Terratek TSMS300LJ User manual

User Manual-Please read and retain for future reference.

305mm Sliding Miter Saw

TSMS300LJ

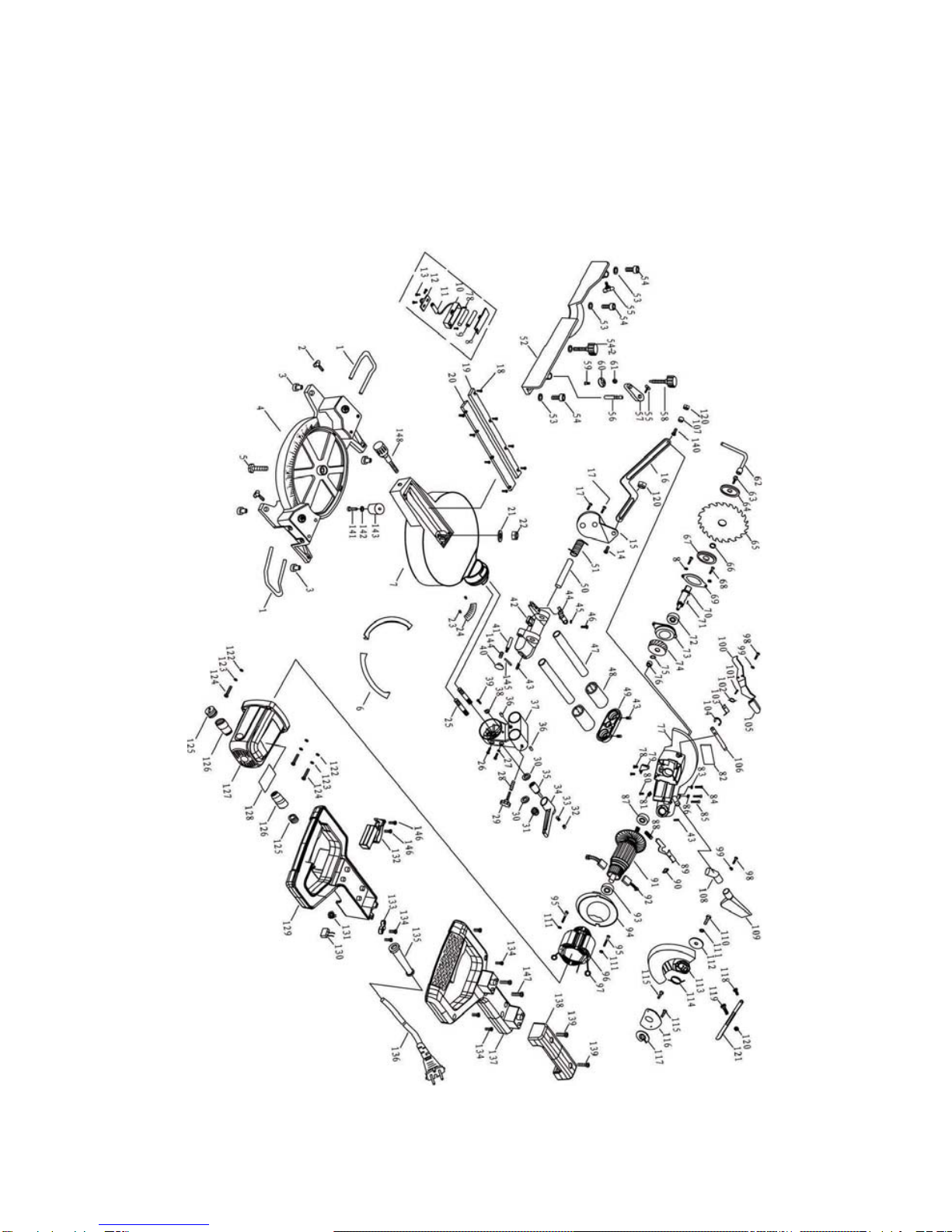

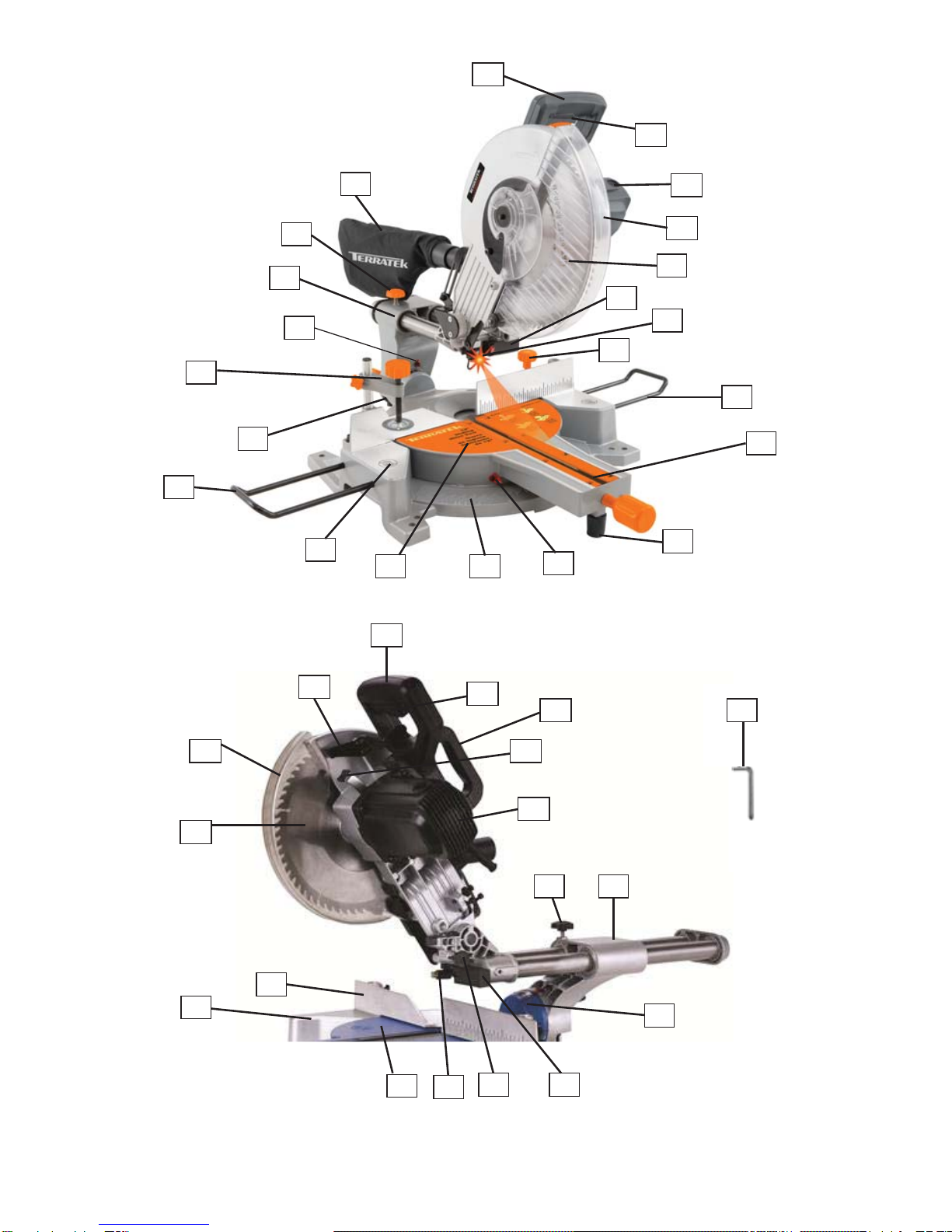

Exploded Assembly Diagram

NOTICE: Actual product may vary from pictures shown.

1

1

29

5

4

3

6

7

2

6

7

27

28

10

10

21

8

20

23

24

22

12

13

15

24 23

19

2825

17 27

18 11

1617

18

Fig. A

Fig. B

14

4

26

1. Handle

2. ON/OFF switch

3. Release lever

4. Motor

5. Saw shaft lock

6. Movable blade guard

7. Saw blade

8. Clamping device

9. Top handle

10. Workpiece support

11. Stop rail

12. Table insert

13. Supporting foot

14. Locking screw

15. Pointer

16. Scale

17. Turntable

18. Fixed saw table

19. Scale

20. Pointer

21. Locking screw

22. Dust bag

23. Drag guide

24. Locking screw for drag guide

25. Safety pin

26. Hex key

27. Laser

28. Battery box

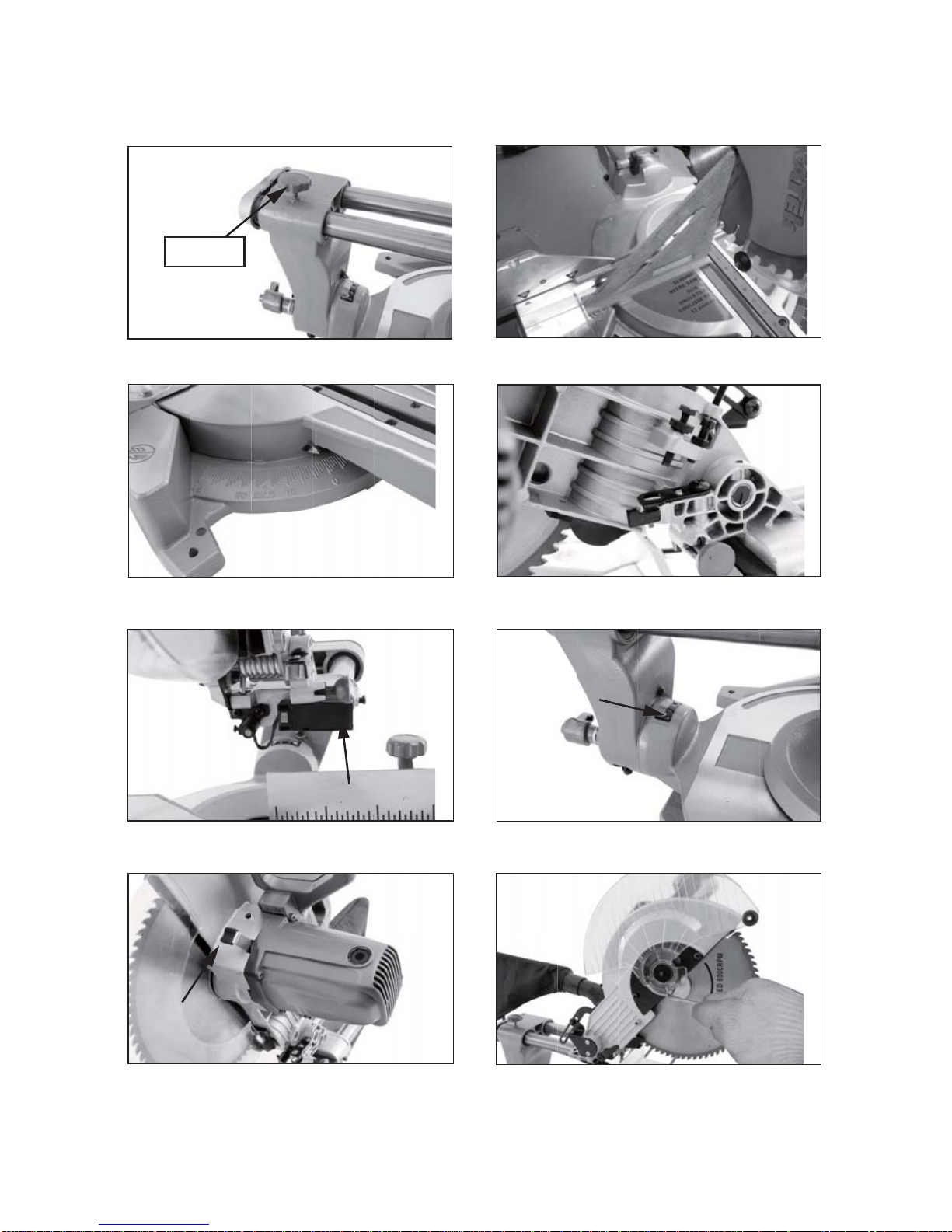

Fig.1

Fig.3 Fig.4

Fig.2

Fig.5

Fig.7

Fig.6

Fig.8

Slide lock

Fig.9 Fig.10

Fig.11 Fig.12

Fig.13 Fig.14

Fig.15 Fig.16

Fig.17 Fig.18

1

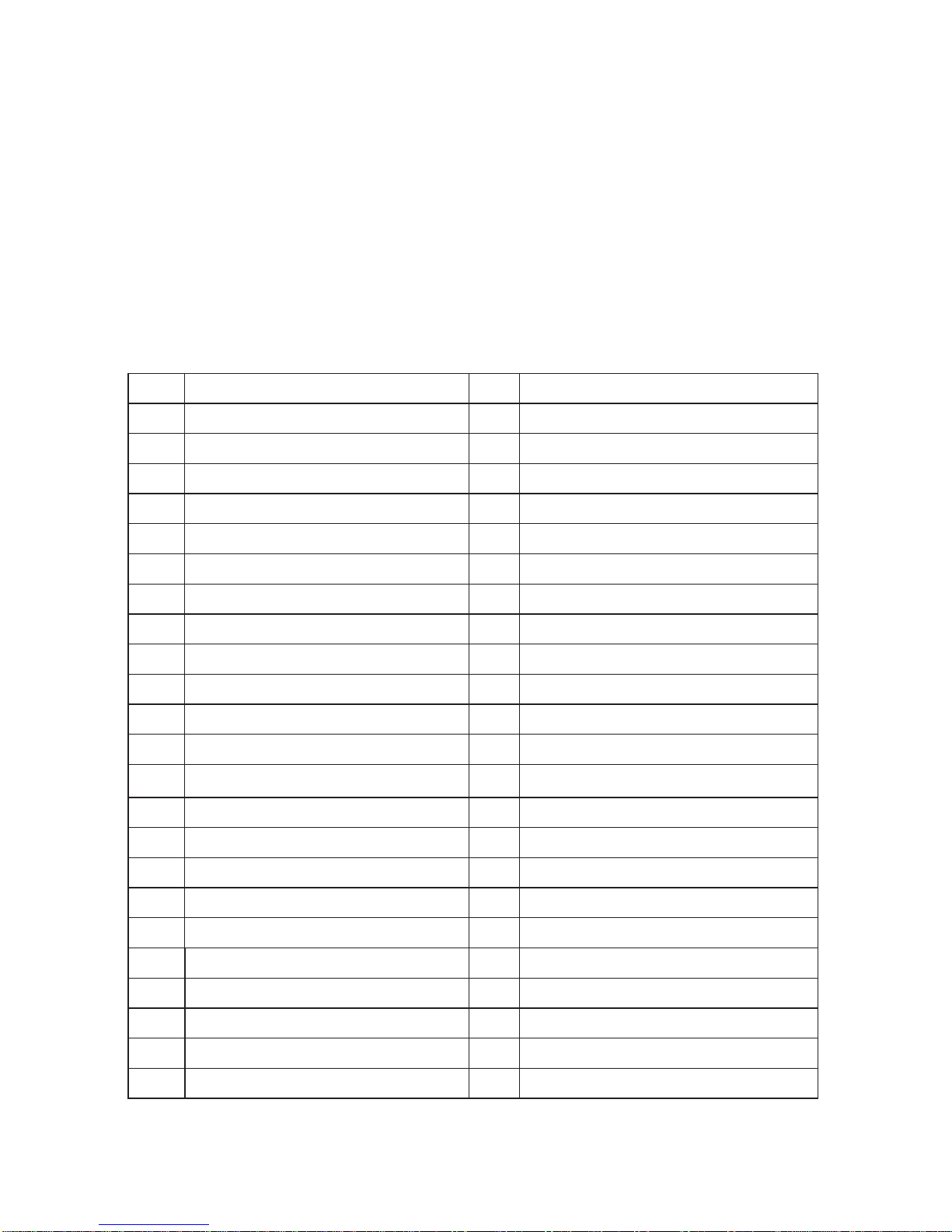

Contents

Parts List

Technical Information

Safety Instructions

Using your tool

Maintenance

Warranty

Parts List

1 Support 74 Large gear

2 Lock knob 75 Bearing circlip

3 Rubber pad 76 Needle bearing HK121610

4 Base 77 Head cover

5 Hex nut M8*50 78 Phillips screw M4*8

6 Turnplate base 79 Baffle

7 Turnplate 80 Phillips screw M5*8

8 Battery box cover 81 Rubber baffle

9 Battery 82 Label 1

10 Battery box 83 Depth-adjusting screw

11 Laser 84 Allen screw M6*35

12 Laser seat 85 Hex nut M6*25

13 Phillips screw M4*8 86 Screw M6

14 Phillips screw M6*14 87 Bearing 6202

15 Support bracket connector 88 Locking pressure spring

16 Connecting pole 89 Lock

17 Phillips screw M6*20 90 Lock cover

18 Phillips screw M5*8 91 Rotor

19 Kerf board (small) 92 Carbon brush

20 Kerf board (big) 93 Bearing 6000

21 Cushion #8 94 Wind deflector ring

22 Lock nut M8 95 Self-tapping screw ST4.8*70

23 Rivet 2*4 96 Stator

24 Ruler 97 Wire

2

25 Double end screw M10*60 98 Phillips screw M4*10

26 Allen screw M6*25 99 Lock washer

27 Screw M6 100 Lock trigger

28 Spring 101 Phillips screw M3*8

29 Lock screw 102 Small torsion spring

30 Cushion #10 103 Spring seat

31 Lock nut M10 104 Circlip

32 Bearing cap 105 Trigger cover

33 Lock spring 106 Connecting rod

34 Lock handle 107 Roller

35 Nut 108 Dust-outlet

36 Rubber locating pin 109 Dust bag

37 Bracket 110 Phillips screw M5*12

38 Pointer 111 Lock washer

39 Phillips screw M5*8 112 Guard spacer

40 Lock handle 113 Clear guard

41 Lock pin 114 Guard spring

42 Connector plug bracket 115 Phillips screw M6*10

43 Fixed nut M5*8 116 Guard spring cover

44 Depth block 117 Guard locating piece

45 Lock washer 118 Connecting rod screw 1

46 Screw 119 Connecting rod screw 2

47 Lead rail 120 Lock nut M6

48 Bearing 121 Inner connecting rod

49 End cap 122 Cushion #6

50 End cap pin 123 Lock washer #6

51 Big spring 124 Phillips screw M6*35

52 Fence 125 Brush holder cap

53 Lock washer 126 Brush holder

54 Nut M8*25 127 Housing

54-2 Lock knob 128 Label 2

55 Lock nut 6*14 129 Handle

3

56 Locating shaft 130 Capacitor

57 Bracket 131 Inductor

58 Lock knob 132 Switch

59 Screw 133 Tension disc

60 Clamp pressure plate 134 Phillips screw ST3.9*16

61 Cushion 135 Cable cover

62 Wrench 136 Cable plug

63 Allen screw M8*16 137 Handle

64 Outer pressure plate 138 Carry handle

65 Blade 139 Phillips screw ST6.3*20

66 Locating ring for blade 140 Phillips screw STM6*28

67 Inner pressure plate 141 Phillips screw M5*20

68 Phillips screw M5*16 142 Plain cushion

69 Bearing cover 143 Base foot

70 Output axis 144 Locking spring

71 Keyway 145 Hollow pin

72 Bearing 6203 146 Phillips screw ST3.9*12

73 Bearing housing 147 Phillips screw M5*45

4

Technical Information

Voltage: 230-240V~ 50Hz

Rated Power: S1 2000W, S6 2200W (40%)

No Load Speed: 4200 RPM

Blade Size: 305x25.4 mm

Cutting Capacity: ÛÛ+[:PP[PP

ÛÛ+[:PP[PP

ÛÛ+[:PP[PP

ÛÛ+[:PP[PP

WHLJKW1:*W:NJV

Copyright© 2013 by ACL*URXS/WG $OOULJKWVUHVHUYHG7KLVPDQXDORUDQ\

DUWZRUNFRQWDLQHGKHUHLQPXVWQRWEHUHSURGXFHGLQDQ\VKDSHRUIRUPZLWKRXW

the expUHVV written conVHnt of ACL*roup Ltd. DiagUDPV within thiVmanual may

not be drawn proportionally'XHWRFRQWLQXLQJLPSURYHPHQWVDFWXDOSURGXFW

PD\GLIIHUVOLJKWO\IURPWKHSURGXFWGHVFULEHGKHUHLQ

5HDGWKLVHQWLUHPDQXDOEHIRUHXVLQJWKLVSURGXFW

)DLOXUHWRGRVRFDQUHVXOWLQVHULRXVLQMXUy6DYHWKLVPDQXDO

for future reference.

5

Read and Keep This Manual

Important SAFETY Information

General Safety Rules

Please read carefully all instructions within this manual. Failure to follow all safety

warnings can result in serious personal injury. The term “Power Tool” in all of the

following warnings refers to your mains operated (corded) or battery operated (cordless)

power tool.

WARNING! Read all instructions. Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury. The term “power tool” in all of the

warnings listed refers to corded or cordless power tools.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Before use, ensure that the power outlet you are using matches the plug on your

power tool and that the voltage of the outlet matches that of your power tool.

Only use grounded extension cords with power tools fitted with 3 pin plugs and if using

outdoors ensure any extension cord is suitable for outdoor use.

Always try to avoid body contact with grounded surfaces, such as radiators, cooking

ranges and any other fixed appliance with metal surfaces.

Do not expose your power tool to wet or damp conditions and NEVER use in rain.

Check regularly the power cord of your machine and any extension cord that you are

using for damage.

Do not carry or pull the machine with the power cord.

Ensure the cord is clear from hot surfaces, oil or sharp objects.

This symbol is to warn you of potential personal

injury hazards. Please read carefully the notes along side

this warning to avoid possible injury or death.

6

Personal safety

Never use your power tool whilst under the influence of alcohol, drugs or medication.

Tiredness can often cause accidents, stay alert.

Never use your power tool without the correct guards in place.

Always use ANSI approved eye protection and dust mask. Non slip safety shoes and

hearing protectors should be worn at all times when using your power tool.

Ensure any dust collecting device supplied with your machine is connected correctly

before use.

Ensure all loose clothing, long hair or jewelry is kept clear of the machine.

Before plugging your power tool into the power outlet ensure the power tool is in the

OFF position.

Check that wrenches or adjusting keys have been removed. Any wrench or key left

attached to a moving part can result in injury.

Power tool use and care.

Keep your power tool clean and well serviced at all times.

Never adjust or service any power tool before disconnecting from the mains electricity

supply.

Always use the correct tool for the job.

Never force the tool to work harder than it is designed to do.

Never use your power tool with broken parts such as switches, guide fences or leg

stands.

ALWAYS keep your power tools away from children.

Keep cutting tools sharp to ensure less stress on the motor.

Only have your power tool serviced by a qualified repair agent using manufacturers

recommended parts.

Service

Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Develop a periodic maintenance schedule for your tool. When cleaning a tool

be careful not to disassemble any portion of the tool since internal wires may

be misplaced or pinched or safety guard return springs may be improperly

mounted. Certain cleaning agents such as gasoline, carbon tetrachloride, ammonia,

etc. may damage plastic parts.

When servicing a tool, use only identical replacement parts. Follow instructions

in the Maintenance section of this manual. Use of unauthorized parts or failure to

follow Maintenance Instructions may create a risk of electric shock or injury.

WARNING: For your own safety read Instruction Manual before operating your power

tool.

A) Wear eye protection.

7

B) Keep hands out of the path of blades/cutters.

C) Do not operate tool without guards in place.

D) Do not perform any operation freehand.

E) Never reach around cutting tools.

F) Turn off tool and wait for blade/cutter to stop before moving workpiece or changing

settings.

G) Disconnect power (or unplug tool) before changing blade/cutter or servicing.

GENERAL SAFETY INSTRUCTIONS

Read this owner's manual completely and make sure you understand all of its

safety guidelines.

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS & WRENCHES. Before turning on the power tool,

make sure the keys and adjusting wrenches have been removed.

3. KEEP WORKAREA CLEAN. Cluttered areas and benches invite accidents.

4. ALWAYS REMAIN ALERT WHEN THE TOOL IS IN USE. Inattention on the part of

the operator may lead to serious injury.

5. DON’T USE INA DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations or expose them to rain. Keep work area well lit.

6. KEEP CHILDRENAWAY. All visitors should remain at a safe distance from work

area.

7. MAKE WORKSHOP CHILD-PROOF with padlocks, master switches or by removing

starter keys.

8. USE THE RIGHT TOOL. Don’t force a tool or attachment to do a job for which it was

not designed.

9. USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. Table (see Table 1) shows the

correct size to use depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the gauge number, the heavier the

cord.

10. DON’T FORCE THE TOOL. It has been designed to operate at maximum safety

and performance levels.

11. DO NOT FORCE THE MATERIAL BEING CUT.Always let the tool cut at its own

speed.

12. WEAR PROPER APPAREL. Do not wear loose clothing, neckties, rings,

bracelets or other jewelry which may get caught in moving parts. Non-slip foot wear

is recommended. Wear protective hair covering if you have long hair.

13. ALWAYS USE SAFETY GLASSES.Also use face or dust mask for commercial

cutting operations. Everyday eyeglasses only have impact-resistant lenses, they

are NOT safety glasses.

14. SECURE WORK. Use clamps or a vise instead of your hand to hold work when

8

practical. This safety precaution allows for proper tool operation using both hands.

15. DON’T OVERREACH. Keep proper footing and balance at all times.

16. MAINTAIN TOOLS WITH CARE. Keep tools clean and in good working condition

for maximum safety performance. Follow instructions for lubricating and changing

accessories.

17. DISCONNECT TOOLS BEFORE SERVICING – when changing accessories, such

as blades, bits, cutters, etc.

18. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in

OFF position before plugging in.

19. USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for

recommended accessories. The use of improper accessories may increase risk of

injury.

20. MAKE SURE YOU USE THE CORRECT TOOL for the job you are doing.

21. NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the

cutting tool is unintentionally contacted.

22. CHECK DAMAGED PARTS. Before further use of the tool, damaged part(s),

(i.e., guard) should be carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and any other condition that may affect

the tools operation. A guard or other part that is damaged should be properly

repaired or replaced.

23. Replace damaged blades/cutters immediately. DO NOT USE DAMAGED BLADES/

CUTTERS. They may cause bodily injury.

24. DIRECTION OF FEED. Feed work into the blade/cutter against the direction of

rotation of the blade/cutter only.

25. NEVER LEAVE TOOL RUNNING UNATTENDED. Turn power off. Don’t leave tool

until it comes to a complete stop.

26. Double Insulated tools are equipped with a polarized plug (one blade is wider than

the other). This plug will fit in a polarized outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not change the plug in any way. Double

Insulation eliminates the need for the three wire grounded power cord and

grounded power supply system.

This power tool is supplied with all the relevant safety guards and features, it should be

checked before every operation, this manual should be read and kept in a safe place.

Whilst we warn of all the possible risks attached to using power tools any operator

must have read and understood the manual and apply their own caution and common

sense when using this power tool.

Following this guide will greatly reduce your risk of electric shock or injury.

Only use qualified repair agents to service this power tool.

Only use qualified electrician to repair any damaged wiring.

NEVER remove the grounding prong from the power tool or extension cord.

9

Check all extension cords for damage before use.

Avoid sharp objects.

Do not position the cord where it could be subMHFWWRWUDI¿FSDVVLQJRYHULW

Symbols

IMPORTANT: Some of the following symbols may be used on your tool.

6SHFL¿F6DIHW\5XOHV

1. Wear eye protection.

2. Keep hands out of path of saw blade. Avoid contact with any coasting blade. It can

still cause severe injury.

3. Do not operate saw without guards in place.

Check blade guard for proper closing before each use. Do not operate saw if blade

guard does not move freely and close instantly. Never clamp or tie the blade guard

in the open position.

4. Do not perform any operation freehand. 7KHZRUNSLHFHPXVWEHVHFXUHG¿UPO\

against the base and guide fence with a vise during all operations. Never use your

hand to secure the work piece.

5. Never reach around saw blade.

6. Turn off tool and wait for saw blade to stop before moving work piece or changing

settings.

7. Unplug tool before changing blade or servicing.

8. To reduce the risk of injury, return carriage to the full rear position after each crosscut

operation.

10. Lock pin which locks the saw head down is for carrying and storage purposes only

and not for any cutting operations.

………… Wear hearing protection.Wear eye protection.Wear respiratory protection.

.....................Read the instruction manual

…………... Electric products should not be disposed of with household waste,

please recycle where facilities exist, Check with your LocalAuthority or

retailer for recycling.

……………..ATTENTION!

……………....Keep hands away, do not touch.

……………....Keep the children away.

V……………….volts

W......................Wattage

Hz………………hertz

~………………. alternating current

…/m……………revolutions per minute

......................class II construction (double insulated)

Kg………………kilograms

no………………No load speed

…………...Direct Current

………………..Conforms to relevant safety standards

DC

10

binds in the work piece during a cutting operation and the saw blade is driven back

rapidly towards the operator. Loss of control and serious personal injury can result.

If blade begins to bind during a cutting operation, do not continue to cut and

release switch immediately.

8VHRQO\ÀDQJHVVSHFL¿HGIRUWKLVWRRO

15. Be careful not to damage the arborÀDQJHVHVSHFLDOO\WKHLQVWDOOLQJVXUIDFHRU

bolt. Damage to these parts could result in blade breakage.

16. Make sure that the turn base is properly secured so it will not move during

operation. Use the holes in the base to fasten the saw to a stable work platform or

bench. NEVER use tool where operator positioning would be awkward.

17. For your safety, remove the chips, small pieces, etc. from the table top before

operation.

18. Avoid cutting nails. Inspect for and remove all nails from the work piece before

operation.

19. Make sure the shaft lock is released before the switch is turned on.

+ROGWKHKDQGOH¿UPOy. The saw moves up or down slightly during start-up and

stopping.

21. Make sure the blade is not contacting the work piece before the switch is turned

on.

22. Before using the tool on an actual work piece, let it run for a while, watch for

vibration or wobbling that could indicate poor installation or a poorly balanced

blade.

23. Wait until the blade reaches full speed before cutting.

24. Stop operation immediately if you notice anything out of the ordinary.

25. Do not attempt to lock the trigger in the “on” position.

26. Stay alert. Blades are extremely dangerous

27. Use only accessories recommended in this manual. Use of improper accessories

such as abrasive wheels may cause an injury.

28. NEVER hold work piece on right side of blade with left hand or vice versa. This is

called cross armed cutting and exposes user to risk of SERIOUS PERSONAL

INJURY.ALWAYS use vise to secure work piece.

29. Do not abuse cord. Never pull on the cord to disconnect it from the receptacle.

Keep cord away from heat, oil, water and sharp objects.

30. Some materials contain chemicals which may be toxic. Take appropriate measures

to prevent dust inhalation and skin contact. Follow material supplier safety data.

Additional Safety rules for Laser

WARNING: This saw is equipped with a Laser light, DO NOT stare into the beam

because serious injury may occur.

LASER LIGHT - DO NOT STARE INTO BEAM, APERTURE, RULQWRDUHÀHFWLRQIURP

a mirror-like surface.

1'RQRWXVHWKHWRROLQWKHSUHVHQFHRIÀDPPDEOHOLTXLGVRUJDVHV

12. Check the blade carefully for cracks or damage before each operation. Replace

cracked or damaged blade immediately. Gum and wood pitch hardened on blades

slows the saw and increases potential for NLFNEDFN.HHSEODGHFOHDQE\¿UVW

removing it from tool, then cleaning it with gum and pitch remover, hot water or

kerosene. Never use gasoline to clean blade.

13. While making a slide cut, KICKBACK can occur. KICKBACK occurs when the blade

11

Unpacking

Carefully remove the product and any accessories from the box. Make sure that

all items listed in the packing list are included.

Package contents

A) Saw

B) Clamp

C) Wrench

D) Dust bag

E) Supports

F) User manual

Functional Description

WARNING:Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Assembly

WARNING:Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories.

Clamp

To install clamp simply insert it into the provided hole on the fence on the right or left

side depending on the cut you are doing and tighten nut. (Fig.1)

AVOID EXPOSURE - LASER LIGHT IS EMITTED FROM FRONT GUARD

APERTURE.

Use of controls or adjustments, or performance of procedures other than those

VSHFL¿HGKHUHLQPD\UHVXOWLQKD]DUGRXVODVer light exposure.

DO NOT DISASSEMBLE LASER MODULE. The laser is a CLASS II LASER PRODUCT

that can emit laser power up to 1 mw 650nm, which could result in exposure with the

module disassembled. The laser unit complies with EN60825-1:2007 .

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER

THAN THOSE SPEC IFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

WARNING: Do not attempt to repair or disassemble the laser level. If unqualified persons

attempt to repair this laser product, serious injury may result. Any repair required on

WKLVODVHUSURGXFWVKRXOGEHSHUIRUPHGE\DXWKRUL]HGVHUYLFHFHnter personnel.

CAUTION: The use of optical instruments with this product will increase H\HKD]DUG

CAUTION

LASER RADIATION.

DO NOT STARE INTO BEAM.

Wave length: 650nm CLASS 2

Max. power output: 1 mW

EN60825-1:2007

AVOID EXPOSURE

Laser radiation is

emitted from this aperture.

12

Dust bag

Place over dust outlet and push on. (Fig.2)

Supports

Insert supports in both ends of table and secure with screw. (Fig.3)

On-Off Switch

Ensure that the switch is in the “OFF” position. If the plug is connected to a receptacle

while the switch is in the “ON” position, the power tool will start operating immediately

and can cause serious injury.

To turn the saw on or off, squeeze and release the on/off switch. (Fig.4)

Turning Laser Beam ON/OFF

CAUTION: LASER RADIATION

Do not stare into beam

To turn on the laser beam, press the upper position (Fig.13) of the switch. Press the

lower position to turn off. Laser line is factory adjusted so that it is positioned within 1

mm (0.04”) from the side surface of the blade (cutting position). Make a test cut and

position material to be cut accordingly.

NOTE: When laser line is dim and almost or entirely invisible because of the direct

sunlight, relocate the work area to a place not exposed to the direct sunlight.

Using your miter saw

Important Note:

Transporting or moving this machine must only be done with the arm in the

locked position using the transit lock pin. (Fig.5)

When assembling your machine do not connect to the power supply until you have

fully read and understood this manual. After carrying out all checks and making any

necessary adjustments check that the machine switch is in the off position, connect to

the power supply and then switch the machine on and off quickly, this will allow you to

check for any loose blades or accessories without the machine gaining full

speed. Disconnect from the power supply before attempting any adjustments.

During manufacturing your machine is set and calibrated to cut accurately however

PRYHPHQWFDQRFFXUGXULQJWUDQVLW,I\RX¿QGWKDW\RXUPDFKLQHLVQRWFXWWLQJ

accurately you can make several small adjustments easily.

Re Setting the Table to 90 degrees with the Blade

1. Disconnect the machine from the mains.

2. Lock the arm in the transit position

13

3. Loosen the Miter Lock Knob. (Fig.6)

4. Align the pointer and table to 0 degrees.

5. Tighten the Miter Lock Knob.

6. Loosen the Bevel Lock Handle. (Fig.7)

7. Position the saw arm to 0 degrees with the blade 90 degrees to the table surface.

8. Tighten the Bevel Lock Handle.

9. Place a 90 deg. Set square against the table and blade (avoiding contact with the

blade teeth) rotate the blade slowly with a gloved hand, checking that it is aligned

correctly. (Fig.10)

10. Adjust the pointer to read 0 degrees. (Fig.11)

11. Retighten Bevel lock handle.

Fence to Table Adjustment

1. Disconnect the machine from the mains.

2. Lock the arm in the transit position

3. Loosen the Miter Lock Knob.

4. Align the pointer and table to 0 degrees.

5. Tighten the Miter Lock Knob.

6. Loosen the 4 fence screws (Pt. #24)

7. Place a set square against the fence and blade (avoiding the blade teeth) (Fig.10)

8. Adjust the fence until square.

9. Retighten the fence screws.

10.Adjust the pointer to read 0 degrees.

Blade Cutting Depth Adjustment (for use when trenching)

The blade is factory set to cut all the way through a piece of timber under normal use.

If you require a trench cut the blade can be adjusted to cut to your pre-determined

depth.

1. Disconnect from the power supply.

2. Lift the saw Arm

3. Adjust the depth cut (Trenching) stop screw to the desired position. (Fig.12)

Always Use clamp (Fig.1) to secure the material. This clamp can be moved to either

side of the table by loosening the locking knob. Ensure this knob is retightened

before using the saw. Support long lengths using roller support stands.

4. Check depth on waste timber before commencing.

Compound Miter Cuts

A compound miter cut uses a Miter cut and a Bevel cut together.

The main uses for this type of cut are: picture frames, cutting moldings, roof framing

and for making boxes with sloping sides.

It is advisable to make a test cut on a piece of scrap wood before cutting into your

actual work piece.

Table of contents

Other Terratek Saw manuals

Popular Saw manuals by other brands

Hilti

Hilti DST 10-CA operating instructions

Makita

Makita LH1040 instruction manual

Scheppach

Scheppach sd1600v Translation from the original instruction manual

Hilti

Hilti WSC 70-A36 operating instructions

Bosch

Bosch Professional GSA 12V-14 Original instructions

Bosch

Bosch GSA 36 V-LI Original instructions