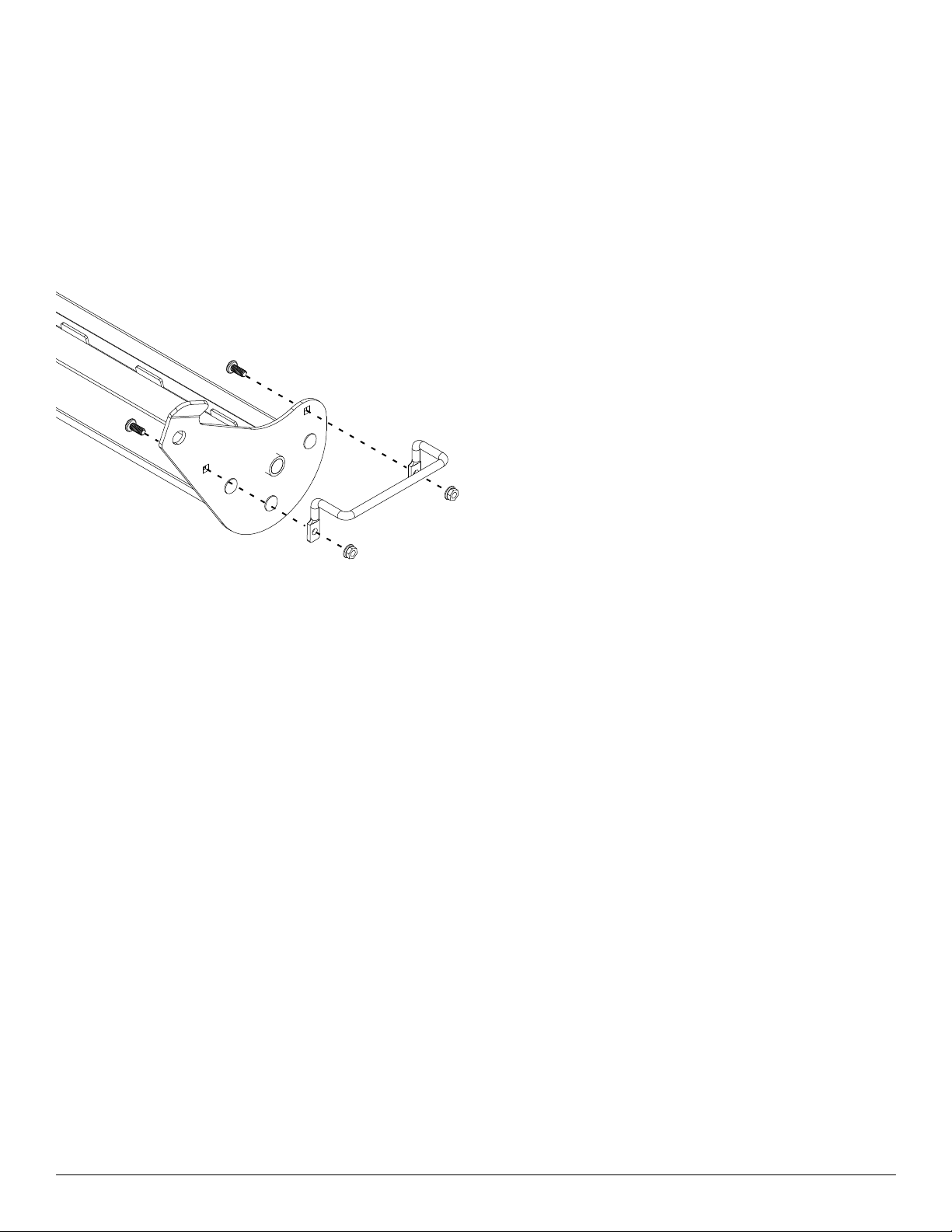

Adjusting Chain Tension

4. Remove bolt (E) and lift bottom of shield until it is

rotated about 90° and pull out.

5. Loosen three bolts (F) and slide the motor mount plate

rearward. The slack-side (G) tension should be 1/4” to

5/16” (6mm to 8mm) of midspan movement.

Re-tighten three bolts.

Chain Lubrication

Schedule chain lubrication:

• Apply lubrication upon removal from storage

• Reapply lubrication every 20 hours of use

• Apply lubrication prior to storage

Cleaning

To protect from corrosion, clean spreader after every use

with warm water and mild detergent.

Do not leave material in the spreader.

Maintenance

E

1/4” to 5/16”

F

G

Volume...................................................5 cu ft (.14 cu m)

Material Capacity.....................................350 lbs (159 kg)

Weight (empty, 3 point)..............................191 lbs (87 kg)

Weight (empty, 2” receiver)........................180 lbs (82 kg)

Weight (maximum, full)............................540 lbs (245 kg)

Weight of rotor tray.......................................48 lbs (22 kg)

Width..........................................................49 in (125 cm)

Depth (3 point)..............................................25 in (64 cm)

Depth (2” receiver)........................................31 in (79 cm)

Height...........................................................28 in (71 cm)

Spreading Width.........................................43 in (109 cm)

Electrical........................................................12 volt / 25A

Specifications

12

2

3

4

6

10

5

11

8

7

11

10

1

9

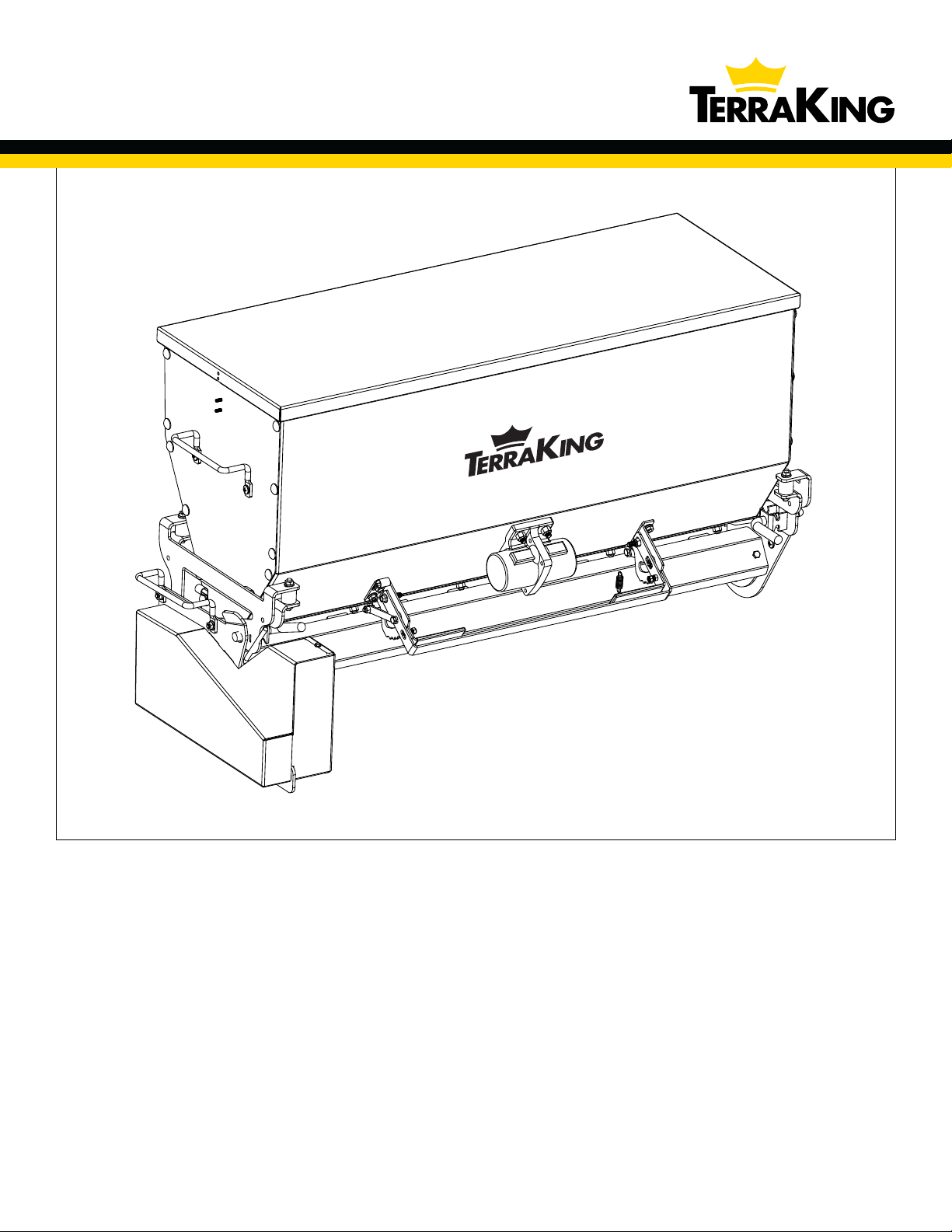

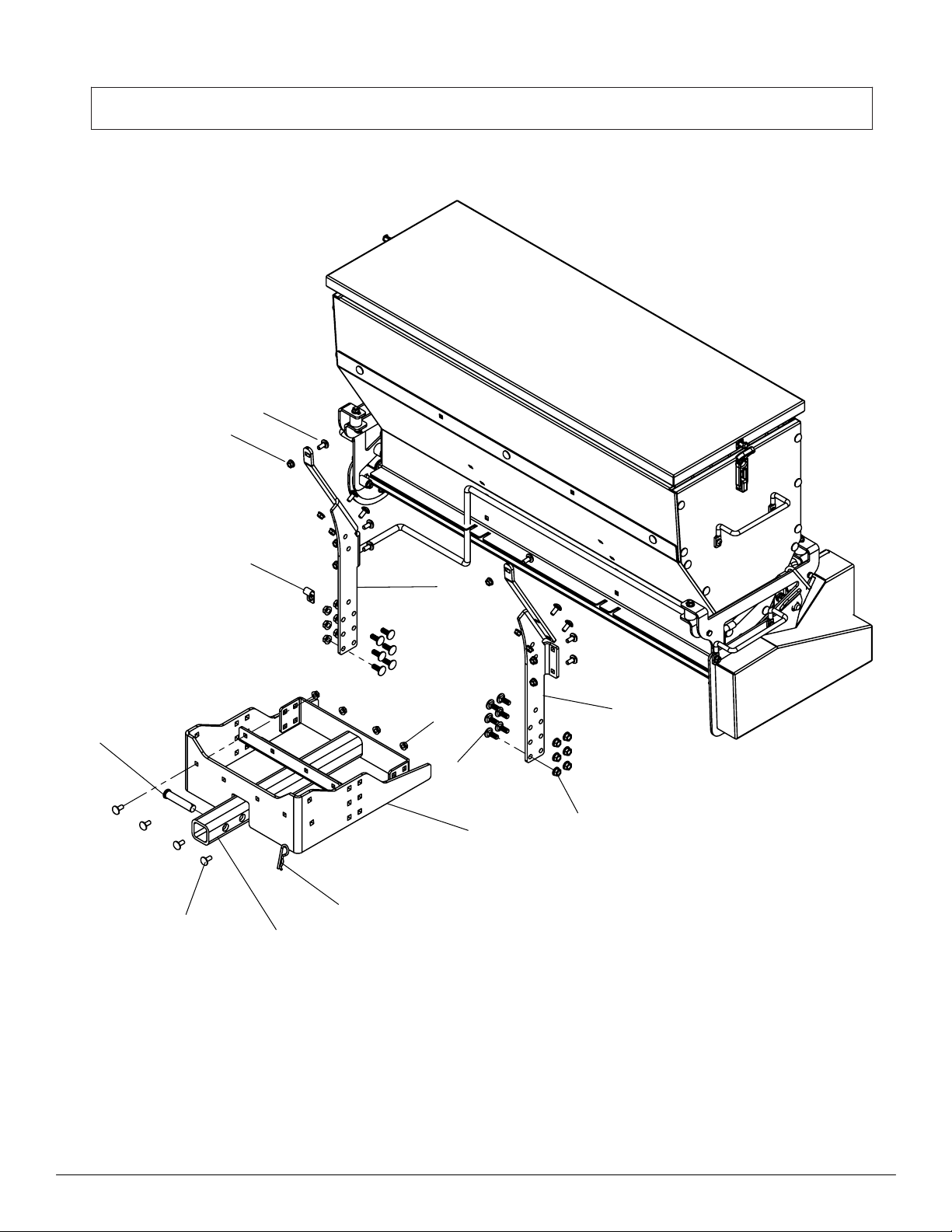

45-0593 Drop Spreader 2-In. Receiver

13

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

ST50454

Leg, Frame

1

2

ST50455

Leg, Frame

1

3

ST50533

Base, Regular profile

1

4

ST50531

2" Receiver Assembly

1

5

ST50373

Clevis Pin ø5/8" x 3"

1

6

ST43469

Spring Cotter Pin

1

7

ST50468

Clamp, 1/2"ID x .75W Vinyl Coated

1

8

ST65136

Bolt, 3/8" x 1" Carriage S.S.

12

9

ST65126

Nut, 3/8" Flange S.S.

12

10

ST65122

Bolt, 5/16" x 3/4" Carriage S.S.

14

11

ST65124

Nut, 5/16" Flange S.S.

14

Not Shown

ST50306

Spreader Safety Label

2

Not Shown

ST50400

Read Manual Label

2

Not Shown

ST50569

Do Not Ride Label

1

Not Shown

ST50251

TerraKing Label

1

Not Shown

ST50552

Reflective DOT-C2 Tape

2

14

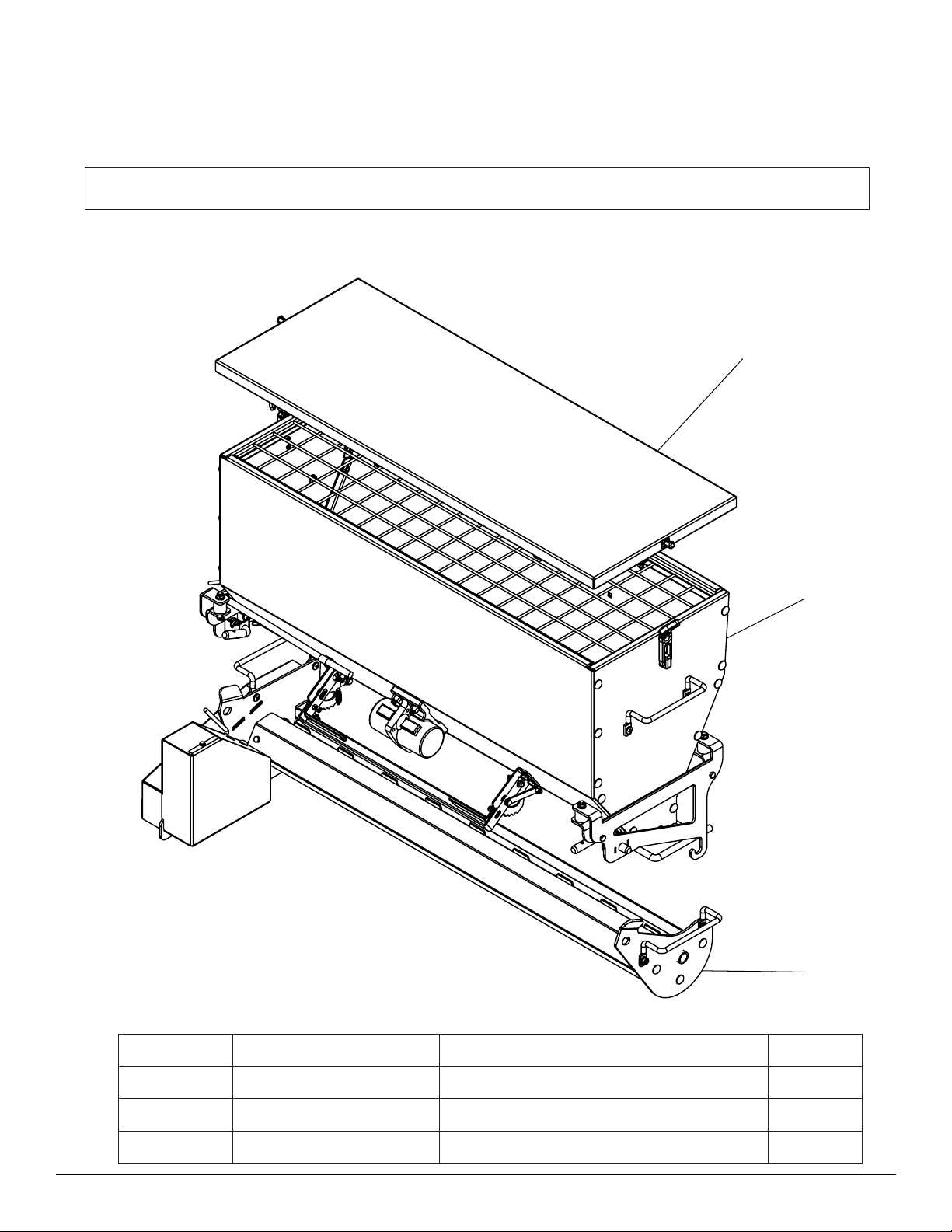

45-0592 - Drop Spreader with 3-Pt. Hitch Mount

3

7 8

4 5

10

2

1

6

11

12

9

13

14

15

17

16

15

45-0592

REVISION HISTORY

Rev. B 03/24/2022

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

ST50454

Frame, Right Leg

1

2

ST50455

Frame, Left Leg

1

3

ST61500

3 Point Hitch A Frame

1

4

ST50533

Frame Base

1

5

ST50527

Frame Spacer

2

6

ST50464

3 Point Hitch Brace

2

7

ST43399

Top Pin, Cat 1

1

8

ST43398

Lynch Pin

3

9

ST50468

Clamp, 1/2"ID x .75W Vinyl Coated

1

10

ST65135

3/8" x 1-1/4" Carriage Bolt S.S.

4

11

ST65136

3/8" x 1" Carriage Bolt S.S.

16

12

ST65126

Nut, 3/8" Flange S.S.

20

13

ST65122

Bolt, 5/16" x 3/4" Carriage S.S.

10

14

ST65124

Nut, 5/16" Flange S.S.

10

15

ST50565

SMV Holder Bracket

1

16

ST50583

SMV mounting spade & Hardware

1

17

ST43647

SMV Sign

1

2

2

2

1

Not Shown

Not Shown

Not Shown

Not Shown

Not Shown

ST50552

Reflective DOT-C2 Tape

ST50306

Spreader Safety Label

ST50400

Read Manual Label

ST50569

Do Not Ride Label

ST50251

TerraKing Label

1

16

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

SA10018

Hopper Assembly

1

2

ST50478

Tray Assembly

1

3

ST50432

Lid Assembly

1

3

1

2

Drop Spreader Assemblies

REVISION HISTORY

Rev. A 10/27/2021

17

This Page Intentionally Left Blank

18

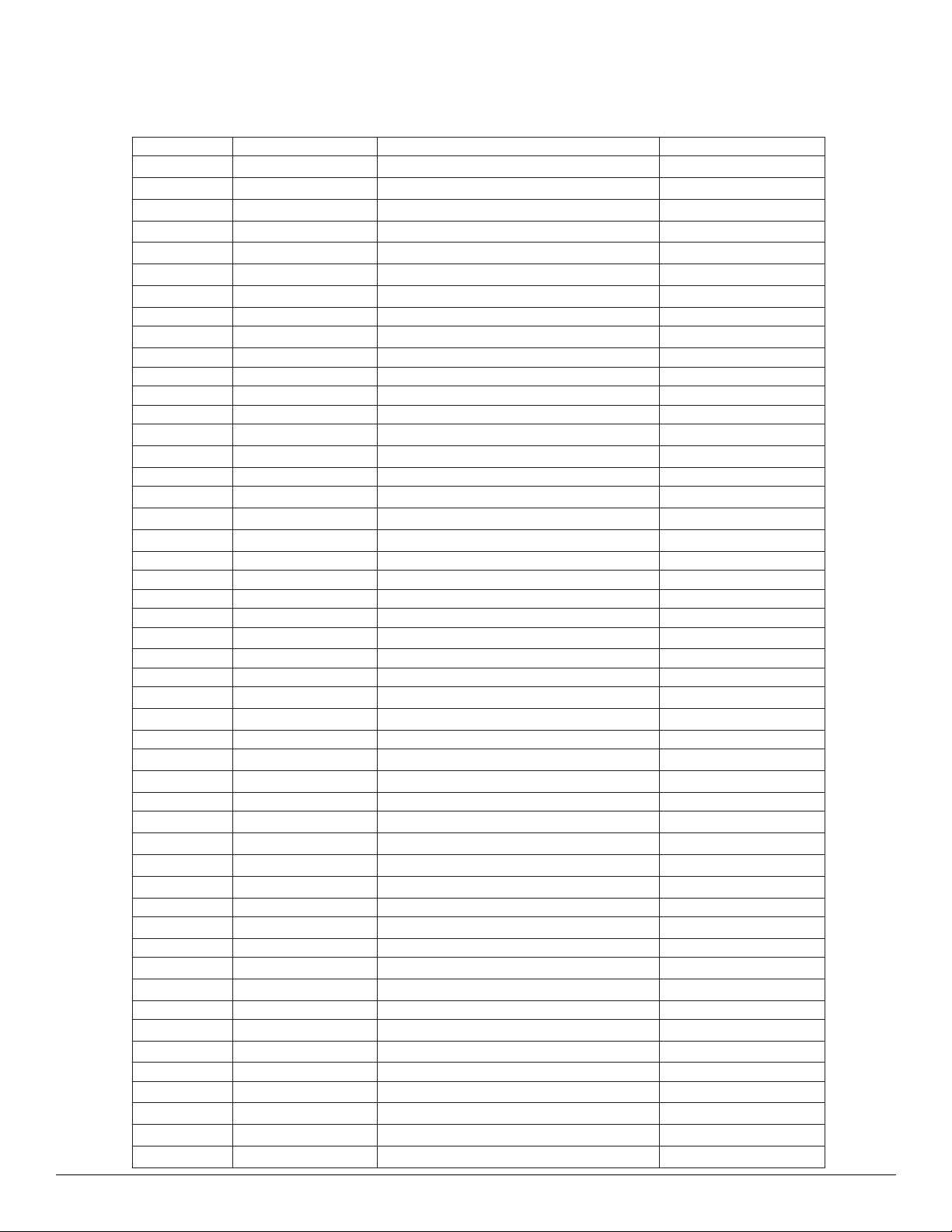

SA10018 - Drop Spreader Hopper Assembly

7

36

23

22

35

41 39 19

38

28

34

14

13

12

29

11

18

30

40

20

21

19 39

4

9

26

24 15

37

27

10

32

25

5

42

39

17

38 16

1

2

42

33

25

10

6

24

15

26

37

3

8

31

43

44

38

19

Motor Controller

SA10028

ITEM NO.

PART NUMBER

DESCRIPTION

Standard/QTY.

1

ST50827

Wall, Front Lower Hopper

1

2

ST50410

Wall, Front Upper Hopper

1

3

ST50408

Wall, Left Hopper

1

4

ST50412

Wall, Back Hopper

1

5

ST50409

Wall, Right Hopper

1

6

ST50479

Left Tray Hanger

1

7

ST50480

Right Tray Hanger

1

8

ST50425

Base, Vibration Mount Left

1

9

ST50426

Base, Vibration Mount Right

1

10

ST50447

Handle

2

11

ST50825

Vibrator, 40 Ibf

1

12

ST50557

Gate Handle

1

13

ST50558

Gate Latch Lever

2

14

ST50561

Handle Grip

2

15

ST50360

Spring

2

16

ST50450

Grate

1

17

ST50453

Clip

2

18

ST50449

Spring

2

19

ST50562

Linkage

2

20

ST50559

Selector, Gate Position

1

21

ST50560

Selector, Gate Position

1

22

ST50437

Gate, Flow Control

1

23

ST50436

Shoulder Washer USA

6

24

ST50359

Locking Pin 5/8"dia S.S

2

25

ST50451

Rubber Latch

2

26

ST50423

Rubber Isolator

4

27

ST50424

Rubber Bumper

2

28

ST50468

Clamp, 1/2"ID x .75W Vinyl Coated

3

29

ST65138

3/8" x 1-1/4" S.S Hex Bolt

4

30

ST65127

Nut, 3/8" Nylock S.S.

4

31

ST65146

Cap Screw 5/16" x 1-1/4" S.S.

2

32

ST65137

Pan Head Phil.#4 5/16"-18 x 3/4" S.S.

4

33

ST65121

Bolt, 5/16" x 1/2" Short Neck Carriage S.S

26

34

ST65124

Nut, 5/16" Flange S.S.

47

35

ST65122

Bolt, 5/16" x 3/4" Carriage S.S.

13

36

ST65099

Nut, 5/16"-18 Nylock S.S.

8

37

ST65168

1/4" x 1-1/2" S.S. Hex Bolt

4

38

ST65115

1/4"-20 S.S. Nylon Lock Nut

14

39

ST65120

Bolt, 1/4"-20 x 5/8" Hex S.S.

6

40

ST65148

10-24 S.S. Nylon Lock Nut

4

41

ST65147

10-24 x 3/4" Cap Screw S.S.

2

42

ST65130

10-24 #2 S/S Pan Screw

4

Not Shown

ST50828

Motor Harness

1

SA10018

REVISION HISTORY

Rev. B 03/24/2022

43

1

44

ST65224

1/4” x 1” Hex Bolt S.S.

4

Not Shown

ST50939

Motor Controller Harness

1

Not Shown

ST50832

Plug 120 Ohm

1

Not Shown

ST50833

3 pin Recpt Cap

1

Not Shown

ST80978

3 pin Plug Cap

1

20

9

6

27

24

20

14

17

19

22

8

7

18

6

27

24

3

29

26

4

2

1

27

11

25

16 15

5

10

12

21

23

24

28

13

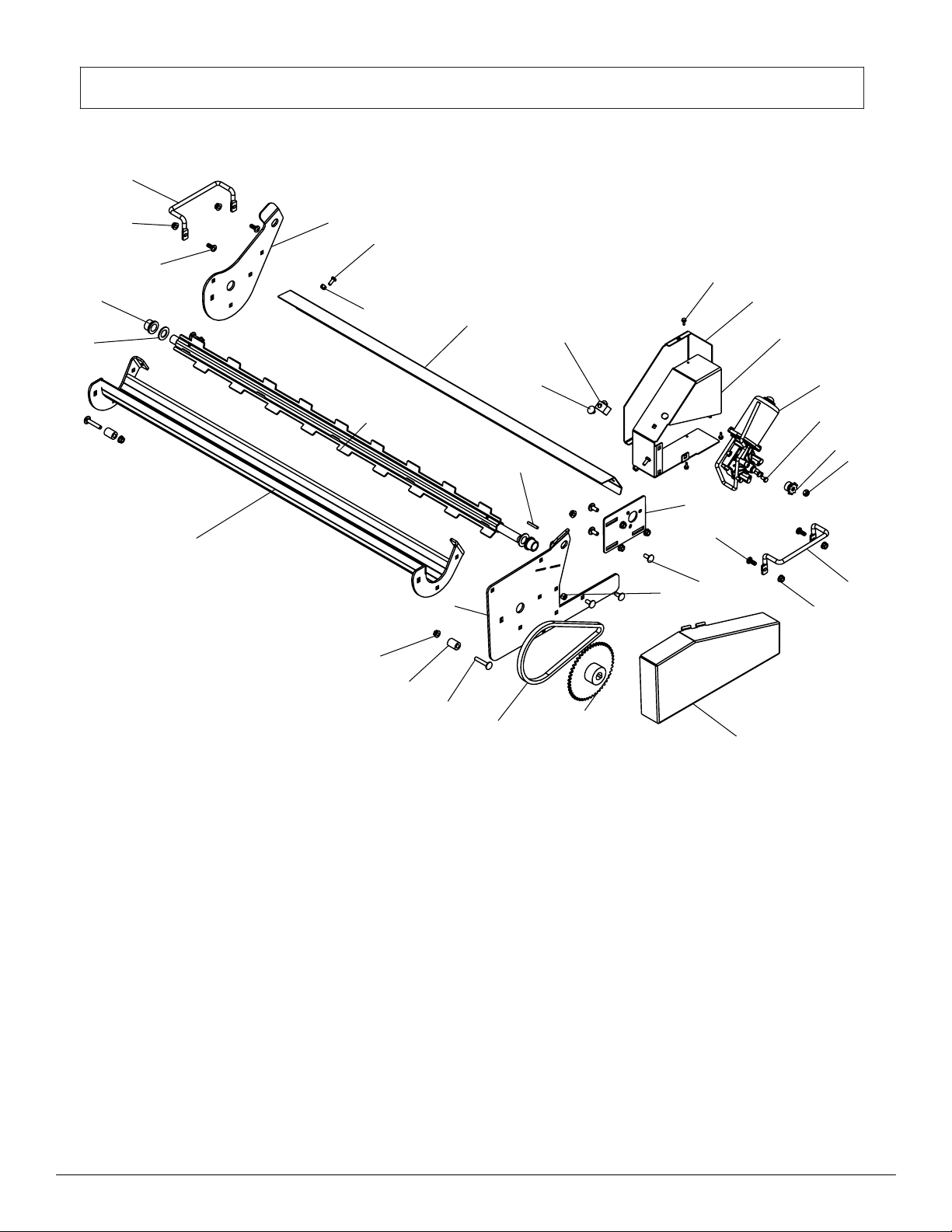

ST50478 - Drop Spreader Tray Assembly

This manual suits for next models

1

Table of contents

Other TerraKing Spreader manuals