Table of contents

407/05/2018

4.10 Type plate ..................................................................................................................................................43

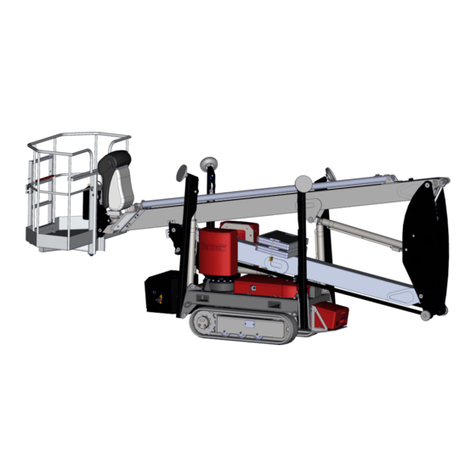

5 Construction and function................................................................................................................................45

5.1 Overview....................................................................................................................................................46

5.1.1 Brief description ...........................................................................................................................47

5.2 Assembly description.................................................................................................................................48

5.2.1 Crawler chassis............................................................................................................................48

5.2.2 Outriggers .................................................................................................................................... 48

5.2.3 Platform........................................................................................................................................ 49

5.2.4 Working basket ............................................................................................................................49

5.2.5 Movable basket boom.................................................................................................................. 49

5.2.6 Combustion engine ......................................................................................................................50

5.2.7 Electric motor ...............................................................................................................................50

5.3 Operating elements and displays ..............................................................................................................51

5.3.1 Outrigger latching.........................................................................................................................51

5.3.2 Control panel and radio control.................................................................................................... 53

5.3.3 Control panel adjustment (optinal) ...............................................................................................55

5.3.4 Combustion engine controller ......................................................................................................56

5.3.5 Control box control panels ...........................................................................................................57

5.3.6 Emergency control .......................................................................................................................58

5.4 Electrical connections ................................................................................................................................58

5.4.1 Feed ............................................................................................................................................. 58

5.4.2 Power sockets, working basket....................................................................................................59

5.5 Work areas and danger zones...................................................................................................................59

5.6 Accessories ...............................................................................................................................................60

5.6.1 Accessories (optional)..................................................................................................................60

5.6.2 Accessories (included) ................................................................................................................. 62

6 Transportation and storage..............................................................................................................................63

6.1 Safety instructions for transportation .........................................................................................................63

6.2 Inspection on receipt of delivery ................................................................................................................63

6.3 Attachment points ......................................................................................................................................64

6.4 Storage ......................................................................................................................................................66

6.5 Transportation on an auxiliary frame for trucks .........................................................................................67

6.5.1 Loading onto the truck ................................................................................................................. 67

6.5.2 Lashing ........................................................................................................................................ 68

7 Operation............................................................................................................................................................71

7.1 Safety instructions for operation ................................................................................................................71

7.2 Connecting the machine to the mains supply ............................................................................................71

7.3 Switching the machine on/off.....................................................................................................................73

7.3.1 Switching the radio control on/off................................................................................................. 73

7.3.2 Switching the machine on/off via the mains supply ..................................................................... 75

7.3.3 Switching the machine on/off using the combustion engine ........................................................ 75

7.4 Shutting down in case of emergency.........................................................................................................77

7.5 Principles of the graphic display screen ....................................................................................................78

7.5.1 Overview ...................................................................................................................................... 78

7.5.2 Possible assignment of the function keys .................................................................................... 78

7.5.3 Examples of the operating modes ............................................................................................... 79

7.5.4 Main menu ................................................................................................................................... 81

7.5.5 Machine data ............................................................................................................................... 81

7.5.6 Service hotline ............................................................................................................................. 82

7.5.7 Settings ........................................................................................................................................ 82

7.6 Driving the machine ...................................................................................................................................87