OP175 System Installation, Operation & Maintenance 9

System Start-Up

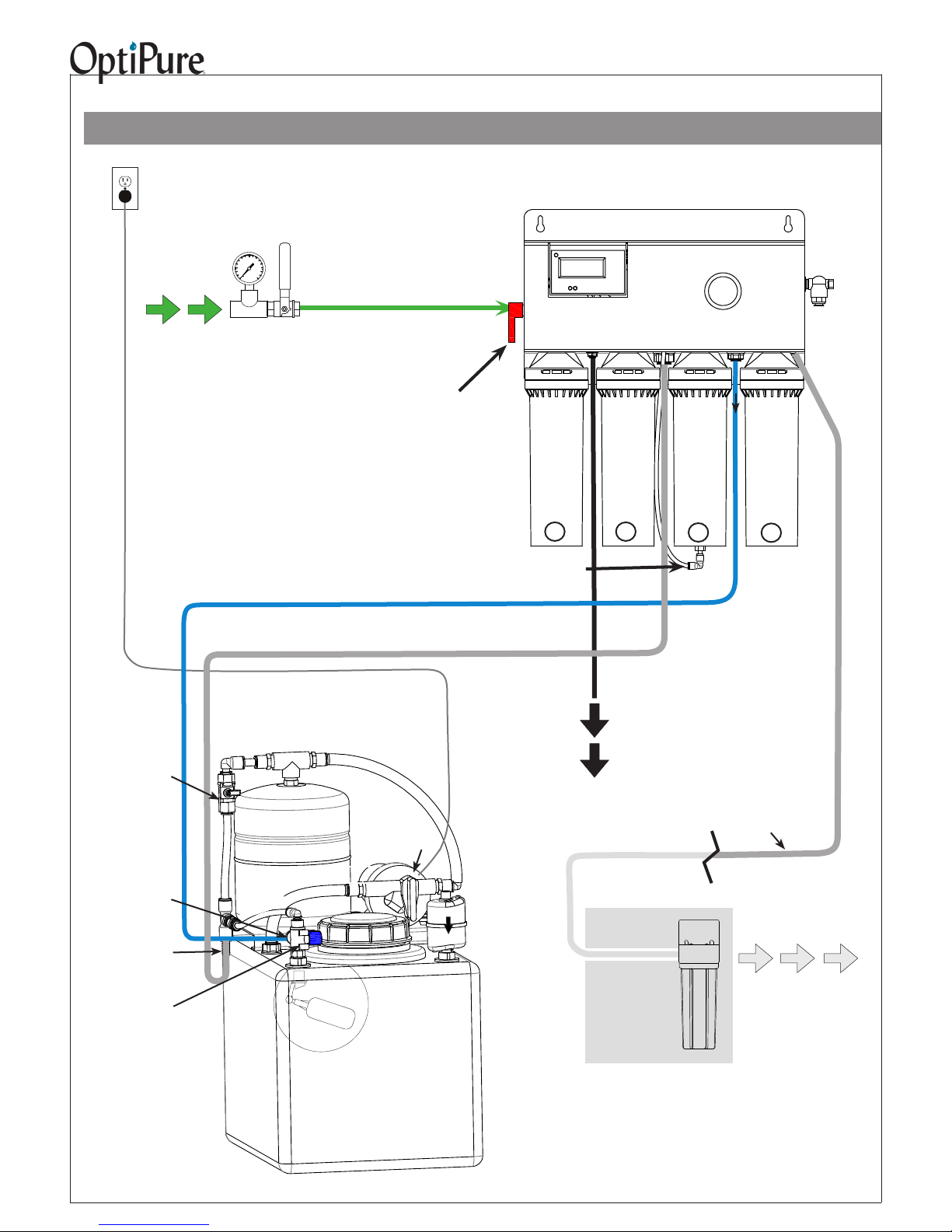

Refer to the illustration in “Typical Installation” (page

5).

IMPORTANT: Before proceeding, position the

Processor EMERGENCY BYPASS VALVE in the

“SERVICE” position, assure that the Buffer Tank Valve

is closed, and position the TANK INLET DIVERT

VALVE to bypass the tank (Blue Valve Handle pointing

up).

1. Slowly open the user-supplied WATER SUPPLY

VALVE and allow the lter housings to ll. Water

will begin to ow from the end of the 1/4” black

tubing routed to the drain. After some time, water

will begin to ow from the gray hose which is

temporarily routed to a bucket or the drain. Allow

several minutes to ush the system until water

ows smoothly from the gray hose and drain line.

Check all of the plumbing connections and correct

any leaks if necessary.

2. The tank must be ll to start-up and purge the

Repressurization Assembly. You can quickly ll the

storage tank using the “System Bypass” on the

processor. To do this use the following:

• Route the 1/2” gray hose from the OPTIMIZED WATER

OUTLET directly into the storage tank.

• Turn the EMERGENCY BYPASS VALVE on the processor

to “BYPASS.” This will allow feed water to bypass the

processor and quickly ll the storage tank.

• When the tank lls to approximately 14 gallons return

the processor EMERGENCY BYPASS VALVE to the

“SERVICE” position. When the tank is full, the shutoff

valve will close, stopping all ow.

• With the tank full, ensure the valve at the top of the BUFFER

TANK is in the OPEN position and that the 1/2” gray hose is

still directed into the storage tank.

3. Plug the power cord from the RP pump into the

outlet. Water should begin to ow rapidly from the

storage tank, through the RP assembly and back

into the storage tank through the gray hose. Allow

the pump to run for several minutes until all of the

air is purged from the Repressurization Assembly.

As the air is purged, the pump will run more

smoothly and the water ow from the gray hose

will become steady.

4. Unplug the RP Pump cord.

Connect to Equipment

You are almost ready to enjoy the benets of

Optimized Water. All that remains is to make the

connection for distribution to your equipment.

1. Remove the 1/2” gray hose from the storage tank

and replace and tighten the lid to the storage tank.

2. Complete the connection of the 1/2” gray hose

from the Optimized Water Outlet on the Processor

to the distribution line feeding the equipment that

will be using the Optimized Water.

3. Ensure that any valves or solenoid valves on the

connected equipment are closed. Plug the RP

pump back in. The pump will run and will ll the

Buffer Tank until the pressure in the Buffer TAnk

reaches 70 psi, and then the RP Pump will shut

off.

4. Open downstream valves at the equipment to

allow air to purge from the distribution lines. When

purging distribution lines do not allow the water

level in the storage tank to drop below 1/4 full.

Once purged and ushed, close the equipment

valves. When there is no demand for water the

pump will shut off automatically.

5. Turn the TANK INLET DIVERT VALVE to the

“TANK” position (blue valve handle pointing down).

Transition to Owner/Operator

The nal step is to meet with the owner/operator,

familarize them with the system and complete the post

installation check list.

The system is now in “normal operating” mode and

the storage tank will ll with Optimized Water from

the processor. Complete the “Check List” to “Conrm

Normal Operation and System Settings” (page 4 of the

“Quick Installation Guide”) with the Owner/Operator.

Allow the tank to ll before beginning operation of the

connected equipment.

1. Push the purple “POWER” button on the Water

Quality Monitor located on the upper left corner.

It will immediately display the “IN” or Optimized

Water TDS (Total Dissolved Solids) in PPM

(parts per million). Document this number as the

Optimized Water TDS.

2. Within 30 seconds, push the “OUT” button to

display the Membrane Permeate TDS and record

this number as the Permeate TDS.

Complete the Installation

Reading the TDS