Application & Operation

Water Quality

Verify that raw water iron, pH, and alkalinity levels are within recommended limits�

Iron—A Common Water Problem

The chemical/physical nature of iron found in natural water supplies is exhibited in four general types:

1. Ferrous Iron - also referred to as “dissolved iron” or “clear water” iron� The Iron-OX5 is rated to remove up to

5 ppm of this type of iron� If a glass is filled with water containing ferrous iron the water will initially be clear�

Upon standing and being exposed to air the water will gradually turn cloudy and colored as the ferrous iron

oxidizes to ferric iron�

2. Particulate Iron—Also called ferric iron� This type of iron is an undissolved particle of iron� The Iron-OX5 filter

will effectively remove these particles but it is not the intended design of the system� If there is a significant

amount of ferric iron additional filtration treatment may be required prior to the Iron-OX5�

3. Organic Bound Iron—This type of iron is strongly attached to an organic compound in the water� The

oxidation / filtration process used in the Iron-OX5 will not remove this type of iron�

4. Bacterial Iron and Colloidal Iron—These types of iron, like organic bound iron will not be removed by the

Iron-OX5 filter�

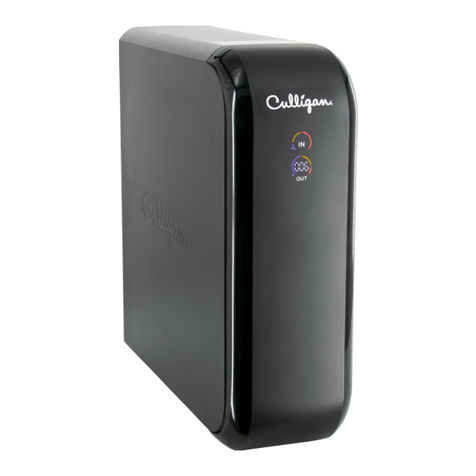

Principles of Operation - Iron-OX5 Aeration System

The Culligan Aquasential Iron-OX5 system utilizes the principle of oxidation to convert ferrous iron to ferric iron, resulting

in removal of the iron as a filterable particle� The process is accomplished by water entering the filter tank being

immediately exposed to an “airhead” at the top of the filter tank to begin the oxidation process� The filter media acts as

a catalyst to help complete the oxidation reaction and retain the precipitated iron� Periodic reconditioning purges the

accumulated iron particles from the filter tank and re-classifies the media bed�

After the backwash cycle the Iron-OX5 control valve replenishes the airhead in the filter tank during the “Air Draw” cycle� During

this cycle air is educted into the filter tank in sufficient volume for the required airhead� During the “Rinse”cycle the air charge is

compressed and stored within the filter tank and the filter media is rinsed prior to the system returning to the service cycle�

Hydrogen Sulfide

Hydrogen Sulfide usually occurs naturally in well water as a dissolved gas� It is typically the result of organic

decomposition� It has a characteristic “rotten egg” odor and can usually be noticed at a concentration above �50 ppm� In

some cases hydrogen sulfide can be caused by Sulfate Reducing Bacteria (SRB)� This system is not designed to treat

hydrogen sulfide caused by SRB� The Culligan Analytical Laboratory can test for both of these contaminants�

Principles of Operation - Sulfur-OX3 Aeration System

The Culligan Aquasential Sulfur-OX3 system utilizes the principle of oxidation to convert hydrogen sulfide to sulfate or a

filterable particle, resulting in the reduction of hydrogen sulfide odor� The process is accomplished by water entering the

filter tank being immediately exposed to an “airhead” at the top of the filter tank to begin the oxidation process� The filter

media acts a catalyst to help complete the oxidation reaction and retain precipitated particles�

Periodic backwashing purges the accumulated particles from the filter tank and reclassifies the media bed� After the

backwash cycle the Sulfur-OX3 control valve replenishes the airhead in the filter tank during the “Air Draw” cycle� During this

cycle Air is educted into the filter tank in sufficient volume for the required airhead� During the “Rinse” cycle the air charge is

compressed and stored within the filter tank and the filter media is rinsed prior to the system returning to the service cycle�

CAUTION!

Do not use where the water is microbiologically unsafe or with water of unknown quality without

adequate disinfection before or after the unit.

Pressure - Although the system is designed and tested to operate at a maximum pressure of 60 psi, it is not expected that

the system should be exposed to such pressure for extended operation� Culligan recommends following the IAPMO Uniform

Plumbing code section 806�2 by installing a Pressure Regulating Valve if the water pressure is greater than 60 psi� Operating

801040684 A 06/21