Tetra Pak Tetra Cardboard Packer 70 User manual

GH100374.eps

Tetra Cardboard Packer 70

Multi infeed

Doc No OM-585572-1

OM

Operation Manual

This page intentionally left blank

This document is valid for:

Series No/ Machine No Sign.

Table of content:

Doc No OM-585572-1

OM

Operation Manual

Tetra Cardboard

Packer 70

670272-060V

Equipment included:

Multi infeed

670292-0405

Wrap around unit

670375-040V

Central lubrication kit

CK-1287000-010V

Note!

This Operation Manual is only

valid for a custom built version

of Tetra Cardboard Packer 70

/ Multi infeed 670272-060V.

Introduction . . . . . . . . . . . . . . . . . . . .1

Safety precautions. . . . . . . . . . . . . . .3

General description . . . . . . . . . . . . .11

Alarms /Troubleshooting . . . . . . . . .15

Preparations . . . . . . . . . . . . . . . . . .23

Start . . . . . . . . . . . . . . . . . . . . . . . . .27

Production . . . . . . . . . . . . . . . . . . . .29

Emptying . . . . . . . . . . . . . . . . . . . . .33

Stop . . . . . . . . . . . . . . . . . . . . . . . . .35

Storing of material . . . . . . . . . . . . . .39

Cleaning. . . . . . . . . . . . . . . . . . . . . .41

Technical data . . . . . . . . . . . . . . . . .43

Lubricants . . . . . . . . . . . . . . . . . . . .45

Issue 9704

Tetra Pak Distribution AB

This page intentionally left blank

1

Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Introduction

This section contains basic information

about the described Tetra Pak equipment

and this document.

WARNING!

To ensure maximum safety for the operator,

always read the section “Safety

precautions” before doing any work on the

machine or making any adjustments.

The purpose usage of this Tetra Pak

equipment

To place Tetra Brik packages or other

packages approved by Tetra Pak Distribution

AB into units made of corrugated cardboard.

Service

In case of problems when operating the

machine, contact the nearest Tetra Pak

service station.

Manufacturer

This Tetra Pak equipment is produced by:

Tetra Pak Distribution AB

Ruben Rausings gata

221 86 Lund

Sweden

Machine identification

The machine plate at the left is the type of

machine plate attached to the machine

frame. The plate carries data needed when

contacting Tetra Pak concerning this specific

machine.

The plate is marked with a CE sign. It means

that this machine complies with the basic

health and safety regulations of the

European Economic Area (EEA).

Machine Type

Drawing Spec.

Machine No.

Manufacturer

Year of manufacture

Tetra Pak

GH300005

Example of machine plate

Introduction

2Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Purpose of Operation Manual (OM)

The purpose of the Operation Manual is to

provide the operator with information on

how to handle and operate the machine

before, during, and after the production. For

instructions on maintenance in connection

with production, see the Maintenance

Manual (MM).

Design modifications

The directives in this document are in

accordance with the design and construction

of the machine at the time it was delivered

from Tetra Pak machine production facility.

Document producer:

The document has been produced by:

Tetra Pak Distribution AB

Ruben Rausings gata

221 86 Lund

Sweden

Further copies

Additional copies can be ordered from

nearest Tetra Pak service station.

When ordering technical publications,

always quote the document number printed

on the front cover of the document

concerned.

Number of pages

This document contains totally 48 pages.

Copyright © 1997

Tetra Pak Distribution AB

All rights reserved. No parts of this

document may be reproduced or copied in

any form or by any means without written

permission from Tetra Pak Distribution AB.

Example of manual

Document number

3

Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Safety precautions

Before any measures are taken, this section

must be read.

Avoid personnel injuries and machine

damages by following the instructions

given.

Tetra Pak will not accept any responsibility

in case of injuries and damages caused by

incorrect use of the machine.

Definitions

Skilled personnel

Service technicians: maintenance staff,

specialists etc.

Electrical: an individual with technical

knowledge or sufficient experience to

enable that individual to avoid hazards

which electricity can create.

Operator: an individual that has required

sufficient knowledge about operating the

machine by reading the Operation Manual,

OM.

General

Only skilled personnel is allowed to

operate the machine.

The machine may only be used in the

manner described in the Operation Manual,

OM.

Always use hearing protectors when the

machine is in operation.

GH200053

GH200053

Safety precautions

4Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Emergency stop

When there is risk of injury or machine

damage, the machine must be stopped

immediately by pushing one of the four

Emergency Stop buttons.

See section General description for

location of Emergency stop buttons.

Signs

The sign to the left indicates that water

must not be flushed towards the area with

the sign.

DANGER!

Failure to observe may result in danger to

your life.

The sign to the left indicates that there is a

hot surface. The temperature may exceed

60° C.

WARNING!

Failure to observe may result in injuries

caused by burning.

The sign to the left indicates that there is

entrapped heat in the area where the sign is

placed. The temperature may exceed

60° C.

WARNING!

Failure to observe may result in injuries

caused by burning.

GH200022

GH200211.eps

GH200212.eps

GH200313.eps

Safety precautions

5

Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Signs (cont’d)

The sign to left indicates that there is

entrapped compressed air in the area where

the sign is placed.

WARNING!

Failure to observe may result in injuries

caused by moving parts.

The sign to left indicates that there is a risk

of electrical shock that may cause injury or

death in the area where the sign is placed.

DANGER!

Failure to observe may result in danger to

your life.

Doors

WARNING!

All doors leading to risk areas are fitted

with safety switches. These switches are

part of the security system and must under

no circumstances be by passed, bridged,

or in any other way put out of working

order.

If any one of the doors on the machine are

opened, it will immediately stop.

Covers

WARNING!

All covers screwed on to the machine must

be securely attached, before starting

the machine.

GH200471.eps

GH100276.eps

GH200495.eps

GH200495.eps

Safety precautions

6Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Electrical cabinet

DANGER!

The voltage is 400V inside the electrical

cabinet. Can cause electrical shock or

serious injury. In case of accident,

immediately call for medical attention.

Work inside the electrical cabinet must be

performed by skilled persons only.

WARNING!

Risk of impaired hearing. Use hearing

protection to minimize the risk of impaired

hearing.

Always wear hearing protection while the

machine is running.

Note!

Always keep the ear protectors clean.

Infeed conveyor

WARNING!

If a safety cover is opened, the infeed

conveyor will still be in motion. Risk of

injuries.

The conveyor only stops when an

Emergency stop button is pushed or

when the machine is completely turned

OFF.

GH200053

GAD00051

GH200053

Safety precautions

7

Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Hot melt equipment

DANGER!

There is high voltage inside the hot melt

unit. Risk of electrical shock that may

cause injury or death.

Always wear safety glasses, protective

gloves, and other protective clothing to

avoid injuries caused by splashing hot melt

material.

Never remove any part or component until

air and electric power have been

disconnected and the pressure of the hot

melt in the system has been relieved.

Failure to relieve any remaining air or liquid

(adhesive) pressure may cause serious

injuries through burning.

All service work on the hot melt unit must

be carried out by skilled personnel.

Hot melt unit

WARNING!

Risk of burning! During heating and

production the unit gets hot.

Do not touch the unit!

GH200019

GH200019

GH200212.eps

Safety precautions

8Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Hot melt unit

DANGER!

Never flush water towards the hot melt unit

when cleaning the machine.

Hot melt

WARNING!

The hot melt tank contains heated hot melt

which can cause serious injuries. Do not

touch the hot melt!

GH200019

GH200211.eps

GH200019

GH200313.eps

Safety precautions

9

Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Infeed brake

WARNING!

The infeed brake contains entrapped

compressed air which can cause serious

injuries.

Wrap around unit

WARNING!

The wrap around squeezer cylinder

contains entrapped compressed air which

can cause serious injuries.

Note!

This warning only applies for machines

equipped with a wrap around unit.

GH200471.eps

GH200804.eps

GH200471.eps

GH200805.eps

Safety precautions

10 Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Production mode changes

All changes concerning packing pattern

and infeed alternatives must be carried out

by skilled personnel.

WARNING!

Do not reach into the machine neither from

above or below, risk of injuries caused by

crushing.

Discharge unit

The machine fulfils the safety demands

only when a discharge unit with covers

Tetra Pak no. C-1074350, C-1074388 is

mounted or similar equipment which fulfils

Machinery directive 89/392/EEC and

subdirectives.

GH200495.eps

GH200495.eps

GH200499.eps

1

Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

This section gives the operator

information on where on the machine the

parts that the operator needs to be in

contact with are located and what the

different regulators control.

General description

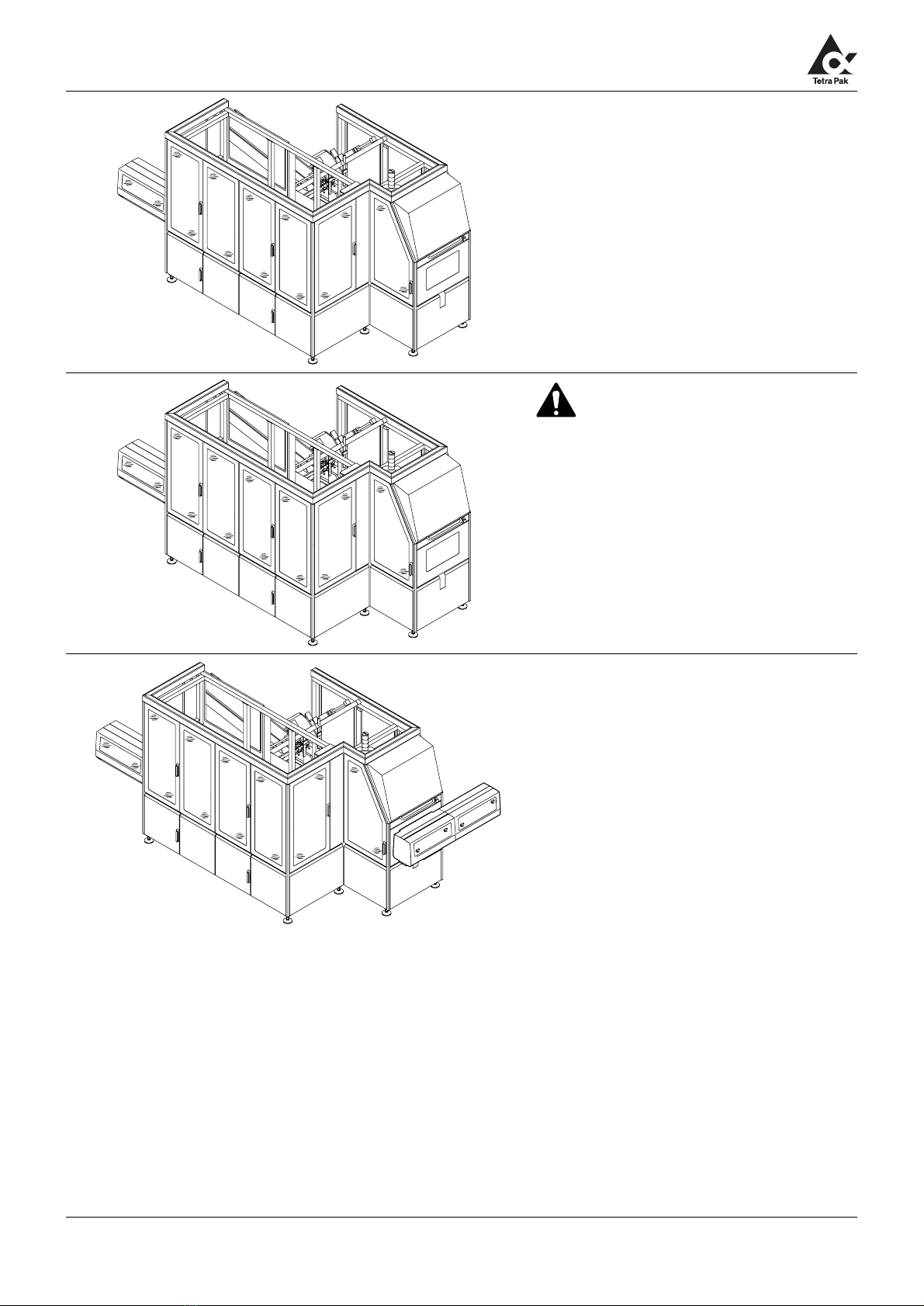

Machine overview

1 Blanks magazine

2 Warning lamp

3 Hot melt unit

4 Emergency stop

5 Pneumatic cabinet

6 Emergency stop

7 Electrical cabinet

8 Main switch

9 Emergency stop

10 Control panel

11 Emergency stop

12 Grouping section

13 Pusher section

123

5

GH300066.eps

4

6

7

8

9

10

11

12

13

7

9

4

12

11

13

86

Z-infeed

U-infeed 10

General description

2Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Status indicators

1 Step 1: Preheating

2 Step 2: Air pressure on

3 Step 3: Production

13 Indication, cardboard unit type

14 Indication, Single / Multi pack

15 Indication, packing pattern length

16 Indication, packing pattern width

Push buttons

4 Emergency stop

5Alarmreset

6 Manual emptying

7 Programme up

8 Programme down

9 Selector, cardboard unit type

10 Selector, Single / Multi pack

11 Selector, packing pattern length

12 Selector, packing pattern width

Status indicators and push buttons

7

13

14

15

16

9

10

11 12 8

5

6

4

1

2

3

Tetra Cardboard Packer 70 Tetra Pak

GH900164.eps

General description

3

Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

1 Main air valve

2 Pressure regulator, working pressure

3 Pressure regulator, vacuum, suction cups

4 Pressure regulator, hot melt gun, left

5 Pressure regulator, hot melt gun, right

6 Pressure regulator, hot melt unit

7 Pressure regulator, folding station

See section Techni cal dat a for settings.

Pressure regulators

12

3

4

5

6

7

GH200209.eps

General description

4Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

1 Temperature regulator, hot melt tank

2 Temperature regulator, hot melt gun, left

3 Temperature regulator, hot melt hose, left

4 Temperature regulator, hot melt gun, right

5 Temperature regulator, hot melt hose, right

6 Temperature regulator, hot melt gun, wrap around,

right

7 Temperature regulator, hot melt hose, wrap around,

right

8 Temperature regulator, hot melt gun, wrap around,

left

9 Temperature regulator, hot melt hose, wrap around,

left

See section Technical data for settings.

Temperature regulators, hot melt unit

GH200814.eps

OFF

100

150

200

C

OFF

100

150

200

C

OFF

100

150

200

C

OFF

100

150

200

C

OFF

100

150

200

C

OFF

100

150

200

C

OFF

100

150

200

C

OFF

100

150

200

C

OFF

100

150

200

C

SYSTEM FAULT

TEMP WARNING

CONTROL ON

SYSTEM READY

REMOTE SHUTDOWN

OVER TEMPERATUREOPEN SENSOR

SHORTED SENSOR

MICROSE

T

MULTISCAN

1

3

2

5

4

7

6

9

8

1

Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Alarms /Troubleshooting

This section describes all the alarms that

can appear and the actions that the

operator should take to correct them.

Warning lamp

When one of the three colours of the

warning lamp flashes, an alarm has been

triggered.

Depending on what kind of alarm that has

been triggered, the result is as follows:

• If the red colour, at the top, is flashing,

this indicates a dangerous status such as

a fault in the supervision circuit of the

doors. This requires an immediate

action from the operator.

• If the yellow colour, in the middle, is

flashing, this indicates an abnormal

status such as low air pressure during

production. This requires an immediate

action from the operator.

• If the blue colour, at the bottom, is

flashing, this indicates an alarm that

requires some action from the operator,

such as loading new blanks into the

magazine.

Note!

When several alarms are triggered at the

same time, only the alarm with the highest

alarm status is giving a signal to the

warning lamp.

When an alarm has been acknowledged but

the alarm still remains, the warning lamp is

steadily alight.

GH100229.eps

GH100228.eps

Alarms /Troubleshooting

2Tetra Cardboard Packer 70 Multi infeed

Doc No OM-585572-1

Control panel

1

6

7

8

91011

12

2345

GH200815.eps

Tetra Cardboard Packer 70 Tetra Pak

Table of contents

Other Tetra Pak Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

HUALIAN

HUALIAN M-PE Series Operation manual

Pro Pack Solutions

Pro Pack Solutions Eagle 710 Operation manual

Oliver

Oliver 1808-D User's operation

Kronos

Kronos H-46 Series Operation, safety and spare parts manual

Robopac

Robopac ROBOT S7 Use and maintenance manual