FITTING

BANDSA

W

BLADE

S (Continued)

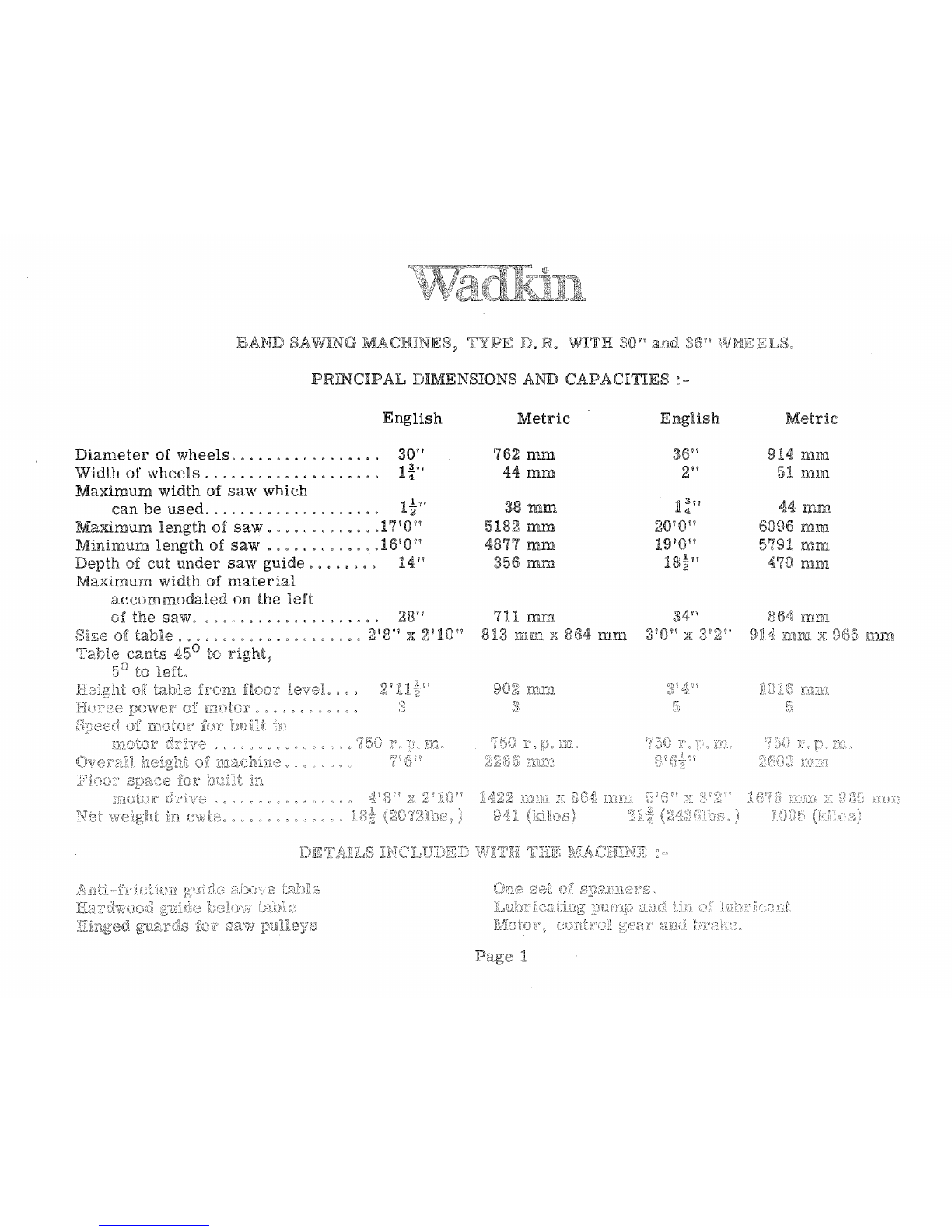

TRACKING -Fig. 9.

Every

saw

has

slightly

different

running

characteristics

on a

band

saw

machine

due to the condition of the

steel

ribbon

it

is

made

from,

the

brazed

joint

and

the

tension

in the

blade

ribbon.

This

is

compensated

by

using

a

crowned

(O,r

slightly

curved)

rubber

on the

wheels

and

prov-

•

iding the top wheel with a

slight

tilting movement.

We

call

this

track-

\

ing

and

by

slackening

the

lock

handle

and

adjusting

the

tracking

hand-

wheel,

it

is

possible

to

adjust

the

tilt

of the top wheel,

so

that the

saw

runs

steadily

in the

centre

of the wheel.

This

is

important

because

the

blade

then

passes

in a

straight

line

between the top and bottom

wheel, and does not snake. When the

latter

occurs

the

back

of the

saw,

keeps

hitting the guide

plate

and

woodwork and damaged guides

result.

Do

not

forget

to

re-tighten

the

tracking

lock

bolt

after

adjusting.

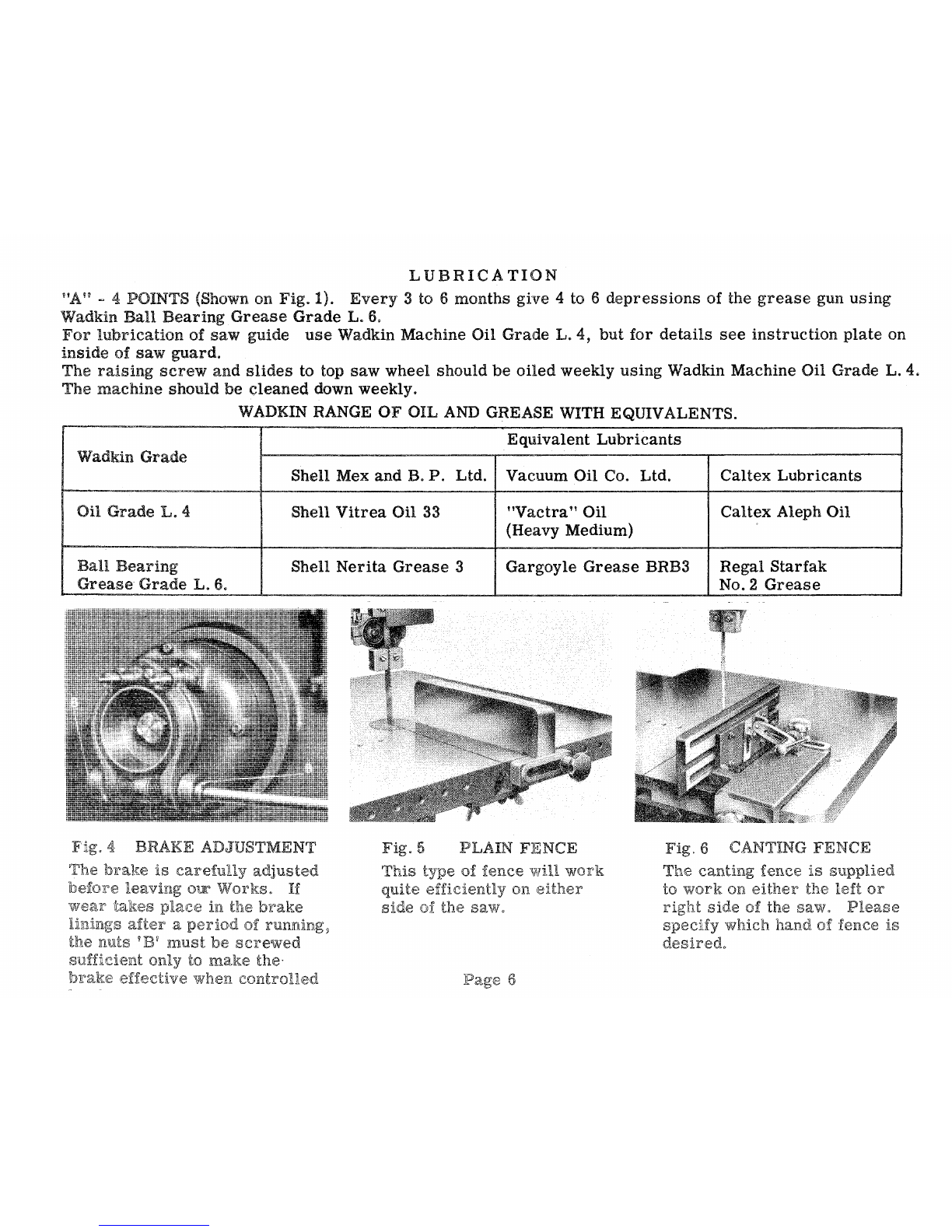

SAW

PULLEYS

A

brush

as

shown

in

Fig. 10

is

provided

on the

bottom

pulley to

remove

sawdust,

whilst

the

rubber

on the top

pulley

should be cleaneq daily to

prevent

accumulation

of

sawdust

which would

cause

the

blades

to

run

out

of

true

line.

.

The

saw

pulleys

must

be

kept

in

accurate

balance

to avoid

vibration.

It

is

essential

that

the

rubbers

on the

faces

of the

pulleys

are

kept

at

an

even

thickness

by

truing

up

occasionally

or

if

they

are

badly

worn

should

be

replaced

by new

ones.

If

the

machine

is

used

with badly

worn

pulleys

the

saw

will

vibrate,

resulting

in

bad

sawing and

broken

saws.

We

have a

service

arrangement

which we

recommend

whereby newly

rubbered

pulleys

can

be

supplied

against

the

return

of the

existing

pulleys,

an

appropriate

charge

being

made

to

cover

re-rubbering

only.

Where

it

is

not pra.ctical

for

the

customer

to

use

our

exchange

service

of

vulcanised

wheels

it

is

possible

for

the

customer

to

carry

out

his

ownre-rubbering,

which,

whilst

not

so

good

as

the

vulcanised

process,

is

satisfactory

if

the

instructions

below

are

carefully

followed. Rubber

bands

and

fixing

solution

can

be

supplied to

order.

Page

8

fC!r

tr::acking saw

Brush

Fig.~

Fig. 10