Tetra Pak Tetra Centri A610HGD-14C User manual

Te t r a PakProcessingCompor)ts

Operator'sManual

TetraCentri®^

Self-cleaningHermeticSeparators

A610HGD-14C

H610HGD-74C

ProductNo.881154-03-01& 881154-01-03

BookNo.1271703-02Rev.2 ATetraPak

TetraPakProcessingComponents

Operator'sManual

TetraCentri®

Self-cleaningHermeticSeparators

A610HGD-14C

H610HGD-74C

ProductNo.881154-03-01/2& 881154-01-03/2

BookNo.1271703-02Rev.2

AlfaLavalTumbaAB

SeparatorManuals,dept.PPDM

SE-14780Tumba,Sweden

Telephone:+468 53065000

Telefax:+468 53031040

PrintedInSweden,01-06

©AlfaLavalTumbaAB2001

Thispublicationoranypartthereofnnaynotbe

reproducedortransmittedbyanyprocessor

meanswithoutpriorwrittenpermissionof

AlfaLavalTumbaAB.

Contents

1SafetyInstructions7

2GeneralInformation13

2.1Foreword14

2.2 Identificationandsafetysigns,machine

A610HGD-14C15

2.3Identificationandsafetysigns,machine

H610HGD-74C17

3Separationprocess19

3.1Basicprinciples20

3.2 General21

3.3Throughput22

4Mechanicalfunction23

4.1Powertransmission24

4.2 Brake25

4.3Sensorsandindicators26

4.4Outlet/inlet28

4.5Axialseals-

coolingsystem29

4.6Bowl31

5Sedimentdischargefunction33

5.1Functiondescription34

6Installationandfirststart37

6.1Preparations38

6.2Beforefirststart39

6.4Operation40

6.5stopping41

6.3Firststart40

7Cleaning43

7.1Checkofcleaning/ discpressure44

8Operatingroutine47

8.1Checl«points48

9Troubletracing51

9.1Mechanicalfunction52

9.2Sedimentdischarge55

9.3Axialseals59

10Demandspecification61

10.1Servicewater62

10.2Compressedair63

11Interfacedescription65

11.1General66

11.2Definitions66

11.3Componentdescriptionand

signalprocessing67

11.4Interconnectiondiagramformonitoringkit72

12Technicalreference73

12.1Technicaldata74

12.2Inandoutletpressures76

12.3Bowlsealingdiagram77

12.4Basicsizedrawing78

12.5Connectionlist81

12.6Foundationdrawing84

12.7Electricmotor86

12.8Guidelinesforfrequencyconverterdrives88

4

2K

STOP

Studyinstructionmanualsandobservethe

warningsbeforeinstallation,operation,

serviceandmaintenance.

Notfollowingtheinstructionscanresultin

seriousaccidents.

In

order

to

maketheinformationclearonlyforeseeableconditions

havebeenconsidered.Nowarningsaregiven,therefore,for

situationsarising

from

theunintendedusageofthemachineandits

tools.

m

1Safety Instructions

Thecentrifugalseparatorincludespartsthat

rotateathighspeed.Thismeansthat:

•Kineticenergyishigh

•Greatforcesaregenerated

•Stoppingtimeislong

Manufacturingtolerancesareextremelyfine.

Rotatingpartsarecarefullybalancedtoreduce

undesiredvibrationsthatcancausea breakdown.

Materialpropertieshavebeenconsidered

carefullyduringdesigntowithstandstressand

fatigue.

Theseparatorisdesignedandsuppliedfora

specificseparationduty(typeofliquid,rotational

speed,temperature,densityetc.)andmustnotbe

usedforanyotherpurpose.

Incorrectoperationandmaintenancecanresultin

unbalanceduetobuild-upofsediment,reduction

ofmaterialstrength,etc.,thatsubsequentlycould

leadtoseriousdamageand/orinjury.

Thefollowingbasicsafetyinstructionstherefore

apply:

•Usetheseparatoronlyforthepurpose

andparameterrangespecifiedby

AlfaLaval.

•Strictlyfollowtheinstructionsfor

installation,operationandmaintenance.

•Ensurethatpersonnelarecompetentand

havesufficientknowledgeofmaintenance

andoperation,especiallyconcerning

emergencystoppingprocedures.

•UseonlyAlfaLavalgenuinespareparts

andthespecialtoolssupplied.

1Safety Instructions

A DANGER

Disintegrationhazards

Usetheseparatoronly

for

thepurpose

andparameterrangespecifiedby

AlfaLaval.

Ifexcessivevibrationoccurs,stop

separatorandkeepbowlfilledwith

liquidduringrundown.

Whenpowercablesareconnected,

alwayscheckdirectionofmotorrotation.

Ifincorrect,vitalrotatingpartscould

unscrew.

Checkthatthegearratioiscorrectfor

powerfrequencyused.Ifincorrect,

subsequentoverspeedmayresultina

seriousbreakdown.

Weldingorheatingofpartsthatrotate

canseriouslyaffectmaterialstrength.

Wearonthelargelockringthreadmust

notexceedsafetylimit.(|)-markonlock

ringmustnotpassopposite(|)-markby

morethanspecifieddistance.

Inspectregularlyforcorrosionand

erosiondamage.Inspectfrequentlyif

processliquidiscorrosiveorerosive.

rAnIn

8

1Safety Instructions

A DANGER

Entrapmenthazards

Makesurethatrotatingpartshavecome

toa completestandstillbeforestarting

anydismantlingwork.

Toavoidaccidentalstart,switchoffand

lockpowersupplybeforestartingany

dismantlingwork.

Assemblethemachinecompletely

beforestart.Allcoversandguardsmust

beinplace.

Electricalhazards

Followlocalregulationsforelectrical

installationandearthing(grounding).

A WARNING

Crushhazards

Usecorrectliftingtoolsandfollowlifting

instructions.

Donotworkundera hangingload.

Noisehazards

•Useearprotectioninnoisy

environments.

1Safety Instructions

A CAUTION

Burnhazards

Lubricationoilandvariousnnachine

surfacescanbehotandcauseburns.

Cuthazards

Sharpedgesonseparatordiscsandlock

ringthreadscancausecuts.

10

1Safety Instructions

Warningsignsinthetext

Payattentiontothesafetyinstructionsinthis

manual.Belowaredefinitionsofthethreegrades

ofwarningsignsusedinthetextwherethereisa

riskforinjurytopersonnel.

A DANGER

Typeofhazard

Thistypeofsafetyinstructionindicatesa

situationwhich,ifnotavoided,couldresultin

fatalInjuryorfataldamagetohealth.

A WARNING

Typeofhazard

Thistypeofsafetyinstructionindicatesa

situationwhich,ifnotavoided,couldresultin

disablingInjuryordisablingdamageto

health.

A CAUTION

Typeofhazard

Thistypeofsafetyinstructionindicatesa

situationwhich,ifnotavoided,couldresultin

lightinjuryorlightdamagetohealth.

NOTE

Thistypeofinstructionindicatesa situation

which,ifnotavoided,couldresultindamage

totheequipment.

11

7K 1Safety Instructions

12

2General information

Contents

2.1Foreword14

2.2 Identificationandsafetysigns,

machineA 610HGD-14C15

2.3Identificationandsafetysigns,

machineH 610HGD-74C17

13

2.1 Foreword 2 General information

2,1Foreword

Thismanualisintendedprimarily

for

theMachine

OperatingPersonnel.Itisessentialthatthese

personshavereadandunderstoodthecontents

ofthisbook.

It

describesthemechanicaland

separating-technicalfunctionsofthemachineas

wellastheprinciplesofoperationanddaily

maintenance.

Thepurposeofthemanualistoenablethe

operatortooperatethemachineandtoachieve

satisfactoryseparatingresultswithregardto

existingsafetyprecautionsandwith

supplementaryoperatingroutine.

Amanualshouldalwaysbeavailablenearthe

placeofoperation.

KeepOperatingroutine,LubricationSchedule,

etc.,easilyvisible.

Letalloperatingpersonnelreadthemanual.

Itisimportanttobefamiliar

with

theSafety

Precautions.

Themanufacturingcompanyreservestherightto

makechangesindesignoraddany

Improvementsonitsproductswithoutany

obligationstoprovidenoticethereofortoinstall

sameonunitspreviouslydeliveredbyit.

14

2General information 2.2 Identification and safety signs, machine A 610HGD-14C

2.2Identificationand

safetysigns,machine

A610HGD-14C

Alfa Laval ref. 556162, rev. 0

1.MachineplateTextonplate:

Separator

ManufacturingserialNo/ Year

ProductNo

Machinetoppart

Outlet

Bowl

Machinebottompart

Max.speed(bowl)

Directionofrotation(bowl)

Speedmotorshaft

El.currentfrequency

Recommendedmotorpower

Max.densityoffeed

Max.densityofsediment

Max.densityofoperatingliquid

Processtemperaturemin./max.

A610HGD-14C

XXXX

881154-03-01

548940-01

548931-03

561182-01

549501-05/-06(50Hz/60Hz)

6240/ 6235r/min(50Hz/ 60Hz)

1500/1800r/min(50Hz/ 60Hz)

50Hz/60Hz

18,5kW

1030kg/m^

1046kg/m^

1000kg/m^

0/100°C

15

2.2 Identification and safety signs, machine A 610HGD-14C 2General information

3.Safetylabel

Textonlabel:

DANGER

Readtheinstructionmanualsbeforeinstallation,

operationandmaintenance.Considerinspection

intervals.

Failuretostrictlyfollowinstructionscanleadto

fatalinjury.

Ifexcessivevibrationoccurs,stopseparatorand

keepbowlfilledwithliquidduringrundown.

Outofbalancevibrationwillbecomeworseifbowl

isnotfull.

Separatormuststoprotatingbeforeany

dismantlingworkisstarted.

AiglHSigl

t

vs6ses6

gSMWWW -

4.Nameplate"TetraPak' A'

Tetra

Pak

6.Arrowindicatingdirectionofrotation

8.Frequencylabel50Hz160Hz

Spacereservedforplateindicating

representative

50Hz

60Hz

16

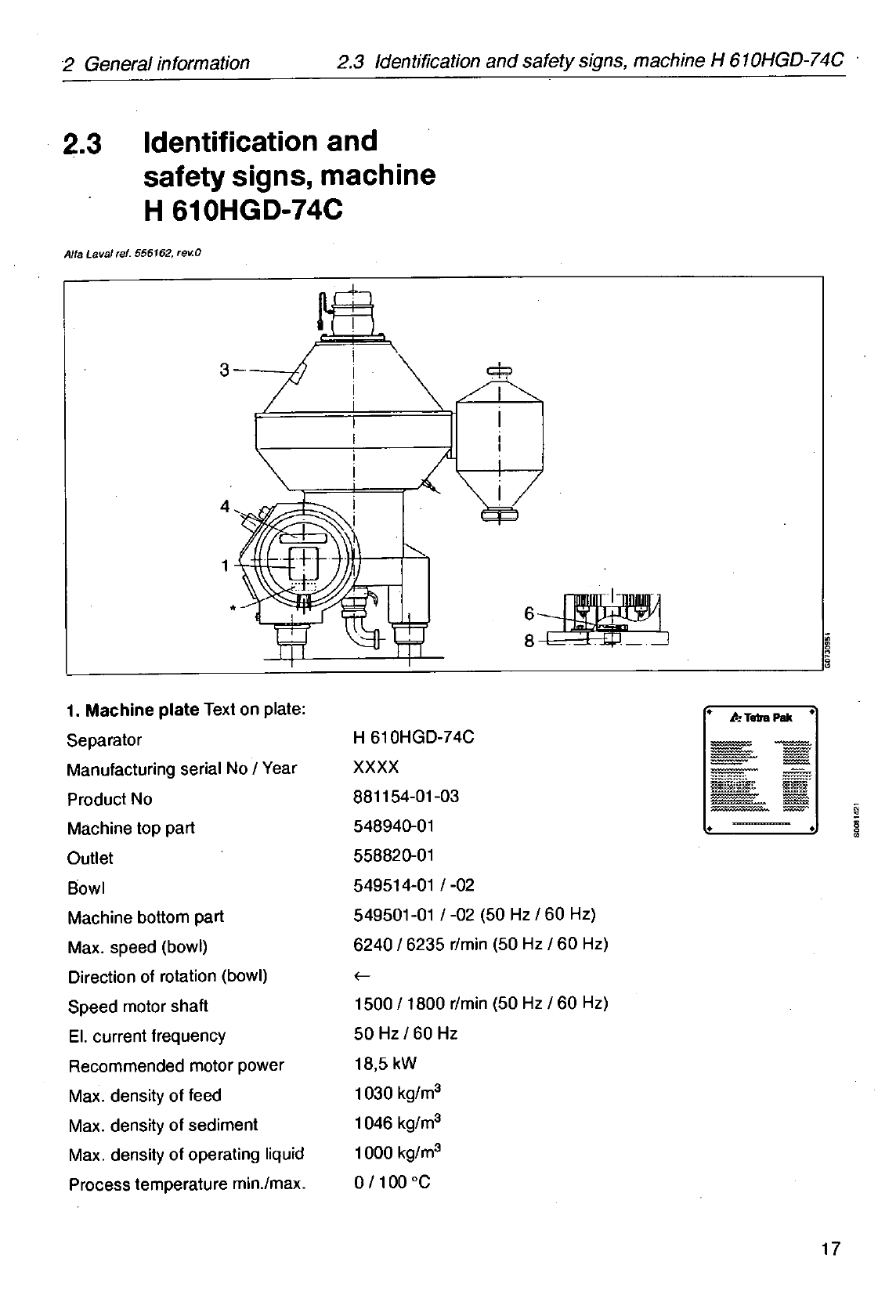

2General information 2.3 Identification and safety signs, machine H 610HGD-74C

2.3Identificationand

safetysigns,machine

H610HGD-74C

Alfa Laval ref. 556762,rev.O

1.MachineplateTextonplate:

Separator

ManufacturingserialNo/ Year

ProductNo

Machinetoppart

Outlet

Bowl

Machinebottompart

Max.speed(bowl)

Directionofrotation(bowl)

Speedmotorshaft

El.currentfrequency

Recommendedmotorpower

Max.densityoffeed

Max.densityofsediment

Max.densityofoperatingliquid

Processtemperaturemin./max.

H

610HGD-74C

XXXX

881154-01-03

548940-01

558820-01

549514-01/-02

549501-01/ -02(50Hz/ 60Hz)

6240/ 6235r/min(50Hz/ 60Hz)

<—

1500/1800r/min(50Hz/ 60Hz)

50Hz/60Hz

18,5kW

1030kg/m^

1046kg/m^

1000kg/m^

0/100°C

^TetrePak

17

2.3 Identification and safety signs, machine H 610HGD-74C 2General information

3.Safetylabel

Textonlabel:

DANGER

Readtheinstructionmanualsbeforeinstallation,

operationandmaintenance.Considerinspection

intervals.

Failuretostrictlyfollowinstructionscanleadto

fatalinjury.

Ifexcessivevibrationoccurs,stopseparatorand

keepbowlfilledwithliquidduringrundown.

Outofbalancevibrationwillbecomeworseifbowl

Isnotfull.

Separatormuststoprotatingbeforeany

dismantlingworkisstarted.

m Aigiliiifgi

m t

jsaas"'-" sssssesssaasasissss^

owowwwowww

VBBBSSSSa

mmmt

sssssesssaasasissss^

owowwwowww

VBBBSSSSa

4.Nameplate"TetraPak" A'TetraPak

6.Arrowindicatingdirectionofrotation

8.Frequencylabel50Hz160Hz

*Spacereservedforplateindicating

representative

50Hz

60Hz

18

This manual suits for next models

1

Table of contents