Tetra Pak HOYER COMET N User manual

Tetra Pak

Hoyer

Tetra Pak Hoyer S.p.A.

Via Monferrato, 54

20098 San Giuliano Milanese (Milano)

Italy

Telephone +39 2 98292.1

Telefax +39 2 9880171

CN 03 - A 01

We hope that the information will be of help to

you.Itisbasedonconcretedataandonthebestof

our current knowledge.

Readthecontentsofthemanualcarefully,including

thewarningsandrecommendations.Alsoreadthe

conditions of sale, including those governing the

warranty.

No part of this manual may be reproduced or

transmittedtothirdpartieswithoutthepriorwritten

permission of TETRA PAK HOYER.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Machine HOYER COMET N

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Serial Number M/221869

Tetra Pak

Hoyer

CN 03 - A 01

1Machine identification data

2General

3Description of the machine and technical data

4Installation

5Adjustments and format change procedures

6Operating stations

7Cleaning and maintenance

8Troubleshooting

9Parts catalogue

10 Annexes contents

HOYER COMET N

1-1

Tetra Pak

Hoyer

CN 03 A A 01

Contents

1 - MACHINE IDENTIFICATION DATA

1.1 Introduction .............................................................................................................. 1-2

1.2 Identification plate ................................................................................................... 1-2

1.3 Service centres ......................................................................................................... 1-3

1-2

Tetra Pak

Hoyer

CN 03 A A 01

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

1.2 Identification plate

For maintenance and service operations not

describedinthis manual or for any other problem

of a technical nature, our Service Department is

at your complete disposal for information or to

arrange for the necessary measures to be taken.

Whencontactingour Service Department, please

Fig. 1.1 - Identification plate

1.1 Introduction

Thank you for having chosen a Tetra Pax Hoyer

machine.

We recommend that you read this manual

carefully as it contains essential information

regarding the installation, checking and

maintenance operations required to keep your

machine in perfect condition.

The manual contains tables, drawings and

diagrams which will allow you to familiarise

yourself with all parts of the machine.

Please let us know if any information is missing

or is not sufficiently detailed. Your comments

will be used to improve this manual.

quote the data given on the identification plate

affixed to the machine and shown in Fig.1.1.

1-3

Tetra Pak

Hoyer

CN 03 A A 01

EUMEA:

Tetra Pak Hoyer A/S

SoerenNymarksVej 13

DK-8270Hoejbjerg

Denmark

Phone: +45 89 39 39 39

Fax: +45 86 29 22 00

Tlx:687 70 alhoy dk

TetraPak Hoyer S.p.A.

Via Monferrato,54

I- 20098 SanGiuliano Milanese

(Milan)

Italy

Phone: + 39 2 98 29 21

Fax: + 39 2 98 80 171

TetraPak Hoyer France

c/oTetraLavalService SARL

R.C.S.Versailles B403 276 223

P.O. Box 56

F-78340LesClayes-Sous-Bois

France

Phone: +33 1 30818184

Fax: +33 1 30818120

NORTHAMERICA:

Tetra Pak Hoyer Inc.

753 Geneva Parkway

P.O. Box 280

Lake Geneva, WI 53127

USA

Phone: +1 414 2497400

Fax: +1 414 2497500

SOUTHAMERICA:

Tetra Pak Hoyer Industria e

ComércioLtda.

Rua Napoleao de Barros, 1038

Cep04024-003 Sao Paulo-SP

Brazil

Phone: +55 11 573 9422

Fax: +55 11 549 5420

ASIA/PACIFIC:

Tetra Pak Hoyer Shanghai

Shanghai Overseas Chinese

Mansion

Room 2105-2107

No.129,Yan'an Xi Lu

200040Shanghai

P.R.China

Phone: +86 21 6249 0860

Fax: +86 21 6249 9064

Tetra Pak Hoyer Service

3rdFloor,MolaceBuilding

2231PasongTamoStreet

Makati,MetroManila

Philippines

Phone: +63 2 8132848

Fax: +63 2 8132866

SOUTHKOREA:

HoyerLtd.

4fl.DookyongBldg.

66-1/9Hannam-Dong

Yong San-Ku

140-210 Seoul

SouthKorea

Phone: +82 2 796 0362

Fax: +82 2 796 0365

THAILAND:

Tetra Pak Hoyer (Thai) Ltd.

1042SoiPoosin,SukhumvitSoi

66/1

Bangchak,Prakanong

Thailand

Phone: +66 2 3611680

Fax: +66 2 3612310

C.I.S.:

Tetra Pak Hoyer A/O

4thRostovskypeureulok

Dom1,stroenie 1

R-11921 Moscow

C.I.S.

Phone: +7 502 2242160

Fax: +7 502 2242162

1.3 Service centres

If you have any requirement or problem that requires

our assistance, please contact one of the following

service centres, which are authorised to perform

maintenance and provide technical service under

warranty for Tetra Pak Hoyer machines.

HOYER COMET N

2-1

Tetra Pak

Hoyer

CN 03 B A 01

Contents

2 - GENERAL

2.1 Declaration of conformity ........................................................................................ 2-2

2.2 Preliminary points .................................................................................................... 2-2

2.3 General safety rules.................................................................................................. 2-2

2.4 Special warnings ...................................................................................................... 2-3

2.5 Residual risks ........................................................................................................... 2-3

2.6 Ambient operating limits ......................................................................................... 2-4

2-2

Tetra Pak

Hoyer

CN 03 B A 01

2.1 Declaration of conformity

This machine has been manufactured in

accordance with international standards and

hygiene and sanitary legislation applicable to

food machinery.

In particular Tetra Pak Hoyer certifies, through

the Declaration of Conformity supplied with the

machine,thattheHOYER COMET Nmachine

isdesignedand manufactured in accordance with

the provisions of Directive 89/392/EC

(Machinery Directive) and with the above-

mentioned standards.

•Theillustrations and drawings of themachine

are intended for general reference only and

are not necessarily accurate in every detail;

•The machine dimensions and specifications

given in this manual are not binding and may

be changed without prior notice;

•The drawings and all other documents

provided as a part of this machine remain the

property of Tetra Pak Hoyer and must not be

passed on to third parties without the written

permission of Tetra Pak Hoyer.

•The manual includes instructions for all

accessories mounted on the standard

machine.

•The machine is covered by warranty as

laid down in the purchase contract. Any

repair work not authorised by Tetra Pak

Hoyer carried out during the warranty

period will automatically invalidate the

warranty.

2.2 Preliminary points

2.3 General safety rules

•THESE SAFETY RULES HAVE BEEN

DRAWN UP IN YOUR INTEREST. Strict

observance will reduce the risk of accident

to yourself or to others.

•DO NOT attempt to move, install or operate

the machine before reading and assimilating

thecontents of thismanual.Ask your superior

in case of doubt;

•make sure that all guards and safety covers

are in place BEFORE starting the machine;

•NEVER leave tools, mechanical parts or

other foreign materials on or inside the

machine;

•in the event of a malfunction, press the

emergency stop button.

•NEVERPUTYOUR HANDS INSIDE THE

MACHINE WHEN IT IS IN OPERATION;

•exercise caution even when the main switch

locatedonthe tunnel is in the "OFF" position,

as the supply conductors will still be live;

•shut off the compressed air supply before

disconnecting any pneumatic component;

•make sure that all guards and safety covers

are correctly in place BEFORE restarting the

production cycle subsequent to maintenance

or repair operations;

•proceed with caution at all times. Remember

that you are responsible for your own safety

and for that of your colleagues;

•make sure that applicable regulations are

observed when moving or lifting the

machine.

Ι

2-3

Tetra Pak

Hoyer

CN 03 B A 01

• All personnel operating the machine must be

familiar with the general safety rules and

must observe them strictly. Failure to follow

these rules may result in personal injury or

damage to machine components;

• maintenance work must be performed with

themachine turned off.Themainswitch must

be in the "OFF" position, the tunnel air val-

ve closed and a “work in progress” sign

affixed to the machine;

• the user must make sure that all the

instructions given in the manual are

scrupulously observed;

• users will be solely responsible for risks

caused by tampering with the safety system;

• The safety of machines used in conjunction

with the STICK PICK-UP, if not supplied

directly by Tetra Pak Hoyer, is the

responsibility of the customer.

• Thepressure,speed,temperatureandvoltage

limits and all instructions given are

indispensable for correct operation of the

machine and must always be complied with

by the customer.

• Ambient conditions must be taken into

consideration during installation.

• National legislation governing this type of

machine must be observed.

2.4 Special warnings

2.5 Residual risks

The Comet N is a linear filling machine in

automaticcycleofsuperiorsizefortheproduction

of cornets, cups, tubs and other containers filled

with ice cream, sorbet and water ice, on more

lines ranging from one to six according to the

dimensions of the container to be processed and

the production values to be reached.

The filling process takes place according to a

pre-set cycle as laid down by the filling

specifications agreed upon with the customer.

Themachineincludesabaseunitfortransferring

thecontaineralongthemotionaxisofaconveyor

beltandasequenceofstationsfitforcarryingout

the required filling cycle with ice-cream and/or

other ingredients.

The process includes:

- placing the container on a conveyor belt

directly from an appropriate dispenser provided

with a storage unit

-conveyingthecontainerplacedontheconveyor

belt, under the work stations

- completion of the filling cycle according to a

predefined sequence with the expected

simultaneous action of the different stations.

- closing and/or sealing the container with a

protective film or an airtight lid.

- product ejection and discharge by means of

conveyor or pick-up

The motion of the conveyor belt is intermittent

and it is achieved by a suitable intermitter

activated by an electric motor and an inverter.

The stations are activated by cams controlled by

the same main drive shaft, with reference to the

approach phases of the former to the containers,

whilstthedosingphasesoftheice-creamandthe

liquid and solid ingredients (chocolate, nuts,

biscuits, etc.) are operated pneumatically.

The issue of adapting the machine to suit the

needs of the operator has brought about several

problemsthathavebeentackledinthefollowing

way:

- centralizing the controls on a single control

board for the following functions:

- automatic cycle with dispenser feeding.

- completion of a plane of work at ergonomic

height for set-up operations.

- ergonomic layout with the stations arranged

along the machine’s axis near its frontal part.

- application of planning criteria to the work

stations and their components such as the fillers

and the dispensers which enable an easy

maintenance and a quick format changeover.

- presence of fixed boards

The following residual risks arise from this kind

of machine; they are highlighted as follows:

- Tray carrier belt.

Thetraycarrierbelt, provided with a step to step

2-4

Tetra Pak

Hoyer

CN 03 B A 01

The machine is suitable for operation in the

following ambient conditions:

• Temperature : from 4°C to 40°C

• Humidity : from 20% to 95%.

.NOTE:

Tetra Pak Hoyer will accept no responsibility for

damage or injury caused by failure to comply

with the above warnings.

2.6 Ambient operating limits

motion, presents a dragging hazard.

The travel low speed makes it compatible with

the applied safety regulations.

For further safety, the residual risk is recalled in

section 3.6 Instructions on ban and danger

signals.

- Extrusion, dosing, lid loading and sealing

stations.

Theoperator’scontactwiththemovementofthe

kinematic mechanisms is inhibited by fixed

boards placed on the work front.

The lateral protection in connection with the

trays is not allowed with this kind of process.

The residual risk is recalled in section 3.6

Instructions on ban and danger signals, in

chapter 6 Work stations, and with a crushing

hazard signal placed on the fixed protection.

- Lid/foil crimping/pressing stations.

The fixed protections placed on the work front

inhibit the operator’s contact with both the

movementofthekinematicmechanismsandthe

high temperature of the pressing masses.

The lateral protection in connection with the

trays is not allowed with this kind of process.

The residual risk is recalled in section 3.6

Instructions on ban and danger signals, in

chapter 6 Work stations, and with a crushing

hazard signal and an extreme high tempera-

ture sign placed on the fixed protection.

Product ejection belts.

The lateral protections of the kinematic

mechanismsinconnectionwiththe traysandthe

release of products are not allowed with these

cone/cup dispenser stations.

The residual risk is recalled in section 3.6

Instructions on ban and danger signals and

with a sign of machine members in motion

placed on the fixed protection.

Power appliance panel

The doors of the power appliance panel can be

opened with suitable kit tools.

The opening of the doors entails isolating the

components downstream of the master switch.

Somecomponentsaresubjecttoresidualelectric

energy for a defined time.

Afteropening, do nottouchthe internal partsfor

at least 5 minutes.

A sign of

high-voltagecomponentsisplacedonthedoor.

HOYER COMET N

3-1

Tetra Pak

Hoyer

CN 03 C A 01

Contents

3 - DESCRIPTION OF THE MACHINE AND TECHNICAL DATA

3.1 Description of the machine ..........................................................................................2

3.3 Operation......................................................................................................................3

3.2 Machine accessories.....................................................................................................3

3.4 Products........................................................................................................................3

3.4.1 Changing the cup size.........................................................................................5

3.4.2 Changing the size of cones .................................................................................5

3.4.3 Formats with icings ............................................................................................6

3.4.4 Changing the size of cones/cups.........................................................................6

3.5. Improper uses .................................................................................................................7

3.6. Demolition and disposal...............................................................................................7

3.7 Technical data...............................................................................................................7

3.8 Instructions on ban and danger signals ........................................................................8

3-2

Tetra Pak

Hoyer

CN 03 C A 01

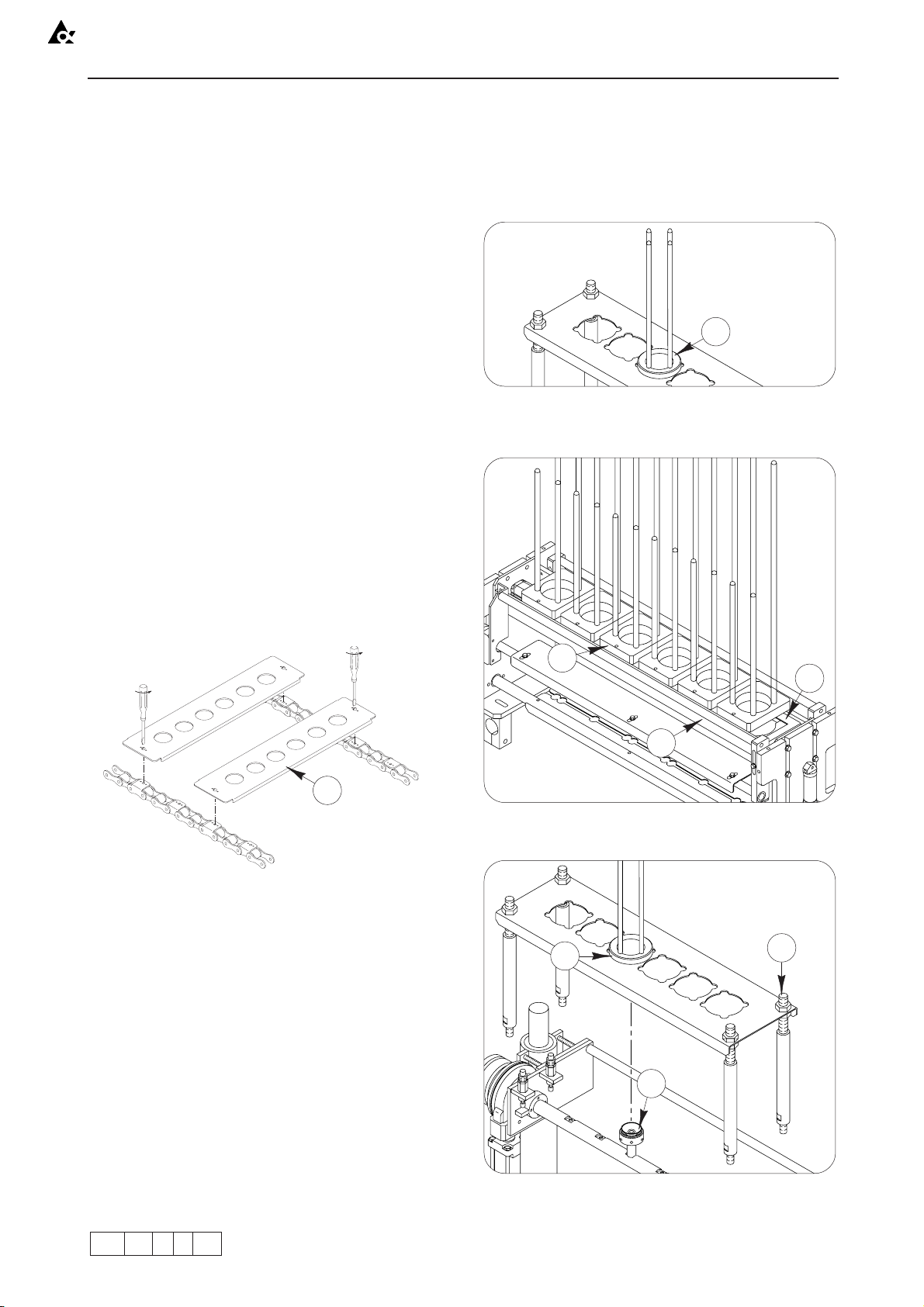

Fig. 3.1

3

9

7c

7a 7b

5

4

122

2

6

14

8

10

12 15

16

13

11

3.1 Description of the machine

TheHOYERCOMETNisalinearfillingmachine

in automatic cycle of superior size for the

production of cornets, cups, tubs and other

containersfilledwithicecream,sorbetandwater

ice, on more lines ranging from one to six

according to the dimensions of the container to

be processed and the production values to be

reached.

The filling process takes place according to a

pre-set cycle as laid down by the filling

specifications agreed upon with the customer.

Themachineincludesabaseunitfortransferring

thecontaineralongthemotionaxisofaconveyor

beltandasequenceofstationsfitforcarryingout

the required filling cycle with ice-cream and/or

other ingredients.

Thecarpentryofthemachine,itsmechanicaland

commercialcomponentsareentirelyreproduced

in stainless steel or anticorrosive materials. All

the parts that touch the product directly are

entirelymade ofstainlessmaterial orsubstances

that are approved for the food industry.

Inorder toavoid anyaccidental contactbetween

the parts of the body and any element of the

machineinmotion,themachine issupplied with

panels, protection boards, lids attached with

screws and/or systems for which the use of

suitable tools together with the operator’s

willingness are required to remove them.

The machine is composed of:

1. Steelstructure(Part.1Fig.3.1).withadjustable

feet (Part.2 Fig.3.1)..

2. Selectivetransmissioncontrolledbyanelectric

motor with inverter.

3. Intermittor with step to step feed.

4. Setof lamellaswith pitsdesigned forthetype

of container to be produced. The lamellas are

supported by two longitudinal members which

lead the belts driven/towed by the gearwheels.

5. Vacuum generator.

6. Pneumatic system.

7. Control panel with operation panel (Part.3

Fig.3.1).

8. Operating stations.

HOYER COMET N is not designed to produce

different kinds of products. For each product

requires the “size” to be set on the operator’s

interface panel. Sizes are stored in the PLC that

manages the operation of the machine.

For information on how to change and select a

“size”, see

paragraph 5.2.1 Setting working parameters

3-3

Tetra Pak

Hoyer

CN 03 C A 01

3.2 Machine accessories

- Cup loading station (Part 4 Fig.3.1) - See

paragraph 6.1.1

- Cone loading station (Part 5 Fig.3.1) - See

paragraph 6.1.2

-Topping**(Part6-6aFig.3.1) -Seeparagraph

6.1.7

- Doser drive (Part 7a-7b-7c Fig.3.1) - See

paragraph 6.1.3

- Ice-cream dosers (2 flavors)* (Part 8 Fig.3.1)

- See paragraph 6.1.5

-Truffledosers*(Part9Fig.3.1)-Seeparagraph

6.1.6

- Ice-cream dosers (1 flavor) (Part 10a 10b

Fig.3.1) - See paragraph 6.1.4

-Chipdoser**(Part11Fig.3.1)-Seeparagraph

6.1.8

- Cocoa doser ** (Part 12 Fig.3.1) - See

paragraph 6.1.9

-Weldingstation(cupssealing)(Part13Fig.3.1)

- See enclosed manual

- Product ejection station (Part 14Fig.3.1) - See

paragraph 6.1.10

The motion of the conveyor belt is intermittent

and it is achieved by a suitable intermitter

activated by an electric motor and an inverter.

The stations are activated by cams controlled by

the same main drive shaft with reference to the

approach phases of the cams to the containers,

whilst the dosing phases of the ice cream, the

3.3 Operation

liquid and solid ingredients (chocolate, nuts,

biscuits, etc.) are operated pneumatically.

.PLEASE NOTE:

The machine is designed to produce different

kinds of products. Operating procedures are

described in paragraph 5.3.

3.4 Products

Sono previsti i formati per la produzione delle

seguenti prodotti coppe e coni:

The production of “SCH 1226” cup requires the

use in sequence of the following stations:

- Cup loading station (Part 4 Fig.3.1);

- Ice-cream doser ( 2 flavor) (Part.8 Fig.3.1);

- Cover loading (Part.12 Fig.3.1);

- Cover sealing (Part.14 Fig.3.1);

- Product ejection station (Part.16 Fig.3.1).

Theproductionof “SCH 1224” cup requires the

use in sequence of the following stations:

- Cup loading station (Part.4 Fig.3.1);

- Ice-cream doser ( 2 flavor) (Part.8 Fig.3.1);

- Ice-cream doser ( 1 flavor “decoration”)

(Part.9 Fig.3.1)

- Cover loading (Part.12 Fig.3.1);

- Cover sealing (Part.14 Fig.3.1);

- Product ejection station (Part.16 Fig.3.1).

The production of “SCH 1225” cup requires the

use in sequence of the following stations:

- Cup loading station (Part.4 Fig.3.1);

- Ice-cream doser ( 2 flavor) (Part.8 Fig.3.1);

- Ice-cream doser ( 1 flavor “decoration”)

(Part.9 Fig.3.1)

- Cover loading (Part.12 Fig.3.1);

- Welding station (Part.13 Fig.3.1);

- Product ejection station (Part.16 Fig.3.1).

The production of MAXI “SCH 1256” cones

requires the use in sequence of the following

stations:

- Cone loading station (Part.5 Fig.3.1);

- Calibrator and chocolate sprinkling (Part.6

Fig.3.1);

- Ice-cream doser ( 2 flavor) (Part.8 Fig.3.1);

- Topping (Part.10 Fig.3.1);

- Chip doser (Part.11 Fig.3.1);

- Cover loading (Part.12 Fig.3.1);

- Cover sealing (Part.14 Fig.3.1);

- Product ejection station (Part.16 Fig.3.1).

3-4

Tetra Pak

Hoyer

CN 03 C A 01

The production of MAXI “SCH 1254 cones

requires the use in sequence of the following

stations:

- Cone loading station (Part 5 Fig.3.1)

-Calibrator andchocolate spray(Part6 Fig.3.1)

- Ice-cream dosers (2 flavors) (Part 8 Fig.3.1)

Ice-creamdoser(1taste, “icing”)(Part9Fig.3.1)

- Topping (Part 10 Fig.3.1)

- Chip doser (Part 11 Fig.3.1)

- Cover loading (Part 12 Fig.3.1)

- Cover sealing (Part 14 Fig.3.1)

- Product ejection station (Part 16 Fig.3.1)

The production of MAXI “SCH 1255” cones

requires the use in sequence of the following

stations:

- Cone loading station (Part 5 Fig.3.1)

- Calibrator and chocolate sprinkling (Part 6

Fig.3.1)

- Ice-cream dosers (2 flavors) (Part 8 Fig.3.1)

- Topping (Part 10 Fig.3.1)

- Chip doser (Part 11 Fig.3.1)

- Cover loading (Part 12 Fig.3.1)

- Cover sealing (Part 14 Fig.3.1)

- Product ejection station (Part 16 Fig.3.1)

The production of MAXI “SCH 1276” cones

requires the use in sequence of the following

stations:

- Cone loading station (Part 5 Fig.3.1)

- Calibrator and chocolate sprinkling (Part 6

Fig.3.1)

-Ice-creamdosers(1flavor“L/I”)(Part9Fig.3.1)

- Topping (Part 10 Fig.3.1)

- Chip doser (Part 11 Fig.3.1)

- Cover loading (Part 12 Fig.3.1)

- Cover sealing (Part 14 Fig.3.1)

- Product ejection station (Part 16 Fig.3.1)

The production of STD “SCH 1257” cones

requires the use in sequence of the following

stations:

- Cone loading station (Part 5 Fig.3.1)

- Calibrator and chocolate sprinkling (Part 6

Fig.3.1)

- Ice-cream dosers (2 flavors) (Part 8 Fig.3.1)

- Chip doser (Part 11 Fig.3.1)

- Cover loading (Part 12 Fig.3.1)

- Cover sealing (Part 14 Fig.3.1)

- Product ejection station (Part 16 Fig.3.1)

The production of STD “SCH 1271” cones

requires the use in sequence of the following

stations:

- Cone loading station (Part 5 Fig.3.1)

- Calibrator and chocolate sprinkling (Part 6

Fig.3.1)

- Ice-cream dosers (2 flavors) (Part 8 Fig.3.1)

- Ice-cream dosers (1 flavor “icing”) (Part 9

Fig.3.1)

- Topping (Part 10 Fig.3.1)

- Chip doser (Part 11 Fig.3.1)

- Cover loading (Part 12 Fig.3.1)

- Cover sealing (Part 14 Fig.3.1)

- Product ejection station (Part 16 Fig.3.1)

The production of STD “SCH 1258” cones

requires the use in sequence of the following

stations:

- Cone loading station (Part 5 Fig.3.1)

- Calibrator and chocolate sprinkling (Part 6

Fig.3.1)

- Ice-cream dosers (2 flavors) (Part 8 Fig.3.1)

- Topping (Part 10 Fig.3.1)

- Chip doser (Part 11 Fig.3.1)

- Cover loading (Part 12 Fig.3.1)

- Cover sealing (Part 14 Fig.3.1)

- Product ejection station (Part 16 Fig.3.1)

3-5

Tetra Pak

Hoyer

CN 03 C A 01

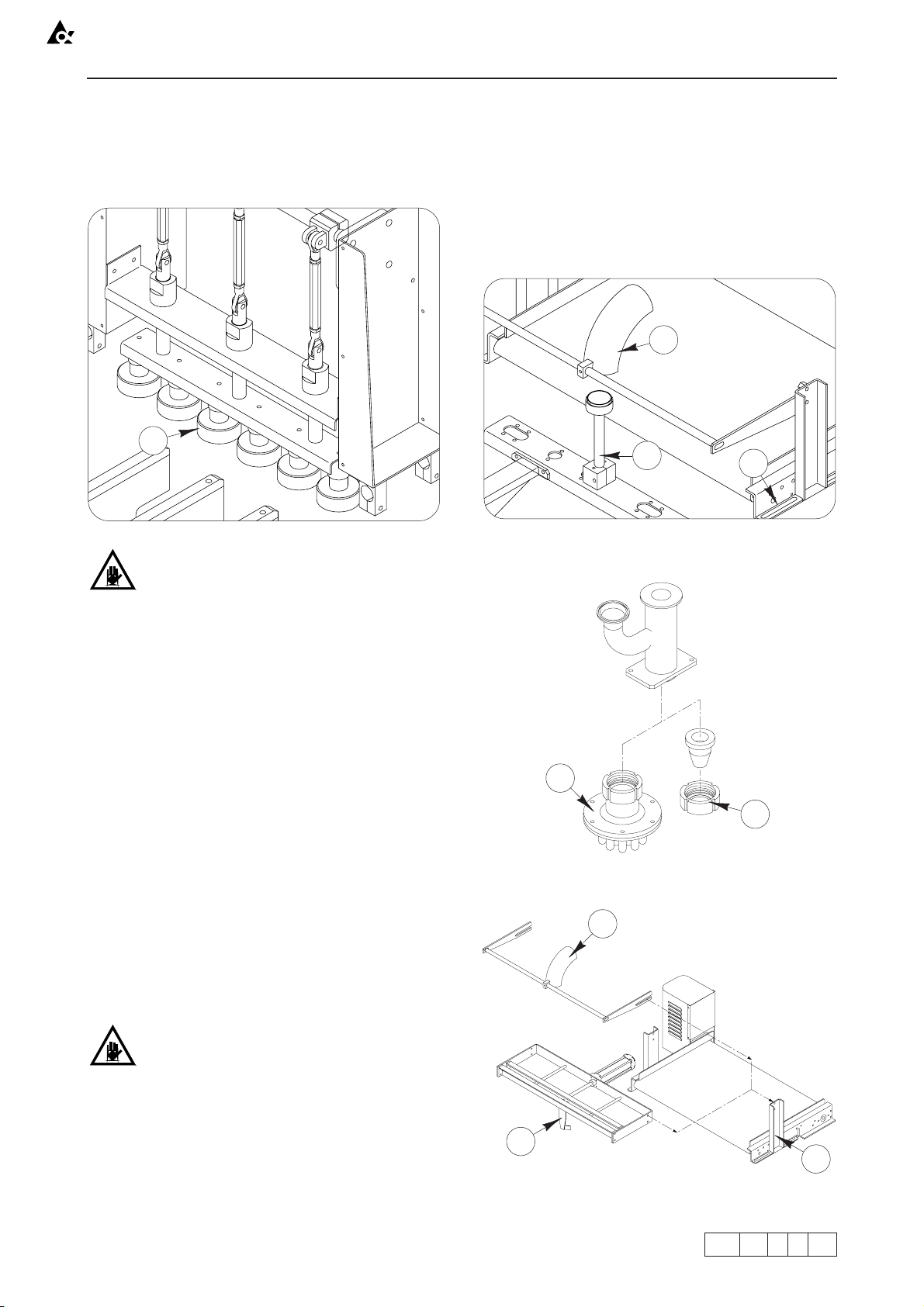

Fig. 3.2

Fig. 3.3

1

Fig. 3.4

Fig. 3.5

1

3

2

1

13

2

3.4.1 Changing the cup size

The geometrical shape and dimensions of cups

“SCH1226”,“SCH1224”e“SCH1225” arethe

same.

Thedifferencesbetweencups“SCH1226”,“SCH

1224”andcup“SCH1225”liesinthegeometrical

shape and in the material of the cover.

- To change the production from “SCH 1226”

and “SCH 1224” cups to cup “SCH 1225”, it is

necessary to replace the storage areas (Part 1

Fig.3.2) of the cover loading station. For

3.4.2 Changing the size of cones

ConesMAXI “SCH1256”, “SCH1254”, “SCH

1255”,“SCH1276”andconesSTD“SCH1257”

,“SCH1271”,“SCH1258”differbecauseofthe

dimensions of the cones and of the cover.

To change the production between MAXI and

STD cones, it is necessary to:

- Replace the shutters (Part 1 Fig.3.3)

information on how to adjust this station,

see paragraph 6.1.10.

- Replace the storage containers of the cone

loading station

(Part 1 Fig.3.4)

- Replace the blades of the cone stopping blades

(Part 2 Fig.3.4)

-Adjusttheheightoftheconestoragecontainers

crossbeam (Part 3 Fig.3.4)

- Replacethestoragecontainers(Part 1 Fig.3.5)

of the cover loading station

Replace thesuction cupsand therelatedholders

(Part 2 Fig.3.5)

-Adjusttheheightofthecrossbeamthatsupports

the cover storage containers (Part 3 Fig.3.5)

3-6

Tetra Pak

Hoyer

CN 03 C A 01

Fig. 3.6 Fig. 3.7

Fig. 3.8

Fig. 3.9

3

1

2

1

2

2

1

1

3

-Replacethecoverclosingtools(Part1Fig.3.6) - Adjust the height of the ejection plates (Part 1

Fig.3.7)

-Replaceand/oradjust the ejection curves (Part

2 Fig.3.7)

-Adjust the dischargeconveyor (Part 3 Fig.3.7)

WARNING!

The adjustments for the stations involved in the

cone size change are described in paragraphs

6.1.2 - 6.1.10 - 6.1.12 - 6.1.15

3.4.3 Formats with icings

To change the formats of products “SCH 1224”,

“SCH 1225”, “SCH 1254” and “SCH 1271”, it

isnecessarytoreplacethenozzle(Part1Fig.3.8)

with the icing plate (Part 2 Fig.3.8) on the ice-

cream doser station (Part 9 Fig.3.1)

3.4.4 Changing the size of cones/cups

To replace cones and cups, it is necessary to

replace the discharge station (Part 1 Fig.3.9)

with the cup discharge unit (Part 2 Fig.3.9) on

the frame of the discharge conveyor (Part 3

Fig.3.9)

WARNING!

The adjustments for the stations involved in the

production change are described in paragraphs

6.1.14 - 6.1.15

3-7

Tetra Pak

Hoyer

CN 03 C A 01

Fig. 3.10

5800

2215

1453

3.7 Technical data

3.6. Demolition and disposal

Useful information on the disposal of the

machinery and its components.

Thedemolitionmustbecarriedoutbespecialized

personnel equipped with personal and general

prevention means in respect of the safety and

environmental regulations.

Building materials:

- steel, stainless steel, aluminium, cast iron

- copper or silver for electric components

- rubber, nylon, PVC, resins and fibres.

No component is either toxic or harmful.

Special care is needed when disposing of the

ratio motors since they are full of oil.

Do not abandon them in the environment and do

not dispose of them as waste.

WARNING! Both machinery and

components, at the end of their period of use are

to be disposed of in respect of the regulations

according to the issue in force in the country of

use.

3.5. Improper uses

Notwithstanding the equipment of the machine

with several safety systems, the operators must

pay attention in order not to cause potentially

dangerous situations for their own and other

people’s safety.

The machine is designed and built for the

exclusive use as indicated in chapter 3.1. Any

other use is to be considered improper and

therefore unreasonable. The builder cannot be

considered responsible for any damage caused

by improper, wrong or unreasonable uses.

All the people who operate the machine have to

betrainedsuitablyontheexactworkingmethods

and they must be informed on the nature and

function of the safety devices.

Standard power supply

220 - 440 V / 3 Ph / 50-60 Hz

Installed power

Main motor: 3 kW

Conveyor motor: 0.18 kW

Total installed power: 5.5 kW

Net weight: 4000 Kg

Gross weight: 5000 Kg

Compressed air

Supply pressure: min 6 bar

Consumption: 1300 Nl/min

Diameter of the supply tube: 3/4" gas

Dimensions

See figure 3.2

Noise

EquivalentlevelofweightedacousticpressureA

at 1 meter: 67.5 dBA

Max.pressureofinstantaneousweightedacoustic

pressure C in workstations: below 130 dB/

20uPa.

3-8

Tetra Pak

Hoyer

CN 03 C A 01

Fig. 3.11

3.8 Instructions on ban and danger signals

WARNING:

Thetray-carrierbeltisequippedwithintermittent

motion and it presents the dragging hazard.

Neverputtools,mechanicalpartsorothermaterial

on the trays during the production cycle. Never

intervene on trays in motion, by removing

products or other.

WARNING :

The flaps of the power appliance panel can be

opened with suitable tool kits.

The opening of the flaps entails isolating the

components downstream of the master switch.

Certaincomponentsaresubjecttoresidualelectric

energy for a defined time.

Afteropening, do nottouchthe internal partsfor

at least 5 minutes.

Asignofhigh-voltagecomponentsisplacedon

the flap.

WARNING :

The lateral protection of the kinematic

mechanisms in connection with the trays is not

allowedwiththesetypesofextrusion,dispensing,

lid-loading and dispensing stations.

Acrushinghazardsignalisplacedon thefixed

protection.

WARNING :

The lateral protection of the kinematic

mechanismsinconnectionwiththetraysandthe

deliveryisnotallowedwiththistypeofcone/cup

unloading stations.

Asignofmachinemembersinmotionisplaced

on the fixed protection.

WARNING :

The lateral protection of the kinematic

mechanisms and the high temperature of the

pressingmassesin connectionwiththe traysand

their release is not allowed with this type of lid-

foil sealing stations.

Signsofcrushinghazardsandriskofextreme

high temperature are placed on the fixed

protection.

HOYER COMET N

4-1

Tetra Pak

Hoyer

CN 03 D A 01

Contents

4.1 Unpacking and delivery checks ............................................................................... 4-2

4.2 Transport and installation......................................................................................... 4-2

4.3 Electrical connection................................................................................................ 4-3

4.4 Checking direction of rotation ................................................................................. 4-3

4.5 Pneumatic connection .............................................................................................. 4-3

4.6 Freezer connections.................................................................................................. 4-3

4 - INSTALLATION

4-2

Tetra Pak

Hoyer

CN 03 D A 01

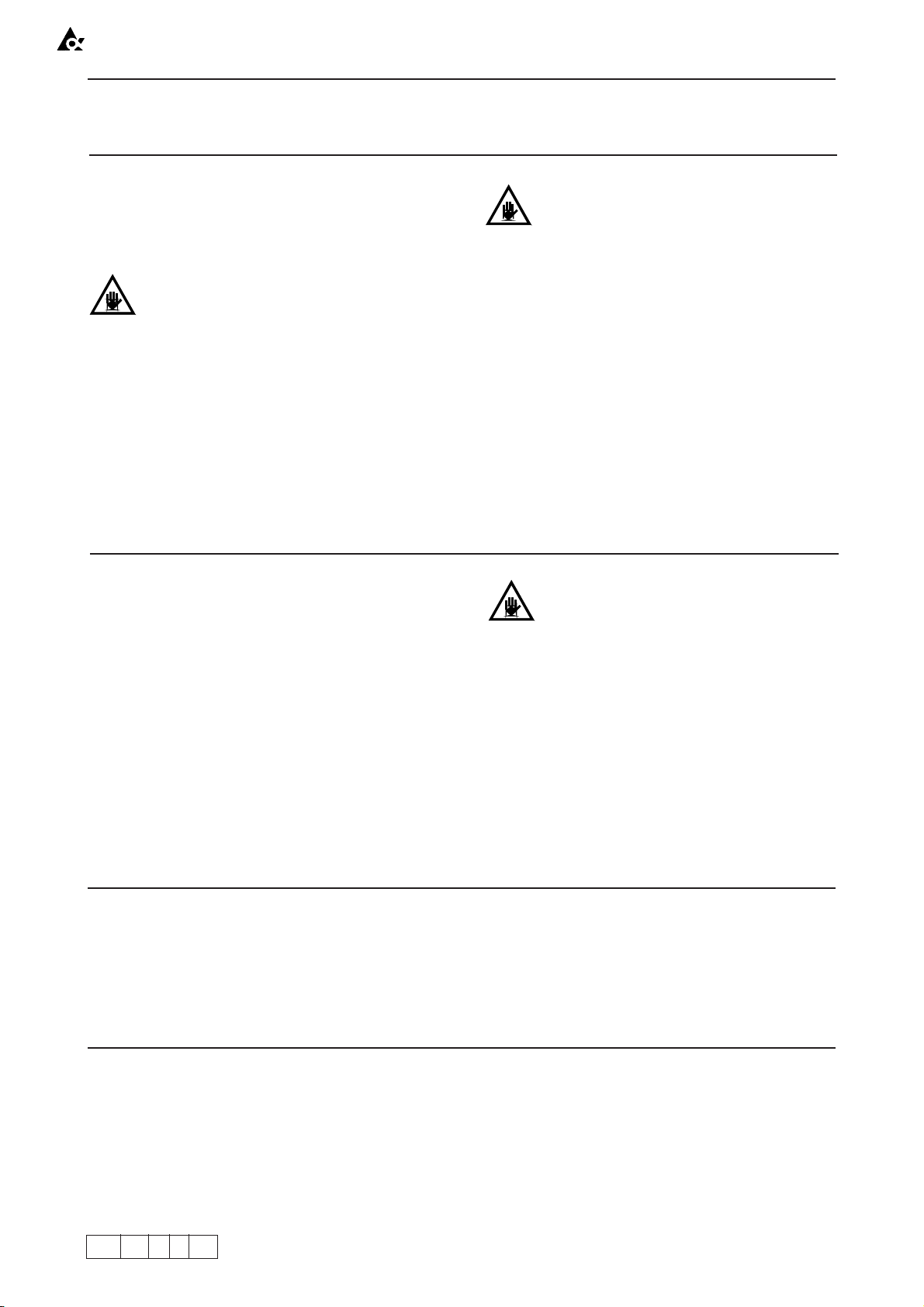

1 1

3

55

2

3 3

4

4

Fig. 4.1

TheHOYERCOMETNmachineandthevarious

operatingstationsaretransportedinspecialcon-

tainers,generallywoodencrates.Unpackingmust

be done near to the final installation position of

themachine.Thecratescanbeeasilytransported

by a lift truck.

When the crate has been positioned correctly,

unpack as follows:

a. Unnail the lid and remove it. Do the same

thing with the side panels. Pay particular

attentiontothewooden spacer blocks located

between the sides of the crate.

b. Remove the spare parts box and other com-

ponents from the crate.

c. Unnail the wooden blocks that hold the ma-

chine in place during transport and remove

the cellophane sheet.

d. Check that the contents of the crate corre-

spondtothedescriptiongiven in the shipping

documents.

e. Check that all the covers and panels have

been correctly fitted and that there are no

loose parts.

f. Visually inspect all the electrical components

to make sure that they are not damaged.

g. If any part/component is missing, stop un-

packing and immediately notify Tetra Pak

Hoyer.

h. If the machine has been damaged during

transit, notify the insurance company

immediately. Do not proceed beyond

unpacking until you are authorised to do so

by the insurance company.

4.1 Unpacking and delivery checks

4.2 Transport and installation

The following measures must be adopted during

the installation of the machine:

a. Position the machine at the place of

production. Move the machine using a fork

lift truck of suitable capacity checking that

there is sufficient space to remove the guards

and allow ease of access to the internal

machine parts.

b. Adjust the feet until the machine is perfectly

level both longitudinally and transversally.

4-3

Tetra Pak

Hoyer

CN 03 D A 01

4.3 Electrical connection (Refer to ALL. 1 Electric diagrams )

Make sure that the bypass valves of the ice-

creampipes(Part3Fig.4.1)areconnectedtothe

dosers (Part 4 Fig.4.1) as required.

Connecttheice-cream tubesfromthefreezersto

the ice-cream dosers by means of the bypass

valves (Part 5 Fig.4.3) located above the

pneumatic valve.

After performing all the electric and pneumatic

connections, it is necessary to perform the

following checks:

• Makesurethereisnoforeignmatterinsidethe

machine that could prevent its operation.

• Release the emergency button.

• Rotate the main switch.

• Open the air supply.

• PresstheJogbuttonandcheckthattheshutters

move from left to right (Part 2 Fig.4.1) looking

at the machine from the operator’s side.

• Press button Stop to stop the chain.

4.4 Checking the direction of rotation

4.6 Connection to the freezers

WARNING:

Ifthedirectionofrotationis incorrect, invert the

phases on the terminal block.

This operation must be performed by qualified

personnelonly,familiarwithlawsregulatingthe

prevention of industrial accidents.

Before starting the freezers connected to the

machine, place a container below the ice-cream

bypass valve and another container on the

opposite side of the machine, under the product

collection slide.

4.5 Pneumatic connections (Refer to ALL. 2 Pneumatic diagrams )

onnect the machine to the supply of compressed

air. The minimum working pressure is 6 bar.

If the pressure is below 4 bar, a special pressure

switch calibrated by the manufacturer stops the

functions of the machine.

Forinformationontheconsumptionofairandon

the dimensions of the supply pipe, see 3.7

Technical specifications.

Themachine’selectricalsystemhasbeenfactory

checked by Tetra Pak Hoyer engineers.

The machine’s components are electrically pro-

tected against short-circuits.

WARNING:

The connection must be made exclusively by

competent technicians familiar with accident

prevention legislation.

It is recommended that the power is taken from

a master switch fitted with thermal overload

cutoutandultra-rapidfusesofadequateamperage.

WARNING:

The differential cutout switch must be class “A”

and suitable for protecting inverter electronic

power circuits.

• Check the data on the identification plate to

ensure that the machine is compatible with

the factory voltage.

• Connect the three phases to terminals R S T

and the earth wire to the earth terminals in

the electric panel.

For the minimum sections of the power supply

cable, refer to the voltage and power values

reportedontheidentificationplateandthe stand-

ards in force in the country of installation.

Other manuals for HOYER COMET N

1

This manual suits for next models

1

Table of contents

Other Tetra Pak Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

optimax

optimax ECOPAX CP320S2-I operating instructions

Siebeck

Siebeck JET Series Translation of the original operating manual

IPG

IPG Interpack ET 2Plus H275 Operator's manual & parts list

vc999

vc999 PACKAGING plus CM610FB Operations & parts manual

Minipack-Torre

Minipack-Torre Pratika 56 CS Series Installation, operation and maintenance

Curtec

Curtec Nestable manual