Teton Grill XT Series User manual

Teton Dynamics

P.O. Box 3031

San Leandro, CA 94578-0031

External/In-line pump

INSTRUCTION MANUAL

MODEL

DATE

JUNE 2023

XT SERIES

XUV16A

XUV40S

XUV80S

XUV120S

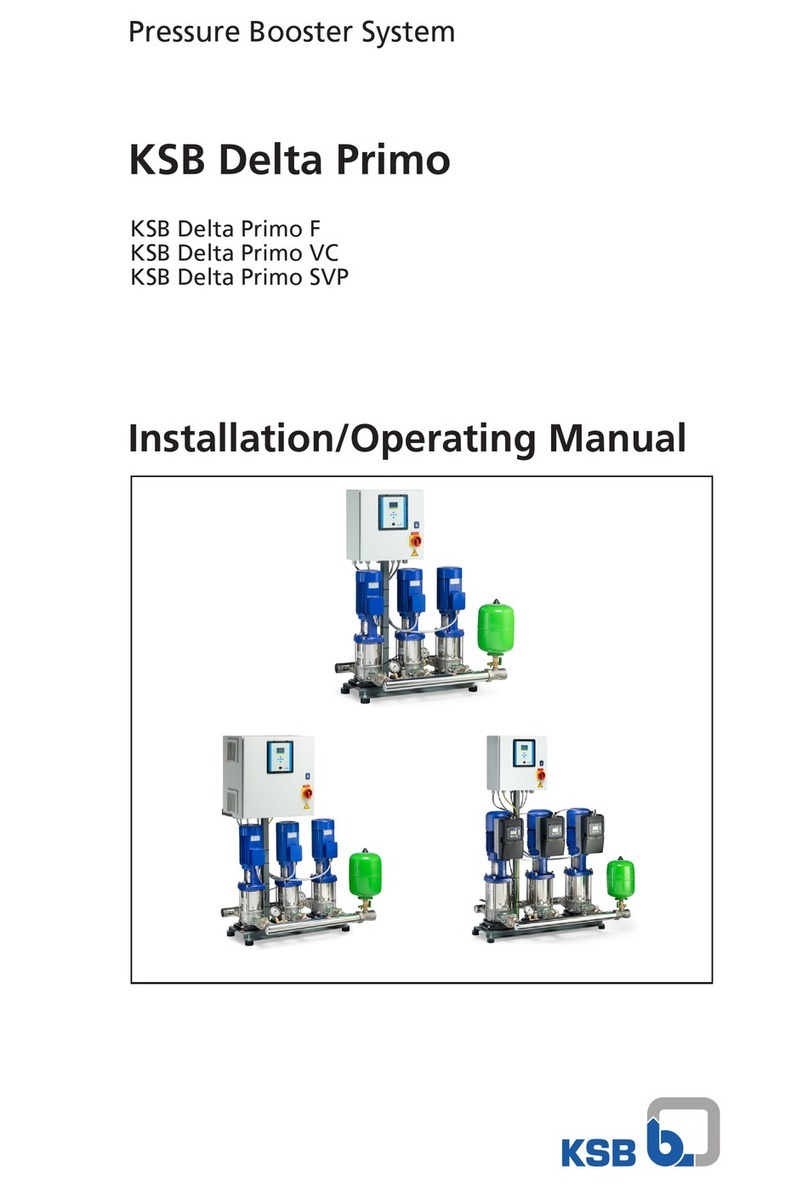

XT SERIES EXTERNAL/INLINE PUMP

XT4000LH/XT3200/XT4400/XT5000/

XT6000/XT7000/XT8000

www.tetonus.com

800.752.0399

info@tetonus.com

WELCOME TO THE WORLD OF TETON,

NATURAL RELIABILITY™!

You Made The Right Choice Investing In

This Quality Product. Thank You And Enjoy.

BEFORE USING THIS PRODUCT, PLEASE READ

THESE INSTRUCTIONS CAREFULLY AND

FAMILIARIZE YOURSELF WITH THE UNIT.

PLEASE KEEP THESE INSTRUCTIONS IN A SAFE

PLACE FOR FUTURE REFERENCE.

Teton Page 2

TECHNICAL SPECIFICATIONS

XT4000LH

4200

12'

166

1.5 @ 115V

115V

1/8

Enclosed

2" FPT /

2” SOC

1 1/2" FPT

2” SOC

XT3200

3300

21'

215

1.9 @ 115V

115/230V

1/8

Enclosed

1 1/2" FPT

2” SOC

1 1/2” FPT

2” SOC

XT4400

4500

21'

253

2.2 @ 115V

115/230V

1/6

Enclosed

1 1/2” FPT

2” SOC

1 1/2” FPT

2” SOC

XT5000

5100

22'

293

2.6 @ 115V

115/230V

1/4

Enclosed

1 1/2” FPT

2” SOC

1 1/2” FPT

2” SOC

XT6000

6100

23'

344

3.0 @ 115V

115/230V

1/3

Enclosed

1 1/2” FPT

2” SOC

1 1/2” FPT

2” SOC

XT7000

7200

22.6'

452

7.3 @ 115V

115/230V

1/2

Enclosed

2” FPT

2” SOC

2” FPT

2” SOC

XT8000

8220

22'

541

7.7 @ 115V

115/230V

1/2

Enclosed

2” FPT

2” SOC

2” FPT

2” SOC

Model

MAX FLOW (gph)

MAX HEAD (feet)

MAX POWER (watts)

MAX CURRENT (amps)

VOLTS

MOTOR HP*

MOTOR

INLET

DISCHARGE

Teton Page 3

IMPORTANT SAFEGUARDS

Please read the operating instructions and familiarize yourself with the equipment

before placing it in service. Correct and safe use of the system requires strict

compliance with these safety instructions. For safety reasons, persons less than

16 years of age or persons that are not familiar with these instructions, should not

use this equipment.

• WARNING: ALWAYS SHUT OFF ELECTRICAL POWER BEFORE INSTALLATION AND / OR

SERVICING THIS PUMP! All electrical wiring should meet state and local ordinances. Improper

wiring may not only be a safety hazard but may permanently damage the motor and/or pump!

230V 50 HZ MOTORS AVAILABLE - CONTACT YOUR SUPPLIER FOR INFORMATION

ELECTRICAL HOOK-UP

1. Check that supply voltages match the motor’s requirements.

2. Check motor wiring and connect, according to instructions on motor, to match supply voltage.

3. Power cord should be protected by conduit or by cable and be of proper gauge. It should be no

longer than necessary.

4. Power should be drawn directly from a box with circuit breaker protection or with a fused

disconnect switch.

Pressure Hazard!

Do not run your pump

with discharge ports

closed or blocked.

Be sure to release

system pressure before

working on the pump.

Electrical Hazard!

Ground pump

before connecting

to power supply!

Risk of shock, burn

or death if not

handled properly.

Burn Hazard!

Operating motor can be

very hot. Do not touch

motor while running.

Allow to cool 30 minutes

after shut down before

handling. Risk of burn.

WARNING WARNING

WARNING

INSTALLATION

Please read carefully! When properly installed the Teton ecostream™ will provide dependable

trouble-free service.

1. Locate the pump as near the water source as possible. A flooded suction situation is preferred.

The pump is not self-priming, therefore, if the fluid level is below the pump, a swing check valve must

be installed and the pump primed prior to start-up. (Figure 2)

2. Mount motor base to a secure, immobile foundation.

3. Use only plastic fittings on both the intake and discharge ports. Seal pipe connections with Teflon™

paste. These fittings should be self-supported and in neutral alignment with each port. (i.e. Fittings

must not be forced into alignment which may cause premature line failure or damage to the pump

volute.) For non-flooded installations, a strainer basket and check valve are recommended.

4. Never restrict the intake. Keep both input and discharge lines as free of elbows and valves as possible.

Always use pipe of adequate diameter. This will reduce friction losses and maximize output.

5. The Teton ecostream™ is not self-priming! It must not be run dry! We recommend a flooded suction

installation. Please read carefully! When properly installed, the Teton ecostream™ will provide dependable,

trouble-free service.

PUMP

SWING CHECK VALVE

FLOODED SUCTION

ABOVE GROUND

BASKET STRAINERBASKET STRAINER

Teton Page 4

PUMP END ASSEMBLY

1. Clean and inspect all pump parts (0-ring, seal seats, motor shaft, etc.).

2. Apply sealant to the bracket bore ID wall and around the seal case - follow sealant mfg. instructions.

We recommend using

Gasgacinch®. Silicone sealant can also be used.

3. Press carbon graphite seal into bracket while taking care not to damage carbon graphite face.

4. Place slinger (rubber washer) over motor shaft and mount bracket to motor.

5. Carefully, lubricate the seal seat elastomer OD and impeller hub ID with water. Press the seal seat into

the impeller

hub making certain that the ceramic is in evenly - the sealing surface should be parallel with the

impeller hub.

6. Carefully lubricate carbon-graphite and ceramic sealing surfaces with CLEAN water. Do not use silicon

lubricants or grease!

7. Assemble Bracket to motor with four M-bolts.

8. Thread impeller onto shaft and tighten! If required, remove motor end-cap and use a screwdriver

on the back of motor shaft to prevent shaft rotation while tightening. Replace motor end cap.

9. Seat large O-ring in volute slot and assemble volute to bracket with screws, washers and nuts.

Tighten in accross pattern (30 in-lbf).

10. Install drain plug with its O-ring in volute drain hole.

11. Before operating pump, allow a proper cure time for the sealant used in step 2.

Disassembly

1. Shut off power to motor before disconnecting any electrical wiring from the

back of the motor.

2. Disassemble volute from bracket by removing the screws.

3. Remove cap covering shaft at back of motor and with a large screwdriver,

prevent shaft rotation while unscrewing impeller.

4. Remove ceramic piece from impeller. (If you are replacing the seal)

5. Detach bracket from motor.

6. Remove carbon-graphite seal from bracket by pressing out from the back.

Do not dig out from the front! (If you are replacing the seal)

LARGE

O-RING

DRAIN PLUG

& O-RING

IMPELLER

WASHER &

LOCK NUT

BRACKET

SEAL

IMPELLER

WASHER

FLANGED

LOCK NUT

SS SEAL

VOLUTE

IMPELLER

BRACKET

M BOLT

SEAL

(XT4000LH)

(XT3200, XT4400,

XT5000, XT6000)

(XT7000, XT8000)

VOLUTE

IMPELLER

DRAIN

P-BOLT

& WASH

LARGE

O-RING

BRACKET

M BOLT SLINGE

VOLUTE

SLINGER

WASHER

LARGE

O-RING

P-BOLT

& WASH

DRAIN PLUG

& O-RING

DRAIN PLUG

& O-RING

SLINGER

M BOLT

P-BOLT

& WASH

INSTALLATION

The UV unit needs maintenance at least once per half year. During maintenance, the UV unit must be

disconnected from the electrical outlet. Chalk deposits and possibly algae must be removed from the quartz

sleeve (K) and the housing (D). The UV-C lamp (J) only has to be changed after 9,000 hours of use.

The actual lifetime is dependent on the number of times it is turned on and off.

1. Unplug the UV unit from the electrical outlet and close the pipes.

2. Ensure that the water is drained out of the UV unit.

3. Loosen the bolt (N) and disconnect the UV-C lamp (J) from the lamp holder (L). If necessary, you

can also replace the lamp.

4. Carefully raise the quartz sleeve (K).

5. The quartz sleeve (K) can be cleaned with an appropriate cleaner. After cleaning, rinse the quartz

sleeve (K) thoroughly. Use a soft cloth to avoid scratches!

6. The housing (D) can now also be cleaned. This can be done with a brush; do not use any

chemicals.

7. After cleaning, place the quartz sleeve (K) back in the housing (D). Ensure that the O-ring (M1&M2)

is seated properly and that the quartz sleeve (K) slides into the holder.

8. Put the UV-C lamp (J) into the lamp fitting (L) and slide both into the quartz sleeve (K).

9. Tighten the nut (N) on the housing (D) hand-tight. (See Installation Step 9).

Note: To change the housing and/or the electronics box, the earth must be completely disconnected.

The component parts must be saved because they do not come with a new housing or electronics

as standard.

MAINTENANCE

Teton Page 5

The UV unit must be placed in a dry, well-ventilated area, out of direct sunlight. The best position, if

possible, is after the filter. The installation must always be carried out vertically. Take into account

accessibility for maintenance (see also Maintenance).

1. Undo the lock nut (H) from the housing (D) and keep this for the connecting link (I) used in Step 7.

2. Carefully unpack the UV-C lamp (J) and slide this into the quartz sleeve (K).

3. Put the UV-C lamp (J) into the lamp holder (L) and slide this further into the quartz sleeve (K).

Make sure that the O-rings (M1&M2) sitting properly.

4. Tighten the nut (N) hand-tight in the housing (D).

5. Mount the pipe clamps (O) in the required place. The UV unit will hang from these. Take into

account the length of the cables (see Step 6).

6. Mount the electronics box (R) in the required place. Take into account the length of the cables.

7. With the lock nut (H), fasten the connecting link (I) to the housing (D), making sure that the

O-rings (M1&M2) are seated properly.

8. Place the apparatus in the pipe clamps (O) and glue the connecting link (I) between the pipes.

9. Ensure that enough water flows through the UV unit and plug the UV unit into the appropriate

socket. You can see if the UV-C lamp is on by looking through the transparent connecting link (I).

Check the whole assembly for possible leaks.

10. The UV unit can be turned off by simply pulling the plug out of the socket.

ASSEMBLY (SEE PAGE 4, FIGURE 2)

1. Place the strain relief clip (A) about 10-12cm from the eye of the earth cable (B).

2. Slide the eye of the earth cable (B) over the earth pin (C) that is fastened to the housing (D).

3. Slide the first spring washer (E1) over the earth pin (C).

4. Place the hexagonal nut (F) on the earth pin and tighten it.

5. Slide the second spring washer (E2) over the earth pin (C).

6. Slide the strain relief clip (A) over the earth pin (C).

7. Place the last lock nut (G) on the earth pin (C) and tighten it carefully with a spanner in Step 8.

8. Ensure that the sequence follows precisely that shown on Page 4, Figure 3.

Teton Page 6

TROUBLE SHOOTING

SYMPTOM RESOLUTION

PROBLEM

MAINTENANCE

Lubrication

Motor - Permanently Lubricated ball bearings - no service required.

Rotary Seal - Requires no lubrication after assembly.

*The pump must be drained before servicing or if stored below freezing temperatures. Periodic

replacement of seals may be required due to normal carbon wear.

Low Flow

Sporadic

Operation

Excessive

Noise

Symptom

No Flow

Prime system with water and purge all air from suction piping

Install check valve.

Insucient Prime

Insucient Power Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Flow Restriction

Ensure valves are open.

Ensure plumbing is clear, including suction strainers, check valves, etc.

Verify check valve orientation and direction of permitted flow.

Clean out leaves or other debris from basket strainer (if applicable).

Air leak Fix air leaks at fittings, connections, strainer basket etc. This typically occurs on the intake side.

System Incompatibility Verify hydraulic compatibility: i.e. pump & pipe are sized for the system.

Air leak

System Incompatibility

Insucient Power

Flow Restriction

Fix air leaks at fittings, connections, strainer basket etc. This typically occurs on the intake side.

Verify hydraulic compatibility: i.e. pump & pipe are sized for the system.

Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Ensure valves are open.

Ensure plumbing is clear, including suction strainers, check valves, etc.

Clean out leaves or other debris from basket strainer (if applicable).

Prime system with water and purge all air from suction piping.

Verify airtight plumbing on the suction plumbing especially fittings!

Clean out leaves or other debris from basket strainer (if applicable).

Increase pipe size where possible.

Decrease suction pipe length, reduce the number of elbows, etc.

Verify hydraulic compatibility: i.e. pump and pipe are sized for the system.

Insucient Power Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Cavitation

Insucient Prime

Cavitation

Poor Ventilation

Verify airtight plumbing on the suction plumbing especially fittings!

Clean out leaves or other debris from basket strainer (if applicable).

Increase pipe size where possible.

Decrease suction pipe length, reduce the number of elbows, etc.

Verify hydraulic compatibility: i.e. pump and pipe are sized for the system.

Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Ensure valves are open.

Ensure plumbing is clear, including suction strainers, check valves, etc.

Verify check valve orientation and direction of permitted flow.

Insucient Power

Flow Restriction

Ensure adequate airflow over motor to prevent overheating.

Teton Page 7

LIMITED PRODUCT WARRANTY

• CMT Group LLC, a California limited liability company d/b/a Teton™ (the “Company”) expressly warrants to the original

purchaser that, for a period of two (2) years from the date of sale, the covered product (the “Product”) will be reasonably free

of defects in materials and workmanship and that when property handled, will conform, within accepted tolerance to applicable

manufacturing specifications. This Limited Product Warranty (“Limited Warranty”) only applies to Company’s Products that are

used, stored, handled, and installed in the manner recommended by the Company in the Product instruction manual.

• Notwithstanding this Limited Warranty, customer acknowledges that some parts of the Product are consumable and may

need to be replaced as part of ongoing Product maintenance, as recommended in the Product instruction manual, and are

therefore not covered by this Limited Warranty.

• Company will, at its option, repair or replace Product without charge, if the Product fails or does perform as warranted solely

due to a manufacturing defect within the warranty period, subject to the exclusions set forth in this Limited Warranty.

• Repair or replacement during this two (2) year warranty shall not include: reasonable labor charges necessary to repair or

replace the defective Product, shipping costs, and packing and insurance costs. During the entire two (2) year warranty,

Company’s obligation as to repair or replacement shall further be limited to repair or replacement with the models of the

Product that are available at the time of the repair or replacement, and shall be limited to the repair or replacement of only the

specific Product that fails due to a manufacturing defect. Any repaired or replaced Product shall also remain subject to the

original two (2) year warranty from the date of the original sale, and any repair or replacement shall not extend the original

warranty period in any manner or start a new warranty period.

• You may obtain coverage under this Limited Warranty by providing Company with proof of original purchase. For service

under this Limited Warranty, you must first contact the seller, distributor, retailer, or dealer from whom you purchased the

Product and provide the following: copy of original receipt, your name and address, a description of the Product (including

the serial number/date code set forth on the Product), and the nature of the defect. To expedite any warranty claims and

processing, please submit to us the product registration card included with your purchased Product promptly after your purchase.

• All warranty repairs must be performed by the Company, or a Company authorized third-party. Any repairs performed by

you or an unauthorized third-party will not be compensated by Company and are not the responsibility of the Company and

will void this warranty.

• DISCLAIMER OF WARRANTIES: Company’s Products must be stored, handled, installed, used, and maintained in accordance

with instructions provided by Company, and this Limited Warranty is conditioned upon compliance with all such instructions.

Copies of the Company’s use guide/care guide are included with the Product and available from the Company at the address

listed below. You may also obtain these materials by contacting Company at (800) 752-0399 or on the Company’s website

www.tetonus.com.

• This Limited Warranty does not cover defects caused by:

• non-compliance with Company’s use guides, care guides, and/or instruction manual. Such failures include, but are not

limited to, exposure to physical abuse, including, but not limited to chemical abuse (e.g. harsh cleansers and solvents), thermal

abuse or shock (e.g. excessive heat or cold), incompatibility of fluid used near the Product, or misuse;

• improper storage, installation, handling, and/or use of the Product;

• damage not resulting from manufacturing defects that occur while the Product is in the customer’s possession;

• unreasonable or unintended use of Product;

• products installed with known or visible manufacturing defects at the time of installation;

• minor conditions such as stains, scratches, etc.

• Any information or suggestion by Company with respect to the Products concerning applications, specifications, or

compliance with codes and standards is provided solely for your convenient reference and are made without any representation

as to accuracy or suitability. You must verify and test the suitability of any information with respect to the Products for your

specific application.

• THE WARRANTIES SET FORTH IN THIS LIMITED WARRANTY ARE THE ONLY WARRANTIES MADE BY COMPANY IN

CONNECTION WITH THE PRODUCT. COMPANY CAN NOT AND DOES NOT MAKE ANY IMPLIED OR EXPRESS WARRANTIES

WITH RESPECT TO THE PRODUCT, AND DISCLAIMS ALL OTHER WARRANTIES, INCLUDING, BUT NOT LIMITED TO, ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. PRODUCTS SOLD BY COMPANY ARE

SOLD ONLY TO THE SPECIFICATIONS SPECIFICALLY SET FORTH BY COMPANY IN WRITING. OTHER THAN THE LIMITED

WARRANTY SET FORTH HEREIN, COMPANY MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. COMPANY’S SOLE

OBLIGATION UNDER THIS WARRANTY SHALL BE REPAIR OR REPLACEMENT OF NON-CONFORMING PRODUCTS. BUYER

ASSUMES ALL RISK WHATSOEVER AS TO THE RESULT OF THE USE OF THE PRODUCTS PURCHASED, WHETHER USED

SINGULARLY OR IN COMBINATION WITH ANY OTHER PRODUCTS OR SUBSTANCES.

• LIMITATION OF LIABILITY: No claim by the buyer/owner of any kind, including claims for indemnification, shall be greater in

amount than the purchase price of the Product in respect to which damages are claimed. IN NO EVENT SHALL COMPANY BE

LIABLE TO BUYER/OWNER IN TORT, CONTRACT OR OTHERWISE, FOR ANY SPECIAL, INDIRECT, INCIDENTAL,

CONSEQUENTIAL, RELIANCE, STATUTORY, SPECIAL, PUNITIVE OR EXEMPLARY DAMAGES, INCLUDING, BUT NOT LIMITED

TO, LOST PROFITS, LOSS OF USE, LOSS OF TIME, LOSS OF REVENUES, INCONVENIENCE, LOSS BUSINESS OPPORTUNITIES,

DAMAGE TO GOOD WILL OR REPUTATION, OR LOSS OF DATA, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES OR SUCH DAMAGES COULD HAVE BEEN REASONABLY FORESEEN, IN CONNECTION WITH, ARISING OUT OF,

OR AS A RESULT OF, THE SALE, DELIVERY, SERVICING, USE OR LOSS OF USE OF THE PRODUCT SOLD HEREUNDER, OR

FOR ANY LIABILITY OF BUYER TO ANY THIRD PARTY WITH RESPECT THERETO.

• All provisions of this Limited Warranty are severable and if any provision shall be deemed invalid, the remaining provisions

shall remain in full force and effect.

• Please consult your retailer for quality original Company replacement parts.

• Visit www.tetonus.com for your nearest dealer.

• Contact Information:

• Any question concerning this warranty should be addressed to:

Teton

P.O. Box, 1044

San Leandro, CA 94577

Phone: 800-752-0399

Website address: www.tetonus.com

This manual suits for next models

7

Table of contents

Other Teton Grill Water Pump manuals

Popular Water Pump manuals by other brands

Intex

Intex ECO15230-2 owner's manual

BWT

BWT PEARL HPT 09 instruction manual

RODEX

RODEX RDX814 instruction manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 80 Series Installation, operation and maintenance manual

kENDALL

kENDALL KANGAROO ePump Operation and service manual

Wilo

Wilo Stratos PICO Installation and operating instructions