Terrco 2000 User manual

Terrco®, Inc.

Model 2000

OPERATING INSTRUCTIONS

ILLUSTRATED PARTS LIST

MAINTENANCE INSTRUCTIONS

Terrco®,Inc.

222 1st Avenue NW • Watertown, SD 57201

Model 2000

222 1st Avenue NW • Watertown, SD 57201

Phone: (605) 882-3888 • Fax: (605) 882-0778

Email: info@terrco.com • Website:www.terrco.com

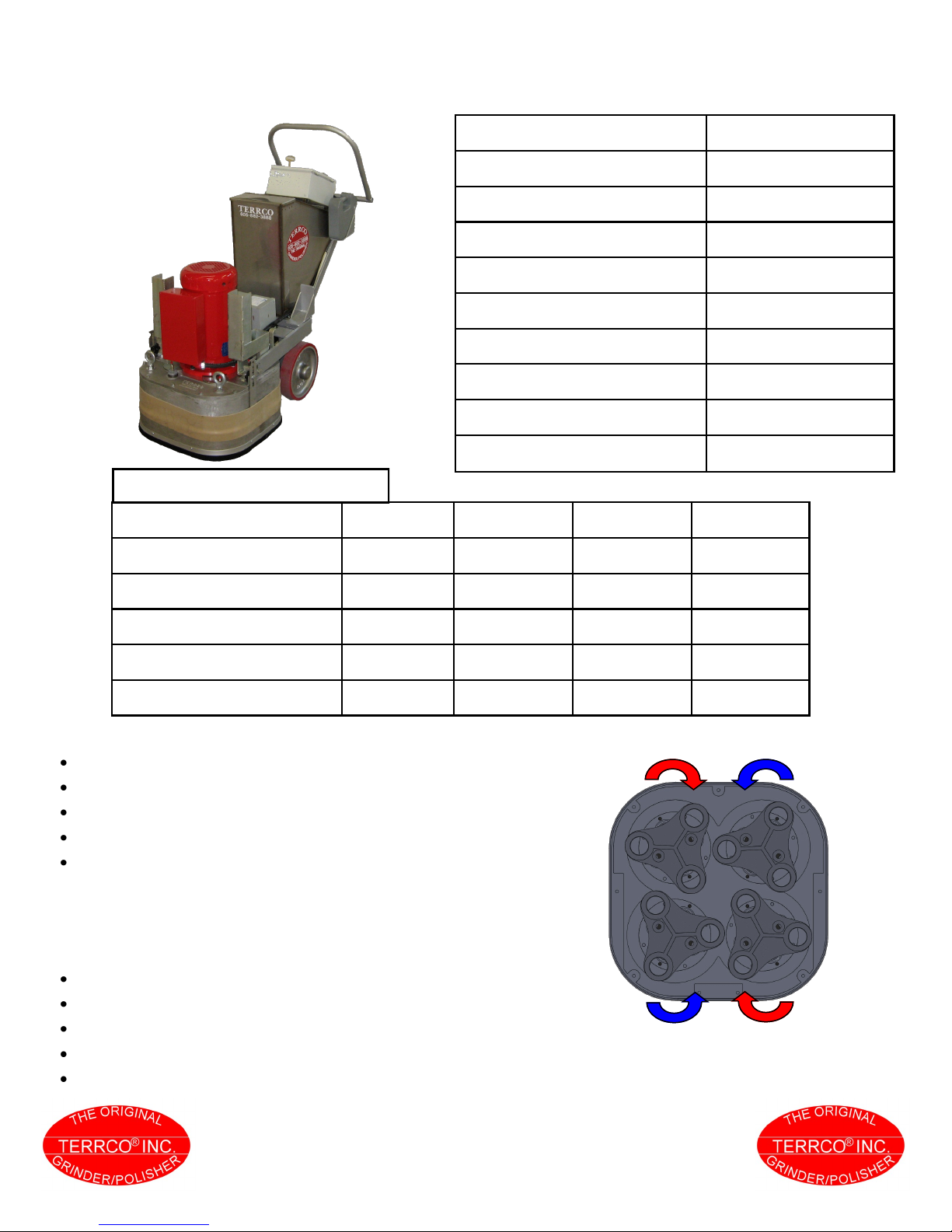

Optimal for jobs exceeding 5,000 sq. ft.

Stainless Steel Guards and Water Tanks

Wet/Dry Setup

Direct Drive, No Belts

Uses Plug Stone Shape, Bolt on to Universal Tool

Plate, or Speed Shift System

Production Rates

Mastic removal rate of 800 sq. ft. per hour

Thin-Set removal rates of 1,200 sq. ft. per hour

Thin-Mil coatings removal of 600 sq. ft. per hour

Concrete polishing rates of 2,000 sq. ft. per polishing pad per hour (depending on grit)

Rough Terrazzo rate of 1,000 sq. ft. per day

HP/KW 15/11.2 or 10/7.5

SWEEP OF DISCS 22-1/2” (571.5 mm)

ABRASIVE PRESSURE 650 LBS (295 kg)

WIDTH OF MACHINE 24” (610 mm)

LENGTH OF MACHINE 67-1/2” (1715 mm)

HEIGHT OF MACHINE 48” (1219 mm)

NET WEIGHT 800 LBS (363 kg)

SHIPPING WEIGHT 975 LBS (442 kg)

WATER TANK 20 gallon (75,7 L)

POWER CORD (6-3) 100 ft. (30,5 m)

VOLTAGE 230 230 460230

PHASE 1 1 33

DRIVE MANUAL VARIABLE VARIABLEMANUAL

AMP DRAW 40 40 1437

BREAKER (AMPS) 60 60 3060

STONE HOLDER RPM 550 500-740 500-740550

VALUES BASED ON A 10 HP MOTOR

ELECTRICAL OPTIONS

Operating Instructions

INTRODUCTION:

This manual has been prepared to assist you in

the proper operation and maintenance of your

machine. Please bear in mind that your

TERRCO®2000 is a precision piece of

machinery manufactured to exacting standards.

In order for you to obtain maximum use of your

TERRCO®2000, we suggest that you read this

manual completely and thoroughly before

attempting to operate your machine. A parts

diagram and parts reference sheet are included

to assist you in ordering the proper parts.

Always give the machine number and model

number when ordering repair parts.

PLELIMINARY PROCEDURES TO FOLLOW BE-

FORE PUTTING THE 2000 IN OPERATION FOR

THE FIRST TIME.

A. Delivery of the Machine

1. On delivery, the contractor should very

carefully examine the shipping crate to see that

no part of the machine is damaged. If damage

is noted, request an inspection immediately and

request a copy of the claim report. When

accepting the machine from the delivering

carrier, note the damage on the Freight Bill

before signing. TERRCO®WILL NOT honor

any claims for broken, damaged, or missing

parts that may have occurred in shipment, as

each machine is checked and inspected for the

same, before leaving our plant.

B. Installation and Replacement of Grinding

Stones

1. Move the counterbalancing weights to the

upper weight baskets.

2. Tilt machine back so that the caster wheel

rests on the floor.

3. Clean mounting surface both on plug

stone and stone holder. On 2” or 3” diameter

plug stone, push stone in the hole and give the

stone a slight twist to be certain it is securely in

place.

4. Grasp machine handle and lower machine

to the floor slowly so that all stones are resting

on the floor. Make certain no stones have

fallen or loosened while lowering the machine

to the floor.

C. Transport of Machine

1. With counterbalancing weights in the

upper weight baskets, tilt the machine so that

the caster wheel is firmly on the floor. You can

push from gear case side.

D. To operate the 2000

1. Disconnect electrical source.

2. Install stones per instructions in #1B.

3. After stones are installed, lower the

machine until it is in operating position.

CAUTION - Never attempt to start the machine

while lowering machine to the floor, as rear

stones will strike on corners resulting in thrown

stones and possible damage to the machine.

4. Before plugging into the electrical

system, check the voltage at the source. The

minimum acceptable voltage is (208 Volt, 60

HZ, single phase), (210/420 Volt, 60 HZ, 3

phase), or (380 Volt, 50 HZ, 3 Phase).

Anything lower than this can result in blown

heaters and possible motor burnout.

5. If the machine is to operate in an area

more than 100 feet from the source, it will be

necessary to use the next larger size cable (#4-

4) from the source to the 100 feet of #6-4 wire

cable that was furnished with the machine.

6. After you have the cable in place, relieve

pressure on the stones by applying your weight

on the handle and push the start button on the

starter switch, then releasing pressure on the

handle to lower the machine to the floor.

7. We recommend that the first pass over

the floor be made with the weights in the upper

weight baskets. After the floor is “roughed”

out, move the weights to the weight baskets

located on the gear case for maximum abrasive

pressure.

8. Be sure to periodically check stone wear,

to prevent grinding with the steel plugs, rather

than the stones.

General Maintenance for your TERRCO®2000

A. The Lubrication of the Machine

1. The lubrication of the main gear case

a. The main gear case contains Mobilith AW-1 grease.

b. Gear case grease level must be checked once a year. The level of grease in the gear

case should be up to half the thickness of the helical gears. (Ref. No. 20 on the parts

diagram).

2. The Lubrication of the Wheel Bearings.

a. Use grease gun and give a 1/2 shot of grease once every six months on each wheel

with Mobilith AW-1 or equivalent.

3. Location of the grease fittings.

a. Four fittings on bearing caps on top of gear case (Ref. No. 10). Lubricate these

fittings with 2 shots of grease every six months with Mobilith AW-1 or equivalent.

B. Keeping Machine Clean

1. Daily schedule after each day’s grinding.

a. Tilt machine back on handle.

b. Clean under carriage with water using garden hose and nozzle.

c. Clean all grease fittings.

2. Do not let any cake-up of cement grinding paste occur as this could create an overload on

your machine as well as more weight to push.

C. Replacement of worn, damaged, or missing parts.

1. Advantages

a. If worn parts (bearings, gears, etc.) are not replaced promptly, serious damage to your

machine could occur.

b. Your machine will operate more efficiently with new TERRCO®parts.

2. Use only authorized TERRCO® parts as our warranty will not apply if other than factory

authorized TERRCO®parts are used.

D. Morflex Flexible Couplings

1. Bolts (Ref. No. 32) should be checked weekly for tightness. Loose bolts cause extreme

vibration and premature failure of rubber inserts in the couplings.

2. Your flexible couplings (Ref. No. 41) should be changed a minimum of once a year

whether you use you machine or not.

E. Stone Wear and Replacement.

1. Check your stones for wear periodically, as the stones may be worn flush with stone

holder plugs and the operator may be grinding with the steel stone spiders.

ITEM NO. PART NUMBER DESCRIPTION QTY

1 FL 1 Lower Gear Case 1

2 FL 3 Gear Case Lid 1

3 FL 5L Helical Gear - Left Hand 2

4 FL 5R Helical Gear - Right Hand 2

5 FL 6 Drive Gear 2

6 FL 4C Plug Stone Holder 4

FL 130 Speed Shift Plate 4

FL 121 Universal Tool Plate 4

7 SM 500 Drive Plate 4

8 SM 088 Morflex Coupling 4

9 T2082 Cotter Pin 1

10 FL 122 Stationary Guard 1

11 FL 123 Adjustable Guard 1

12 FE 133-SS Water Tank Clip 2

13 FLN 009A Handle Bar 1

14 Z02-1330 Capscrew 2

15 LW 076 Emergency Stop Button 1

16 SM 174 Water Valve 1

17 SM 175 Pipe Nipple 1

18 T3007 Set Screw 1

19 SM 170X Water Valve Lever 1

20 SM 186 Lock Collar 2

21 SM 182 Compression Spring 1

22 FL 114 Water Lever 1

23 T2122 Capscrew 1

24 FD 043 Water Lever Guide 1

25 05-5010-9 Hex Head Nut 4

26 FE 277 Variable Speed Drive, 20 HP 1

FE 283 Variable Speed Drive, 15 HP 1

SM 091C Manual Start - 10 HP, 1 PH, 230 V 1

SM 091D Manual Start - 10 HP, 3 PH, 230 V 1

SM 091D-460 Manual Start - 10 HP, 3 PH, 460 V 1

27 X-84 Switch Box Mounting Bracket 4

28 FE 251 Vibration Mounts 4

29 T2029 Carriage Bolt 2

30 SM 537 Hand Knob 2

31 SM 457 Y-Pipe 1

32 FE 246 Pocket Weight 42 lbs. 4

33 T3015 Washer 16

34 HB 088A Caster 1

35 T1031 Capscrew 2

36 T1030 Lock Washer 15

37 FE 074 Water Tank Bracket 1

38 DS 007 Wheel 2

39 FE 031B-SS Water Tank - Stainless Steel 1

40 FL 012 Motor Plate 1

41 FE 027 Bearing Cap 4

42 SM 016 Helical Gear Shaft 4

43 SM 072 Gear Key 4

44 SM 037, SM 036 Bearing and Bearing Cone 4

45 T1089 Capscrew 12

46 T1022 Lock Washer 9

47 T2148 Washer 2

48 FD 040 Dowel Pin 6

49 SM 043, SM 036 Bearing and Bearing Cone 4

50 T2008 Nylon Lock Nut 10

51 T1009 Capscrew 4

52 T3011 Socket Flat Head 16

53 170 Grease Zerk 4

54 FL 011 Motor Pinion 1

55 FL 118 Motor Plate Seal 1

56 T1024 Capscrew 4

57 FL 124 10 HP, 3 PH, 230/460 V, 60 Hz Motor 1

X-99 10 HP, 1 PH, 230 V, 1800 RPM 1

FL 115 15 HP, 3 PH, 230/460 V, 1800 RPM 1

58 T2111 Capscrew 4

59 T3048 Capscrew 4

60 X 100 Gear Case Plug 1

61 DS 184 Breather Cap 1

62 T3050 Jam Nut 4

63 X 16 Lift Ring 4

64 SM 028 Stationary Guard Bracket 9

65 T2013 Capscrew 9

66 T1007 Lock Washer 18

67 T2130 Capscrew 9

68 SM 172 Hose Clamp 1

ITEM NO. PART NUMBER DESCRIPTION QTY

69 T2012 Woodruff Key 4

70 SM 169 Seal 4

71 SM 171 Capscrew 16

72 T1012 Lock Washer 24

73 X 118L Guard Bracket - Left Hand 1

74 X 118R Guard Bracket - Right Hand 1

75 FL 133 Guard Strap 2

76 FE 020B Wheel Shaft 2

77 T 2007 Jam Nut 2

78 DS 005 Wheel Cap 2

79 X 120R Weight Saddle - Right Hand 1

80 X 120L Weight Saddle - Left Hand 1

81 FE 114 Motor Key 1

82 T1025 Capscrew 7

83 T2004 Capscrew 2

84 T2141 Wheel Bearing Spacer 4

85 FL 134 Tilt Stop 1

86 Jam Nut 2

ITEM NO. PART NUMBER DESCRIPTION QTY

NOT PICTURED

PART NUMBER DESCRIPTION QTY

DS 135 6-3 Cable (1 PH Input) 100'

DS 134 6-4 Cable (3 PH Input) 100'

SM 420 MALE PLUG, 50A , 1 PH 1

SM 421 FEMALE PLUG, 50A, 1 PH 1

SM 424 MALE PLUG, 50A, 3 PH 1

SM 425 FEMALE PLUG, 50A, 3 PH 1

FE 207 VACUUM HOSE

LW 078 BRUSH STRIP

FL 030 DUST SEAL 1

SM 173 36" Water Hose 1

X 94 Reducer Bushing 1

X 97 Straight Cord Connector 2

X 90 Connector Lock Nut 2

LW 086 Hose Clamp - Booster 1

SM 176 Hose Clamp - Water Hose 2

T1065 Grease Zerk Cap 6

T1104 4" Cable Tie 2

WARRANTY CLAIM PROCEDURE

Each new machine is covered by two separate, distinct warranties—one on

the machine and one on the electric motor of gasoline engine. Read VERY

CAREFULLY the Terrco® warranty covering the machine, as this will tell you

whether you have a warranty claim or not. If your machine is under warranty and

malfunctions, determine whether your problem is electrical or mechanical, and do

the following:

I. Electrical.

A. Consult the list of authorized motor repair stations sent with the

machine and locate the station nearest you.

B. Contact the repair station, giving them the following information:

1. Complete nameplate date from the motor.

2. Tell them that the machine is a terrazzo grinding and

polishing machine.

3. Give them a description or rundown of the trouble.

4. Inform them of the voltage and amperage readings

II. Mechanical

A. Contact your Terrco®Distributor giving them the following:

1. Model and date purchased.

2. Horsepower.

3. Accurate description of the malfunction.

B. If there is no Terrco®Distributor in your area call or write to us

with the above information.

LIMITED ONE YEAR WARRANTY

TERRCO®, Inc. warrants the original purchaser of the Terrco®grinding

equipment to be free from defects in materials and workmanship under normal

use and service. Our obligation under this warranty shall be limited to the repair

or exchange of any part or parts which may prove defective under normal use and

service within one year from date or purchase by, the original purchaser, and

which our examination shall disclose to our satisfaction to be defective.

All equipment returned for repairs or exchange must be returned to: TERRCO®,

Inc., at the purchaser’s expense and within the warranty period. All repaired or

exchanged equipment will be shipped back to the purchaser F.O.B. Watertown,

South Dakota.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRATNIES

EXPRESSED OR IMPLIED INCLUDING THE WARRANTIES OR

MERCHANTABILITLY AND FITNESS FOR USE AND ALL OTHER

OBLIGATIONS OR LIABILITIES ON THE PART OF TERRCO®, INC. AND

WE NEITHER ASSUME OR AUTHORIZE ANY OTHER PERSON TO

ASSUME FOR US, ANY OTHER LIABILITY IN CONNECTION WITH THE

SALE IF THIS EQUPIMENT. SOME STATES DO NOT ALLOW THE

EXCLUSIONS OR LIMITATIONS ON IMPLIED WARRANTIES OR DO NOT

ALLOW THE EXCLUSION OF LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE EXCLUSIONS OR

LIMITAIONS MAY NOT APPLY TO YOU. THIS WARRANTY SHALL NOT

APPLY TO ANY EQUIPMENT OR PART THEREOF WHICH HAS BEEN

SUBJECT TO ACCIDENT, NEGLIGENCE, ALTERATIONS, ABUSE,

MISUSE, OR IMPROPER MAINTENANCE. TERRCO®, INC. MAKES NO

WARRANTIES WHATSOEVER IN RESPECT TO ACCESSORIES OR PARTS

NOT MANUFACTURED OR SUPPLIED BY US.

Other manuals for 2000

1

Table of contents

Other Terrco Floor Machine manuals

Popular Floor Machine manuals by other brands

U.S. Products

U.S. Products KING COBRA 300 Information & operating instructions

Nobles

Nobles Power Eagle 1016 Operator and parts manual

Clemas & Co

Clemas & Co T1 Operator's manual

Tennant

Tennant 8010 Instruction bulletin

Nobles

Nobles Speed Scrub 2001 Operator and parts manual

Windsor

Windsor LB1500 operating instructions