Version: Leo 18 GT_GB_02-2008

43/2

TABLE OF CONTENTS:

Foreword page 3

1. THE FUNCTION AND FABRICATION page 4

1.1 The function page 4

1.2 Technical data page 5

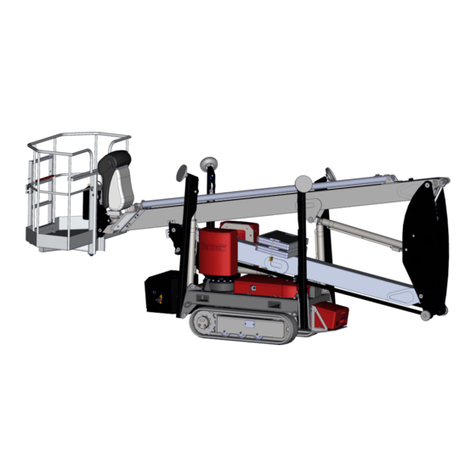

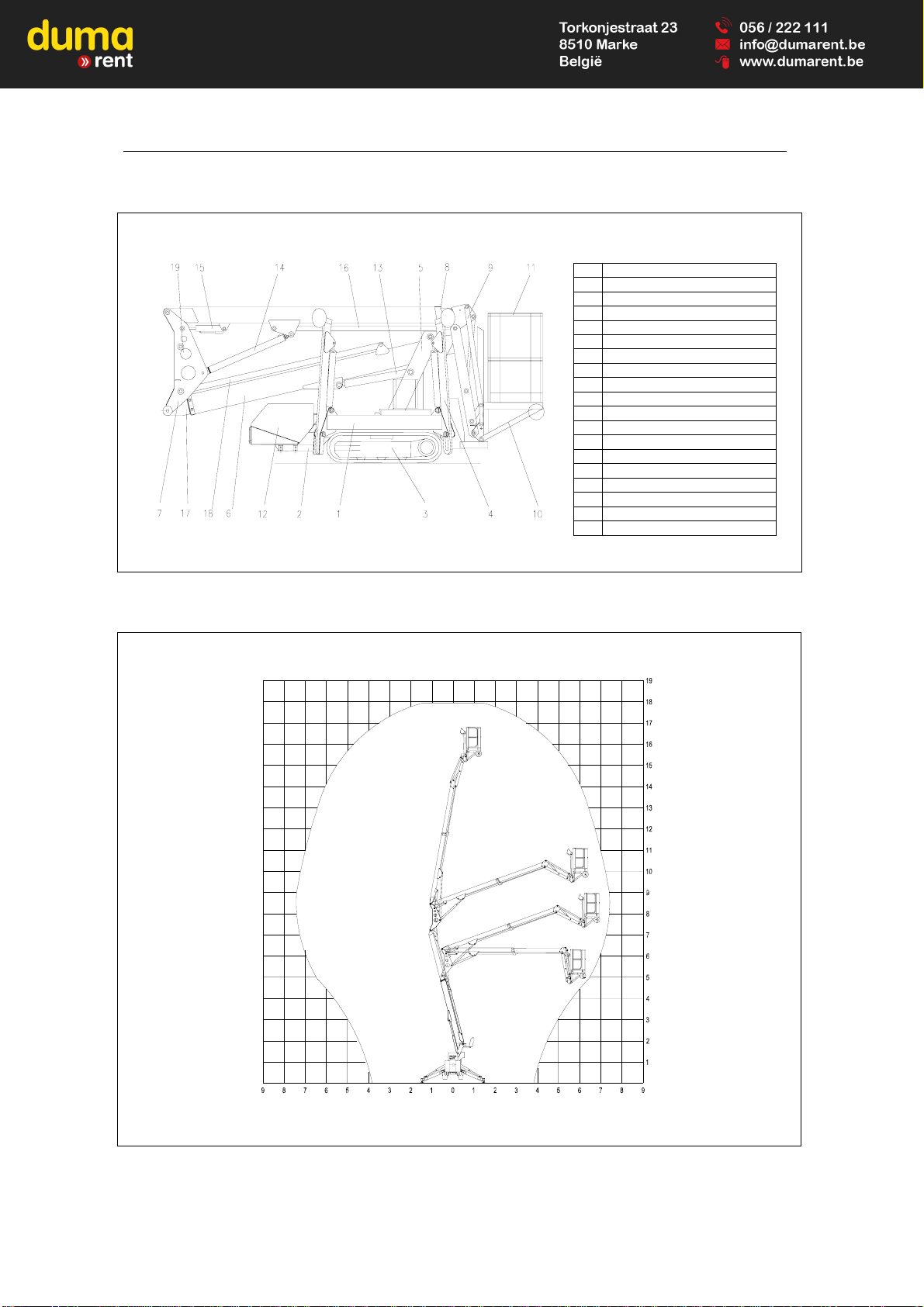

1.3 General description page 7

1.3.1 Frame and the supports page 7

1.3.2 Lifting arm support page 7

1.3.3 Articulated-telescopic arms page 7

1.3.4 Working cage page 8

1.3.5 Controlling of the elevating machine page 8

1.3.6 Rubber caterpillar track running gear page 8

1.3.7 Safety instructions page 9

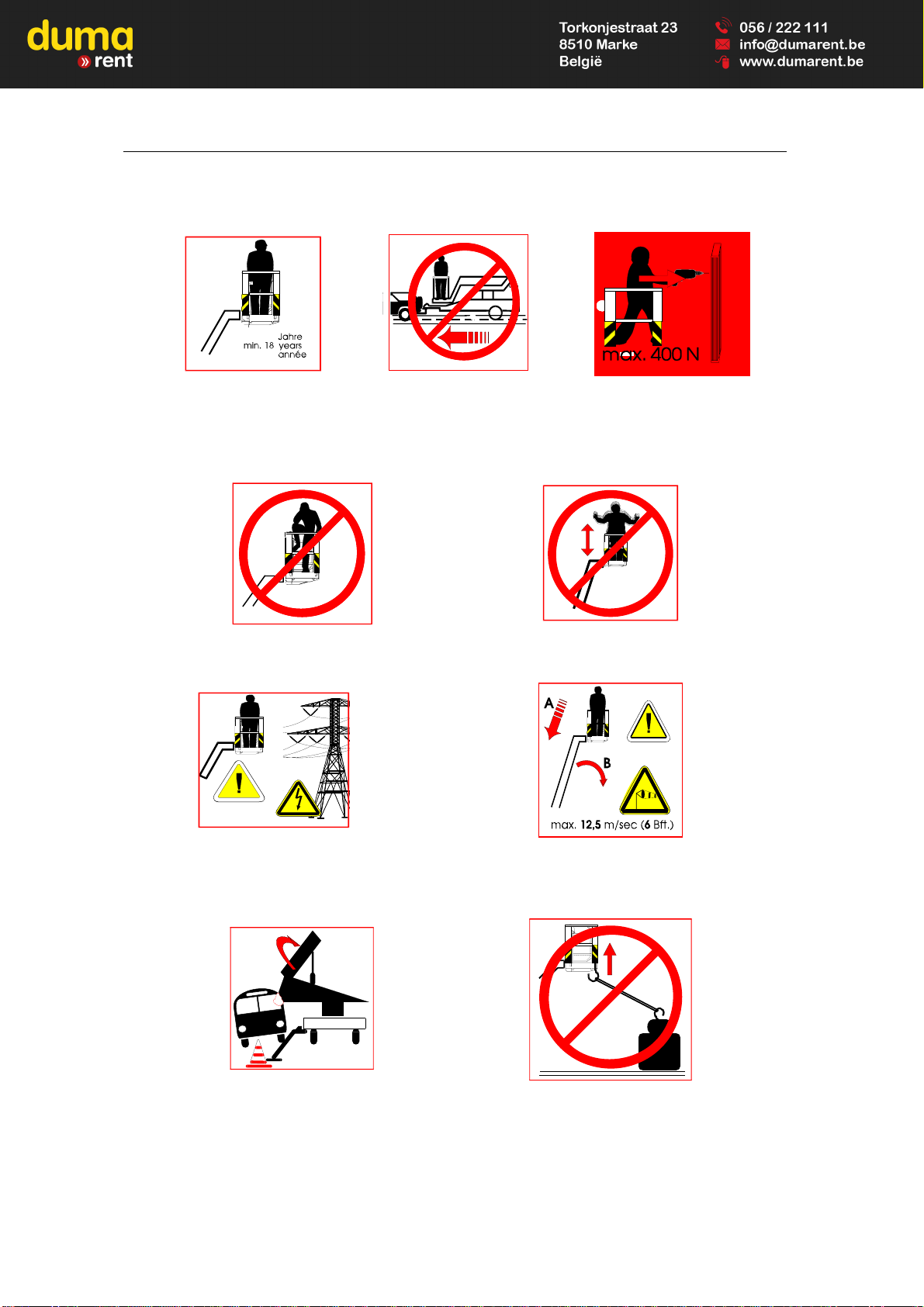

1.3.8 Meaning of the warning and informative

signs placed on the machine page 10

2. DIRECTIVES OF SAFETY ENGINEERING AND

ENVIRONMENT PROTECTION page 13

2.1 Safety engineering page 13

2.2 Environmental directives page 14

3. HYDRAULIC RUNNING GEAR FOR THE RUBBER

CATERPILLAR TRACKS page 15

3.1 Elevation adjustment of the running gear page 15

3.1.1 Gauge narrowing (narrow gauge) page 15

3.1.2 Gauge widening (wide gauge) page 15

3.1.3 Safety devices page 16

4. HANDLING AND USAGE OF THE MACHINE page 17

4.1 Transporting the machine page 17

4.2 The requirements for the operator page 19

4.3 To be in operation page 20

4.4 Function descriptions of the machine page 20

4.4.1 Disassembling and assembling of the basket page 20

4.4.2 The installation of the power supply of the machine page 21

4.4.3 Traveling with the machine page 25

4.4.4 Stabilizing of the machine page 27

4.4.5 The control and the operating of the superstructure page 28

4.4.6 Emergency control page 29

4.4.7 Working on the slope page 31

4.4.8 Instructions for operating in Winter page 32

4.4.9 Working on electrical equipments and next to the electrical ones page 32

4.5. Instructions after finishing of the operating of the machine page 32

5. MAINTENANCE AND LUBRICATION OF THE MACHINE page 33

5.1 Safety instructions of the maintenance page 33

5.1.1 Lubrication and checking tasks page 34

5.1.2 Bogie maintenance instruction page 35

5.2 Operating trouble and prevention of those page 41

5.3 The maintenance of the explosive engine page 42