Terrco 01-S Series User manual

Terrco® Inc.

222 1st Avenue NW • Watertown, SD 57201

Phone: (605) 882-3888 • Fax: (605) 882-0778

Website: www.terrco.com • Email: inf[email protected]

OPERATING INSTRUCTIONS

MAINTENANCE INSTRUCTIONS

ILLUSTRATED PARTS LIST

Terrco ®, Inc.

01-S SERIES

VOLTAGE 230 230 230 230 460

PHASE 1 1 3 3 3

DRIVE MANUAL VARIABLE MANUAL VARIABLE VARIABLE

AMP DRAW 34 34 22 22 11

BREAKER (AMPS) 50 50 30 30 30

STONE HOLDER RPM 390 390-585 390 390-585 390-585

ELECTRICAL OPTIONS

Terrco® Inc.

222 1st Avenue NW • Watertown, SD 57201

Phone: (605) 882-3888 • Fax: (605) 882-0778

Website: www.terrco.com • Email: inf[email protected]

Terrco® 01-S SERIES

• Optimal for jobs under 5,000 sq. ft.

• Stainless Steel Guards

• Stainless Steel Water Tanks

• Wet/Dry Setup

• Variable Speed or Magnetic Start

• Direct Drive, No Belts

• Leveling System

• Adjustable Handle

• Uses Plug Stone Shape, Bolt on to Universal

Tool Plate, or Speed Shift System

PRODUCTION RATES

• Mastic removal rate of 350 sq. ft. per hour

• Thin-set removal rates of 400 sq. ft. per hour

• Thin-Mil coatings removal rates of 200

sq. ft. per hour.

• Concrete polishing rates of 450 sq. ft. per hour

(depending of grit)

• Rough Terrazzo rate of 600 sq. ft. per day

HP/KW 7.5-5.6

SWEEP OF DISCS 27” (685.8 mm)

ABRASIVE PRESSURE 440 lbs (200 kg)

WIDTH OF MACHINE 28” (711 mm)

LENGTH OF MACHINE

HANDLE UP 29-1/4”

(743 mm)

LENGTH OF MACHINE

HANDLE DOWN 56-1/2”

(1435 mm)

HEIGHT OF MACHINE 54” (1371 mm)

NET WEIGHT 775 lbs (352 kg)

SHIPPING WEIGHT 860 lbs (390 kg)

WATER TANK 7 gallons (26.5 l)

POWER CORD (8-3) 100 ft (30.5 m)

* WEIGHT MEASURED WITH FOUR POCKET WEIGHTS

SAFETY PRECAUTIONS

This machine is intended for commercial use.

It is designed exclusively to grind and polish Terrazzo and concrete oors.

Use only recommended accessories and abrasives.

When the machine is in need of repair, use only Terrco approved parts.

All operators must read, understand and practice the following safety precautions.

WARNING: Rotating grinding wheels can cause injury, keep hands and loose

clothing clear.

WARNING: Disconnect power at the machine before servicing or changing

grinding stones.

WARNING: Always check ground (earth) connection prior to operating machine.

FOR SAFETY:

• Have electrician hook up power to machine.

• Always operate machine with ground fault protection.

• Eye, hearing and respiratory protection advised.

• Service and adjust guards for maximum protection. Never remove the guards.

• Keep machine clean and properly serviced.

SAFETY LABEL

The safety label is located on the drive box of the machine.

Replace label if it is damaged or illegible.

WARNING

FOR SAFETY, READ OWNERS

MANUAL BEFORE USING MACHINE

ROTATING CUTTERS

KEEP GUARDS IN PLACE AND ADJUSTED

KEEP HANDS AND FEET AWAY WHEN OPERATING

GRINDING CAN GENERATE DUST

DUST MAY AFFECT BREATHING

AVOID DUST CONTACT BY USE OF

MASK OR RESPIRATOR

DISCONNECT POWER BEFORE CHANGING

TOOLING OR SERVICING THE MACHINE

ALWAYS CHECK GROUND (EARTH) PRIOR TO

OPERATING MACHINE

WEAR EYE AND HEARING PROTECTION

WHILE OPERATING THE MACHINE

INTRODUCTION

This Manual has been prepared to assist you in the proper maintenance and operation of your Terrco® Machine. Please

bear in mind that your 501-S or 701-S machine is a precise piece of machinery manufactured to exacting standards. In

order for you to obtain maximum use of your machine, we suggest that you read this manual completely and thor-

oughly before attempting to operate your machine. A parts diagram and parts list are included to assist you in order-

ing the proper parts. Always give the machine number and model number when ordering your repair parts.

PRELIMINARY PROCEDURES TO FOLLOW BEFORE OPERATING MACHINE FOR THE FIRST TIME:

DELIVERY OF MACHINE

1. On delivery the contractor should very carefully examine the shipping crate to see that it has not been mishandled.

Before accepting the shipment, uncrate the machine and very carefully examine the machine to ensure that nothing

has been damaged. If damage is noted, request an inspection immediately and request a copy of the claim report.

When accepting the machine from the delivery carrier, note the damage on the bill of lading before signing.

2. Terrco® WILL NOT honor any claims for broken, damaged, or missing parts that may have occurred in shipping, as

each machine is checked and inspected before leaving our plant.

The machine has been fully lubricated at the factory before shipping.

ON-THE-JOB INSTRUCTIONS

INSTALLATION INSTRUCTIONS-STONES

1. Remove the weights and raise adjustable handle as far forward as possible, lock into position and put one foot on

the rubber-tired wheel.

2. Tip the machine back to the oor so that the handle lays on the oor.

3. Clean stone mounting surface.

4. IMPORTANT! Install the plug stones in the following manner. Place the stone rmly into the plug stone holder and

twist.

5. After the stones are installed raise the machine until it is in operating position with all stones on the oor. Lower

handle to position best suited for the operator, and replace the removable weights.

6. CAUTION! NEVER ATTEMPT TO START THE MACHINE WHILE LOWERING TO THE FLOOR, as the rear stones will strike

on the corners resulting in thrown stones and possible damage to the machine.

ELECTRICAL AND PLUG-IN INSTRUCTIONS

1. General Instructions

•Always operate your machine with ground faults wired at the electrical source.

•Low voltage is a common occurrence on many terrazzo jobs, and hence it is necessary that the terrazzo contractor

know his incoming voltage and amperage at the machine.

•As a result of the low voltage and the use of a 230 Volt motor, Terrco® has installed a booster box with pre-wired

plugs already connected to your machine.

•If the machine is to operate on an area more than 100 feet from the electrical source it will be necessary to use the

next lower number (larger) size cable from the source to the 100 foot wire cable that we furnished with the machine.

•If additional cable is necessary, be sure all connections are of the proper size and that they are tight.

•As a nal step before starting the machine, we strongly recommend that a voltage reading is taken; this requires very

little time and could save a great deal of trouble.

OPERATING AND MAINTENANCE INSTRUCTIONS

01-S Series

GENERAL MAINTENANCE AND REPAIR INSTRUCTIONS

THE LUBRICATION OF THE MACHINE

1. The lubrication of the main gear case.

•The main gear case contains 6-1/4 pounds of Mobilith AW-1 grease.

•Gear case level shoud be checked once a year. The level of the grease in the gear case should be up to half the

thickness so the helical gears (Ref. number 13 and 35 on the parts diagram).

2. The lubrication of the wheel bearings.

•Use grease gun and grease each wheel with 1 shot of grease monthly (Ref. number 14 on the Suspension Assembly)

with Mobilith AW-1 or equivalent.

3. Location of other Grease Fittings

•Two ttings on bearing caps on top of gear case (Ref. number 7). Lubricate these ttings with Mobilith AW-1 every

month with 2 shots of grease.

•One tting on foot leveling device (Ref. number 86); recommended grease Mobilith AW-1 or equivalent every six

months with 1/2 shot of grease or as needed.

•There are four shoulder bolts located at the pivot points of the handle bar that require 1/2 shot of Mobilith AW-1 or

equivalent every six months or as needed.

KEEPING MACHINE CLEAN

1. Schedule daily cleaning after each days grinding.

•Tilt machine back on handle.

•Clean under carriage with water using a garden hose and nozzle.

•Clean all grease ttings.

2. Do not let any cake-up of cement grinding paste occur as this could create an overload on your machine.

3. Avoid direct spraying of drives/ starter boxes if using a pressure washer to clean the machine.

REPLACEMENTS OF WORN, DAMAGED, OR MISSING PARTS

1. Advantages

•If worn parts (bearings, gears, etc) are not replaced promptly, serious damage to your machine could occur.

•Your machine will operate more effi ciently with new Terrco® parts.

2. Use only authorized Terrco® parts as our warranty will not apply if other than factory authorized Terrco® parts are

used.

MORFLEX FLEXIBLE COUPLINGS

1. Bolts, (Ref. number 87) should be checked weekly for tightness. Loose bolts cause extreme vibrations and premature

failure of rubber inserts in the couplings.

2. Your exible couplings (Ref. number 37) should be changed a minimum of once a year whether you use your ma-

chine or not.

HIGH MOTOR TEMPERATURE

1. Introduction

•“Running Hot” is normal for the smaller, lighter “t” type motor.

•Even though they will run hotter, the “T” motors run more effi ciently.

•Skin cannot withstand a temperature over 135° F yet, most electric motors on Terrco® machines are designed to

operate effi ciently at 165°.

2. Operating Characteristics

•The temperatures of motors are rated by temperature rise and full load over and above room temperature

(25°C or 77°F).

•To convert degree Centigrade to degree Fahrenheit, multiply degree Centigrade by the fraction 9/5 and add 32.

•Older (repulsive-induction) type motors were rated 40° Centigrade rise, or approximately 150° Fahrenheit.

3. Conclusion

•It is recommended that you keep you hands off the motors when they are hot.

•If you desire to know the temperature of the motor do the following:

1. Place a 200°F thermometer on the frame of the motor.

2. Place a glob of putty over the bulb of the thermometer.

3. Take the temperature readings.

•Also, do not forget we use a thermal protected starters on Terrco® machines, and this protects the motor against low

voltage and overload conditions which might raise the temperature of the motor beyond safe limits.

STONE WEAR AND REPLACEMENT

1. Check your stones for wear periodically, as the stones may be worn ush with stone holder plugs and the operator

may be grinding with steel stone spiders.

EXCLUSIVE FEATURES OF THE 01-S SERIES

ADVANTAGES OF “T” TYPE MOTOR

1. Less amperage draw.

•15% less in the 5 HP size.

•9-1/2% less in the 7-1/2 HP size.

2. Higher safe operating temperature (165°F)

3. Lightweight.

•42-1/2% less in the 5 HP size.

•34-1/2% less in the 7-1/2 HP size.

4. Less maintenance.

•No brushes.

•Less internal wiring.

DESIGN ADVANTAGES OF NEW MANUAL FOOT LEVELING DEVICE

1. Improved machine control.

2. Faster and greater range of adjustments.

•Six leveling adjustments.

•1/8” increments

3.Simple to operate by merely pushing down on foot lever and raising up on handle.

ADVANTAGE OF LIGHTWEIGHT MACHINE

1. Ease of transportation

2. Still has suffi cient abrasive pressure by use of the removable weights.

TEN POSITION HANDLE

1. Advantages.

•Easier to “break” machine when changing stones.

1. A er removing the weighs, unscrew safety knob (Ref. number 107), push knob (Ref. number 18) to the rear to release

the locking mechanism. Raise handle two or three notches, lock handle by reversing the above procedure and tilt stone

holders off the oor.

2. Pushing the handle for ward two or three notches creates a safe stone position for changing, as the machine will not

have a tendency to “ ip-up”. It also makes it much easier to get at the stone changing area.

2. Operation

•The adjustable handle is very easy to operate. You merely unscrew the safety knob (Ref. number 107), push knob

(Ref. number 18) to the rear to release the locking mechanism. When you have raised or lowered the handle to your

desired position, push knob (Ref. number 18) forward as far as you can and screw the safety knob (Ref. number 107)

tight. This will lock the handle in position.

•Make sure that you have pulled knob (Ref. number 18) completely to the rear to assure full unlocking of mechanism

and the safety knob (Ref. number 107), is screwed up tight.

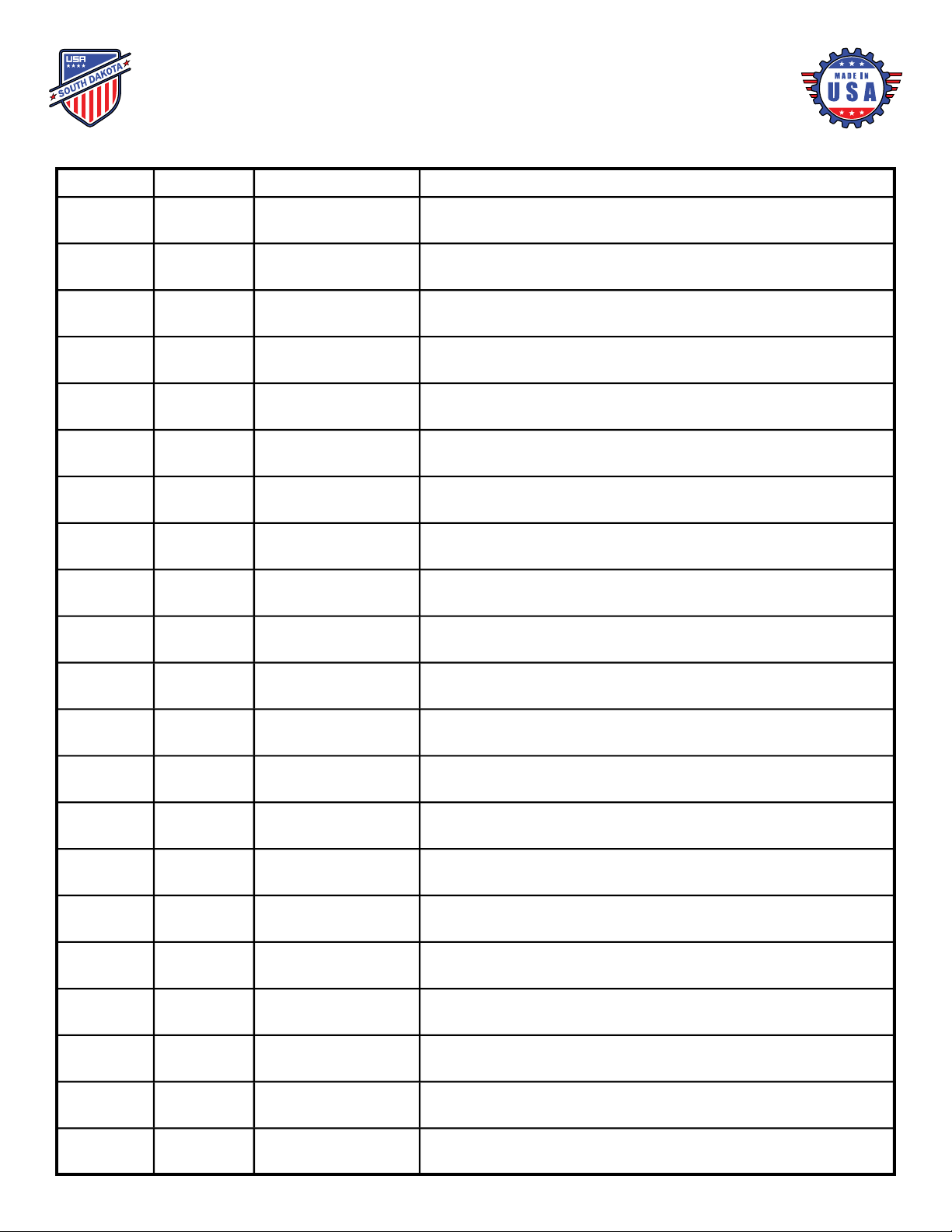

PART # DATE CHECKED BY: AREAS OF CONCERN

01-S

MAINTENANCE CHART

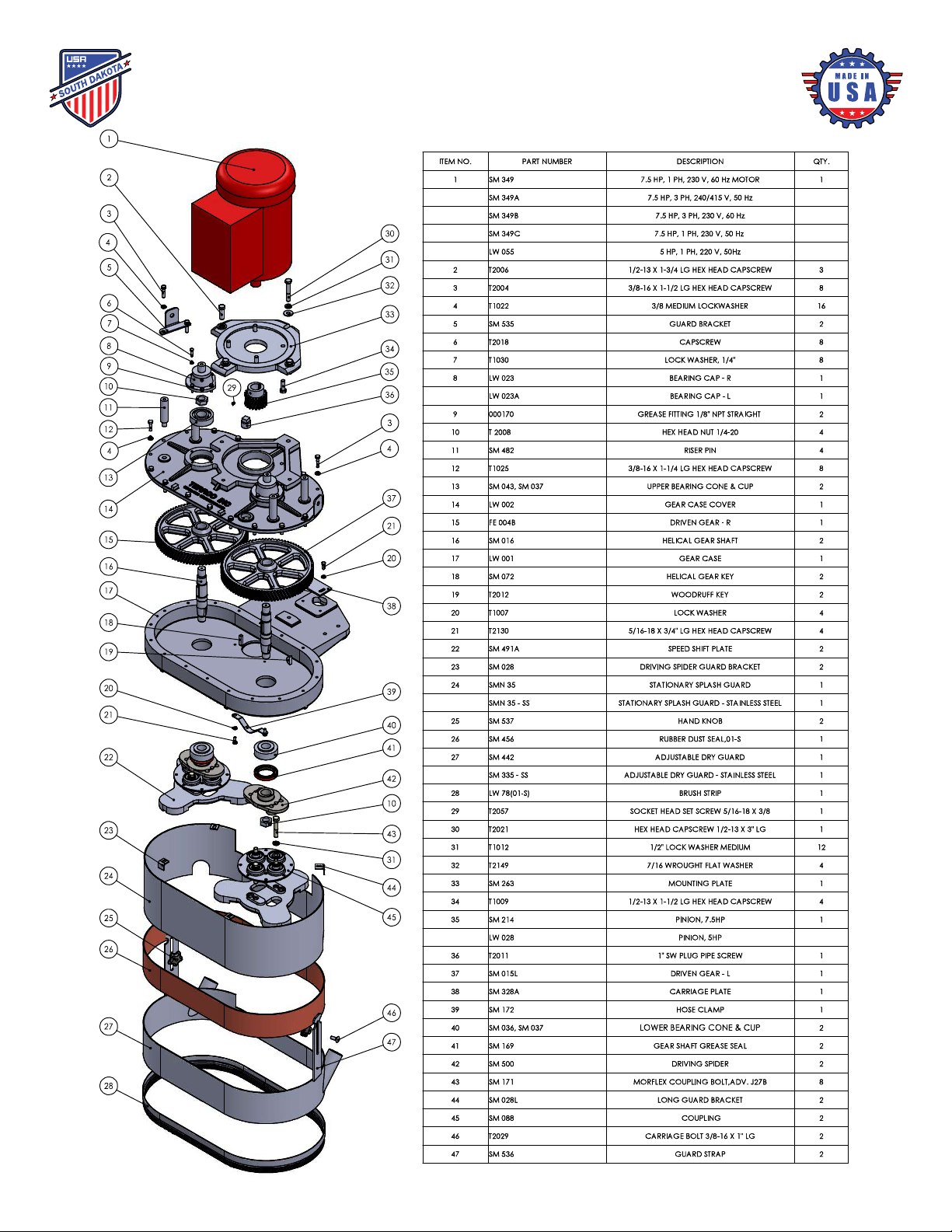

01-S PARTS LIST

(GEAR CASE ASSEMBLY)

01-S PARTS LIST

(HANDLEBAR ASSEMBLY)

01-S PARTS LIST

(HANDLEBAR CONTINUED)

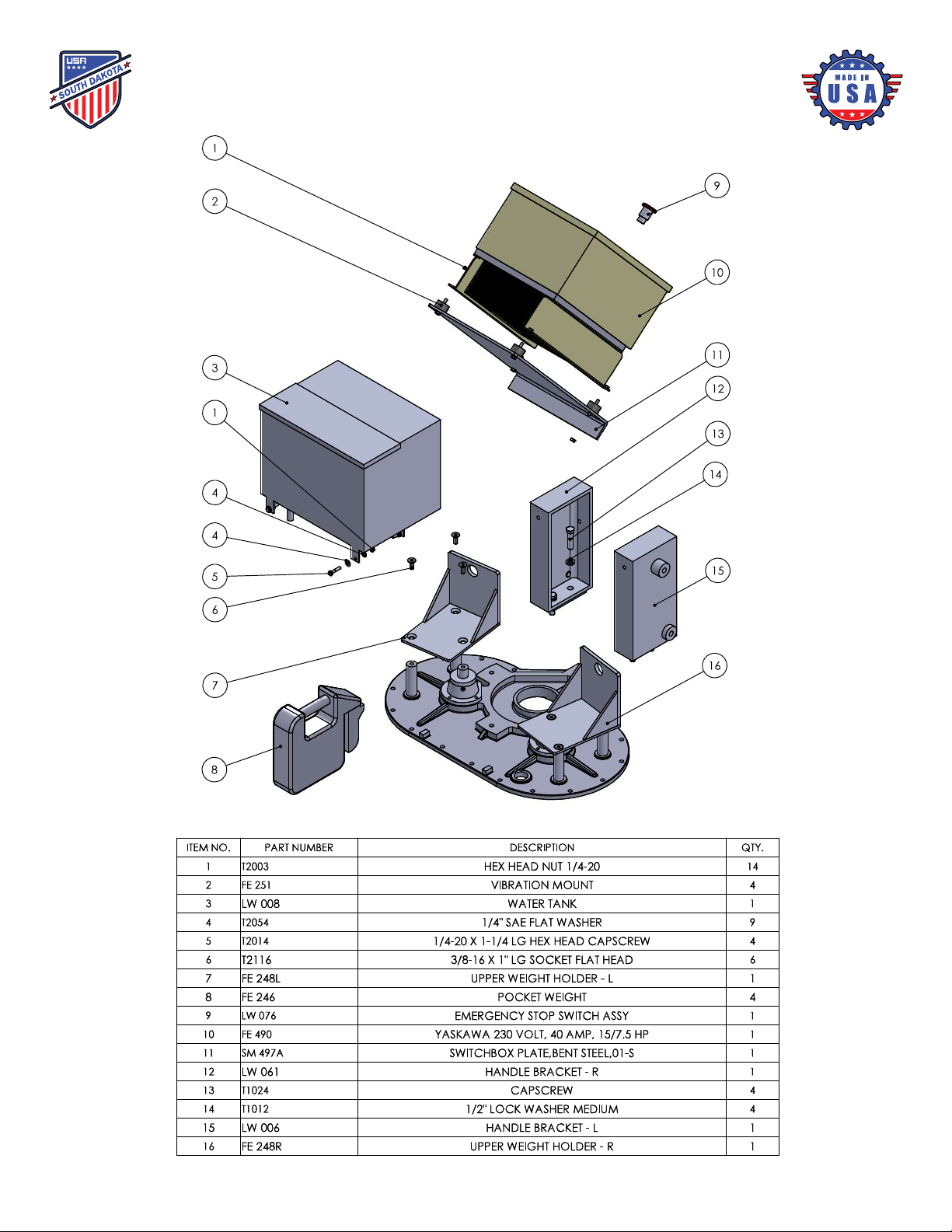

01-S PARTS LIST

(SUSPENSION ASSEMBLY)

Each new machine is covered by two separate, distinct warranties: one on the machine and one on the electric motor

or gasoline engine. Read VERY CAREFULLY the Terrco® warranty covering the machine, as this will tell you whether you

have a warranty claim or not. If your machine is under warranty and malfunctions, determine whether your problem is

electrical or mechanical, and do the following:

ELECTRICAL

1. Consult the list of authorized motor repair stations sent with the machine and locate the station nearest you.

2. Contact the repair station, giving them the following information:

• Complete nameplate date from the motor.

• Tell them that the machine is a terrazzo grinding and polishing machine.

• Give them a description or rundown of the trouble.

• Inform them of the voltage and amperage readings as outlined on page 2 of this manual.

MECHANICAL

1. Contact your Terrco® Distributor giving them the following:

• Model and date purchased.

• Horsepower.

• Accurate description of the malfunction.

2. If there is no Terrco® Distributor in your area call or write to us with the above information.

WARRANTY CLAIM PROCEDURE

TERRCO® Inc. warrants the original purchaser of the Terrco® grinding equipment to be

free from defects in materials and workmanship under normal use and service. Our

obligation under this warranty shall be limited to the repair or exchange of any part or

parts which may prove defective under normal use and service within one year from

date of purchase by, the original purchaser, and which our examination shall disclose

to our satisfaction to be defective.

All equipment returned for repairs or exchange must be returned to: TERRCO®, Inc.,

at the purchaser’s expense and within the warranty period. All repaired or exchanged

equipment will be shipped back to the purchaser F.O.B. Watertown, South Dakota.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRATNIES EXPRESSED OR

IMPLIED INCLUDING THE WARRANTIES OR MERCHANTABILITLY AND FITNESS FOR USE

AND ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF TERRCO®, INC. AND WE

NEITHER ASSUME OR AUTHORIZE ANY OTHER PERSON TO ASSUME FOR US, ANY OTH-

ER LIABILITY IN CONNECTION WITH THE SALE IF THIS EQUPIMENT. SOME STATES DO

NOT ALLOW THE EXCLUSIONS OR LIMITATIONS ON IMPLIED WARRANTIES OR DO NOT

ALLOW THE EXCLUSION OF LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAG-

ES, SO THE ABOVE EXCLUSIONS OR LIMITAIONS MAY NOT APPLY TO YOU. THIS WAR-

RANTY SHALL NOT APPLY TO ANY EQUIPMENT OR PART THEREOF WHICH HAS BEEN

SUBJECT TO ACCIDENT, NEGLIGENCE, ALTERATIONS, ABUSE, MISUSE, OR IMPROPER

MAINTENANCE. TERRCO®, INC. MAKES NO WARRANTIES WHATSOEVER IN RESPECT TO

ACCESSORIES OR PARTS NOT MANUFACTURED OR SUPPLIED BY US.

LIMITED ONE YEAR WARRANTY

Other manuals for 01-S Series

1

Table of contents

Other Terrco Floor Machine manuals

Popular Floor Machine manuals by other brands

Tennant

Tennant B1 Series Operator and parts manual

FIORENTINI

FIORENTINI I 16 Operating instructions and maintenance guide

Advance acoustic

Advance acoustic Advenger 56601000 Instructions for use

Clarke

Clarke FOCUS II MICRO RIDER 26D Instructions for use

Kärcher

Kärcher KMR 1000 T operating instructions

Onfloor

Onfloor Striker 2010 Operator's manual