Terrco 6200 User manual

Terrco®, Inc.

Model 6200

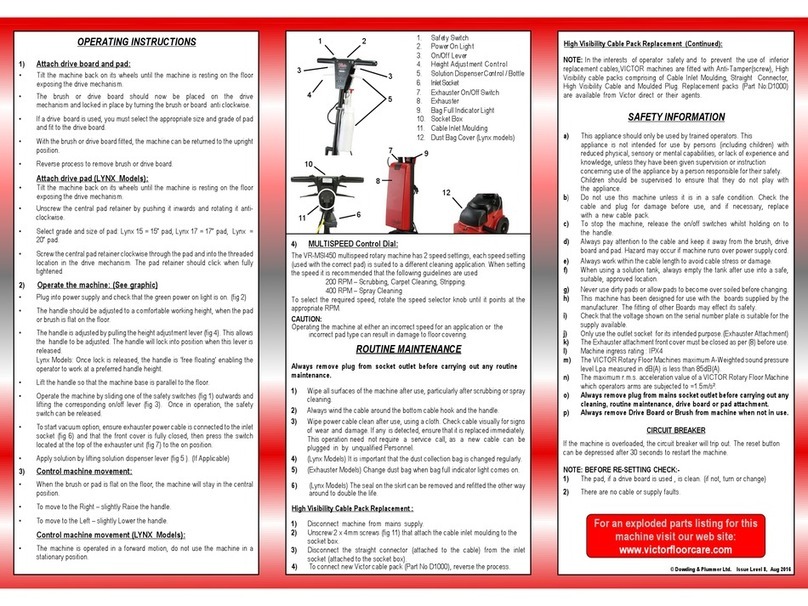

OPERATING INSTRUCTIONS

ILLUSTRATED PARTS LIST

MAINTENANCE INSTRUCTIONS

Terrco®, Inc.

222 1st Avenue NW • Watertown, SD 57201

Phone: (605) 882-3888 • Fax: (605) 882-0778 • Email: info@terrco.com

Specifications: Production Rates:

Mastic removal Rate of 1,000 sq. ft. per

hour

Thin-Set removal rates of 1,000 sq. ft.

per hour

Thin-Mil coatings removal of 800 sq. ft.

per hour

Concrete polishing rates of 10,000 sq.

ft. per polishing pad

Terrco® Model 6200

Optimal for jobs exceeding 20,000 sq.

ft.

Despite the weight and size the 6200 is

easily maneuverable

Movable weights for easy one person

operation

Variable Speed Drive

Stainless Steel Guard with four vacuum

ports

Dry Setup

Handle Separates from Gear Case to

Allow Handle and Case to go through

Standard 36" Door

Ten 42 lbs. Pocket Weights to Control

Grinding Pressure

Terrco®, Inc.

222 1ST AVE. NW WATERTOWN, SD 57201

PHONE: (605) 882-3888 FAX: (605) 882-0778

EMAIL: [email protected]m

WEBSITE: www.terrco.com

HP/KW 40/30

Voltage 460

Phase 3

Drive Variable

Amp Draw 46

Breaker (Amps) 60-80

Stone Holder RPM 400-760

Sweep of Discs 53-1/2” (1397 mm)

Abrasive Pressure 1885 lbs (855 kg)

Width of Machine 55” (1397 mm)

Length of Machine 80” (2032 mm)

Height of Machine 54” (1372 mm)

Net Weight 2300 lbs (1043 kg)

Shipping Weight 2565 lbs (1163 kg)

Power Cord (6-4) 100 ft (30,5 m)

SAFTY PRECAUTIONS

-----------------------------------------------------------

This machine is intended for commercial use. It is designed ex-

clusively to grind and polish Terrazzo and concrete floors. Use

only recommended accessories and abrasives.

When the machine is in need of repair, use only Terrco parts.

All operators must read, understand and practice the following

safety precautions.

WARNING: Rotating grinding wheels can cause injury, keep

hands and loose clothing clear.

WARNING: Disconnect power at the machine before servicing

or changing grinding stones.

WARNING: Always check ground (earth) connection prior to

operating machine.

For Safety:

1: Have electrician hook up power to machine.

2: Always operate machine with ground fault protection.

3: Eye, hearing and respiratory protection advised.

4: Service and adjust guards for maximum protection. Never remove the guards.

5: Keep machine clean and properly serviced.

SAFETY PRECAUTIONS WHEN RUNNING

TERRCO GRINDERS

A.Have a qualified electrician hook up correct power

to the machine, grounded properly, with correct

breakers at electrical source.

B.When breaking down machine to change stones or to

check machine always disconnect power to the

machine.

C.Check for wear to ensure no exposed wires.

D.When grinding wet, employees must wear proper

footwear.

E.Always wear appropriate safety protection such as

eyewear, hearing and if needed respiratory

protection.

F.When grinding, watch for problems on the floor such

as bad joints, electrical covers, studs that can cause

injury to operator or machine.

G.Keep machines clean so any potential problems are

visible.

H.When using base machines, use guards for wet or

dry grinding.

I. Also when using base machines, operate with

flexible shaft and housing as parallel to motor as

possible to avoid kinks. Keep flex-shaft greased.

Operating Instructions

INTRODUCTION:

This manual has been prepared to assist you in

the proper operation and maintenance of your

machine. Please bear in mind that your

TERRCO® 6200 is a precision piece of

machinery manufactured to exacting standards.

In order for you to obtain maximum use of your

TERRCO® 6200, we suggest that you read this

manual completely and thoroughly before

attempting to operate your machine. A parts

diagram and parts reference sheet are included

to assist you in ordering the proper parts.

Always give the machine number and model

number when ordering repair parts.

PLELIMINARY PROCEDURES TO FOLLOW BE-

FORE PUTTING THE 6200 IN OPERATION FOR

THE FIRST TIME.

A. Delivery of the Machine

1. On delivery, the contractor should very

carefully examine the shipping crate to see that

no part of the machine is damaged. If damage

is noted, request an inspection immediately and

request a copy of the claim report. When

accepting the machine from the delivering

carrier, note the damage on the Freight Bill

before signing. TERRCO® WILL NOT honor

any claims for broken, damaged, or missing

parts that may have occurred in shipment, as

each machine is checked and inspected for the

same, before leaving our plant.

B. Installation and Replacement of Grinding

Stones

1. Move the counterbalancing weights to the

upper weight baskets.

2. Using the flop handle, tilt machine back

so that the caster wheel rests on the floor.

3. Clean mounting surface both on plug

stone and stone holder. On 2” or 3” diameter

plug stone, push stone in the hole and give the

stone a slight twist to be certain it is securely in

place.

4. Grasp machine handle and lower machine

to the floor slowly so that all stones are resting

on the floor. Make certain no stones have fall-

en or loosened while lowering the machine to

the floor.

C. Transport of Machine

1. With counterbalancing weights in the

upper weight baskets, tilt the machine so that

the caster wheel is firmly on the floor. You can

use the flop handle to pull the machine or you

can fold the flop handle over and push from

gear case side.

D. To operate the 6200

1. Disconnect electrical source.

2. Install stones per instructions in #1B.

3. After stones are installed, lower the

machine until it is in operating position.

CAUTION - Never attempt to start the machine

while lowering machine to the floor, as rear

stones will strike on corners resulting in thrown

stones and possible damage to the machine.

4. Before plugging into the electrical

system, check the voltage at the source. The

minimum acceptable voltage is (210/420 Volt,

60 HZ, 3 phase), or (380 Volt, 50 HZ, 3 Phase).

Anything lower than this can result in blown

heaters and possible motor burnout.

5. If the machine is to operate in an area

more than 100 feet from the source, it will be

necessary to use the next larger size cable (#4-

4) from the source to the 100 feet of #6-4 wire

cable that was furnished with the machine.

6. After you have the cable in place, relieve

pressure on the stones by applying your weight

on the handle and push the start button on the

starter switch, then releasing pressure on the

handle to lower the machine to the floor.

7. We recommend that the first pass over

the floor be made with the weights in the upper

weight baskets. After the floor is “roughed”

out, move the weights to the weight baskets

located on the gear case for maximum abrasive

pressure.

8. Be sure to periodically check stone wear,

to prevent grinding with the steel plugs, rather

than the stones.

General Maintenance for your TERRCO® 6200

A. The Lubrication of the Machine

1. The lubrication of the main gear case

a. The main gear case contains Mobilith AW-1 grease.

b. Gear case grease level must be checked once a year. The level of grease in the gear

case should be up to half the thickness of the helical gears. (Ref. No. 20 on the parts

diagram).

2. The Lubrication of the Wheel Bearings.

a. Use grease gun and grease with 1/2 shot once every six months on each wheel with

Mobilith AW-1 or equivalent.

3. Location of the grease fittings.

a. Eight fittings on bearing caps on top of gear case (Ref. No. 10). Lubricate these

fittings with three shots of Mobilith AW-1 or equivalent every six months.

B. Keeping Machine Clean

1. Daily schedule after each day’s grinding.

a. Tilt machine back on handle.

b. Clean under carriage with water using garden hose and nozzle.

c. Clean all grease fittings.

2. Do not let any cake-up of cement grinding paste occur as this could create an overload on

your machine as well as more weight to push.

C. Replacement of worn, damaged, or missing parts.

1. Advantages

a. If worn parts (bearings, gears, etc.) are not replaced promptly, serious damage to your

machine could occur.

b. Your machine will operate more efficiently with new TERRCO® parts.

2. Use only authorized TERRCO® parts as our warranty will not apply if other than factory

authorized TERRCO® parts are used.

D. Morflex Flexible Couplings

1. Bolts (Ref. No. 34) should be checked weekly for tightness. Loose bolts cause extreme

vibration and premature failure of rubber inserts in the couplings.

2. Your flexible couplings (Ref. No. 41) should be changed a minimum of once a year

whether you use you machine or not.

E. Stone Wear and Replacement.

1. Check your stones for wear periodically, as the stones may be worn flush with stone

holder plugs and the operator may be grinding with the steel stone spiders.

Ref. # Part # Description Qty Ref. # Part # Description Qty

1FE147B 40 H.P., 3 PH, 1770 RPM, 230/460V Motor 151 FEN26 Handle Assembly 1

22142 Capscrew 452 2038 Capscrew 4

32140 Lock Washer 353 1030 Lock Washer 4

4X85 90 Degree Cord Connector 154 2003 Nut 5

52111 Mounting Ring Bolts 455 HB88B Caster 1

6FE-130-6200 Motor Mounting Plate 156 FE72 Water Valve 1

7FE254 Pinion, 30HP Elec Motor, 1.875" 157 2012 Key 8

8FE-114 Motor Key, Electric 158 FE20B Wheel Shaft 2

93011 Machine Screw 32 59 2141 Wheel Bearing Spacer 4

10 T2118 Grease Fitting 45 Degree 860 DS236 Wheel Bearing Seal 4

11 FE-27 Bearing Cap 861 DS235 Wheel Bearing Cone 4

12 2008 Lock Nut 18 62 DS234 Wheel Bearing Cup 4

13 SM-43 Bearing Cone 863 DS5 Wheel Cap 2

14 SM-37 Bearing Cup 16 64 FE189 Valve Stem 2

15 2139 Capscrew 465 FE79 Water Tank Rod 1

16 2099 Capscrew 16 66 LW10 Water Valve Lever 1

17 1022 Lock Washer 30 67 2082 Cotter Pin 1

18 1025 Capscrew 30 68 SM172 Hose Bracket Clamp 1

19 FE252 Gear Case Cover 169 FS39 Clear Water Hose 1

20 FE125B Drive Gear, Electric 270

21 T2130 Capscrew 271 X84 Bracket 4

22 FE4B Driven Gear RH 472 FE263 Inverter Starter-40HP 1

23 SM16 Gear Shaft 873 LW76 Emergency Stop 1

24 SM72 Helical Gear Key 874 FE251 Rubber Mount 4

25 FEN17 Grease Vent Assy 175 FE246 Pocket Weight, Casting, 42 Lb. 10

26 SM15 Driven Gear LH 476 Lower Weight Basket 2

27 FE253 Gear Case 177 2018 Capscrew 1

28 FD40 Dowel Pin 678 FE271 Strap Bracket 2

29 FE259 Stationary Guard 179 SM182 Spring 1

30 FEN9 Splash Guard Lock Nut 380 FD43 Water Guide Bracket 1

31 FE153 Splash Guard Bolt 381 2080 Set Screw 1

32 SM171 Capscrew 32 82 SM186 Handle Spacer Collar 1

33 2027 Washer 32 83 DS7 Wheel 2

34 FE256 Upper Weight Basket 2

35 SM36 Bearing Cone 8

36 SM169 Grease Seal 8 Parts Not Pictured

37 SM89 Driving Spider 8SM424 50 Amp Male Plug 2

38 2148 Washer 4SM 425 50 Amp Connector 2

39 1007 Lock Washer 12 DS134 6-4 Cable, Feet 100

40 1033 Capscrew 12 X86 Straight Cord Connectors 2

41 SM88 Morflex Coupling 8FE266 Vacuum Pipes 2

42 SM192B Stone Spider-Plug 8FE262 Rubber Dust Seal 1

43 2027 Washer 32 FE270 Front Guard Bracket 1

44 SM171 Capscrew 32 LW78 Brush Strip 2

45 FR594 Plug Stone-2" Diameter (Not Included) 24

46 FE260 Movable Splash Guard Assy 1

47 SM57 Handle Grips 2

48 FE256B Lower Weight Basket 2

49 HB-25 Washer 16

50 FE29SS Splash Guard Strap 3

Model 6200 Parts List

MODEL 6200 HANDLE

ITEM NO. PART NUMBER DESCRIPTION QTY.

1 FEN 025 HANDLE BAR - 6200 1

2 FE 307 CONTROL ASSEMBLY 1

3 FE 251 VIBRATION MOUNT 4

4 FE 263 VARIABLE SPEED DRIVE - 40 HP 1

5 LW 076 EMERGENCY STOP 1

6 SM 057 HANDLE GRIP 2

7 SM 457 Y-PIPE RH 1

8 SM 457LH Y-PIPE LH 1

9 HB 088B CASTER 1

10 FE 474 UPPER BELT GUARD 1

11 FE 475 LOWER BELT GUARD 1

12 FE 294 V-BELT 1

13 FE 293 PULLEY 1

14 X-81 STRAIGHT CORD CONNECTOR 3

15 FE 292 2 HP MOTOR 1

16 FE 291 PULL PIN 2

17 FE 285 KEYLESS LOCKING HUB 2

18 FE 280 AXLE DRIVE PLATE 2

19 FE 290 WHEEL BEARING 6

20 FE 267 SELP PROPELLED WHEEL 2

21 FE 287 PILLOW BLOCK 2

22 FE 284 TRANSAXLE 1

23 T3047 HOSE BARB 1

24 FE 289 EXPANSION TANK 1

25 SM 113-SMALL BOX ENCLOSURE 1

T6010 CONTACTOR 1

T6110 OVERLOAD 1

26 X-80 90 DEG CORD CONNECTOR 3

27 SM 091-BUTTON START/STOP BUTTON 1

Other manuals for 6200

2

Table of contents

Other Terrco Floor Machine manuals