Terratek PTS10U User manual

10" TABLE SAW WITH STAND

PTS10U

SCIE À TABLE AVEC SUPPORT 10 PO

SIERRA DE MESA CON SUPPORTE DE 10"

User Manual – Please

read and retain for

future reference.

See page 1 Voir page 15 Ver la págeina 30

Guide d’utilisation

– Veuillez lire et

conserver ceguide

pour vous y reporter

ultérieurement.

Manual del usuario –

Por favor lea este

manual y guárdelo para

referencia futura.

CM

L

I

S

T

E

D

CUS

3150598

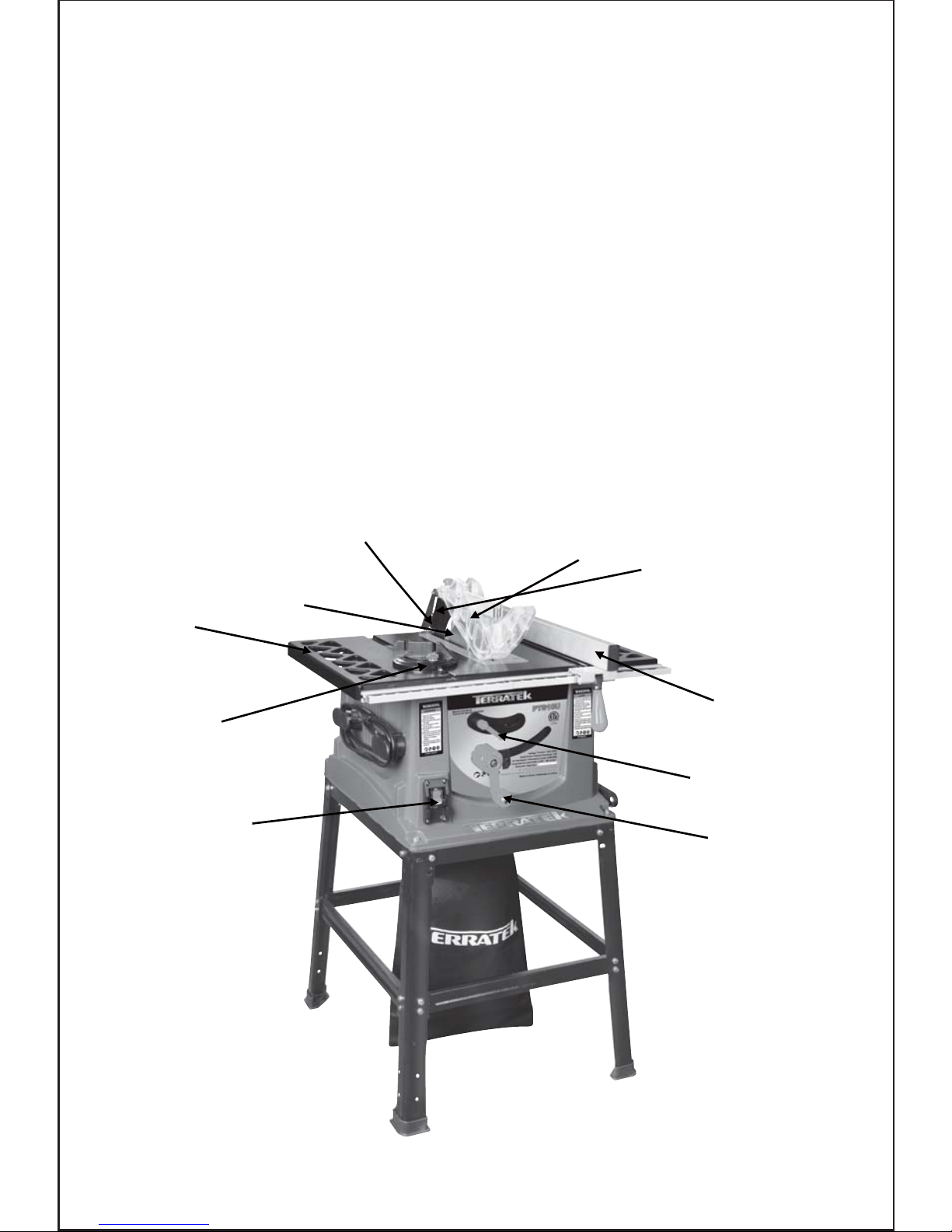

Table Saw

Structure

1. Table top

2. Blade

3. Safety guard

4. Anti kick back fingers

5. Wood splitter

6. Sliding miter guide

7. Adjustable ripping fence

8. Blade height adjustment

wheel

9. Blade angle lock lever

10. On / Off Switch

2

4

1

6

10 8

9

7

5

3

Composants de

la scie à table

1. Plateau

2. Lame pour couper le bois

3. Protège-lame

4. Ergots antiretour

5. Fendeuse à bois

6. Guide d’onglets coulissant

7. Guide de refente réglable

8. Molette de réglage de

hauteur de lame

9. Levier de blocage d’angle

de lame

10. Interrupteur marche-arrêt

La tabla vio la

estructura

1. Sobremesa

2. Cuchilla

3. Guardia de la seguridad

4. Anti golpeen detrás los dedos

con el pie

5. Divisor de madera

6. Deslizar la guía del inglete

7. Cerca de rasgadura ajustable

8. Rueda del ajuste de altura de

cuchilla

9. Palanca de la cerradura del

ángulo de cuchilla

10. Interruptor con./desc.

.QO

.QO

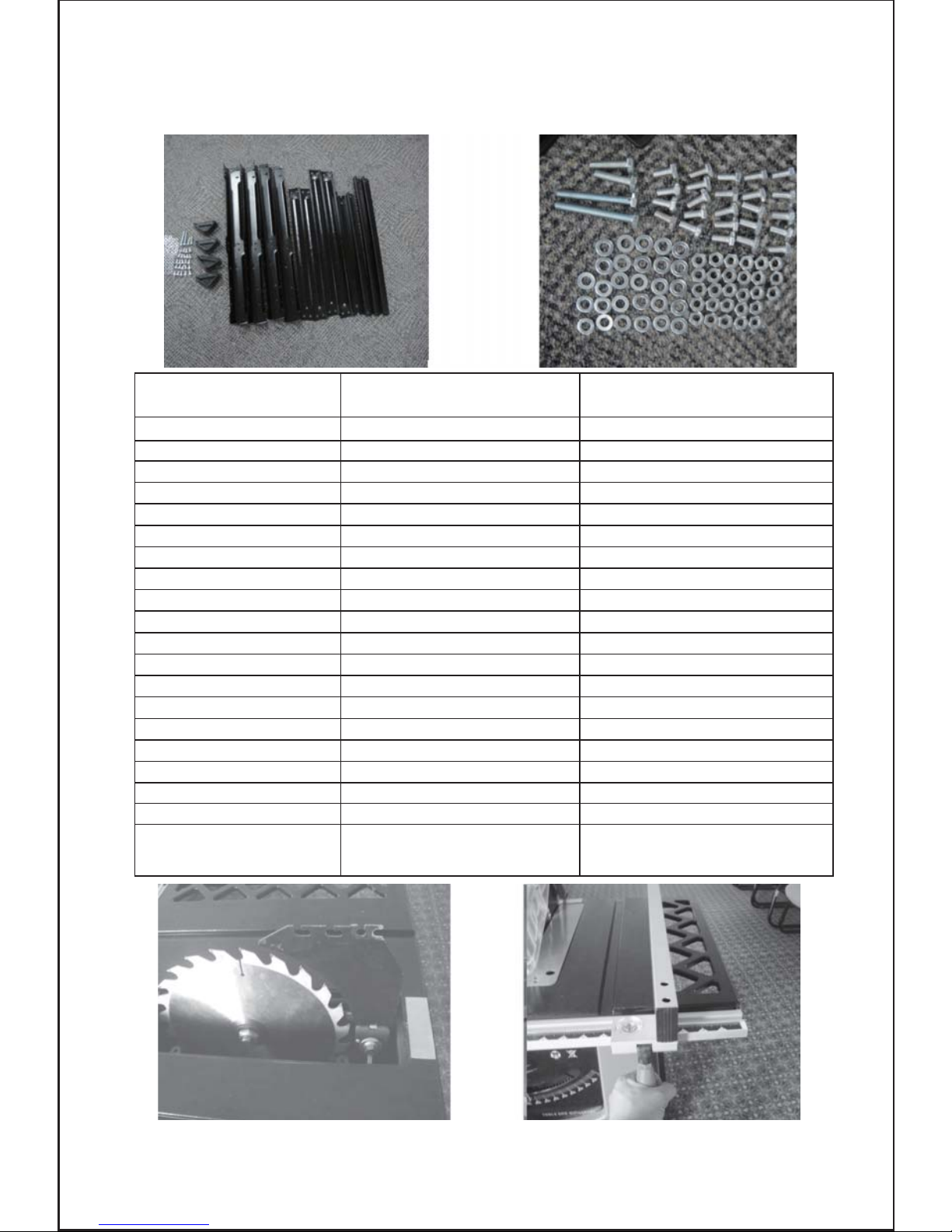

Packing Contents Contenu de la boîte d’emballage Contenido del embalaje

1. Machine Body

2. Ripping Fence Assembly

3. Sliding Mitre Fence

4. Safety Blade Guard

5. Wood Cutting Saw Blade

6. Blade Changing Key

(Spanners) x 2

7. Hex Key

8. Push Stick

9. Blade height adjustment

knob

1. Bâti

2. Ensemble guide de refente

3. Guide d’onglets coulissant

4. Protège-lame

5. Lame pour couper le bois

6. Clé pour changement

de lame (2)

7. Clé hexagonale

8. Poussoir

9. Molette de réglage de

hauteur de lame

1.Cuerpo de máquina

2.Rasgadura del montaje de

la cerca

3.Desplazamiento de la cerca

del inglete

4.Guardia de cuchilla de la seguridad

5.Cuchilla de sierra para madera

6.Llave cambiante de la cuchilla(2)

7.Liave hexagonal.

8.Impulsor

9.Botón del ajuste de altura

de cuchilla

1. Long Top Rails

2. Short Top Rails

3. Long Lower Support Rails

4. Short Lower Support Rails

5. Legs

6. Rubber Feet

7. Leg stand nuts and bolts

1. Traverses supérieures longues

2. Traverses supérieures courtes

3. Traverses inférieures longues

4. Traverses inférieures longues

5. Pattes

6. Pieds en caoutchouc

7. Écrous et boulons pour support

1.Carriles superiores largos

2.Carriles superiores cortos

3.Carriles superiores largos

4.Carriles superiores cortos

5.Piernas

6.Patas de cancho

7.Tuercas y pernos del soporte.

Leg Stand Support Leg Stand

.QO .QO

.QO .QO

.QO .QO

126

127

(Short)

(Short)

(Iong)

(Iong)

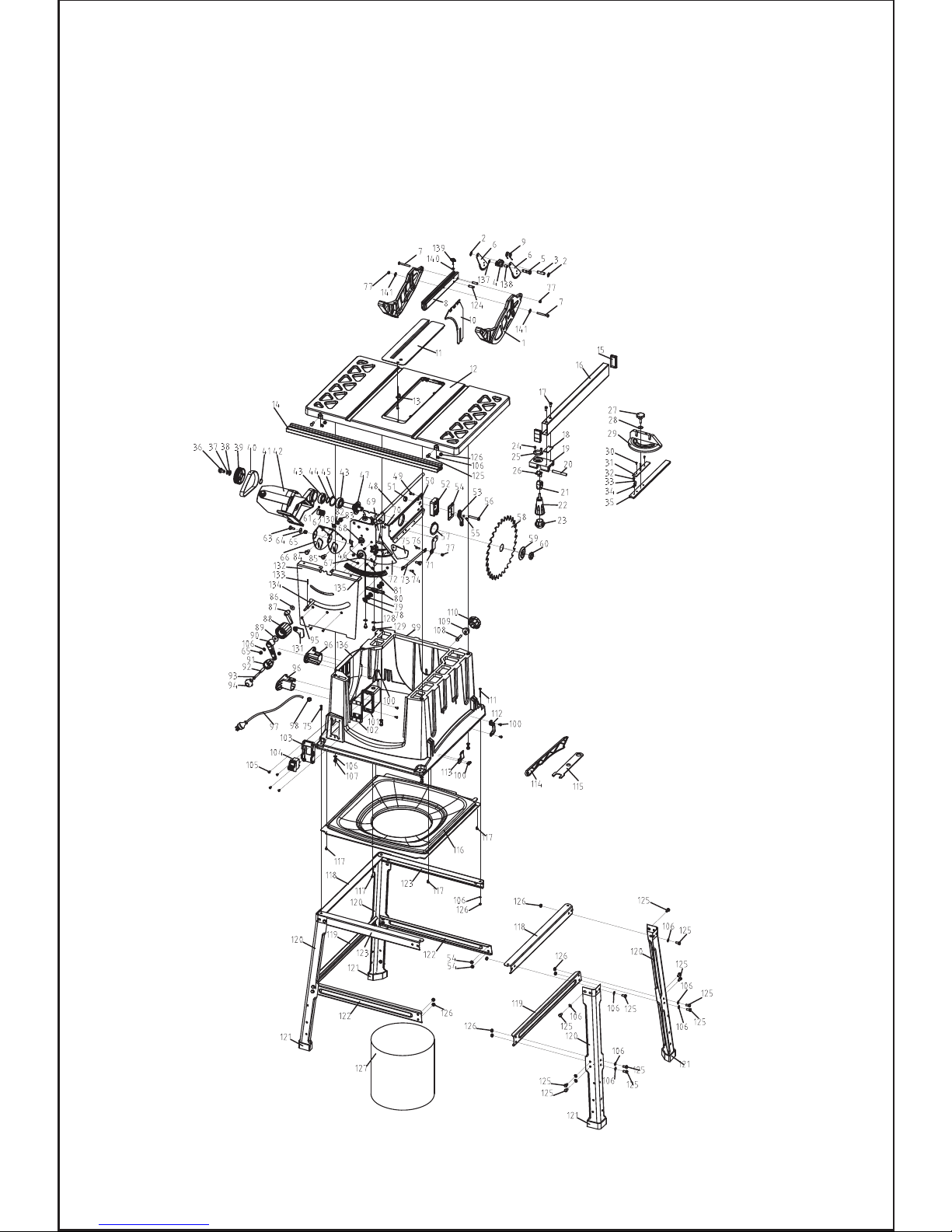

Exploded Assembly Diagram

Vue éclatée

Dibujo despiezado del conjunto

1

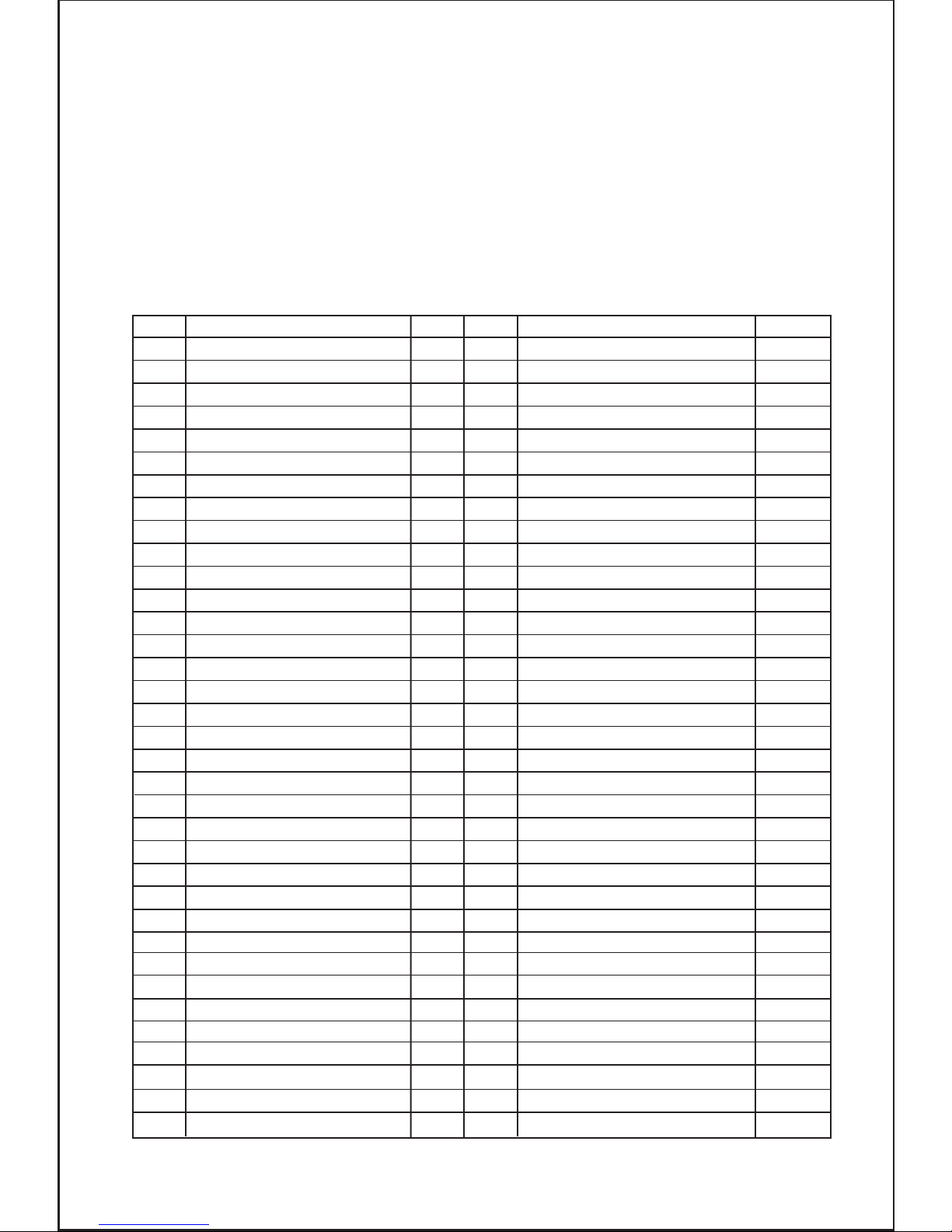

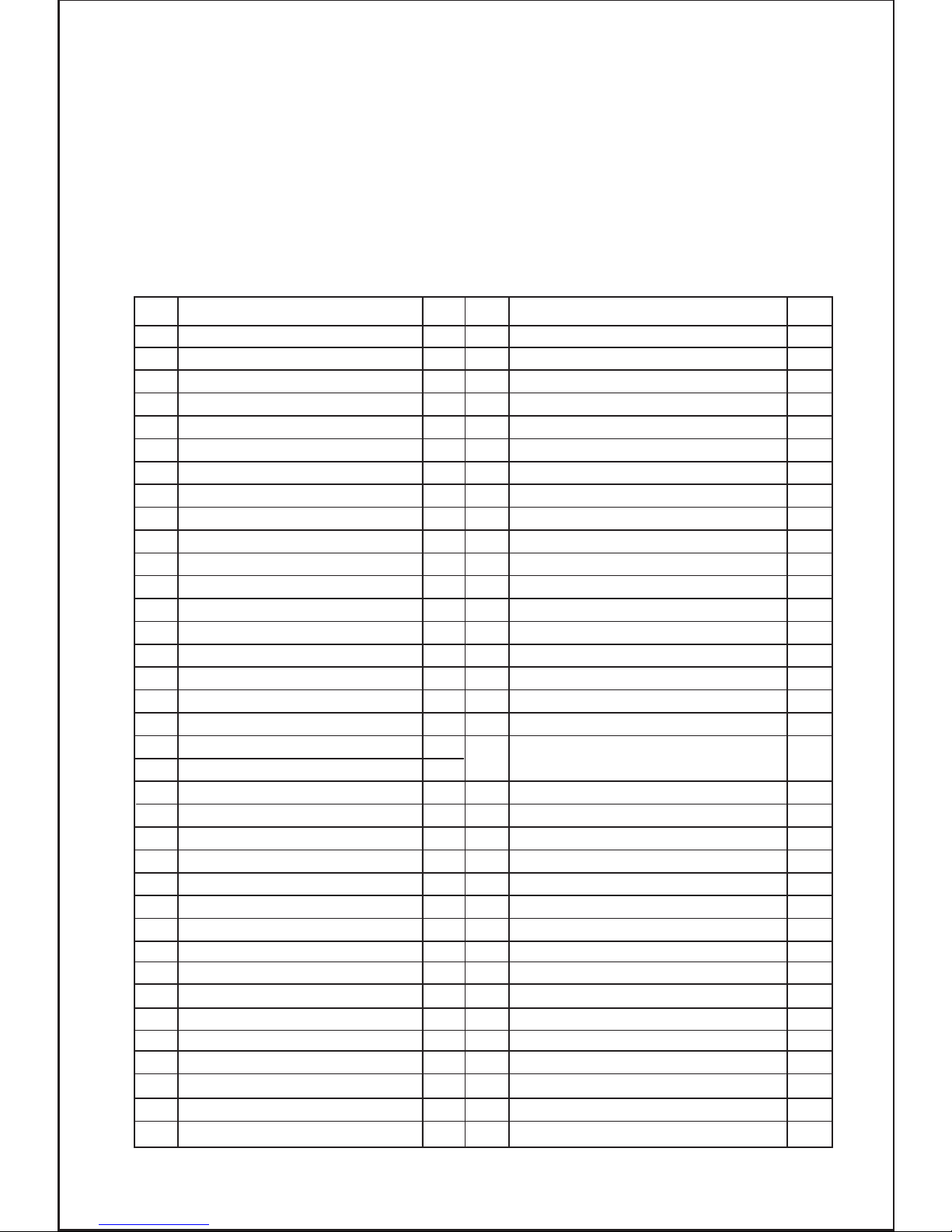

Parts List

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

1

2

1

1

1

2

2

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

1

1

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

2

4

1

1

1

1

1

2

1

1

3

1

1

4

1

4

1

4

1

2

1

1

1

1

1

1

1

2

2

2

1

1

1

1

2

Blade guard

Bead flange 8

Cylindrical pin 8×30

Anti-kickback support

Locking shaft

Anti-kickback

Screw M5×45

Guard support

Spring

Riving knife

Table insert

Table

Locking dog

Slide rail

Fence cap

Fence

Cheese head screw M5×10

Plate

Slide carriage

Cardinal axis

Cam

Tension knob

Tension knob cover

ScrewM4×6

Magnifying glass

Tension washer

Nut

Flat washer 6

Angle gauge

Sunken screw M4×8

Angle gauge plate

Screw M4×8

Flat washer 4

Indicator

Angle gauge rod

Cheese-head screw M8×14

Spring washer 8

Flat washer 8

Driven pulley

Poly V-belt

Elastic collar 17

Motor

Bearing 6003-2Z

Dottle pin

Elastic collar 35

Hex nut M4

Shaft assembly

Live shaft assembly

Cheese-head screw M5×12

Riving knife plate

Self-locking nut M8

Riving knife support

Handle

Riving knife pressing plate

Screw M3×4

Hexagon bolt M8×40

Elastic collar 45

Blade

Flange

Nut M16×1.5

Set screw M6×8

Drive pulley

Bolt

Spring/B/12.5

Self locking nut M6

Bracket holder

Gear

Square neck bolt M6×14

Leading track

Screw M5×14

No Description Qty No Description Qty

Contents

Table Saw Structure

Packing Contents

Parts List

Technical Information

Safety Instructions

Assembly

Using your saw

Maintenance

Warranty

2

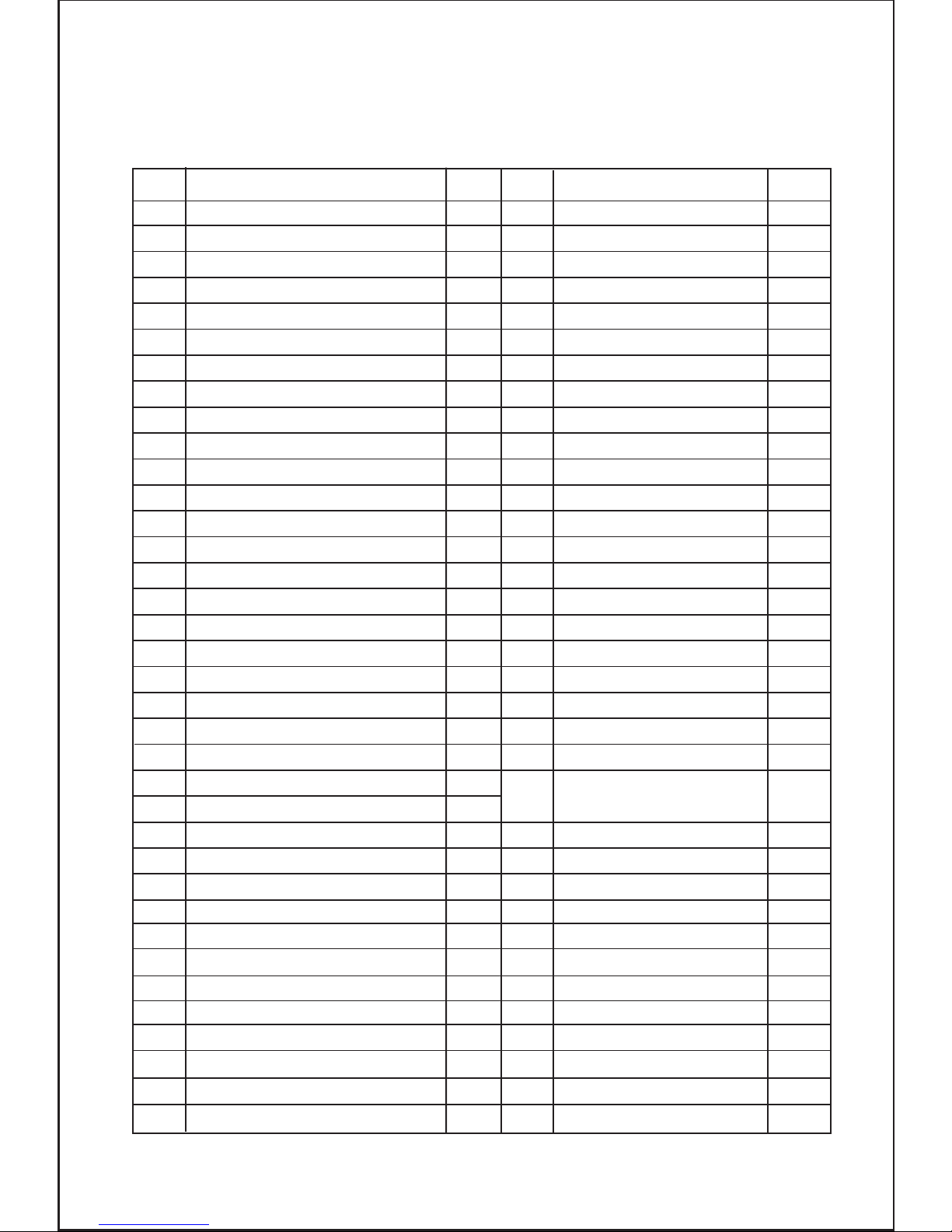

Parts List

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

1

1

1

1

1

1

4

2

4

1

6

4

4

2

2

1

1

1

1

1

1

1

1

1

3

2

1

3

1

4

1

1

1

1

2

46

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

4

1

1

1

2

1

1

1

2

1

4

2

2

4

4

2

2

2

46

46

1

4

4

4

1

1

1

1

1

1

1

1

1

1

2

Tie bar

Protective plate

Lever

Screw M5×14

Rotating plate

Screw M5×14

Self-locking nut M5

Spring washer

Hex nut M8

Screw shaft

Sunken screw M4×10

Flat washer 8

Hex nut M8

Sunken screw M8×25

Cheese-head screw M8×25

Flat washer 6

Handle

Wheel handle

Washer 6

Rocker arm

Wheel handle

Tube

Slotted cheese-head screw M6×50

Wheel handle

Sunken screw M4×10

cable support

Cable

Cable gland

Box

Tapping screw ST4.2×16

Connection box

Earth plate

Switch plate

Switch

Tapping screw ST3.5×13

Flat washer 6

Hexagon bolt M6×30

Hexagon bolt M6×35

Blade support

Tension knob

Hexagon bolt M6×50

Front clip

Back clip

Push stick

Wrench

Bottom plate

Tapping screw ST3.5×13

Beam

Beam

Leg

Foot

Beam

Beam

Cylindrical pin 5×22

Hexagon bolt M6×12

Hex nut M6

Dust bag

Spring washer 10

Slotted cheese-head

screw M10×20

Spring washer 8

Angle pointer

Front plate

Cylindrical pin 3×20

Threaded rod

Gear rack

Base guard

Split washer 6

Spring

Knob

Square nut M5

Flat washer 5

No Description Qty No Description Qty

3

Technical Information

Voltage: 120V~60Hz

Rated Power: 13A

No Load Speed: 5700 RPM

Cutting capacity: 0º/90º: 2-3/4" ;

45º: 2-1/2"

Blade Size: 10"x5/8"

Table size: 26"x17-5/16"

Weight NW/GW: 44/49.7 Lbs

Read this entire manual before using this product.

Failure to do so can result in serious injury. Save this manual

for future reference.

Copyright© 2010 by Terratek Intl Ltd. All rights reserved. This manual or any artwork

contained herein must not be reproduced in any shape or form without the express

written consent of Terratek Intl Ltd. Diagrams within this manual may not be drawn

proportionally. Due to continuing improvements, actual product may differ slightly

from the product described herein.

Important SAFETY Information

This symbol is to warn you of potential personal

injury hazards. Please read carefully the notes along side

this warning to avoid possible injury or death.

General Safety Rules

WARNING! Read all instructions. Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury. The term “power tool” in all of the

warnings listed refers to corded or cordless power tools.

Work area safety

Read and Keep This Manual

Electrical safety

Before use, ensure that the power outlet you are using matches the plug on your

power tool and that the voltage of the outlet matches that of your power tool.

Only use grounded extension cords with power tools fitted with 3 pin plugs and if

using outdoors ensure any extension cord is suitable for outdoor use.

Always try to avoid body contact with grounded surfaces, such as radiators, cooking

ranges and any other fixed appliance with metal surfaces.

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes

Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

Please read carefully all instructions within this manual. Failure to follow all safety

warnings can result in serious personal injury. The term “Power Tool” in all of the

following warnings refers to your mains operated (corded) or battery operated (co-

rdless) power tool

4

Personal safety

Never use your power tool whilst under the influence of alcohol, drugs or medication.

Tiredness can often cause accidents, stay alert.

Never use your power tool without the correct guards in place.

Always use ANSI approved eye protection and dust mask. Non slip safety shoes and

hearing protectors should be worn at all times when using your power tool.

Ensure any dust collecting device supplied with your machine is connected correctly

before use.

Ensure all loose clothing, long hair or jewelry is kept clear of the machine.

Before plugging your power tool into the power outlet ensure the power tool is in the

OFF position.

Check that wrenches or adjusting keys have been removed. Any wrench or key left

attached to a moving part can result in injury.

Power tool use and care.

Keep your power tool clean and well serviced at all times.

Never adjust or service any power tool before disconnecting from the mains electricity

supply.

Always use the correct tool for the job.

Never force the tool to work harder than it is designed to do.

Never use your power tool with broken parts such as switches, guide fences or leg

stands.

ALWAYS keep your power tools away from children.

Keep cutting tools sharp to ensure less stress on the motor.

Only have your power tool serviced by a qualified repair agent using manufacturers

recommended parts

5

WARNING: For your own safety read Instruction Manual before operating miter saw.

Do not expose your power tool to wet or damp conditions and NEVER use in rain.

Check regularly the power cord of your machine and any extension cord that you are

using for damage.

Do not carry or pull the machine with the power cord.

Ensure the cord is clear from hot surfaces, oil or sharp objects.

A) Wear eye protection.

B) Keep hands out of the path of saw blade.

6

GENERAL SAFETY INSTRUCTIONS

Read this owner's manual completely and make sure you understand all of its safety

guidelines.

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS & WRENCHES. Before turning on the power tool,

make sure the keys and adjusting wrenches have been removed.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

4. ALWAYS REMAIN ALERT WHEN THE SAW IS IN USE. Inattention on the part of

the operator may lead to serious injury.

5. DON’T USE IN A DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations or expose them to rain. Keep work area well lit.

6. KEEP CHILDREN AWAY. All visitors should remain at a safe distance from work area.

7. MAKE WORKSHOP CHILD-PROOF with padlocks, master switches or by removing

starter keys.

8. USE THE RIGHT TOOL. Don’t force a tool or attachment to do a job for which it was

not designed.

9. USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table (see Table 1) shows the correct

size to use depending on cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number, the heavier the cord.

10. DON’T FORCE THE TOOL. It has been designed to operate at maximum safety and

performance levels.

11. DO NOT FORCE THE MATERIAL BEING CUT. Always let the tool cut at its own

speed.

12. WEAR PROPER APPAREL. Do not wear loose clothing, neckties, rings, bracelets

or other jewelry which may get caught in moving parts. Non-slip foot wear is reco-

mmended. Wear protective hair covering if you have long hair.

13. ALWAYS USE SAFETY GLASSES. Also use face or dust mask for commercial

cutting operations. Everyday eyeglasses only have impact-resistant lenses, they

are NOT safety glasses.

C) Do not operate tool without guards in place.

D) Do not perform any operation freehand.

E) Never reach around saw blade. (Or never reach in back of saw blade)

F) Turn off tool and wait for saw blade to stop before moving workpiece or changing

settings.

G) Disconnect power(or unplug tool) before changing blade or servicing

7

This power tool is supplied with all the relevant safety guards and features, it should

be checked before every operation, this manual should be read and kept in a safe place.

Whilst we warn of all the possible risks attached to using power tools any operator must

have read and understood the manual and apply their own caution and common sense

when using this power tool.

Following this guide will greatly reduce your risk of electric shock or injury.

14. SECURE WORK. Use clamps or a vise instead of your hand to hold work when

practical. This safety precaution allows for proper tool operation using both hands.

15. DON’T OVERREACH. Keep proper footing and balance at all times.

16. MAINTAIN TOOLS WITH CARE. Keep tools clean and in good working condition

for maximum safety performance. Follow instructions for lubricating and changing

accessories.

17. DISCONNECT TOOLS BEFORE SERVICING – when changing accessories, such

as blades, bits, cutters, etc.

18. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in

OFF position before plugging in.

19. USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for recom-

mended accessories. The use of improper accessories may increase risk of injury.

20. MAKE SURE YOU USE THE CORRECT TOOL for the job you are doing.

21. NEVER STAND ON TOOL. Serious injury could occur if the wet saw is tipped or if

the cutting tool is unintentionally contacted.

22. CHECK DAMAGED PARTS. Before further use of the tool, damaged part(s), (i.e.,

guard) should be carefully checked to determine that it will operate properly and

perform its intended function. Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and any other condition that may affect

the tools operation. A guard or other part that is damaged should be properly rep-

aired or replaced.

23. Replace damaged blades immediately. DO NOT USE DAMAGED BLADES. They

may cause bodily injury.

24. DIRECTION OF FEED. Feed work into the blade against the direction of rotation

of the blade only.

25. DO NOT ALTER THE PLUG OR USE A 2-PRONG RECEPTACLE. This saw is

equipped with a 3-prong electrical plug.

26. NEVER LEAVE TOOL RUNNING UNATTENDED. Turn power off. Don’t leave tool

until it comes to a complete stop.

8

Only use qualified repair agents to service this power tool.

Only use qualified electrician to repair any damaged wiring.

NEVER remove the grounding prong from the power toll or extension cord.

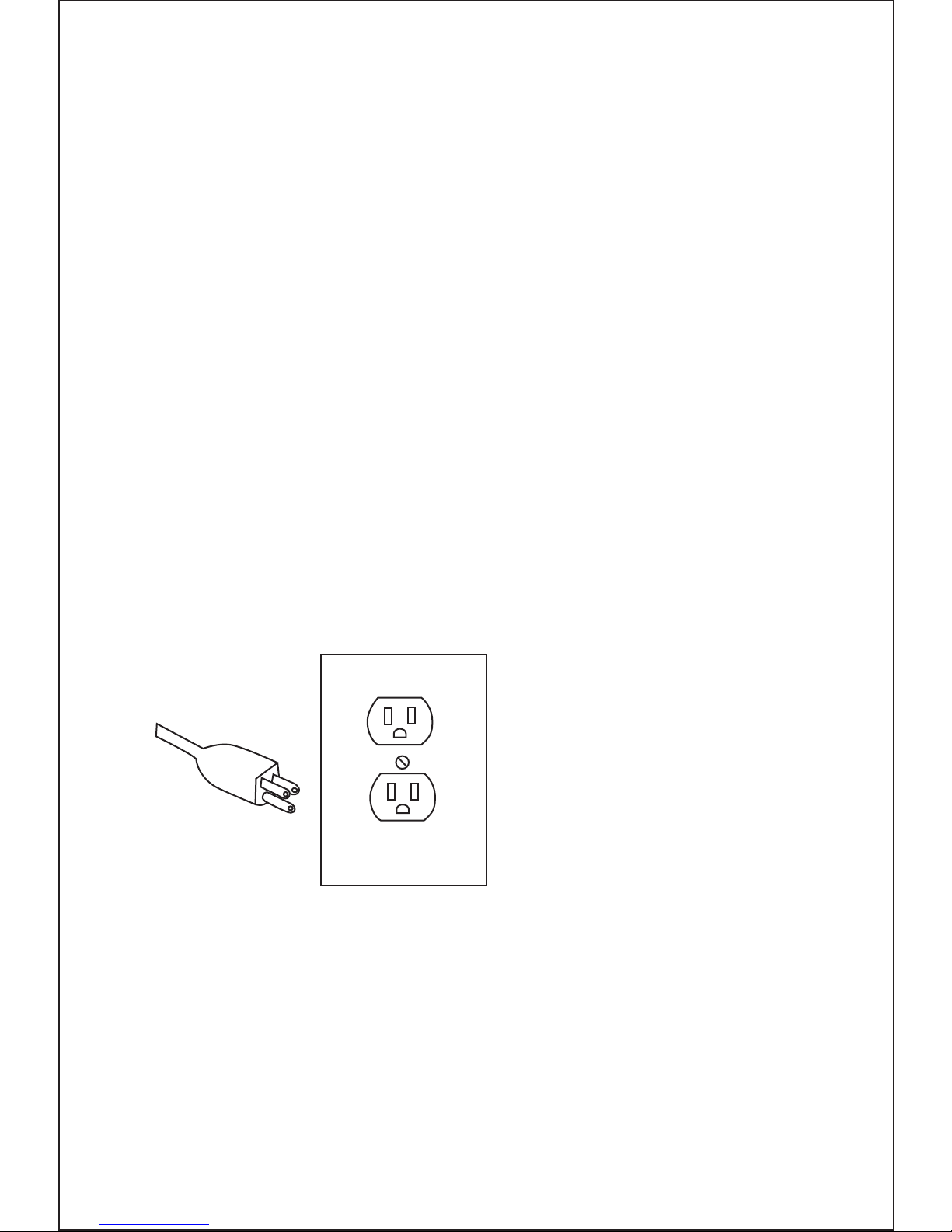

Grounding Tools

Electrical Powered Connections

3-Prong Plug and Outlet

Any electric powered tool that is marked Ground Required must have fitted a three

wired power cord. The main importance of this is the green wire within the cord, this

green wire must at all times be connected to the grounding prong of the plug. This

prong must never be removed or discarded. The green wire Must NEVER be conne-

cted to any other prong. The Three prong plug must only be connected to the power

supply through a three prong power outlet.

The Illustration above shows a three prong plug and outlet.

This product must be grounded. In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to reduce the risk of electric shock.

This product is equipped with an electric cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed

by a qualified electrician.

Check with a qualified electrician or service personnel if the grounding instructions are

not completely understood, or if in doubt as to whether the product is properly grounded.

Repair or replace a damaged or worn cord immediately.

This product is for use on a nominal 120 V circuit and has a grounding plug similar to

the plug illustrated in Table1. Only connect the product to an outlet having the same

configuration as the plug. Do not use an adapter with this product.

Grounding Instructions

9

Outlets for 2-Prong Plug

Any electric powered tool that is marked Double insulated only need a two prong

connection and will be perfectly safe to operate.

These tools do not require grounding as they are fitted with an additional insulation

system internally that complies with all relevant electrical safety standards.

Unlike the three prong tools these tools CAN be connected through outlets suitable

for two prong or three prong plugs.

The Illustration above shows the outlets that this type of tool can be connected to.

Power Extension Cords

Any power tool marked ‘Grounding required’ MUST only be connected to a three

wire extension cord. Only double insulated tools can be connected to two wire cords.

When using any extension cord the machine will suffer a power reduction due to

the drop in voltage caused by the length of the cord. This can be partially offset by

selecting extension cords with lower gauge wire.

Double Insulated Power Tools

Plug and outlet, 2 prong

Table 1

MINIMUM GAGE FOR CORD SETS

Total Length of Cord in Feet(Meter)

0-25 26-50 51-100 101-150

(0-7.6) (7.9-15.2) (15.5-30.5) (30.8-45.7)

Ampere Rating

AWG

0 6 18 16 16 14

18 16 14 12

18 16 14 12

14 14 Non Recommended

6 10

10 12

12 16

More Not More

Than Than

10

e.g. Cords marked 14 gauge can carry a higher current than cords marked 16 gauge

therefore when linking extension cords make sure each cords wire gauge matches.

Note: Outdoor extension cords used in must carry the letters “W-A” (USA) or “W”

(Canada)

Check all extension cords for damage before use.

Avoid sharp objects.

Do not position the cord where it could be subject to traffic passing over it.

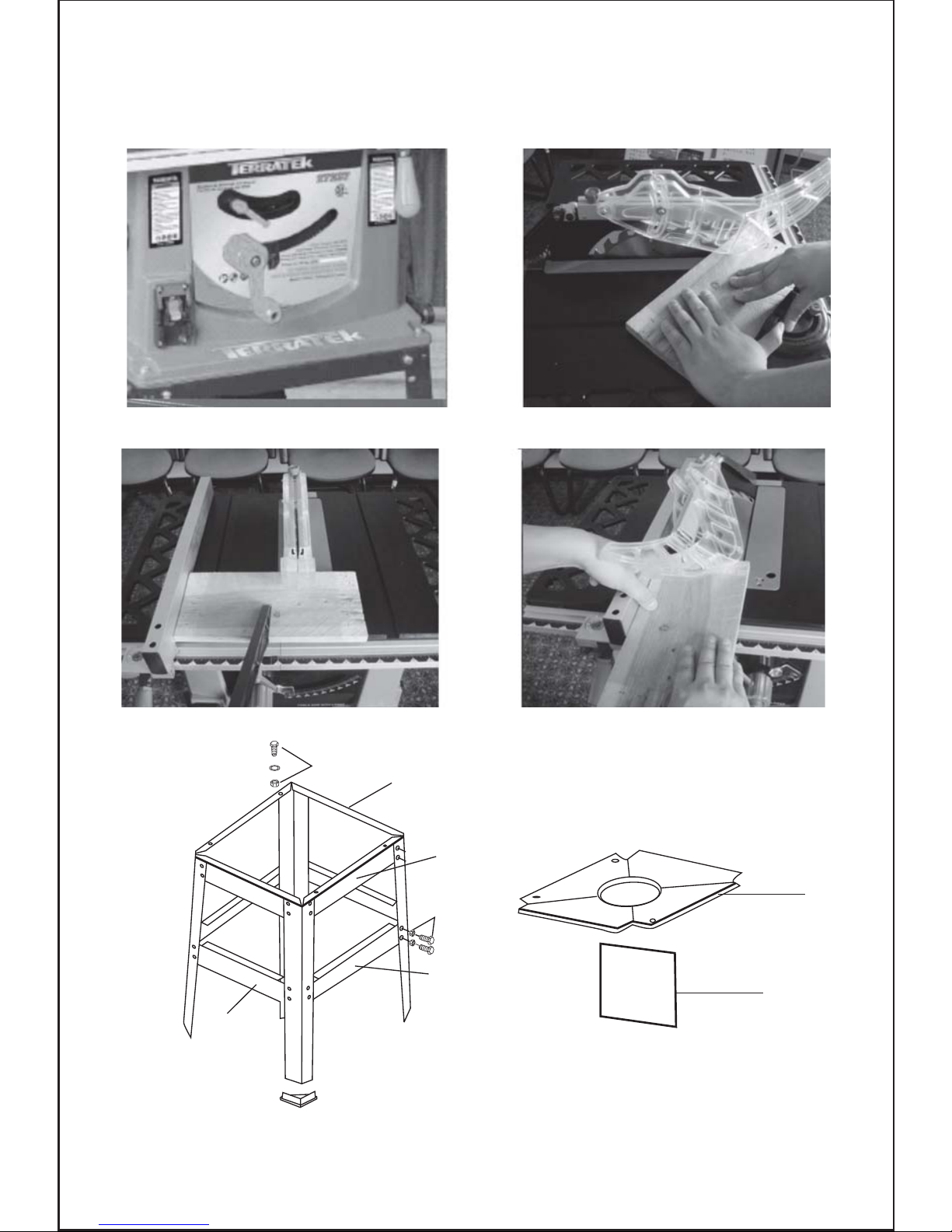

NOTE: Parts of leg stand (Fig.7) have the locating holes for mounting the dust bag

adaptor plate and the saw bench, these holes must be positioned to the top of the leg

stand. During assemble ensure all locking washers are used in the correct position and

that all connecting nuts and bolts are securely tightened.

1. Lay the saw bench top down.

2. Locate the dust collector bag adaptor plate (Pt.116),

3. Add the completely assembled leg stand securing both the leg stand and adaptor

plate to the machine body with the enclosed nuts bolts and locking washers.

4. Once assembled turn the complete machine over so that it now stands on the legs,

this requires two people to avoid injury when lifting.

5. Secure the dust bag (Pt.127) to the dust bag adaptor plate (Pt 116) (Fig.8)

When assembling your machine do not connect to the power supply until you have

fully read and understood this manual. After carrying out all checks and making any

necessary adjustments check that the machine switch is in the off position, connect

to the power supply and then switch the machine on and off quickly, this will allow you

to check for any loose blades or accessories without the machine gaining full speed.

Disconnect from the power supply before attempting any adjustments.

During manufacturing your machine is set and calibrated to cut accurately however

movement can occur during transit. If you find that your machine is not cutting accur-

ately you can make several small adjustments easily.

Assembly

Warning !!

Before Assembly DO NOT CONNECT TO POWER SUPPLY.

Leg Stand Assembly

Mounting the saw bench

Saw Bench Assembly

Carefully remove the product and any accessories from the box. Make sure that all

items listed in the packing list are included.

11

Fitting the Blade’s Safety Guard

Mounting the Rip Fence

Blade height adjustment wheel.

Fitting Sliding Miter Fence

Warning: Always ensure the Rip fence is parallel to the saw blade before use to

avoid blade jam and timber kick back.

Warning. First time use or after changing the saw blade. With the machine DISC-

ONNECTED from the power supply, rotate the blade carefully by hand to ensure

that nothing fouls its operation.

Mounting the blade

1. Ensure the machine is disconnected from the power supply,

2. Remove the screw holding the blade locating plate (Pt.11) in the table top, remove

the locating plate.

3. Rotate the blade height adjustment wheel to lift the motor to its highest position.

4. Remove blade locking nut (Pt.60) and outside blade washer (Pt.59), (Fig.1)

5. Fit blade ensuring blade teeth are facing forward. (Fig.1)

6. Re-fit the blade washer and locking nut using the blade lock keys (spanners) ensu-

ring that the blade lock nut is tight.

7. Re-fit the blade locating plate with the screw.

1. The safety guard is pre-assembled at the factory.

2. Simply remove the lock nut on the guard locating peg at the rear of the table, slide

the guard support seat (Pt.52) onto the locating peg, refit and retighten the lock nut.

1. Loosen the locking handle

2. Slide the Rip fence onto the table top from the left side of the machine ensuring that

the guides on the rip fence locate into the slide guide. (Fig.2)

The locking handle can be screwed in or out to increase or decrease the tension on

the locking lever.

This wheel adjusts the blade height by turning clockwise, it raises the blade giving a

deeper cutting depth, turning anti clockwise reduces cutting depth. (Fig.3)

Before using, fit the plastic peg to the front of the knob to give more accurate control.

1. Simply slide miter fence into the grooved guide way on the table top.

2. Connect to the power supply, switch the machine on for 2-3 seconds and then turn

off before it runs to maximum speed. (This will confirm that the blade is running free)

Once you have checked that the blade is secure and running free you are able to pr-

oceed to use the bench saw.

12

On-Off Switch

Bevel cutting

Rip Cutting (Cutting with the grain or length wise)

Using your Table Saw

The Power Switch assembly is equipped with a Safety Key to help prevent unauthorized

use of the saw.

To provide power, connect the Power Cord/Plug of the Power Switch assembly to the

nearest electrical outlet. Insert the Safety Key into the Power Switch (Fig. 3) and pull

up on the Power Switch to provide power to the saw. To shut off power to the saw,

push down on the Power Switch and remove the Safety Key. Store the Safety Key in

a safe location, out of reach of children and other unauthorized users.

Miter cutting/Cross cutting

Cross cutting is an operation where the work piece is cut across the grain, this can be

either at 90 degrees or at any other required angle. Using the bevel cutting miter gauge

(Fig.4) loosen the lock knob, adjust the gauge to the required angle, hold the work piece

firmly and push through the blade.

Loosen the hand wheel lock lever (Fig.3) and push the hand wheel until the required

angle of cut is shown on the angle scale on the front cover. Lock the hand wheel at

this required position. The saw blade should be now angled giving you the required

cut. (Fig.6)

This bevel action can be used for both cross cutting (using Angle guide) or rip cutting

(Using rip fence).

This action must be done using the Ripping fence.

Before turning on the machine, adjust the ripping fence to the required cutting width,

lock the fence into the position, turn on the machine and when maximum speed is

reached feed the timber into the blade holding it firmly against the ripping fence, Always

use the Push stick(Pt.114) (Fig.5) provided to finish the cut. NEVER reach over the

table or try finishing the cut freehand, the push stick is supplied to ensure your safety

when used correctly

Warning: to avoid injury

When cross cutting or ripping ALWAYS use the correct guide fence, NEVER try

these operations free hand. Always set the blade depth approx. 1/8”(3.5mm)

above the work piece thickness, this not only provides the safest method of

cutting but also gives the maximum number of blade teeth in the work piece at

any one time, reducing stress on the motor.

13

Your machine is supplied with a dust collection bag, for your health and safety always

ensure that the dust bag is fitted, emptied regularly and cleaned. This bag is designed

to collect dust particles up to 5 micron however when cutting some materials dust pa-

rticles can be smaller, again for your health and safety we recommend wearing additi-

onal face dust mask. Always ensure that the bench saw is positioned in on a level st-

able surface without obstruction.

NOTE: In case of an electrical fault always turn your power tool OFF and disconnect

from the mains electric supply before attempting to diagnose and resolve the problem.

1. Keep the air vents free from obstruction and clean regularly.

2. Check regularly for any dust particles entering the grills around the motor and the

switch. Use a soft brush to remove any dust particles. Wear safety glasses to protect

your eyes whilst cleaning.

3. Regularly wipe any saw dust from the fence. A buildup of dust on the fence can pr-

event accurate cutting.

4. Monitor the dust bag and empty when approximately half full. Always empty into an

appropriate container. REMEMBER: dust can be hot and cause fire.

5. If the blade has become dirty, use a blade cleaner (not included) to clean it. Dirty

blades will bind more easily, and will more often overheat and burn the wood as it

cuts. Overheated blades dull more easily.

6. If the Blade has become dull, replace it. Dull blades will cause increased tear-out

and ragged edges on the cuts.

7. Lubricate all moving parts at regular intervals.

8. To clean the body of the power tool, only use a soft damp cloth. Do NOT immerse

in water. A mild detergent can be used but NOT petrol or any alcohol based product.

9. After extensive use of this power tool the grease in the gearbox will require replacing.

10. Should the power cord become damaged only allow a fully qualified electrician to

replace or repair.

Terratek and/or it’s distributor has provided the parts list and assembly diagram as a

reference tool only. Neither Terratek or it’s distributor makes any representation or

warranty of any kind to the buyer that he or she is qualified to do any repairs or replace

any parts of this product. Terratek and it’s distributor expressly state that all repairs or

parts replacement should be done by certified or licensed technicians. The buyer

assumes all risk and liability arising out of his or her repairs or parts replacement to the

original product.

Please read the following carefully

General Maintenance

Added safety information.

14

LIMITED WARRANTY

This product is covered by a two year warranty from the date of purchase. If the product

is defective in workmanship or material and upon returning the product to its distributor/

dealer in its original packaging, the distributor will repair and/or replace it free of charge.

This warranty DOES NOT COVER normal wear, or any damage as a result of accidents,

misuse, abuse or negligence. Terratek Intl. obligations under this warranty shall be

limited to the repair and/or replacement of the product. Terratek Intl. is not responsible

for direct, indirect, or incidental damages. This warranty is void if the product or any

of its components are modified, altered, or in any way changed, or if the product is

used in a manner or with parts that are not recommended by Terratek Intl. To receive

a replacement power tool or requested warranty service, you must present proof of

purchase and return all original equipment packaged with the original product. The

replacement power tool will be covered by the limited warranty for the balance of the

two year period from the date of the original purchase. This warranty applies only to

the original purchaser and cannot be transferred.

15

Liste des pièces

Réf. Description Qté Réf. Description Qté

Contenu

Composants de la scie à table

Liste des pièces

Données techniques

Consignes de sécurité

Contenu de la boîte d’emballage

Assemblage

Utilisation de la scie à table

Entretien

Garantie

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

1

1

1

2

2

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

1

1

2

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

4

1

1

1

1

1

2

1

1

3

1

1

4

1

4

1

4

1

2

1

1

1

1

1

1

1

2

2

2

1

1

1

1

2

Capot de lame

Bride de perle

Goupille cylindrique 8x30

Appui d'anti-contrecoup

Axe de verrouillage

Anti-contrecoup

Vis M5x45

Support de garde

Ressort

Couteau le déchirant

insertion de table

Table

Verrouillage du chien

Glissez le rail

Chapeau de barrière

Guide

Vis principale de fromage M5x10

Plaque

Chariot de glissière

Axe cardinal

Came

Bouton de tension

Couverture de bouton de tension

Vis M4x6

Loupe

Rondelle de tension

Écrou

Rondelle plate

Règle d’onglets

Vis submergée M4x8

Plat de mesure d'angle

Vis M4x8

Rondelle plate

Indicateur

Tige de règle d’onglets

Vis principale de

fromage M8x14

Rondelle de ressort 8

Rondelle plate 8

Poulie conduite

Poly V-ceinture

Collier élastique 17

Moteur

Roulememt 6003-2Z

Aiguille dottle

Collier élastique 35

Écrou hexagonal M4

Axe

Axe de phase

Vis principale de fromage M5x12

Plat le déchirant de couteau

Écrou de verrouillage d'individu M8

Appui le déchirant de couteau

Poignee

Plaque de pression la

déchirant de couteau

Vis M3x4

Boulon de sortilège M8x40

Collier élastique 45

Llame

Bride

Écrou M16x1.5

Vis de réglage M6x8

Poulie d'entraînement

Boulon

Ressort/B/12.5

Écrou de verrouillage d'individu M6

Support de parenthèse

D’engrenages

Boulon de cou carrée

Principale voie

Vis M5x14

Table of contents

Languages:

Other Terratek Saw manuals