Teryair SN24ST Instruction Manual

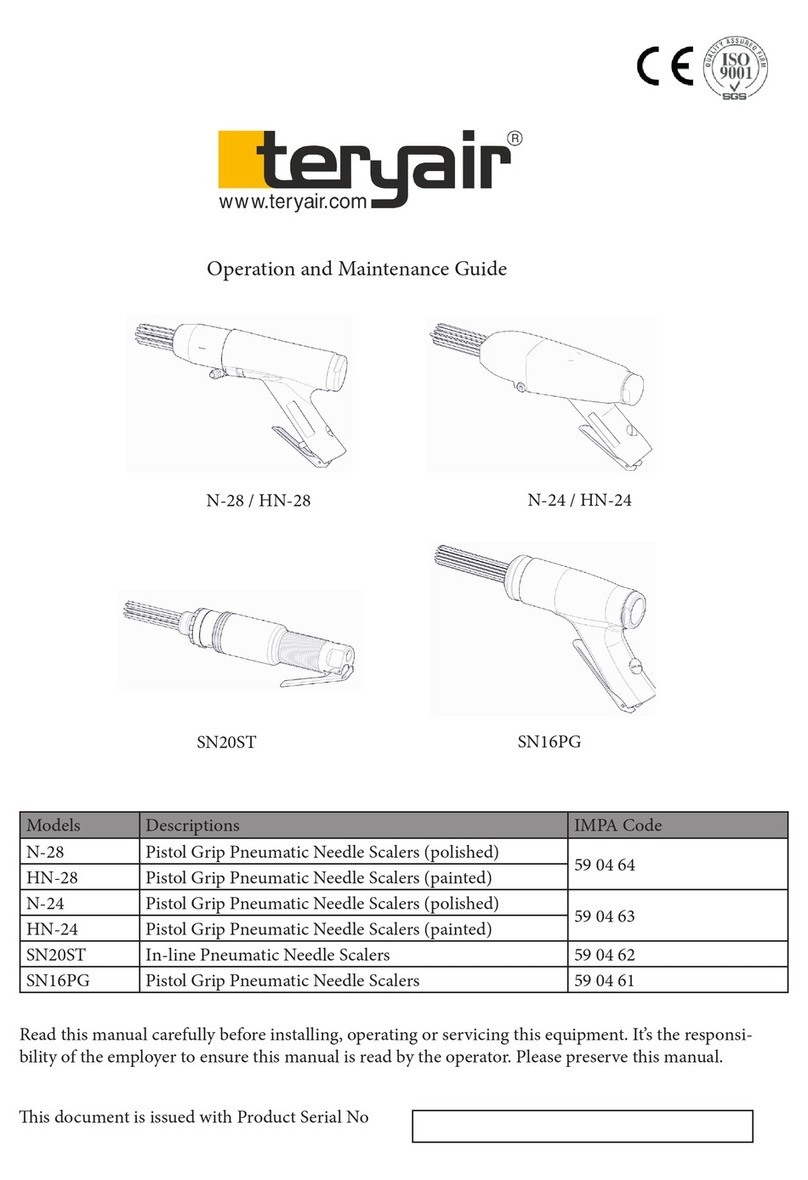

Models Descriptions IMPA Code

SN24ST In-line Pneumatic Needle Scalers 59 04 81

SN24PG Pistol Grip Pneumatic Needle Scalers 59 04 82

SN29PG Pistol Grip Pneumatic Needle Scalers 59 04 83

SN39STVL In-line Pneumatic Needle Scalers 59 05 18

SN39PGVL Pistol Grip Pneumatic Needle Scalers 59 05 00

SN45PGVL Pistol Grip Pneumatic Needle Scalers 59 05 10

Read this manual carefully before installing, operating or servicing this equipment. It’s the responsi-

bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

is document is issued with Product Serial No

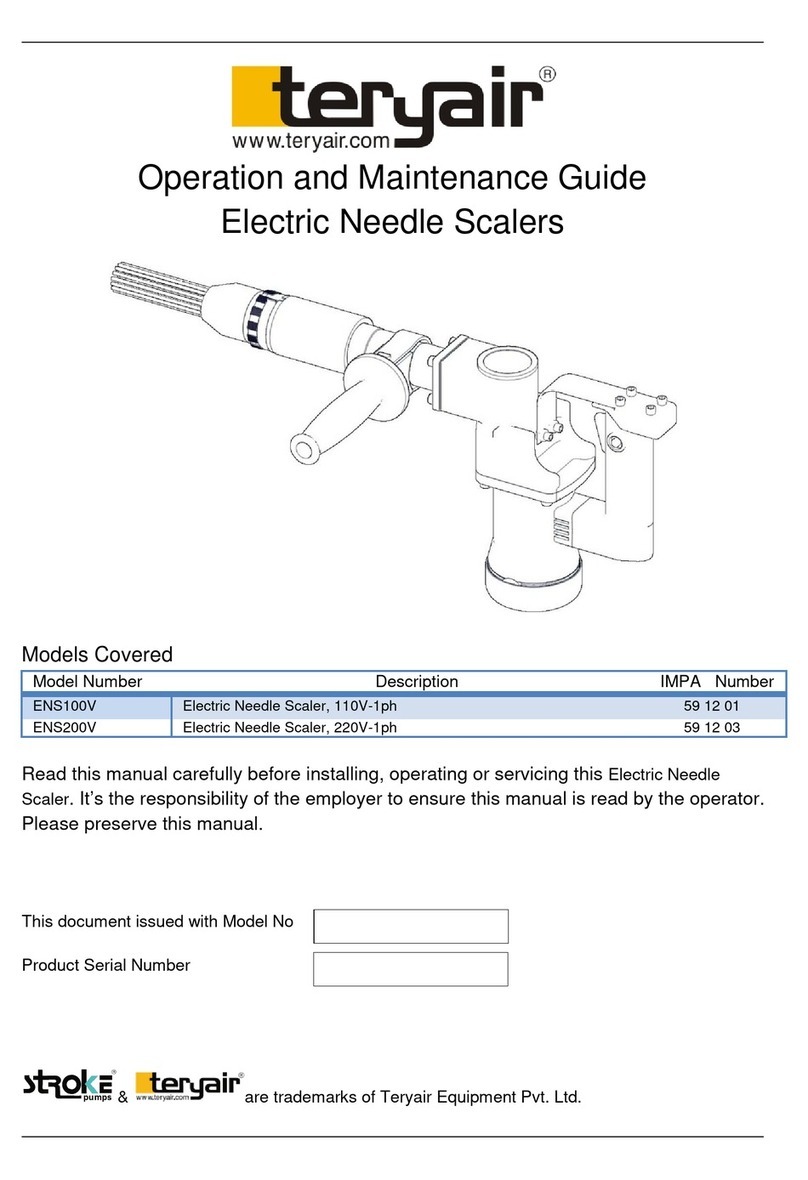

Operation and Maintenance Guide

SN24ST

SN24PG SN29PG

SN39STVL

SN39PGVL SN45PGVL

FF-MM-300-REV - 00

Page 2

Operation and Maintenance Guide Pneumatic Needle Scalers

Table of Contents

3 Introducon

3 Technical Data

3 SafetyInstrucons

4 OperangInstrucons

5 SuggestedLubricants

5 DiassemblyandRe-assemblyforSN24ST

6 ExplodedViewforSN24ST

7 BillofMaterialsforSN24ST

8 DiassemblyandRe-assemblyforSN24PG

9 BillofMaterialsforSN24PG

10 ExplodedViewforSN24PG

11 DiassemblyandRe-assemblyforSN29PG

12 ExplodedViewforSN29PG

13 BillofMaterialsforSN29PG

14 DiassemblyandRe-assemblyforS39PGVL

15 BillofMaterialsforSN39PGVL

16 ExplodedViewforSN39PGVL

17 DiassemblyandRe-assemblyforS39STVL

18 BillofMaterialsforSN39STVL

19 ExplodedViewforSN39STVL

20 DiassemblyandRe-assemblyforSN45PGVL

21 BillofMaterialsforSN45PGVL

22 ExplodedViewforSN45PGVL

23 TestCercateOfMaterials,Performance

24 EuDeclaraonOfConformity

25 WarrantyCercate

FF-MM-300-REV - 00

Page 3

Operation and Maintenance Guide Pneumatic Needle Scalers

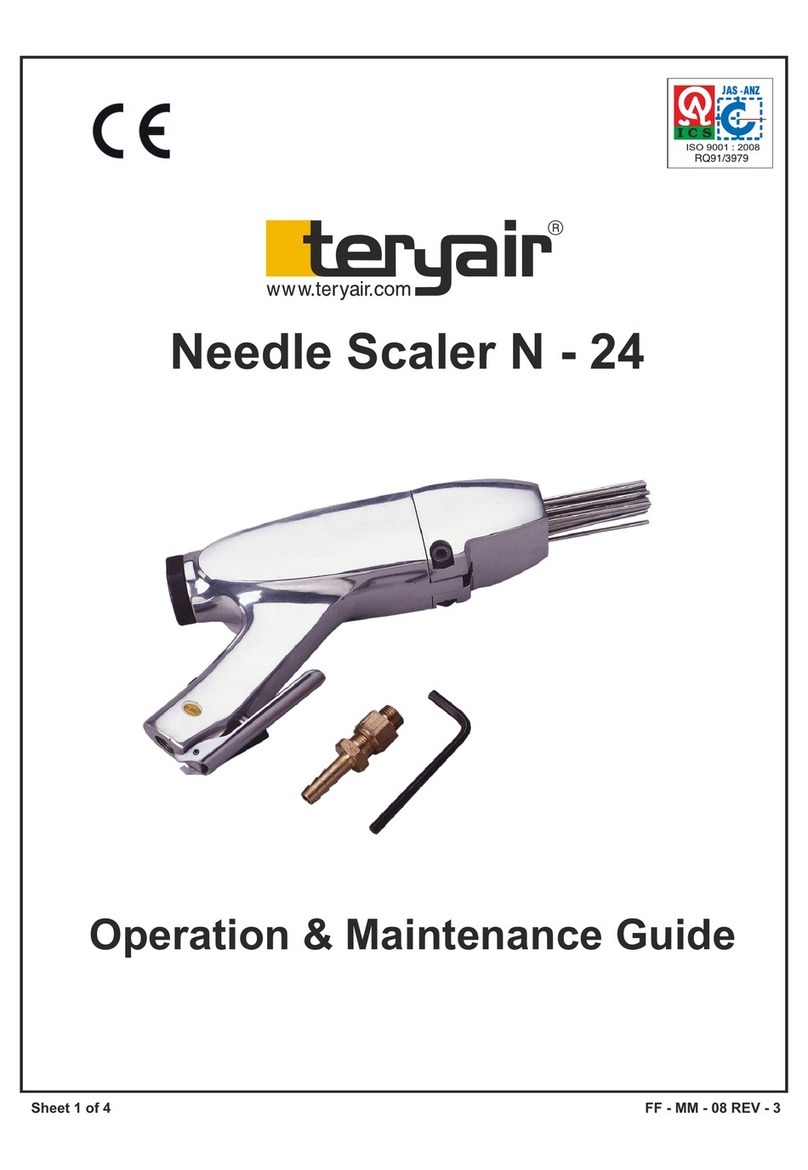

Introduction

Teryair needle guns are rugged tools. ey are designed to be easy to use and maintain. ey are

ideal for removing layers of paint, corrosion and chemical coatings etc. from metal and non

metal surfaces. ese tools work well on irregular surfaces and in crevices and corners. e

needles are heat treated and are quickly replaceable.

Technical Data

Models

IMPA

Number

equiva-

lent

Maximum

operating

pressure

Air

Consumption

(No Load)

Blows

per

min

Sound

Power

Level

(Load)

Vibra-

tion

Level

Mass

(Weight)

Thread

Size

of Air

Inlet

Needles

CFM m3/

min (BPM) LwA b(A) m/s2 Kg

SN24ST 59 04 81

6kg/cm2

(90 psi)

5.5 0.16 3000 113.3 9.3 2.6 1/4" 3mm x

19 Nos.

SN24PG 59 04 82 5.5 0.16 3000 113.3 12.6 2.6 1/4" 3mm x

19 Nos.

SN29PG 59 04 83 8 0.23 2200 114.5 18.9 3.7 1/4" 3mm x

28 Nos.

SN39STVL 59 05 18 4 0.11 2400 90.7 2.56 2.4 1/4" 3mm x

19 Nos.

SN39PGVL 59 05 00 4 0.11 2400 90.7 2.75 2.7 1/4" 3mm x

19 Nos.

SN45PGVL 59 05 10 5.5 0.16 3000 109.5 2.3 3.5 1/4" 3mm x

28 nos.

Warning

is manual must be read and the operating

instructions carefully followed.

Warning

Safety and protective clothing, eyewear, head-

gear, ear protection, gloves and footwear to be

worn during operation of this Pneumatic Needle

Scaler. Please see Table A at end of this section.

Warning

Operators under 18 not allowed to operate this

Pneumatic Needle Scaler. Operators must be

made familiar with the instructions in this

manual before attempting to operate the

Pneumatic Needle Scaler. Ensure that job site is

clear of by standers

Caution

Use only genuine Teryair or Teryair approved

accessories.

Intended Use

Needle scalers are used for surface prepara-

tion work involving the cleaning or removal

of paint, rust, dirt, or weld slag from metal &

non - metal surfaces. ese tools also work well

on irregular surfaces such as crevices & cor-

ners. e needles are heat - treated & quickly

replaceable. Needle scalers are used in marine,

oshore & petrochemical plants.

Safety Instructions

Following symbols are used through out this

manual.

FF-MM-300-REV - 00

Page 4

Operation and Maintenance Guide Pneumatic Needle Scalers

• Eye and faceand ear protection must be worn

at all times during operation of the

Pneumatic Needle Scaler. ere is a chance

of ying debris from the jobsite and the

quality of wear should be such to protect

against such ying debris such as akes of

the removed layer.

• Suitable gloves must be worn at all times

during operation.

• Safety Shoes with toe cap protection are a

must during operation.

• Scalers are rugged dependable tools designed

to give you years of satisfactory service.

Follow the instructions mentioned here to

enhance life and performance of your scalers.

Daily Before Operating

Disconnect and pour in 1 to 2 ounces of

recommended oil into the Pneumatic Needle

Scaler and reconnect hose aer blowing out any

accumulated dirt in the hose line before

connection

Lubrication Requirements

Always install a line lubricator on the air line as

close to the Pneumatic Needle Scaler as possible.

A Filter Regulator Lubricator unit (FRL)is

strongly recommended. Keep the lubricator bowl

topped up with recommended grade of oil and

check that the oil is reaching the Pneumatic Nee-

dle Scaler. Running the Pneumatic Needle Scaler

without lubrication is likely to cause damage to

the components causing premature replacement.

Operating Instructions

Warning

is Pneumatic Needle Scaler is not designed

for use in an explosive environment.

Caution

Completely turn o the Pneumatic Needle

Scaler and disconnect air supply line before

attempting any service. Read Assembly and

Disassembly instructions.

Warning

Take care not to exceed the maximum 6 bar

(90 psi) supply air pressure. Use a lter and

regulator and lubricator as close to the Pneu-

matic Needle Scaler inlet as operation will

allow ensuring a clean and regulated and

lubricated air ow.

Caution

Do not exert excessive pressure against the

work surface. Keep hoses in good condition.

Check hoses for signs of wear, cracks & bulges

and ensure that they are secure. Accidental

disconnection while hose is pressurized makes

the hose whip and can be a safety hazard.

Caution

• Please check the hose connection prior to

starting Needle Scaler.

• Be aware that these Pneumatic Needle

Scalers can create dust & ying debris.

• Keep hands & clothing away from moving

parts.

• Store these Pneumatic Needle Scalers in

secure & dry environment.

• Do not allow the Pneumatic Needle Scaler

to run unattended.

• Do not modify this Pneumatic Needle

Scaler in any way as this will invalidate the

warranty and could lead to serious injury.

• Do not allow the Pneumatic Needle Scaler

to run continuously whilst not in contact

with the surface being prepared.

• Do not hold the exposed needles whilst

the Pneumatic Needle Scaler is in use

this could cause vibration damage to the

hands.

• Do not drag this Pneumatic Needle Scaler

by air hose.

Warning

Do not use the Pneumatic Needle Scaler in

potentially explosive environments.

FF-MM-300-REV - 00

Page 5

Operation and Maintenance Guide Pneumatic Needle Scalers

Suggested Lubricants

Brand Above 27C / 80F 5C to 27C / 41F to 80F Below 5C / 80F

Shell Toona R 72 Toona R 41 Toona R 27

Mobil Almo 529 Almo 527 Almo 525

Esso -- Arox EP.65 Arox EP.45

Caltex Rando Oil 100 Rando Oil 100 Rando Oil 46

Cp -- -- Airolene Tool OiI

Texaco Regal Oil F (R&O) Regal Oil PE(P&E) Regal Oil PE(R&O)

Daltron Silkolene 881 Silkolene 548/T Silkolene 733

Burmah Castrol Castrol RD Oil 3 Castrol RD Oil Light Megna SPX

Duckham Garnet 7 Garnet 6 Zero Fio 5

Sternol Merlin 87 Merlin 71 Merlin 54

Petrona Purifoc 53 Purifoc 46 Purifoc 32

Chevron Vistac Oil 18X Vistac Oil 19X Vistac Oil 9X

Indoil Servo Spyn -22 -- --

Air Supply

e Scalers work best at 6.2 bar (90 psi) air pres-

sure. e air should be clean, dry and lubricated.

Install a FRL unit as close as operation will

permit.

Hoses

Daily before operation check the hoses, especially the

high pressure hoses for damage or leaks

Use genuine Teryair spares and if possible mention the

serial number of the Pneumatic Needle Scaler when

ordering spares. Use genuine Teryair spares and if pos-

sible mention the serial number of the Pneumatic

Needle Scaler when ordering spares.

a. Shut o the air supply and allow residual

Pressure to bleed o.

b. Unscrew Allen Bolt (19) from Straight

Front Tube (16). Now remove Straight

Front Tube (16).

c. Unscrew similar Allen Bolt (19) from Inter-

mediate Tube (17). Now remove Interme-

diate Tube (17), Anvil (14), Needle Holder

(15) with Needles (20), and Compression

Spring (18) and replace it with new ones. (If

found damaged/worn-out)

d. Unscrew Valve Body (5) from Main Body

(1). Now remove Piston (3), O-ring (2), and

Sleeve Grip (4) from Main Body (1).

Diassembly and Re-assembly for SN24ST

e. Unscrew Valve Cap (6) with O-ring (7) from

Valve Body (5). Now remove Valve Spring

(8), Valve Stem (9), and O-ring (10) from

Valve Body (5) and replace them with new

ones. (If found damaged/worn-out).

f. Remove O-ring (7) from Valve Cap (6) and

replace it with the new one.

g. Remove Roll Pin (12) from Valve Body (5).

Now remove rottle Lever (11) from Valve

Body (5).

h. Coat parts with the recommended light oil

before re-assembling. Now follow the above

steps in a reverse manner to reassemble the

Needle Scaler.

FF-MM-300-REV - 00

Page 6

Operation and Maintenance Guide Pneumatic Needle Scalers

6

7

1

2

3

14

4

5

8

9

10

12

13

11

15

16

17

19

18

20

Exploded View for SN24ST

FF-MM-300-REV - 00

Page 7

Operation and Maintenance Guide Pneumatic Needle Scalers

Bill of Materials for SN24ST

Illustration

Number Part Number Description SN24ST

1 112 21 01 MAIN BODY 1

2 112 40 11 O' RING FOR MAIN BODY 1

3 112 21 02 PISTON 1

4 112 40 12 SLEEVE GRIP 1

5 112 21 07 VALVE BODY 1

6 100 21 06 VALVE CAP 1

7 100 40 15 O' RING - VALVE CAP 1

8 100 51 14 VALVE SPRING 1

9 100 25 11 VALVE STEM 1

10 124 40 01 O' RING - VALVE SEAT 1

11 100 30 12 THROTTLE LEVER 1

12 100 50 19 ROLL PIN (Ø3.17 x 25/26) 1

13 100 40 18 PLASTIC PLUG 1

14 112 21 03 ANVIL 1

15 112 21 04 NEEDLE HOLDER (Ø3) 1

16 112 32 13 STRAIGHT FRONT TUBE 1

17 112 32 14 INTERMEDIATE TUBE 1

18 112 51 15 COMPRESSION SPRING 1

19 200 90 68 CAP HEAD SCREW (M8X30) 2

20 022 90 04BL NEEDLE (Ø3 X 180) 19

Optional Accessories

Part No Description Qty

112 21 16 NEEDLE HOLDER (Ø2 OPTIONAL) 1

022 90 08BL NEEDLE (Ø2 X 180) 51

FF-MM-300-REV - 00

Page 8

Operation and Maintenance Guide Pneumatic Needle Scalers

Diassembly and Re-assembly for SN24PG

a. Shut o air supply and allow residual Pres-

sure to bleed o.

b. Unscrew Allen Bolt (21) from Straight

Front Tube (18) & remove.

c. Unscrew similar Allen Bolt (21) from In-

termediate Tube (19) & remove Anvil (16),

Needle Holder (17) with Needles (22) and

Compression Spring (20) from Intermedi-

ate Tube (19) and replace it with new ones.

(If found damaged/worn-out)

d. Unscrew Cylinder (1) from Cover Assem-

bly (6), Now remove Piston (4), O-ring

(3),& O-ring (2) from Cylinder (1) and

replace it with new ones (If found dam-

aged/worn-out).

e. Unscrew Valve Body (7) from Cover Assem-

bly (6) & remove rubber handle grip (5).

f. Unscrew Valve Cap (8) with O-ring (9) on

Valve Body (7). Now remove Valve Spring

(10) and Valve Stem (11) with O-ring (12)

from Valve Body (7) and replace with new

ones. (If found damaged/worn-out)

g. Remove O-ring (9) on Valve Cap (8) and

replace with new one.

h. Remove Roll Pin (14) on valve body (7) &

remove throttle Lever (13).

i. Coat parts with the recommended light oil

before re-assembling. Now follow the above

steps in reverse manner to reassemble the

Needle Scaler.

FF-MM-300-REV - 00

Page 9

Operation and Maintenance Guide Pneumatic Needle Scalers

Bill of Materials for SN24PG

Illustration

Number Part Number Description SN24PG

1 110 21 02 CYLINDER 1

2 110 40 03 “O” RING FOR CYLINDER 1

3 110 40 04 “O” RING FOR CYLINDER 1

4 112 21 02 PISTON 1

5 100 40 17 RUBBER HANDLE GRIP 1

6 110 97 06 COVER ASSY 1

7 100 21 07 VALVE BODY 1

8 100 21 06 VALVE CAP 1

9 100 40 15 “O” RING – VALVE CAP 1

10 100 51 14 VALVE SPRING 1

11 100 25 11 VALVE STEM 1

12 124 40 01 “O” RING – VALVE SEAT 1

13 100 30 12 THROTTLE LEVER 1

14 100 50 19 ROLL PIN 1

15 100 40 18 PLASTIC PLUG 1

16 112 21 03 ANVIL 1

17 112 21 04 NEEDLE HOLDER (Ø3) 1

18 112 32 13 STRAIGHT FRONT TUBE 1

19 112 32 14 INTERMEDIATE TUBE 1

20 112 51 15 COMPRESSION SPRING 1

21 200 90 68 CAP HEAD SCREW (M8X30) 2

22 022 90 04BL NEEDLE (3 X 180MM) 19

Optional Accessories

Part No Description Qty

022 90 08 NEEDLE (2 X 180 MM) 51

100 21 23 NEEDLE HOLDER (Ø2 ) 1

FF-MM-300-REV - 00

Page 10

Operation and Maintenance Guide Pneumatic Needle Scalers

Exploded View for SN24PG

21

18

19

20

17

22

16

6

4

2

3

1

5

13

8

9

10

11

12

7

15

14

FF-MM-300-REV - 00

Page 11

Operation and Maintenance Guide Pneumatic Needle Scalers

Diassembly and Re-assembly for SN29PG

a. Shut o the air supply and allow residual

Pressure to bleed o.

b. Unscrew Allen Bolt (11) from Straight

Front Tube (6). Now remove Straight

Front Tube (6).

c. Unscrew similar Allen Bolt (11) from In-

termediate Tube (7). Now unscrew Inter-

mediate Tube (7) from Cylinder (1).

d. Remove Anvil (8), Needle Holder (9) with

Needles (10), and Compression Spring (5)

from Intermediate Tube (7) and replace it

with new ones. (If found damaged/worn-

out)

e. Unscrew Cylinder (2) from Cover Assem-

bly (1), Now remove O-ring (4), O-ring

(20), and Piston (3) from Cylinder (2) and

replace it with new ones.

f. Unscrew Valve Body (19) from Cover Assem-

bly (1).

g. Unscrew Valve Cap (13) with O-ring (15)

from Valve Body (19). Now remove Valve

Spring (14) and Valve Stem (12) with O-ring

(18) from Valve Body (19) and replace them

with new ones. (If found damaged/worn-out)

h. Remove O-ring (15) from Valve Cap (13) and

replace it with the new one.

i. Remove Roll Pin (17) from valve body (19).

Now remove rottle Lever (16) from valve

body (19).

j. Coat parts with the recommended light oil

before re-assembling. Now follow the above

steps in a reverse manner to reassemble the

Needle Scaler.

FF-MM-300-REV - 00

Page 12

Operation and Maintenance Guide Pneumatic Needle Scalers

Exploded View for SN29PG

13

20

19

18

12

15

14

17

22

21

4

3

2

8

10

9

5

7

11

6

1

16

FF-MM-300-REV - 00

Page 13

Operation and Maintenance Guide Pneumatic Needle Scalers

Bill of Materials for SN29PG

Illustration

Number Part Number Description SN29PG

1 100 97 16 COVER ASSEMBLY 1

2 100 21 02 CYLINDER 1

3 100 21 03 PISTON 1

4 100 40 12 O'RING FOR CYLINDER 1

5 100 51 08 COMPRESSION SPRING 1

6 100 24 09 STRAIGHT FRONT TUBE 1

7 100 24 10 INTERMEDIATE TUBE 1

8 100 21 04 ANVIL 1

9 100 21 05 NEEDLE HOLDER(Ø3) 1

10 022 90 04BL NEEDLE (Ø3 X 180) 28

11 200 90 68 CAP HEAD SCREW 2

12 100 25 11 VALVE STEM 1

13 100 25 06 VALVE CAP 1

14 100 51 14 VALVE SPRING 1

15 100 40 15 O' RING - VALVE CAP 1

16 100 30 12 THROTTLE LEVER 1

17 100 50 19 ROLL PIN 1

18 124 40 01 O' RING - VALVE SEAT 1

19 100 21 07 VALVE BODY 1

20 100 40 18 PLASTIC PLUG 1

21 100 40 13 O'RING FOR CYLINDER 1

22 100 40 17 RUBBER HANDLE GRIP 1

Optional Accessories

Part No Description Qty

100 21 22 NEEDLE HOLDER(Ø2) 1

100 21 23 NEEDLE HOLDER(Ø4) 1

022 90 08 NEEDLE (Ø2 X 180) 65

022 90 06 NEEDLE (Ø4 X 180) 14

FF-MM-300-REV - 00

Page 14

Operation and Maintenance Guide Pneumatic Needle Scalers

Diassembly and Re-assembly for S39PGVL

a. Shut o air supply and allow residual Pres-

sure to bleed o.

b. Unscrew Front tube (18) from Interme-

diate Tube (12). Now remove Insert for

Front Tube (16) and Front Spring (20)

from Front Tube (18).

c. Remove O-ring (17), Needle Holder (14)

with Needles (15) and Piston (10), Piston

Cushion (13) from Intermediate Tube

(12). Now remove Piston Ring (11) and

Valve Pin (9) from Piston (10) and replace

it with new ones. (If found damaged/

worn-out)

d. Unscrew Intermediate Tube (12) from

Cover Assembly (1).

e. Remove O-ring (4) from Guide Plate (2).

Now remove Ball Retaining O-ring (7) and

Ball (8) from Cylinder (6) and replace it

with new ones. (If found damaged/worn-

out)

f. Unscrew Valve Body (21) from Cover As-

sembly (1).

g. Remove Rubber Grip (19) from Cover As-

sembly (1) and replace with new ones. (If

found damaged/worn-out)

h. Unscrew Valve Cap (22) with O-ring (23)

from Valve Body (21). Now remove Valve

Spring (24), Valve Stem (25) and O-ring

(26) and replace with new ones. (If found

damaged/worn-out)

i. Remove O-ring (23) from Valve Cap (22)

and replace with new one.

j. Remove Roll Pin (28) from Valve body (21

& remove rottle Lever (27and replace

with new ones. (If found damaged/worn-

out).

k. Coat parts with the recommended light oil

before re-assembling. Now follow the above

steps in reverse manner to reassemble the

Needle Scaler.

FF-MM-300-REV - 00

Page 15

Operation and Maintenance Guide Pneumatic Needle Scalers

Bill of Materials for SN39PGVL

Illustration

Number Part Number Description SN39PGVL

1 136 97 01 COVER ASSEMBLY 1

2 136 21 02 GUIDE PLATE 1

3 136 40 09 GUIDE PLATE SEAL 1

4 100 40 12 O' RING FOR GUIDE PLATE 1

5 136 40 13 CYLINDER STEM REACTION RING 1

6 136 21 03 CYLINDER 1

7 022 90 30 BALL RETAINING 'O' RING 1

8 148 09 11 BALL 1

9 148 50 21 VALVE PIN 1

10 136 21 04 PISTON 1

11 136 36 08 PISTON RING 1

12 136 24 06 INTERMEDIATE TUBE 1

13 136 40 10 PISTON CUSHION 1

14 136 21 05 NEEDLE HOLDER (3MM) 1

15 022 90 04HTBL NEEDLE (Ø3 X 180) 19

16 136 40 12 INSERT FOR FRONT TUBE 1

17 100 40 13 O' RING FOR FRONT TUBE LOCKING 1

18 136 24 07 FRONT TUBE 1

19 100 40 17 RUBBER HANDLE GRIP 1

20 136 51 14 FRONT SPRING 1

21 100 21 07 VALVE BODY 1

22 100 21 06 VALVE CAP 1

23 100 40 15 VALVE CAP 'O' RING 1

24 100 51 14 VALVE SPRING 1

25 100 25 11 VALVE STEM 1

26 100 40 16 VALVE SEAT 'O' RING 1

27 100 30 12 THROTTLE LEVER 1

28 100 50 19 ROLL PIN 1

29 100 40 18 PLASTIC PLUG 1

Optional Accessories

Part No Description Qty

136 21 15 NEEDLE HOLDER (2MM) 1

022 90 08 NEEDLE (Ø2 X 180 ) 48

FF-MM-300-REV - 00

Page 16

Operation and Maintenance Guide Pneumatic Needle Scalers

Exploded View for SN39PGVL

1

19

22

18

16

12

13

20

14

15

10

9

11

6

875423

17

23

24

27

25

26

21

29

28

FF-MM-300-REV - 00

Page 17

Operation and Maintenance Guide Pneumatic Needle Scalers

Diassembly and Re-assembly for S39STVL

a. Shut o air supply and allow residual Pres-

sure to bleed o.

b. Unscrew Front tube (24) from Intermedi-

ate Tube (21) & remove Insert (23), Front

Spring (22).

c. Remove O-ring (26), Needle Holder (15)

with Needles (16) and Piston (11), Piston

Cushion (13) from Intermediate Tube

(21). Now remove Piston Ring (12) and

Valve Pin (14) from Piston (11) and re-

place it with new ones. (If found damaged/

worn-out)

d. Unscrew Intermediate Tube (21) from

Cover Assembly (1).

e. Remove O-ring (27) from Guide Plate (4)

& remove Ball Retaining O-ring (6) and

Ball (3) from Cylinder (5) Replace parts

with new ones. (If found damaged/worn-

out).

f. Unscrew Valve Cap (19) with O-ring (9) from

Cover Assembly (1) & remove Valve Spring

(17), Valve Stem (8) and O-ring (18). Replace

parts with new ones. (If found damaged/worn-

out).

g. Remove O-ring (9) from Valve Cap (19) and

replace with new one.

h. Remove Roll Pin (25) from Cover Assembly (1)

& remove rottle Lever (27) from Cover As-

sembly (1) and replace with new ones. (If found

damaged/worn-out).

i. Coat parts with the recommended light oil be-

fore re-assembling. Now follow the above steps

in reverse manner to reassemble the Needle

Scaler.

FF-MM-300-REV - 00

Page 18

Operation and Maintenance Guide Pneumatic Needle Scalers

Bill of Materials for SN39STVL

Illustration

Number Part Number Description SN39STVL

1 144 21 01 COVER ASSEMBLY (IN LINE) 1

2 100 30 12 THROTTLE LEVER 1

3 148 09 11 BALL 1

4 136 21 02 GUIDE PLATE 1

5 136 21 03 CYLINDER 1

6 148 40 12 BALL RETAINING 'O' RING 1

7 136 40 09 GUIDE PLATE SEAL 1

8 100 25 11 VALVE STEM 1

9 100 40 15 O' RING - VALVE CAP 1

10 136 40 13 CYLINDER STEM REACTION RING 1

11 136 21 04 PISTON 1

12 136 36 08 PISTON RING 1

13 136 40 10 PISTON CUSHION 1

14 148 50 21 VALVE PIN 1

15 136 21 05 NEEDLE HOLDER (3MM) 1

16 022 90 04HTBL NEEDLE (Ø3 X 180) 19

17 100 51 14 VALVE SPRING 1

18 124 40 01 O' RING - VALVE SEAT 1

19 100 21 06 VALVE CAP 1

20 100 40 18 PLASTIC PLUG 1

21 136 21 06 INTERMEDIATE TUBE 1

22 136 51 14 FRONT SPRING 1

23 136 40 12 INSERT FOR FRONT TUBE 1

24 136 24 07 FRONT TUBE 1

25 100 50 19 ROLL PIN 1

26 100 40 13 O' RING FOR FRONT TUBE LOCKING 1

27 100 40 12 O' RING FOR GUIDE PLATE 1

Optional Accessories

Part No Description Qty

136 21 15 NEEDLE HOLDER (2MM ) 1

022 90 08 NEEDLE (Ø2 X 180) 48

FF-MM-300-REV - 00

Page 19

Operation and Maintenance Guide Pneumatic Needle Scalers

Exploded View for SN39STVL

24

23

26

21

22

15

16

11

12 14 13

5

10 364727

2

25

1

20

18

8

17

9

19

FF-MM-300-REV - 00

Page 20

Operation and Maintenance Guide Pneumatic Needle Scalers

Diassembly and Re-assembly for SN45PGVL

a. Shut o air supply and allow residual Pres-

sure to bleed o.

b. Unscrew Front tube (17) from Interme-

diate Tube (8) & remove Insert (16) and

Front Spring (15).

c. Remove O-ring (10), Needle Holder (13)

with Needles (14) and Piston (11), Piston

Cushion (7) from Intermediate Tube (8).

Now remove Piston Ring (12) and Valve

Pin (19) from Piston (11) and replace it

with new ones. (If found damaged/worn-

out)

d. Unscrew Intermediate Tube (8) from Cov-

er Assembly (20).

e. Remove O-ring (10) from Guide Plate (4)

& remove Ball Retaining O-ring (3) and

Ball (2) from Cylinder (6) to replace it

with new ones. (If found damaged/worn-

out)

f. Unscrew Valve Body (21) from Cover

Assembly (20).

g. Remove Rubber Grip (1) from Cover

Assembly (20) and replace with new

ones. (If found damaged/worn-out)

h. Unscrew Valve Cap (22) with O-ring

(23) from Valve Body (21) & remove

Valve Spring (24), Valve Stem (25) and

O-ring (26) to replace with new ones. (If

found damaged/worn-out)

i. Remove O-ring (23) from Valve Cap

(22) and replace with new one.

j. Remove Roll Pin (28) from Valve body

(21) & remove rottle Lever (27) to re-

place with new ones. (If found damaged/

worn-out).

k. Coat parts with the recommended light

oil before re-assembling. Now follow the

above steps in reverse manner to reas-

semble the Needle Scaler.

This manual suits for next models

11

Table of contents

Other Teryair Tools manuals