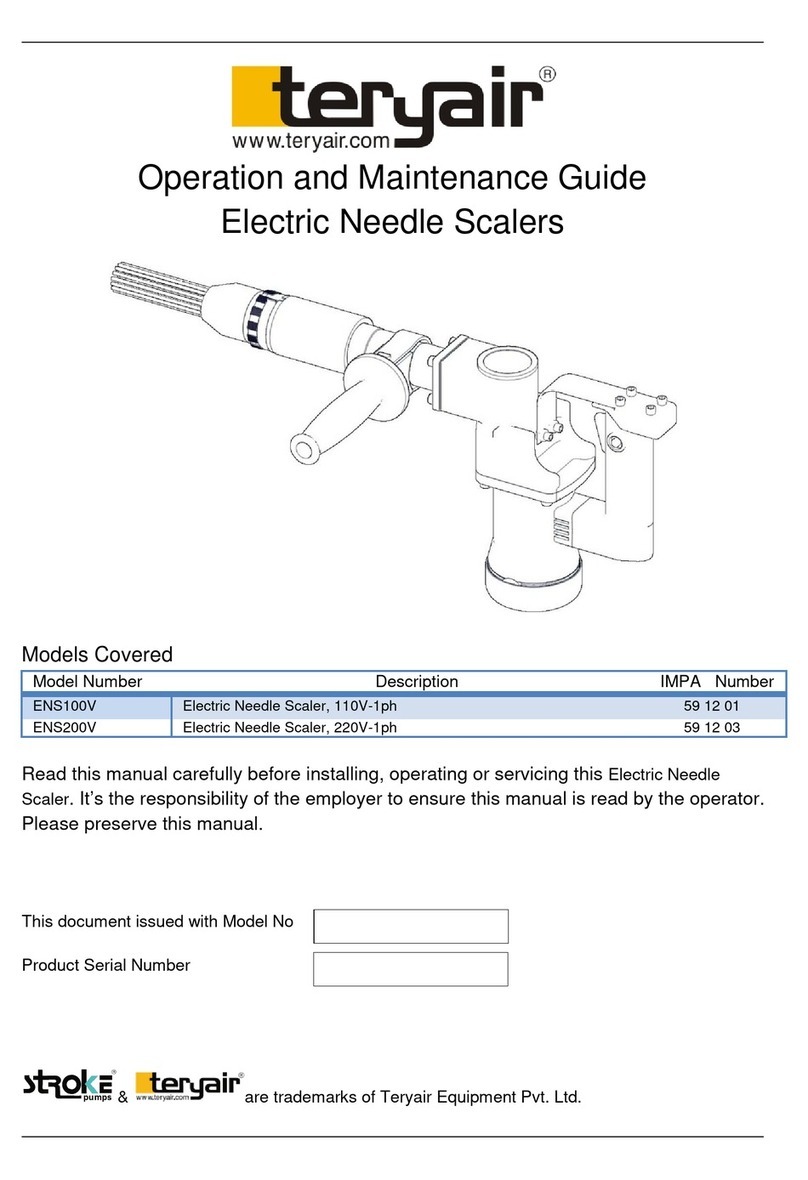

Teryair ENS100V Instruction Manual

Models Descriptions IMPA Code

ENS 100V Electric Needle Scaler, 110V-1ph 59 12 01

ENS 200V Electric Needle Scaler, 220V-1ph 59 12 03

Read this manual carefully before installing, operating or servicing this equipment. It’s the responsi-

bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

is document is issued with Product Serial No

Operation and Maintenance Guide

ENS 100V / ENS 200V

FF-MM-319-REV - 02

Page 2

Operation and Maintenance Guide Electric Needle Scalers

Table of Contents

3 Introducon

3 Technical Data

3 SafetyInstrucons

4 OperangInstrucons

6 Diassembly and Re-assembly for ENS 100V & ENS 200V

8 Bill of Materials for ENS 100V & ENS 200V

9 Exploded View for ENS 100V & ENS 200V

10 TestCercateOfMaterials,Performance

11 EuDeclaraonOfConformity

12 WarrantyCercate

FF-MM-319-REV - 02

Page 3

Operation and Maintenance Guide Electric Needle Scalers

Introduction

Teryair Electric Needle Guns are rugged tools. Designed to be easy to use and maintain. they are

ideal for removing layers of paint, corrosion and chemical coatings from surfaces. Rotating handle

can be xed at any position to make operation easier.

Safety Instructions

Warning

is manual must be read and the operating

instructions carefully followed.

Warning

Safety and protective clothing, eyewear, head-

gear, ear protection, gloves, and footwear to be

worn during operation of this Electric Needle

Scaler.

Warning

Operators under 18 are not allowed to oper-

ate this Electric Needle Scaler. Operators must

be made familiar with the instructions in this

manual before attempting to operate the Electric

Needle Scaler. Ensure that the job site is clear of

bystanders

Following symbols are used through out this

manual.

Intended Use

• Removal of Coatings.

• Hold cleaning, general deck and surface

cleaning, removal of heavy rust on tankers,

and dry dock applications.

• Tank descaling, Descaling of structures

before painting.

• Paint removal.

• Other industrial coating removals from

oors and other surfaces.

• Removal of concrete residue from re-bar

Cleaning cement from plant and vehicles.

• Weld cleaning.

Prohibitive use

• Any use in an explosive atmosphere is

prohibited.

• Use of materials containing asbestos is

prohibited.

• Use by an underage, untrained, or person

who is under the inuence of drugs or

alcohol.

• Use with non-genuine spare parts or acces-

sories is prohibited.

Note 1: Standard equipment includes one set of 3mm Needles, replacement needles sets available.

Note 2: Optional needles in 2mm with corresponding needle supporters can be ordered separately.

Technical Data

Teryair Model No ENS100V ENS200V

IMPA Code 59 12 01 59 12 03

Power Supply (AC) 110V-1Ph 220V-1Ph

Overall length LxWxH mm 480 X 240 X 100

Rated Power Consumption (W) 900 900

Rated Current (A) 6.0 3.0

Duty Cycle (Min) 10 - 12 10 - 12

Needle Stroke (mm) 20 20

Stroke Speed (Min) 2900 2900

Needles (Qty) 2mm X 53 pcs. Or 3mm X 23 pcs.

Power Cord Length (Mtr) 2 2

Weight (Kg) 7 7

FF-MM-319-REV - 02

Page 4

Operation and Maintenance Guide Electric Needle Scalers

• Scalers are rugged dependable tools designed

to give you years of satisfactory service.

Follow the instructions mentioned here to

enhance the life and performance of your

scalers.

• Use genuine Teryair spares and if possible

mention the serial number of the Electric

Needle Scaler when ordering spares.

Safety check before operating the

Needle Scaler

1. Read the section in “Operating and safety

precautions”.

2. Make sure the electric supply is consistent

with the electric motor requirements. e

scaler comes with a standard cable length

of 2.5 meters, avoid using a longer cable to

avoid voltage drop.

3. Connect the supply cable as shown. e Male

portion is connected to the Scaler (Factory

tted). e female side electrical connection

is to be made at the customer end as per the

model no. and supplied voltage.

• First, li the cover and pull the plug from the

assembly.

• Now remove the screws from the inner side

of the female plug. is will allow removing

the rear portion and connection points will

available. Refer to the below gure for wire

connection.

• Connection detail for 1-phase

• First, disassemble the male & female plug by

liing the spring-loaded lock.

Operating Instructions

Caution

Use only genuine Teryair or Teryair approved

accessories.

Warning

is Electric Needle Scaler is not designed for

use in an explosive environment.

Warning

Always use both hands during operation. Do

not run the scaler continuously for more than

15 minutes to avoid overheating. Take must be

taken to select the correct power supply as per

the model.

Caution

Do not exert excessive pressure against the

work surface. Keep wire cables in good condi-

tion. Check for any loose connection from the

source.

Caution

• Be aware that these Electric Needle Scalers

can create dust & ying debris.

• Keep hands & clothing away from moving

parts.

• Store these Electric Needle Scalers in a

secure & dry environment.

• Do not allow the Electric Needle Scaler to

run unattended.

• Do not modify this Electric Needle Scaler

in any way as this will invalidate the war-

ranty and could lead to serious injury.

• Do not allow the Electric Needle Scaler

to run continuously whilst not in contact

with the surface being prepared.

• Do not hold the exposed needles whilst

the Electric Needle Scaler is in use this

could cause vibration damage to the

hands.

• Do not drag this Electric Needle Scaler by

the cable.

Warning

Do not use the Electric Needle Scaler in

potentially explosive environments.

Warning

Eye and face and ear protection must be worn

at all times during the operation of the Elec-

tric Needle Scaler. ere is a chance of ying

debris from the job site and the quality of

wear should be such to protect against such

ying debris such as akes of the removed

layer.

Warning

Suitable gloves must be worn at all times

during operation. Safety Shoes with toe cap

protection are a must during operation.

FF-MM-319-REV - 02

Page 5

Operation and Maintenance Guide Electric Needle Scalers

• Now remove the two screws as shown to remove the

rear cover of female plug to see the terminals.

• Insert the cable from the back of the cover through

the holder and terminate the respective wire. Make

sure to tighten the holder so that wiring conn. should

not come out if the cable pulled from the cover.

FF-MM-319-REV - 02

Page 6

Operation and Maintenance Guide Electric Needle Scalers

Diassembly and Re-assembly for ENS 100V & ENS 200V

Disconnect the plug & switch o power supply

from the source.

Needle Replacement

• First remove the Lock (14).

• Now rotate the front cover (4) counter

clockwise.

• Now slide out the needle supporter (13)

along with needles (12) and spring (11).

• Push the worn out needles (12) from the

front side to remove from the needle

supporter (13).

• Replace the old needles with new one and

assemble in reverse manner.

Needle size Needle Part no. Needle Supporter

Ø2 022 90 08 (53 No.s) 022 40 47

Ø3 022 90 04 (23 No.s) 022 40 45

FF-MM-319-REV - 02

Page 7

Operation and Maintenance Guide Electric Needle Scalers

Carbon Brush Replacement

• Remove the screws (26) from the bottom

to disassemble the cover(25).

• Now remove the cap (22) and pull the

carbon brush (21).

• Replace with new one and assemble in a

reverse manner.

FF-MM-319-REV - 02

Page 8

Operation and Maintenance Guide Electric Needle Scalers

Bill of Materials for ENS 100V & ENS 200V

Illustration

Number Part Number Description ENS 100V ENS 200V

1 655 91 01 MAIN HOUSING-100V 1 -

1 655 91 02 MAIN HOUSING-200V - 1

2 655 21 01 ANVIL 1 1

3 655 21 02 STRIKER 1 1

4 655 21 03 FRONT TUBE 1 1

5 655 21 04 MAIN BODY 1 1

6 655 21 05 INNER ANVIL 1 1

7 655 40 01 RUBBER GRIP 1 1

8 655 40 02 'O' Ring 1 1

9 655 40 03 'O' Ring 1 1

10 655 40 04 'O' Ring 1 1

11 655 51 01 SPRING 1 1

12 022 90 04OL NEEDLE (Ø3mm x 180mm) 23 23

13 022 40 45 NEEDLE SUPPORTER (Ø3mm) 1 1

14 022 90 13 SAFETY BAND 1 1

15 655 21 06 SPACER 1 1

16 655 40 05 'O' Ring 1 1

17 655 97 01 GRIP HANDLE ASSEMBLY 1 1

18 655 21 07 FLANGE HOUSING 1 1

19 655 40 06 GASKET 1 1

20 655 40 07 'O' Ring 1 1

21 655 98 01 SPRING WITH CARBON BUSH 2 2

22 655 08 02 CAP 2 2

23 150 40 26 ALLEN BOLT 4 4

24 536 90 04 SPRING WASHER 4 4

25 655 31 01 BACK GUARD 1 1

26 655 90 01 SELF TAPPING SCREW 2 2

27A 653 91 03 PLUG 1 1

27B 653 91 04 SOCKET 1 1

Optional Accessories

Part No Description Qty

022 90 08 NEEDLE (Ø2mm x 180mm) 53

022 40 47 NEEDLE SUPPORTER ((Ø2mm) 1

FF-MM-319-REV - 02

Page 9

Operation and Maintenance Guide Electric Needle Scalers

Exploded View for ENS 100V & ENS 200V

27B

27A

26

25

7

19

22

21

20

10

16

3

15

2

14

23

12

11

9

13

24

5

6

17

4

18

8

1

FF-MM-319-REV - 02

Page 10

Operation and Maintenance Guide Electric Needle Scalers

TEST CERTIFICATE OF MATERIALS, PERFORMANCE

Date :

Model number :

Part description & s.No. :

We hereby certify that the above referenced product has tested and inspected in accordance with our standard test proce-

dures and meets the specications for material and performance values as published in our literature. We further certify that

the product has been given our standard factory test and meets all quality and performance standards established by the

company.is product is certied to be produced in our factory, and is of current production.

Authorised Signatory

Q.A Manager

Place - Vasai, Maharastra

FF-MM-319-REV - 02

Page 11

Operation and Maintenance Guide Electric Needle Scalers

EU DECLARATION OF CONFORMITY

We hereby certify that the Listed Product stipulated below comply with all relevant provisions of the machinery direc-

tive (2006/42/EC) and the national laws and regulations adopting this directive.

Description :

Model Number :

Date :

Serial Number :

Is in conformity with the provisions of the following European Directives: (2006/42/EC) Machinery Safety and Har-

monized standards

ISO 12100-1: 2010: Safety of Machinery –general Principles for Design –Risk Assessment and Risk Reduction.

Registered Oce : 416 Gundecha Industrial Complex, Akuril Road,

Kandivali East, Mumbai – 400101, Maharashtra, India.

Web site : www.teryair.com

Works : A-1, Tirupati Udyog Nagar, Sativali Road, Vasai East,

Palghar – 401208, Maharashtra, India.

CE certication registration no – C E 16831

Issued by – BMQR Certications Pvt Ltd.

www.cemarking-india.com

Valid Till – 03/11/2021

Signed for and on behalf of

TERYAIR EQUIPMENT PVT. LTD. Place of Issue:

Date:

FF-MM-319-REV - 02

Page 12

Operation and Maintenance Guide Electric Needle Scalers

Warranty Certificate

Every product manufactured by Teryair

is built to meet the highest standards of quality.

Teryair warrants that the Products, accessories and parts manufactured or supplied

by the company be free from defects in material and workmanship for a period of six

months from date of Teryair authorized dealer invoice to customer, or one year from

date of Teryair invoice to dealer, whichever is earlier. Failure due to normal wear,

misapplication, or abuse is, of course, excluded from this warranty.

Since the use of Teryair products and parts is beyond our control, Teryair cannot

guarantee the suitability of any product or part for a particular application and Teryair

shall not be liable for any consequential damage or expense arising from the use or

misuse of its products on any application. Teryair does not warranty bought out

products or components such as electric motors and hardware but will assist in

directing warranty queries to the dealer/manufacturer responsible. Teryair

responsibility is limited solely to replacement or repair of defective Teryair products

or components.

Dealer/End User shall have no right or remedy and Teryair shall have no liability or obligation under the warranty, if:

(i) a Product is altered, changed, modified or tampered with in any way, (ii) a Product is damaged after deposit with the

transporter for shipment; (iii) a Product is not properly preserved, packaged, stored, processed or handled after receipt; (iv) a

Product is not used and maintained in accordance with Teryair's recommended operating and maintenance manuals,

instructions and procedures, if any; (v) a Product is not properly incorporated or installed in, or not properly combined with, an

Other Product; (vi) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises

out of, a failure, substandard performance or other issue with another product, material, component or part not supplied by

Teryair; (vii) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of,

compliance with any design, specification or other specific requirement of Dealer/End User; (viii) a Product is used in a manner,

with a substance or for a purpose other than the normal manner, substance and purpose for which it is intended or is otherwise

subjected to abnormal use or service; (ix) a Product is subjected to a power surge, brown out or other similar occurrence; (x)

the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of, normal wear

and tear of such Product (including, without limitation, things such as worn seals, diaphragms, balls, O rings, gaskets, chisels,

cutters, hoses and other such wearing components; (xi) the issue with a Product is directly or indirectly.

Dated :

Product Model Number :

Product Serial Numbar : Ajay Bhagat, Q.A. Manager

(Company Seal)

FF-MM-319-REV - 02

Page 13

Operation and Maintenance Guide Electric Needle Scalers

is page is intentionally

Le blank.

Other manuals for ENS100V

1

This manual suits for next models

3

Table of contents

Other Teryair Tools manuals