Tetratec Instruments M16 User manual

TetraTec Instruments GmbH

Gewerbestrasse 8

D-71144 Steinenbronn

Deutschland

E-Mail: in o@tetratec.de

Tel.: 07157/5387-0

Fax: 07157/5387-10

OPERATION MANUAL

M16

Pneumatic Precision Vacuum Regulator

*** VERSION 1.0 ***

Update: 22.04.2021

Operation Manual

M16

INDEX OF CONTENTS

INDEX OF CONTENTS.........................................................................................................2

ENERAL INFORMATION...................................................................................................3

TECHNICAL DESCRIPTION................................................................................................3

SPECIFICATIONS.................................................................................................................4

Pressure Control Ranges....................................................................................................4

Response Behaviour...........................................................................................................4

Operating Conditions..........................................................................................................4

Media Compatibility.............................................................................................................4

Flow Behaviour....................................................................................................................4

Enclosure..............................................................................................................................4

Process Connections..........................................................................................................4

INSTALLATION.....................................................................................................................5

NOTICE..................................................................................................................................5

ADJUSTMENTS....................................................................................................................5

OPERATION..........................................................................................................................5

MAINTENANCE.....................................................................................................................5

CAUTION...............................................................................................................................5

TROUBLE SHOOTIN .........................................................................................................5

DIMENSIONS........................................................................................................................6

FUNCTIONAL DRAWIN .....................................................................................................7

MOUNTIN BRACKETS......................................................................................................9

Page 2 M16_man_e.doc

Operation Manual

M16

ENERAL INFORMATION

Precision Regulator or Vacuum and Overpressure

Pressure Control Ranges rom -0,9 to 10,0 bar

Response Sensitivity better 0,9 % F.S.

Input Pressure Dependency better 0,1 % F.S./bar

Open Pressure Regulator with Relie Valve

TECHNICAL DESCRIPTION

The M16 precision pressure regulator is a direct acting proportional regulator or vacuum and

overpressure with regulation range limits rom -0,9 bar and +0,15 up to +10,0 bar. It can be used

or both operation modes: inline to regulate mixed pressures out o vacuum and overpressure and

by-pass operation as pure vacuum regulator versus atmosphere.

Between the spring-diaphragm-system and the counteracting output pressure arises a orce

balance, which keeps the outlet pressure almost constant or large input pressure changes. This is

supported by the continuous bleeding o a small amount o air through a relie valve, which

prevents the regulator rom riction caused pausing. In addition to small pressure dependency the

regulator there ore shows high control sensitivity and ast response behaviour.

M16_man_e.doc Page 3

Operation Manual

M16

SPECIFICATIONS

Pressure Control Ranges

Upper Limits o Output or Set Point Pressure: -0,9 to +0,15 / 0,7 / 2,0 / 7,0 / 10,0 bar

Input or Primary Pressure: > 150 % F.S. (max. 17 bar)

Response Behaviour

Response Sensitivity: < 0,9 % F.S.

Input Pressure Dependency: < 0,1 % F.S./bar

Operating Conditions

Input Pressure: -0,9 bar vacuum and up to 17 bar

overpressure

Temperature: -40 ... +93 °C

Humidity: 0 ... 90 % r.H. (non-condensing)

Media Compatibility

Clean, dry, oil- ree air; humidity non-condensing.

Flow Behaviour

Air Mass Flow at 7 bar Primary Pressure and

1,4 bar Set Point Pressure:

1100 Nl/min

Air Mass Flow or By-pass Operation,

Atmosphere versus Vacuum:

70 Nl/min

Air Mass Flow or Inline Operation,

Atmosphere versus Vacuum:

1 Nl/min

Air Consumption (Constant Bleed): < 5,5 Nl/min

Approximated lows with ully opened valve or standard conditions

(1013 mbar abs., 0 °C, 0 % r.H.).

Enclosure

Dimensions Regard page 6 “Dimensions”

Material Housing: Aluminium, anodised

Control Knob: Plastic

Valve Assembly: Stainless steel, brass and zinc-plated steel

Diaphragm: Nitrile on Dacron

Weight Total: 940 g

Process Connections

Pressure Standard: 1/4“ NPT (3 x)

Optional: 3/8“ NPT (3 x)

Manometer: Standard: 1/4“ NPT (2 x)

Optional: 1/4“ BSPT (2 x)

Options:

c,d,e Respectively single chooseable options

A Silicone elastomers

H BSPP (Parallel) instead o NPT thread inline

I Tamper proo

J Fluorocarbon elastomers

L Controller with low low

U BSPT (Tapered) instead o NPT thread inline

Page 4 M16_man_e.doc

Operation Manual

M16

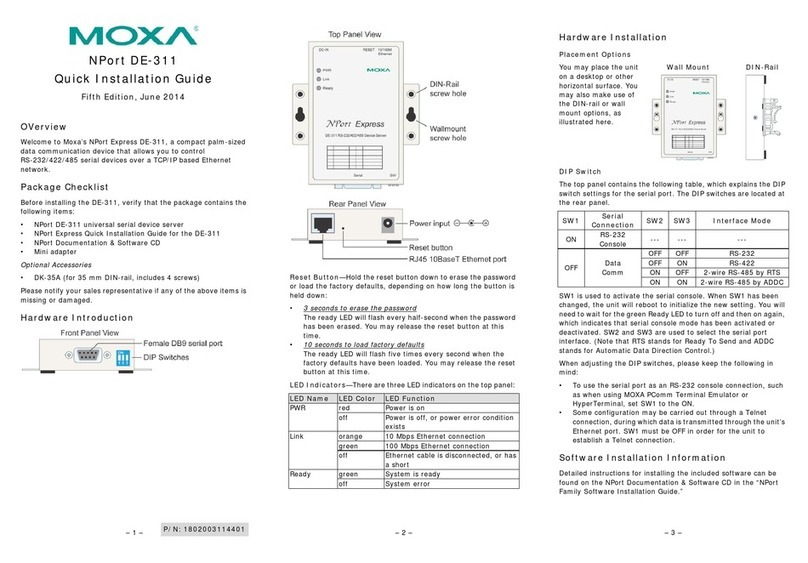

INSTALLATION

Clean pipe lines to remove dirt and scale be ore installation is made. Apply minimum amount o

pipe compound to male threads o air line to avoid possibility o getting compound into regulator.

Install regulator in air line, body is itted with a 1/4" or 3/8” NPT or inlet and outlet connections.

Regulator can be mounted in any position without a ecting its operation. Inlet and outlet

connections are labeled ( look or arrows denoting direction o low on underside o unit ) and

should be tightened securely. Avoid undersized ittings that will limit low through the regulator and

cause pressure drop downstream. The use o a ilter to remove dirt and entrained liquid in the air

line ahead o the regulator is recommended or best per ormance. I an air line lubricator is used ,

it should be located downstream beyond the regulator in order to avoid inter erence with the

regulator per ormance.

NOTICE

The presence o certain diester oils in the airlines may hasten deterioration o the elastomers and

thus decrease the use ul li e o this unit.

ADJUSTMENTS

No ield adjustments are necessary.

OPERATION

Relieve pressure on range spring be ore putting regulator into service or the irst time. When

operating at pressure above atmospheric, turn the adjusting screw slowly in a clockwise direction

until required downstream pressure is obtained. For pressure below atmospheric, turn the

adjusting screw counterclockwise until the desired setting is obtained. Turned in a clockwise

direction, the screw compresses the range spring causing increased output pressure. For

decreased output pressure, or set a lower vacuum setting, turn the screw counterclockwise.

MAINTENANCE

The Regulator is easily disassembled or the occasional cleaning or removal o oreign matter.

Be ore this is done, however, shut o valve upstream o the regulator to prevent escape o air

when regulator is disassembled. Also shut o the controlled vacuum to avoid pressurizing the

system. There is no need to remove the regulator rom the pipe line, remove the two No.10 - 32

screws on the bottom o the unit and pull out the inner valve assembly. Wash inner valve

assembly with solvent exercising care to avoid damaging diaphragms and valve acings. Replace

assembly care ully. The vent hole in the bonnet should be kept clear. The adjusting screw should

be lubricated with Molycote type “G” grease.

CAUTION

(Avoid such solvent as acetone, carbon tetrachloride, trichlorethylene)

TROUBLE SHOOTIN

Problem Check

Leakage Body screw thightness Diapraghm

High Bleed Relie pintle and relie seat or damage or contamination

Di icult to Adjust Adjusting screw and ball Seal ring lubrication

M16_man_e.doc Page 5

Operation Manual

M16

DIMENSIONS

AMounting threads or mounting brackets

BVent keep clear

CVacuum pump

DMax. Atmosphere or pressure supply

EControl system pressure

F1/4" or 3/8” NPTF

1/4" NPT manometer connections on both sides

Page 6 M16_man_e.doc

Operation Manual

M16

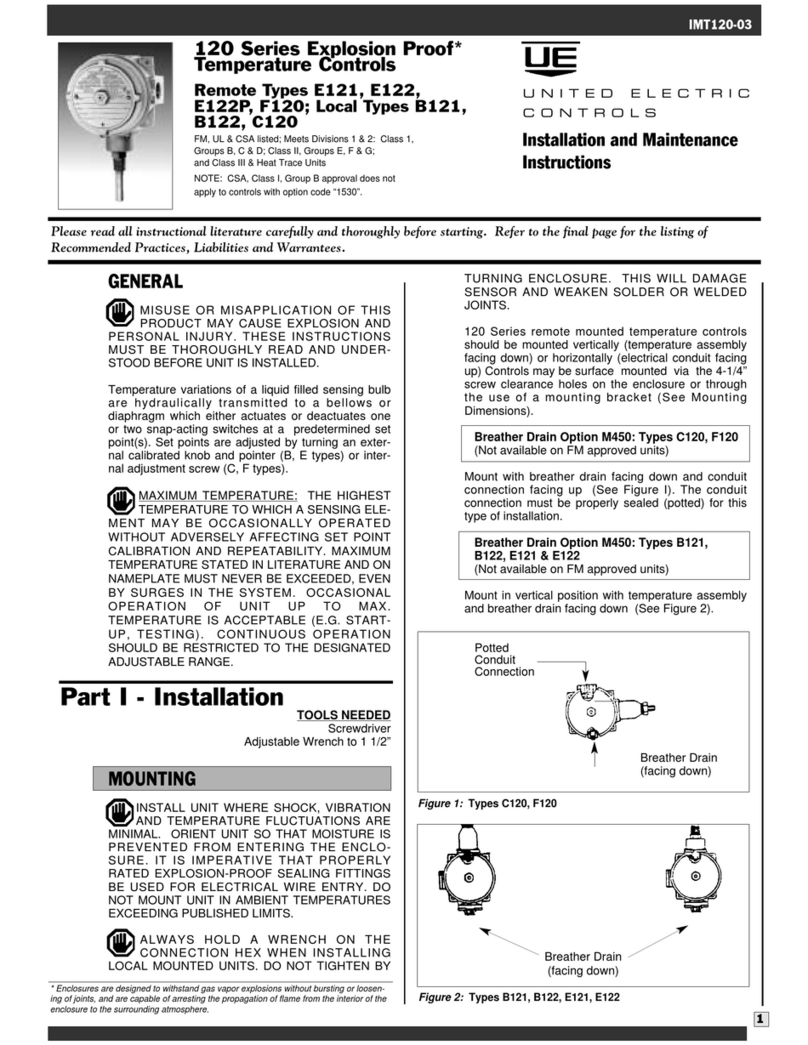

FUNCTIONAL DRAWIN

1Vent or Blow o (keep Clear)

2Connection or Pressure Supply

3Control System Pressure

4Piston combined with diaphragm bedded springs bothsides (Signal diaphragm)

5Piston combined with diaphragm bedded with spring on the top (Control diaphragm)

6Connection or vacuum pump

7Relie valve combined with diaphragm bedded with supply valve spring on the bottom

Po Aspirator tube or controlling the actual pressure at operation

M16_man_e.doc Page 7

Operation Manual

M16

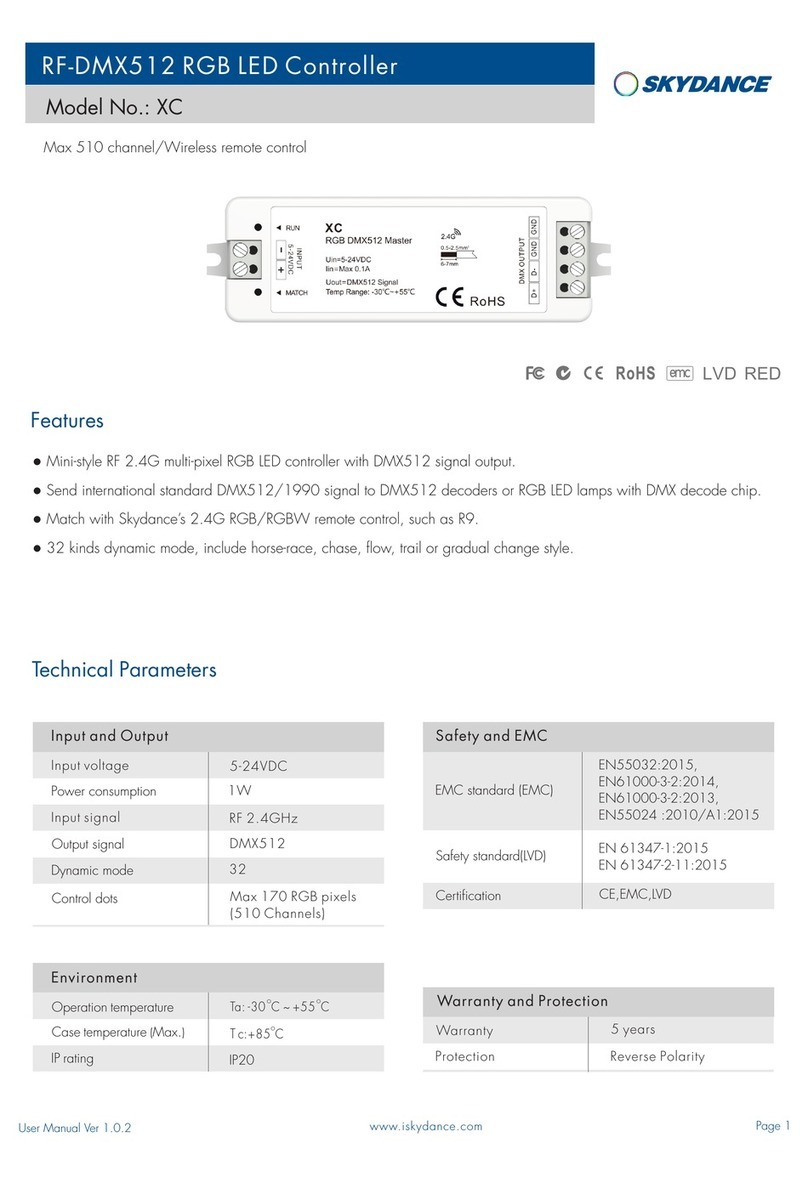

CONNECTION OPTIONS

Advantageous connection o the vacuum regulator, i the vacuum tank should be evacuated and

controlled very quickly. In this case the vacuum pump operates directly to the vacuum tank and is

not throttled through the regulator.

Advantageous connection o the vacuum regulator, i the tank should be illed with overpressure in

one case and should be evacuated in the other case. The supply pressure can be opened

alternatively to atmosphere.

Notice: Connection side to atmosphere or supply pressure should be equiped with a pressure

ilter.

Page 8 M16_man_e.doc

Operation Manual

M16

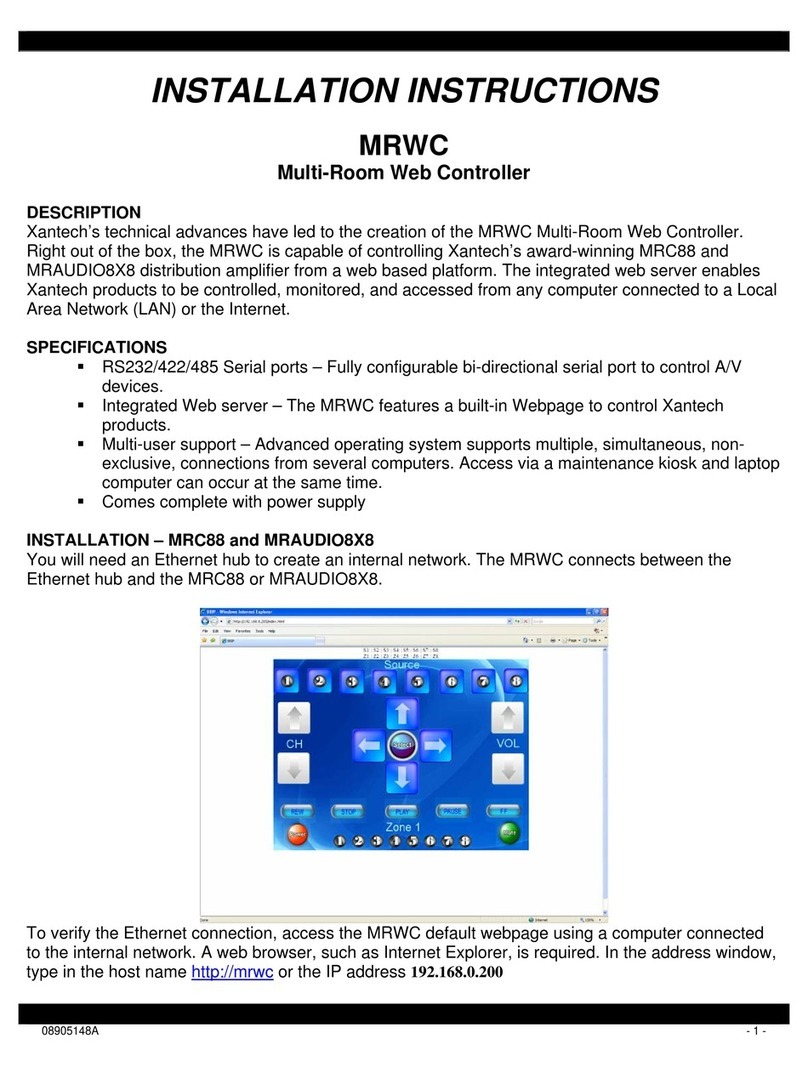

MOUNTIN BRACKETS

Zinc plated steel (Accessory)

316 Stainless steel (Accessory)

M16_man_e.doc Page 9

Table of contents

Popular Controllers manuals by other brands

ENERMAX

ENERMAX Aquafusion manual

Victron energy

Victron energy Isolated SmartSolar MPPT RS 450/100 manual

HORNER

HORNER XLE Firmware update manual

Jesco

Jesco TOPAX DX operating instructions

Sunlight Supply

Sunlight Supply Titan Controls Helios 1 instruction manual

SEW-Eurodrive

SEW-Eurodrive Movipro MPCI-DCMA-82-MMCX Addendum to the operating instructions

Parker

Parker A4AT-DN Installation and Service Information

Omron

Omron Sysmac NJ-series Instruction & reference manual

Danfoss

Danfoss EKC 326A user guide

Honeywell

Honeywell LYNX Touch L5200 Series Quick installation guide

HORNER

HORNER XL6 Prime Data Sheet / Manual

Mitsubishi Electric

Mitsubishi Electric MR-MQ100 user manual